- DL manuals

- Hague Quality Water

- Water Dispenser

- Maximizer

- Owner's Manual

Hague Quality Water Maximizer Owner's Manual

Summary of Maximizer

Page 1

Series 96 owner’s manual rev. 2.0

Page 2: Table of Contents

Table of contents introduction 1 routine care 2 series 96 and your water 4 installation 5 programming the series 96 8 blending valve adjustments/ how and when to use the bypass 14 troubleshooting 15 parts, diagrams 17 brine valve elbow installation 32 brine cabinet data 33 cycle settings 34 equipmen...

Page 3: Introduction

Introduction congratulations on your decision to purchase a hague series 96 water treatment appliance. Recognized internationally for built-in quality, dependability, and ease of service, this appliance represents the state-of-the-art in home water treatment. While your appliance should be installed...

Page 4: Routine Care

Routine care salt a brine solution is used during regeneration to remove calcium and magnesium from the softening resin. Maintain salt level at least 1/3 full; do not let the brine tank run out of salt. Use solar or pellet salt; do not mix the two. Be sure to purchase a clean grade of salt. Rock sal...

Page 5: Recommendations

Recommendations water used for lawns and gardens does not require softening. To achieve maximum efficiency from your series 96: 1. Protect your series 96, including the drain line, from freezing. 2. If dirt, sand, or large particles are present in your water supply, consult your hague dealer for fil...

Page 6: Series 96 and Your Water

Series 96 and your water water testing the series 96 like any other appliance, requires correct installation and setting for optimum performance. To ensure proper settings, you need to obtain an accurate water test. Your representative has probably already tested your water for you and determined th...

Page 7: Installation

Installation pre-installation checklist be sure to check the following items before installing a series 96: water pressure — not less than 20 psi (138 kpa) nor greater than 120 psi (828 kpa). Minimum flow rate required — 2.4 gpm at the end of drain line. Drain — drain the appliance to a floor drain ...

Page 8: Where to Locate The

Where to locate the series 96 where you will locate the series 96 depends on what other water treatment equipment you currently have installed. The series 96 should be located: after: before: water meter water heater pressure tank typical 96 series installation figure 1 keep in mind that you need to...

Page 9: Connecting The

Connecting the series 96 1. Place the series 96 in the desired location. (see figure 1.) 2. Turn off the electricity and/or water supply to the water heater. For gas heaters, turn gas cock to “pilot”. 3. Make sure the inlet, outlet and drain connections comply with local codes. 4. Check arrows on th...

Page 10: Programming The Series 96

Programming the series 96 the series 96 allows a variety of programming options, from setting the time of regeneration and the number of people to adjusting the hardness, capacity settings, and cycle settings*. Here’s how it works: the series 96 calculates how much water a family will need in a day ...

Page 11

Figure 2 service settings this section is recommended for qualified service personnel only. The appliance control must be set correctly for proper performance. Regenerate function: multi-purpose. 1.) used to put the appliance into an immediate regeneration. Press and hold (approximately 5 seconds) u...

Page 12

Description of the two series 96 operating modes caution: be sure the controller is firmly “locked” onto the drive end cap assembly.” the four tabs on top of the drive end cap will allow the clips on the bottom of the controller case to lock onto the end cap tabs. (see detail diagram on page 18; fig...

Page 13

7.00 push the display button to step to the next parameter. The display will show: comp. Hard. 00025 this parameter is the calculated compensated hardness using the hardness, iron and manganese settings. The formula is (4 x each ppm iron) + (4 x each ppm manganese) + hardness = compensated hardness....

Page 14

13.00 push the display button to step to the next parameter. The display will show: salt lbs. 06.0 this parameter sets the amount of salt to be used to achieve the capacity setting. 13.00a push the select and change buttons until the desired salt setting is displayed. In this example, set to: salt l...

Page 15

This is the normal operation display for operating mode 2. The 00979 represents the number of gallons of softening capacity between regenerations. This completes the service settings mode. Even though the service setting mode has been completed, the series 96 is not ready for service until the custo...

Page 16: Blending Valve

Blending valve adjustment in some situations, a blending valve may be desired. The amount of hardness blended back into the water line is determined by the hardness of the incoming water and the setting of the blending valve. Where extremely hard water is present, the blending valve may only need to...

Page 17: Troubleshooting

Troubleshooting this section describes solutions to the most common problems that can occur. If you cannot solve the problem easily, call your hague dealer for service. Problem cause action notes: ______________________________________________________________________________________ series 96 owner’...

Page 18: Troubleshooting

Troubleshooting problem cause action series 96 owner’s manual 16 flow is indicated when water is not being used. (fig. 2.) there is a leak in your household plumbing system repair the leak. No read-out in display. Electric cord is unplugged. Plug in transformer. (fig. 1.) no electric power at outlet...

Page 19

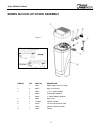

Series 96 hook-up/cover assembly series 96 owner’s manual 17 figure 3 item no qty. Part no. Description 1 1 54501 media cabinet cover assembly 2 2 90837 bypass nut gasket 3 2 90254 1" or ¾" copper adapter 2 90256 pvc adapter (optional) 2 90258 1" copper adapter (optional) 4 2 90251 bypass nut 5 1 co...

Page 20: Series 96 Brine

Series 96 brine tank assembly series 96 owner’s manual 18 for brine tank information on water depth and salt usage, see page 34 figure 4.

Page 21: Series 96

Series 96 tank/cabinet assembly series 96 owner’s manual 19 figure 5 no. Part no. Qty description 1 93809 2 screw 2 93870 4 screw 3 90614 1 drain end cap assembly 4 93808 2 o-ring 5 93835 2 sleeve 6 93838 2 o-ring 7 90615-94 1 bypass assembly 8 93833 1 cord clip 9 90828 1 o-ring 10 (not used) 11 953...

