- DL manuals

- Hague Quality Water

- Water Dispenser

- Maximizer 400

- Installation And Service Manual

Hague Quality Water Maximizer 400 Installation And Service Manual

Summary of Maximizer 400

Page 1

I n s t a l l a t i o n a n d s e r v i c e m a n u a l maximizer 400 ® 4343 s. Hamilton rd. Groveport, oh 43125 version 1.0 400

Page 2

Owner's reference ..............................................................................................................................1 getting maximum efficiency from your appliance ..............................................................................2 checklist before installati...

Page 3

1 o ow wn ne err''ss r re effe erre en nc ce e to achieve the maximum benefit and performance from your appliance, familiarize yourself with this manual and your appliance. Keep it handy for a reference guide and service log. Warning: this appliance must be applied to potable water only. Note: manuf...

Page 4

2 g ge ettttiin ng g m ma ax xiim mu um m e effffiic ciie en nc cy y f frro om m y yo ou urr a ap pp plliia an nc ce e d do o n no ott m miix x d diiffffe erre en ntt t ty yp pe ess o off s sa alltt 1. When the salt level drops below the water level in the brine cabinet fill the salt cabinet. You ma...

Page 5

3 water quality—if your water supply contains sand, sulfur, bacteria, iron bacteria, tannins, algae, oil, acid, or other unusual substances, you may need to pretreat your water to remove these contaminants before the water supply enters the appliance, unless the appliance is represented as being cap...

Page 6

4 d do o 1. Comply with all local building, plumbing, and electrical codes. 2. Install before the water heater. 3. Install after the pressure tank on well-water installations. 4. Install a pressure-reducing valve if the inlet pressure exceeds 90 psi (6.2 bar). 5. Install a gravity drain on the cabin...

Page 7

5 we recommend that you have your water treatment specialist install and maintain this appliance. Each water treatment appliance comes with 8 feet (2.4 metres) of drain line. Note: your appliance may come with an optional bypass that enables you to remove the appliance from service when necessary. S...

Page 8

6 iin nsstta alllla attiio on n s stte ep pss a an nd d s stta arrtt--u up p p prro oc ce ed du urre ess figure 3: three-way bypass plumbing figure 2: example of a commercially available bypass valve d. Make sure the inlet/outlet and drain connections meet the applicable state and local codes. E. Ch...

Page 9

T tu urrn n o offff w wa atte err s su up pp plly y a. Turn off the water supply. B. Open the hot and cold water taps to depressurize the lines. C co on nn ne ec ctt w wa atte err l liin ne ess a. Remove the valve cover. 1. Open the salt port lid on the valve cover and slide it down. 2. Place your f...

Page 10

C co on nn ne ec ctt g grra av viitty y o ov ve errffllo ow w c co on nn ne ec cttiio on n the overflow line drains away excess water should the tank fill with too much water or the appliance malfunctions. A. Connect 1/2-inch i.D. Tubing (size cannot be reduced) to the gravity overflow connection. T...

Page 11

F fllu ussh h l liin ne ess ((c co on ntt..)) b. Open the nearest cold water faucet to flush the plumbing of any excess soldering flux, air, or any other foreign material. C ch he ec ck k ffo orr l le ea ak kss a. Close all faucets. B. Check all lines and connections for leaks. If leaks are found 1....

Page 12

10 iin nsstta alllla attiio on n s stte ep pss a an nd d s stta arrtt--u up p p prro oc ce ed du urre ess p pllu ug g iin n tth he e t trra an nssffo orrm me err a. Plug the transformer into an appropriate outlet. (see figure 15.) b. Ensure that the outlet selected is not operated by an on/off switc...

Page 13

11 iin nsstta alllla attiio on n s stte ep pss a an nd d s stta arrtt--u up p p prro oc ce ed du urre ess f fiillll tth he e b brriin ne e t ta an nk k w wiitth h s sa alltt a. If the grid plate is not sitting on its supports at the bottom of the brine tank, carefully reposition it. B. Fill the brin...

Page 14

12 w wh he en n a an nd d h ho ow w t to o u usse e tth he e b blle en nd diin ng g v va allv ve e b blle en nd diin ng g v va allv ve e a ad djju ussttm me en ntt in some situations, a blending valve option (3/4-inch or 1-inch) may be desired. The amount of hardness blended back into the water line...

