- DL manuals

- Hafco

- Sander

- WBS-1836

- Instruction manual

Hafco WBS-1836 Instruction manual

Summary of WBS-1836

Page 1

Instruction manual wbs-1836 wide belt sander (240v) 420mm l124 page 1 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 2

L124 wide belt sander wbs-1836 instruction & parts manual 7-10-10 page 2 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 3: Wbs-1836

1 wbs-1836 wide-belt sander page 3 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 4: Table of Contents

2 preface------------------------------------------------------------------------------------3 general safety rules for woodworking machinery ------------------------4-5 specifications --------------------------------------------------------------------------6 machine legend ------------------------...

Page 5: Preface

3 thank you for choosing this belt sander. We are pleased to offer you our best machinery and service, and trust that you will find our machinery economical, productive and easy to operate. This manual covers the proper operation, safety and maintenance of the machine. It is important that this manu...

Page 6

4 there is a certain amount of hazard involved with the use of woodworking machinery. Using the machine with the respect and caution demanded as far as safety precautions are concerned will considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked o...

Page 7

5 18. Do not wear gloves or other hand covering articles around moving machinery. 19. Cover long hair with a hair net or cap. 20. Protective guards and shields must be in place at all times unless they must be removed for specific service or maintenance. They should be immediately replaced when serv...

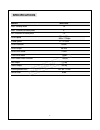

Page 8: Specifications

6 model wbs -1836 max. Sanding width 18" max. Thickness of work piece 4" min. Thickness of work piece 1/4" drum speed 50hz-1420rpm 60hz-1720rpm freed speed 6 ~ 22 fpm drum diameter 82mm drum length 407mm drum drive motor 2.2kw feed drive motor 130w dust hood outlet diameter o100mm net weight 215 kg ...

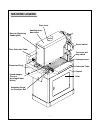

Page 9: Machine Legend

7 door for replacing sanding belt conveyor cover conveyor belt key switch dust chute power switch extension table rear extension table adjusting screw for conveyor belt cabinet sanding drum dust cover machine legend door extension wing infeed stopper (prevent pressing&power failure) page 9 instructi...

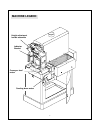

Page 10: Machine Legend

8 height adjustment handle assemble indicator bracket sanding drum motor conveyor feed motor machine legend page 10 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 11: Electrical Connection

9 a:power switch b:conveyor belt key switch, it only works after turning on the power switch. C:conveyor belt speed adjustment konb : speed range:6fpm~30fpm using the height adjustment handle to adjust the height according to the thickness of the work piece. Revolving to anti-clockwise can rise the ...

Page 12

10 1. Loose a 2. Afterwards, spinning object b(b)to anti-clockwise direction to low object f(f)down so that you can loose the sanding belt. 3. Then loose object c(wing screw), remove object d. 4. Remove and replace the sanding belt. 5. Reverse the procedure to load the sanding belt back:screw and lo...

Page 13

11 motor is electrified when sanding belt touched limit switch a/b, the motor (c) turns front and reverse to control the roller swings. Warning : please don’t adjust dividing scale unless sanding belt swings unusually. Figure5 if the conveyor belt runs to the right or left during operation, or the c...

Page 14: Replacing The Conveyor Belt

12 common causes which require replacement of the conveyor feed belt are:normal wear and tear, inadvertent contact with the sanding drum abrasive during operation, tears caused by mistracking of the conveyor feed belt, or excessive build-up of non-removable film. The following steps describe how to ...

Page 15

13 1. Check the tightness of the elevation tension adjustment screws(figure 9). The tightness of these screws must be adjusted to allow smooth height adjustments, while ensuring a tight enough fit to limit drum will deflection.(if the screws are too loose, the drum will deflect during use, causing a...

Page 16: Warning

14 the machine is provided with one 4-inch dust chutes. Use ring clamps to attach dust collection hoses to the chutes. ! Warning do not operate this machine without a dust collector attached and running. Attaching a dust collector dust chute page 16 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 17: Lubrication and Maintenance

15 note before performing any maintenance or lubrication, disconnect the machine from the power source. 1. The table height adjustment screw shafts located at either end of the machine must be well lubricated with grease. 2. Make sure all nuts and screws are tight before sanding. Check that the sand...

Page 18: Assembly Diagram

16 wbs-1836 assembly diagram page 18 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 19: Assembly Diagram

17 wsb-1836 assembly diagram page 19 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 20: Assembly Diagram

18 wbs-1836 assembly diagram page 20 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 21: Assembly Diagram

19 wbs-1836 assembly diagram page 21 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 22: Assembly Diagram

20 wbs-1836 assembly diagram page 22 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 23: Assembly Diagram

21 wbs-1836 assembly diagram page 23 instructions manual for wbs-1836 (l124) 07/08/2017.

Page 24: Assembly Diagram

22 wbs-1836 assembly diagram page 24 instructions manual for wbs-1836 (l124) 07/08/2017.

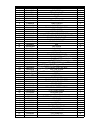

Page 25

Part no. Refence no. Description qty 1 20702015a front stand 1 2 s0010505 cap screw 19 3 s0230506 spring washer 42 4 s0210500c flat washer 33 5 22200002 cover 1 6 s0400420 key 2 7 s0230400 spring washer 22 8 21600020 table spacer 4 9 s0010615m cap screw 14 10 s0030307 round head cross screw 4 11 222...

Page 26

Part no. Refence no. Description qty 53 s0020501 screw 14 54 20900049 bearing cover 7 55 c1106201 bearing 6201 2 56 22200006 lower roller 1 57 22200007 roller holding bracket 1 58 21600008 motor base 1 59 s0010502 cap screw 9 60 s0010305 cap screw 5 61 22200048 driven roller 1 62 20900033 motor roll...

Page 27

Part no. Refence no. Description qty 108 21600063 worm shaft bush 1 109 21600096 buttom plate 1 110 22200062 handle rod 1 111 21600061 handle adjustment block 1 113 s0010440m cap screw 6 114 s0190500m hex nut 1 116 21600088 cover board 1 120 21600085 table bracket (right) 1 123 21600086 table bracke...

Page 28

Part no. Refence no. Description qty 170 j2160005 label 1 171 j2160001 label 1 174 j2160004 warning label 1 175 j2090002 label 2 176 j20706002 label 1 178 j2090007 label 1 179 j2090010 label 1 180 v0017460c belt 2 181 22200098 front extension table 1 182 i2160001 manual 1 183 12100038 knob 2 184 j21...

Page 29

Part no. Refence no. Description qty 244 21600128 limited switch position plate (left) 1 245 21800112 bearing fixed pad 1 246 21600129 limited switch fixed plate (right) 1 247 21600130 oblong iron 1 248 21600131 connecting shaft 1 249 21600132 motor cover 1 250 wl001121 limited switch 1 251 wl001001...