- DL manuals

- Hague Quality Water

- Water Dispenser

- HomeGuard 400

- Owner's Information

Hague Quality Water HomeGuard 400 Owner's Information

Summary of HomeGuard 400

Page 1

O o w w n n e e r r ’ ’ s s m m a a n n u u a a l l a a n n d d i i n n s s t t a a l l l l a a t t i i o o n n g g u u i i d d e e v v e e r r s s i i o o n n 1 1 . . 1 1.

Page 2: 10 Year Limited Warranty

10 year limited warranty to whom warranty is extended this warranty is issued to the original owner at the original location site and is not transferable to other sites or to subsequent owners of the system. To place the equipment under warranty, the warranty registration card must be completed and ...

Page 3: Contents

Contents owner information......................................................................................................................................4 general information .........................................................................................................................

Page 4: General Information

Homeguard ® owner’s manual 9/29/2009 4 general information congratulations on choosing a superior hague water treatment appliance! Soon you and your family will be enjoying clean, clear water. Use this guide to attain the maximum benefit from your appliance. As an owner, you may find the first few p...

Page 5: Efficiency Statements

Getting maximum efficiency from the appliance to achieve the maximum benefit and performance from this appliance, familiarize yourself with this manual and the appliance. 1. The salt level should always be at least 1/3 full. Refill the salt when the level drops below the water level in the brine cab...

Page 6: Five-Button Controller

Five-button controller this appliance features a five-button controller with an lcd display. The controller can be used to view the appliance’s status, perform regenerations, and change settings. An independent hague dealer should set the service settings during installation of the appliance. Figure...

Page 7

Five-button controller, cont. Controller part function buttons, cont. The change, select, display, and scroll back buttons are used when changing customer settings and service settings. Select the select button is used to move the cursor when setting parameters. 1. Press and release the select butto...

Page 8: Customer Settings

Customer settings service settings must be set before customer settings; service settings should be set during installation of the appliance. To set customer settings, press and hold the display button for about five seconds while “customer setting” displays. Release the button when “set time” displ...

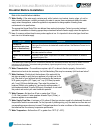

Page 9: Nstallation And

I nstallation and m aintenance i nformation checklist before installation refer to this checklist before installation. Water quality—if the water supply contains sand, sulfur, bacteria, iron bacteria, tannins, algae, oil, acid, or other unusual substances, consider pre-treating the water to remove t...

Page 10: Precautions

Checklist before installation, cont. Drain—drain the appliance to an appropriate drain, such as a floor drain or washer drain that will comply with all local and state plumbing codes. To prevent back-siphoning, provide an adequate air gap or a siphon break. See installation steps and start-up proced...

Page 11

Installation steps and start-up procedures step 1 prepare the placement area a. Make sure the placement area is clean. B. Turn off the electricity and water supply to the water heater. For gas water heaters, turn the gas cock to “pilot.” c. Examine the inlet plumbing to ensure that the pipe is not p...

Page 12

Installation steps and start-up procedures, cont. S s tep 2 turn off water supply a. Turn off the water supply. B. Open the hot and cold water taps to depressurize the lines. Tep 3 connect water lines note: see optional plumbing procedures for information on copper fittings and joining plastic pipe....

Page 13

Installation steps and start-up procedures, cont. S s s tep 4 connect gravity overflow connection the overflow line drains away excess water should the tank fill with too much water or the appliance malfunction. A. Check that the overflow elbow is in the down position. B. Connect 1/2-inch (12.7 mm) ...

Page 14

Installation steps and start-up procedures, cont. S s s tep 7 check for leaks a. Close all faucets. B. Check all lines and connections for leaks. If leaks are found: 1. Turn off the main water supply. 2. Open a cold water faucet to depressurize the lines. 3. Close the faucet to eliminate any siphoni...

Page 15

Installation steps and start-up procedures, cont. Step 11 fill the brine cabinet with salt a. If the grid plate is not sitting on its supports at the bottom of the brine cabinet, carefully reposition it. B. Fill the brine cabinet with salt. (see figure 11.) use clean, white pellet or solar salt. Do ...

Page 16: Bypass Valve

Bypass valve the bypass valve can isolate the appliance should the appliance malfunction or leak. It can also permit the use of untreated water for watering plants, shrubs, or lawns. The bypass is located on the main control valve. See figure 12. To engage the bypass, turn the knob to the bypass pos...

Page 17

Optional plumbing procedures, cont. Plastic (pvc/cpvc) pipe joining procedure to ensure reliable joint integrity when using solvent cement for pvc/cpvc plumbing, follow these recommendations: a. Cutting—the pipe must be cut square to allow for the proper interfacing of the pipe end and the fitting s...

Page 18: Regenerate Button

Setting and using the controller the controller must be set up correctly for the appliance to perform properly. Note: ensure that the bottom of the controller is firmly locked onto the four tabs on the top of the drive end cap assembly. See figure 15. Regenerate button the regenerate button is used ...

Page 19: Service Settings

Service settings to program service settings on the controller, press and hold the select and display buttons while “service settings” is displayed until “set language eng” is displayed. Programming service settings is similar to programming customer settings (see customer settings for programming d...

Page 20: Service Settings, Cont.

Service settings, cont. Display meaning possible values comments brine/rinse 30.0 number of minutes the brine and slow rinse cycle lasts 00.0 to 99.9 set to the nearest tenth of a minute backwash 2 05.0 number of minutes the second backwash cycle lasts 00.0 to 99.9 set to the nearest tenth of a minu...

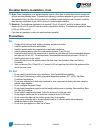

Page 21: Service Settings, Cont.

Service settings, cont. Mode 1 (timer mode) and mode 2 (meter delayed mode) setting chart this section provides guidance for using different service settings to achieve the desired capacity. 400 mode 1 and 2 yes regeneration frequency as required 96 hour regeneration (if iron present—yes) 1 — #1 sal...