Page 15

13 o op pttiio on na all p pllu um mb biin ng g p prro oc ce ed du urre ess this section provides information on plumbing with copper fittings and with plastic pipe. H ha arrd d p pllu um mb biin ng g tth he e b by yp pa assss w wiitth h c co op pp pe err f fiittttiin ng gss do not use qest fittings...

Page 16

14 o op pttiio on na all p pllu um mb biin ng g p prro oc ce ed du urre ess p plla assttiic c ((p pv vc c//c cp pv vc c)) p piip pe e j jo oiin niin ng g p prro oc ce ed du urre ess ((c co on ntt..)) e. Application of solvent cement—apply the solvent cement evenly and quickly around the outside of t...

Page 17

D de ette errm miin ne e h ha arrd dn ne essss a an nd d p ph h the first step is to determine the hardness and ph of your well or city water. A. Use the hardness test strips if provided with your appliance or have a sample of your untreated water tested by a water testing laboratory or your water t...

Page 18

16 s se ettttiin ng g a an nd d u ussiin ng g tth he e c co on nttrro olllle err in addition to the (r) button, the controller has the following buttons that are used when programming service settings and customer settings. C c b bu utttto on n the c, s, p, and (scroll back) buttons are used when ch...

Page 19

17 to program service settings, press and hold both the p button and the s button while “service settings” is displayed until “set lang” is displayed. Programming service settings is similar to programming customer settings. The values that can be set are listed below along with available values and...

Page 20

18 salt warning: when iron and/or manganese are present in the water supply, it is not advisable to use potassium chloride as a regenerate. Iron and/or manganese bacteria may develop and foul the conditioning media and may void the warranty. If no iron or manganese is present in your water and you c...

Page 21

19 to program customer settings, press and hold the p button for about 5 seconds while “customer settings” is displayed. Release the p button when set time is displayed. S se ett t tiim me e o off d da ay y the display reads “set time” followed by the current time that is set. The cursor will be und...

Page 22

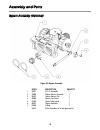

20 a asssse em mb blly y a an nd d p pa arrttss 1 56300 valve cover assembly 1 2 93245 us transformer 115v 1 c0915 europe transformer 220v 1 c0915-uk uk transformer 220v 1 c0916 japan transformer 100v 1 3 56022 computer control assembly 1 4 56004 cabinet 1 5 56006 support panel 1 c ca ab biin ne ett...

Page 23

21 a asssse em mb blly y a an nd d p pa arrttss c ca ab biin ne ett a an nd d a asssse em mb blliie ess part# description quantity 1 93809 screw 2 2 93870 screw 4 3 90614-3-0 drain end cap 1 4 93808 o-ring 2 5 v185 drain fitting, 1/2" (12.7 mm) 1 6 93842 drain hose, 8' (2.4 m) 1 7 93838 o-ring 2 8 5...

Page 24

22 a asssse em mb blly y a an nd d p pa arrttss 3 3//4 4"" ii//o o a ad da ap ptte err a asssse em mb blly y w wiitth h b blle en nd diin ng g v va allv ve e ((s stta an nd da arrd d)) part# description quantity 1 93521 3/4" i/o assembly 1 2 90802 screw 3 3 90252 blending dial cap 1 4 90222 blending...

Page 25

23 a asssse em mb blly y a an nd d p pa arrttss 1 1"" ii//o o a ad da ap ptte err a asssse em mb blly y w wiitth h b blle en nd diin ng g v va allv ve e ((o op pttiio on na all)) figure 25: 1" i/o adapter assembly with blending valve part# description quantity 1 93252 1" i/o adapter assembly 1 2 908...

Page 26

24 a asssse em mb blly y a an nd d p pa arrttss b by yp pa assss a asssse em mb blly y ((o op pttiio on na all)) part# description quantity 1 93521 3/4" i/o assembly 1 2 93858 turbine sensor assembly 1 3 90232 turbine sensor cap 1 4 90809 sensor cap screw 1 5 54320 plastic turbine axle 1 6 90522 tur...