Page 22: Series 96 Injector

Series 96 injector assembly series 96 owner’s manual 20 part number 93501 figure 6 no. Part no. Qty item description 1 93223 1 injector throat creates the vacuum that draws the brine solution from the brine cabinet in conjunction with the injector nozzle (part no. 93221). The center hole should be c...

Page 23

Notes: ______________________________________________________________________________________ series 96 owner’s manual 21 no. Part no. Qty item description 4 93232 1 top (thin) seals between the injector nozzle and the injector cap. The gasket must be injector seal free of defects such as tears or c...

Page 24: Series 96 Bypass

Series 96 bypass assembly series 96 owner’s manual 22 figure 7 no. Qty. Part no. Description 1 12 90807 screw 2 1 90262 bypass endcap - left 3 2 93808 o-ring 4 4 90802 screw 5 1 90252 cap - blending valve 6 1 90222 blending valve 7 1 90827 o-ring 8 1 90246 bypass housing 9 1 90616 bypass piston asse...

Page 25

Series 96 owner’s manual 23 part no. Qty item description 90246-94 1 bypass makes the connection between the plumbing and the main valve body. Also, housing contains the “hard water” blending valve and bypass piston. The recommended seal for the 1 ¼" male inlet-outlet threads is the nylon hook-up nu...

Page 26

Series 96 owner’s manual 24 part no. Qty item description 90802 6 bypass handle and sensor housing screw and blending valve cap screw 90522 1 turbine assembly the turbine has a 1/8" diameter rare earth magnet pressed into place adjacent to the axle opening. When assembled to the axle, the turbine sh...

Page 27

Series 96 drive end cap assembly part number 95301t-jg (note: motor and magnet disc must be ordered separately.) series 96 owner’s manual 25 figure 8 no. Qty. Part no. Description 1 2 90802 screw 2 1 90217 drive motor 3 2 93891 ¼" hex nut 4 1 93238 drive gear 5 2 90809 screw 6 1 93219 piston slide c...

Page 28

Part no. Qty item description 93583 1 drive end cap seals the two openings on the main valve body. The larger diameter opening is sealed with an o-ring used as an axial or "face" seal. The o-ring sits in a groove in the drive end cap. This groove must be free of defects such as pits or scratches and...

Page 29

Series 96 brine valve housing assembly part number 93601-jg series 96 owner’s manual 27 figure 9 no. Qty. Part no. Description 1 1 93620 piston assembly (includes o-ring & spring) 2 1 90821 o-ring 3 1 93260 housing 4 1 93254 quad ring retainer 5 1 90843 .5 gpm flow control 6 1 93805 o-ring 7 1 93243...

Page 30

Part no. Qty item description 93260 1 housing should have a quad-ring for the piston seal. The quad-ring (4) is held in place by the brine valve retainer(5). The brine valve housing has four retaining lugs that secure the brine valve retainer. Just inside the entrance hole for the brine piston (1) i...

Page 31: Fill Plug Assembly

Fill plug assembly part number 90618 series 96 owner’s manual 29 (1) 90238 fill plug: the fill plug seals the media access ports in the media tank. Care should be taken that the o-ring seal areas are kept clean and free of debris. Also, both o-rings should be in the proper locations, one under the f...

Page 32

Series 96 drain end cap assembly series 96 owner’s manual 30 figure 10 no. Part no. Qty item description 1 93808 1 end cap o-ring 2 90268 1 drain end cap seals the left opening on the main valve body. The opening is sealed with an o-ring used as an axial or "face" seal. The o-ring sits in a groove i...

Page 33: Series 96 Safety Shutoff

Series 96 safety shutoff assembly series 96 owner’s manual 31 figure 11.

Page 34

Safety brine valve elbow installation series 96 owner’s manual 32 figure 12 no. Qty. Part no. Description 1 1 54112 1/2" compressed assembly 2 1 54138 3/8" compressed assembly d c the nut, gripper and retainer sleeve are a 3 piece assembly that can come apart if removed from the elbow body. Parts mu...

Page 35: Brine Cabinet Data

Brine cabinet data based on the water level measured from the bottom of the maximizer brine cabinet with grid plate, the following depths correlate to the amount of salt used per regeneration: salt (lbs.) depth (inches) 1.0 5 3/4 3.0 8 7/8 6.0 11 7/8 9.0 15 3/8 to maintain peak performance of your a...

Page 36: Cycle Settings

Cycle settings series 96 owner’s manual 34 1 lb. Salt setting service setting english unit hardness setting number ______ (?) iron ppm (clear water)* capacity in grains 5,600 backwash 1 (minute) 03.0 brine/rinse (minute) 07.0 backwash 2 (minute) 01.0 96 hour regeneration yes/no salt (lbs.) 1 3 lb. S...

Page 37

Equipment specifications - model 96mm series 96 owner’s manual 35 maximum compensated hardness* 90 gpg / 1,541 mg/l maximum ferrous iron reduction* 10 ppm reduced to below 0.3 ppm minimum ph 7 “ultra-fil” self-cleaning sediment filtration 20 microns nominal salt use:use clean, white pellet or solar ...

Page 38

15 year limited residential warranty series 96 owner’s manual 36 to place the equipment under warranty, the warranty registration card must be completed and returned by the original owner to hague quality water international within 30 days of installation. Coverage this warranty covers the hague max...

Page 39

Series 96 owner’s manual 37.

Page 40

System conforms to nsf/ansi 44 softening performance, efficiency, barium reduction and radium 226/228 reduction as verified and substantiated by test data. Barium/radium reduction occurs as long as the unit is softening the water. Test product water every 12 months with the hardness test strips to c...