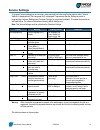

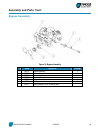

Page 22: Assembly and Parts

Assembly and parts cabinet and cover assemblies figure 14: cabinet and cover assemblies figure 15: controller tab lock detail part # description quantity 1 55300 valve cover assembly 1 2 93245 transformer 115v 1 3 54550 computer control assembly 1 4 56004 cabinet 1 5 56006 support panel 1 homeguard ...

Page 23: Assembly and Parts, Cont.

Assembly and parts, cont. Cabinet and assemblies figure 16: cabinet and assemblies part # description quantity 1 93809 screw 2 2 93870 screw 4 3 90614-2.4 drain end cap 1 4 93808 o-ring 2 5 v185 drain fitting, 1/2" (12.7 mm) 1 6 93842 drain hose, 8' (2.4 m) 1 7 93838 o-ring 2 8 54512 bypass assembly...

Page 24: Assembly and Parts, Cont.

Assembly and parts, cont. Injector assembly figure 17: injector assembly part # description quantity 1 93810 injector screen 1 2 93223 injector throat 1 3 93220 injector seal (thick) 1 4 93221 injector nozzle 1 5 93232 top injector seal (thin) 1 6 93222 injector cap 1 7 90807 screw 4 93501 entire as...

Page 25: Assembly and Parts, Cont.

Assembly and parts, cont. Injector assembly cont. 93223 injector throat in conjunction with the injector nozzle, part # 93221, it creates the vacuum that draws the brine solution from the brine cabinet. The center hole should be clear of debris, round and undamaged. The throat should be pressed flus...

Page 26: Assembly and Parts, Cont.

Assembly and parts, cont. Drive end cap assembly figure 18: drive end cap assembly part # description quantity 1 90802 screw, self-tapping 2 2 90217 drive motor 1 3 93891 1/4" hex nut 2 4 93238 drive gear 1 5 90809 screw, self-tapping 2 6 93219 piston slide cam cover 1 7 93217 piston slide cam 1 8 9...

Page 27: Assembly and Parts, Cont.

Assembly and parts, cont. Drive end cap assembly cont. 90217 the motor is held in place by two 1/2-inch self-tapping screws. The screws should be “snug.” the brass pinion gear on the motor should engage the plastic drive gear. The wires should be securely fastened to the control. Drive motor 93238 d...

Page 28: Assembly and Parts, Cont.

Assembly and parts, cont. Bypass assembly figure 19: bypass assembly part # description quantity 1 54512 bypass assembly 1 2 93860 turbine sensor assembly 1 3 90809 sensor cap screw 1 4 54320 plastic turbine axle 1 5 90522 turbine assembly 1 6 93838 o-ring 2 54512 entire assembly (all of the above p...

Page 29: Assembly and Parts, Cont.

Assembly and parts, cont. Brine valve housing assembly concave side static o-ring figure 20: brine valve housing assembly part # description quantity 1 53511 piston assembly (includes o-ring & spring) 1 2 90821 o-ring 1 3 53510 housing 1 4 90843 0.5 gpm flow control 1 5 93805 o-ring 1 6 93243 housin...

Page 30: Assembly and Parts, Cont.

Assembly and parts, cont. Drain end cap assembly figure 21: drain end cap assembly part # description quantity 1 93808 o-ring 1 2 90268 drain end cap 1 3 h2086-2.4 drain line flow control 1 4 90267 retainer 1 90614-2.4 entire assembly (all the above parts) 1 90268 drain end cap the drain end cap (90...

Page 31: Assembly and Parts, Cont.

Assembly and parts, cont. Safety shutoff assembly figure 22: safety shutoff assembly part # description quantity 1 54226 safety shutoff 1 2 56018 float 1 3 56200 air check 1 56024 entire assembly (all of the above parts) homeguard ® owner’s manual 9/29/2009 31.

Page 32: Assembly and Parts, Cont.

Assembly and parts, cont. Safety shutoff valve elbow installation figure 23: safety shutoff valve elbow installation part # 3/8" nut 3/8" retainer sleeve 3/8" plastic insert 3/8" plastic gripper safety shutoff valve 3/8" poly tube 2 hex nut 1 wrist pin 1/2" retainer sleeve 1/2" plastic gripper 1/2" ...

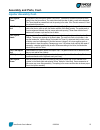

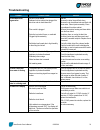

Page 33: Troubleshooting

Troubleshooting problem possible cause solution no salt in brine cabinet add salt sediment in brine cabinet has plugged the brine line and air check/draw tube remove the brine line and flush clean remove the air check/draw tube and flush with clean water. Clean injector assembly. Clean any sediment ...

Page 34: Troubleshooting, Cont.

Troubleshooting, cont. Problem possible cause solution controller not attached properly make sure the controller is pushed all the way onto the drive end cap defective magnet disk replace magnet disk foreign object in valve body remove foreign object(s) from the valve body appliance stays in regener...

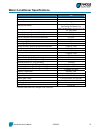

Page 35

Water conditioner specifications 400 max compensated hardness gpg (mg/l) 35 (600) minimum ph (standard units) 7 maximum ferrous iron 3 chlorostat (2.0 lb) self cleaning filter media.(1.5 lb) super fine mesh resin 0.4 cu. Ft (0.01 cu. M) media type and amounts *salt usage (used per regeneration) / ca...

Page 36: Homeguard

Homeguard ® has these third-party listings: the wqa gold seal assures that this product has been tested and validated by the water quality association. This validation assures that all electrical components are ul or csa listed and all components that are in contact with the treated water are fda or...