Page 27

25 a asssse em mb blly y a an nd d p pa arrttss d drriiv ve e e en nd d c ca ap p a asssse em mb blly y part# description quantity 1 90802 screw 2 2 90217 drive motor 1 3 93891 1/4" hex nut 2 4 93238 drive gear 1 5 90809 screw 2 6 93219 piston slide cam cover 1 7 93217 piston slide cam 1 8 93583 dri...

Page 28

26 a asssse em mb blly y a an nd d p pa arrttss iin njje ec ctto orr a asssse em mb blly y part# description quantity 1 93810 injector screen 1 2 93223 injector throat 1 3 93220 injector seal (thick) 1 4 93221 injector nozzle 1 5 93232 top injector seal (thin) 1 6 93222 injector cap 1 7 90807 screw ...

Page 29

27 a asssse em mb blly y a an nd d p pa arrttss 93223 injector throat: in conjunction with the injector nozzle, part # 93221, it creates the vacuum that draws the brine solution from the brine cabinet. The center hole should be clear of debris, round and undamaged. The throat should be pressed flush...

Page 30

28 a asssse em mb blly y a an nd d p pa arrttss part# description quantity 1 93620 piston assembly (includes o-ring & spring) 1 2 90821 o-ring 1 3 93260 housing 1 4 90843 0.5 gpm flow control 1 5 93805 o-ring 1 6 93243 housing cap 1 7 90807 screw 2 93601 entire assembly (all of the above parts) b br...

Page 31

29 a asssse em mb blly y a an nd d p pa arrttss s sa affe etty y s sh hu utto offff a asssse em mb blly y parts# description quantity 1 54226 safety shutoff 1 2 56018 float 1 3 56200 air check 1 56024 entire assembly (all of the above parts) figure 30: safety shutoff assembly.

Page 32

30 a asssse em mb blly y a an nd d p pa arrttss the nut, gripper and retainer sleeve are a three-piece assembly that can come apart if removed from the elbow body. Parts must be reassembled exactly as shown to function properly. When connecting the 3/8" poly tube, first assemble the nut, gripper, an...

Page 33

31 a asssse em mb blly y a an nd d p pa arrttss 90268 drain end cap: the drain end cap (2) seals the left opening on the main valve body. The opening is sealed with an o-ring used as axial or “face” seal. The o-ring sits in a groove in the end cap. This groove must be free of defects such as pits or...

Page 34

32 a asssse em mb blly y a an nd d p pa arrttss 93524 barbed drain end cap assembly: the barbed drain end cap (2) seals the left opening on the main valve body. The opening is sealed with an o-ring (1) used as axial or “face” seal. The o-ring sits in a groove in the end cap. This groove must be free...

Page 35

33 t trro ou ub blle essh ho oo ottiin ng g no soft water after regeneration. No salt in brine cabinet. Sediment in brine tank has plugged the brine line and air check. Drain line is pinched, frozen, or restricted. Clogged injector assembly. (see injector assembly in assembly and parts.) salt bridge...

Page 36

34 excess water in brine tank. Restricted, frozen, or pinched drain line. Plugged brine line, brine line flow control, or air check. (see the safety shutoff assembly in assembly and parts.) plugged injector assembly. (see the injector assembly in assembly and parts.) sticking brine refill valve. Rem...

Page 37

35 s sp pe ec ciiffiic ca attiio on nss maximum compensated hardness—grains/gallon (mg/l) 35 (600) minimum ph (standard units) 7 media type and amounts built-in, whole house self-cleaning filter. Filters dirt and sediment down to 20 micron. Super fine mesh resin 0.4 ft 3 (0.01 m 3 ) *salt usage (use...

Page 38

36 1 10 0 y ye ea arr l liim miitte ed d w wa arrrra an ntty y to whom warranty is extended this warranty is issued to the original owner at the original location site and is not transferable to other sites or to subse- quent owners of the system. To place the equipment under warranty, the warranty ...

Page 39

37 n no otte ess.

Page 40

Copyright 2009 maximizer 400 4343 s. Hamilton rd. Groveport, oh 43125 litho usa form # rv0209tl iin n b bu ussiin ne essss s siin nc ce e 1 19 95 56 6 400