Technical overview page 1 english table of contents introduction ..................................................................................................................................... 2-11 nomenclature ......................................................................................

Page 2 english introduction nomenclature - model name explanation nomenclature 1 u 18 es 2 v h a unit type a = indoor unit 1 = single zone outdoor 2 = two zone outdoor 3 = three zone outdoor 4 = four zone outdoor unit type u = outdoor b = cassette type indoor d = slim duct type indoor m = mid static...

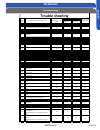

Page 3 english introduction specifications multi-zone indoor.

Page 4 english introduction specifications multi-zone indoor.

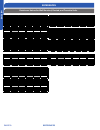

Page 5 english introduction specifications multi-zone outdoor.

Page 6 english introduction safety overview read these safety precautions be sure to read the safety precautions before conducting work. The items are classified into “warning” and “caution.” the “warning items are especially important since they can lead to death or serious injury if not followed c...

Page 7 english introduction safety overview read these safety precautions be sure to use the specified cable to connect between the indoor and outdoor units. Make the connections securely and route the cable properly so that there is no force pulling the cable at the connection terminals. When conne...

Page 8 english introduction overview & introduction auto mode when the running mode is turned to auto after starting the system, the system will first determine the running mode according to the current room temperature and then will run according to the determined mode: tr means room temperature; t...

Page 9 english introduction overview & introduction heat mode mode. * temperature control range: 60---86°f * temperature difference: ±2°f control feature: the temperature compensation is automatically added and the system will send the heating signals to the outdoor system. If tr≤ts, the outdoor com...

Page 10 english introduction overview & introduction low load protection control in order to prevent the frosting of the indoor heat interaction device, the outdoor system will be stopped if the indoor heat interaction temperature is 32°f for 5 minutes, but the fan will continue to operate. The outd...

Page 11 english introduction overview & introduction multi-zone outdoor multi-zone outdoor the control of the outdoor unit expansion valve when unit starts, the eev valves will energize and change to a standard opening. When operation starts, the eev will change position to keep the suction vapor su...

Technical overview page 12 english outdoor unit technical overview introduction - overview outdoor unit technical overview the outdoor unit features a variable speed rotary type com- pressor that delivers refrigerant flow to up to 4 individual indoor units. The system uses r-410a refrigerant mixed w...

Technical overview page 13 english technical overview electronic control unit circuit board (ecu) electronic control unit circuit board (ecu) the electronic control unit operates the outdoor fan motor, crankcase heater, eev stepper motors and the 4-way valve. This board also controls the general ope...

Technical overview page 14 english technical - overview outdoor unit technical overview module circuit board (mcb) 1 the module circuit board generates 3 phase dc power to operate the variable speed compressor. The compressor is connected to the mcb via terminals cn-5. Cn-6 and cn-7. 2 a reactor coi...

Technical overview page 15 english technical overview outdoor unit technical overview power circuit board (pcb) the purpose of the power circuit board is to filter out poten- tial electrical noise before it reaches the outdoor unit elec- tronic circuits. All voltage to operate the outdoor unit circu...

Technical overview page 16 english 4 way valve the 4 way valve is energized during heating mode operation. The valve is energized with 230 volts via a connection plug on the ecu. When energized, the valve directs the compressor hot gas to the indoor coil. During cooling mode and defrost mode operati...

Technical overview page 17 english outdoor unit components compressor the compressor is a variable speed dual rotary type com- pressor. The compressor has a built in accumulator to protect against liquid floodback during running operation. A factory supplied crankcase heater will protect the compres...

Technical overview page 18 english t emperature sensors outdoor unit the outdoor unit has two groups of temperature sensors. The first group of sensors are liquid and gas sensors that are asso- ciated with each indoor unit eev. These sensors monitor the leaving liquid temperature from the eev and th...

Operations page 19 english the outdoor unit is capable of controlling up to 4 individual indoor units. The outdoor unit will vary compressor capacity and outdoor fan motor speed to match the demand requirement from the indoor units. All capacity and diagnostic decisions are con- trolled by the outdo...

Operations page 20 english valve. The 4 way valve will direct the hot gas to the outdoor coil. The refrigerant will condense in the outdoor coil and be slightly subcooled. The refrigerant is now in a liquid state. 2 temperature sensor toci the temperature of the hot gas leaving the 4 way valve will ...

Operations page 21 english on a call for heating, the indoor unit will send the room temperature and set-point requirement to the outdoor unit ecu via the data signal wire path. The data travels from the indoor unit to the outdoor unit via the wire located on terminal 3. The indoor unit’s louver wil...

Operations page 22 english the indoor heat exchanger temperature sensor will monitor the temperature of the indoor coil to ensure it is hot enough to prevent blowing cold air. Once adequately warm temperature is sensed at the indoor coil, the ecu will energize the indoor fan to a higher speed. The h...

Operations page 23 english outdoor unit control information outdoor unit temperature sensor responses 10.2.1 outdoor frequency control a. The compressor running frequency is range is 20-95 rps. 10.2.2 electronic expansion valve (eev) control a: eev specification: maximum open angle is 500 pulses. Dr...

Operations page 24 english 10.2.6 forced defrost operation the system can be placed into a forced defrost cycle from the wired controller. The system will remain in defrost until sensor te has sensed 53.6°f for at least 1 minute or until the defrost cycle has reached 10 minutes total runtime. A forc...

Operations page 25 english outdoor unit temperature sensor responses there are times when the switch is not active. The periods of inactive switch operation are: 1. When the compressor starts up the switch will be off for 8 minutes. 2. When the system is defrosting the switch is not active. 3. In th...

Testing page 26 english outdoor unit testing procedures compressor testing if the compressor fails to start, the compressor may have an internal electrical failure, the compressor may be seized me- chanically, or the module control board (mcb) may be bad. To test for a bad failed compressor, perform...

Testing page 27 english 4 way valve testing the 4 way valve will control the direction of hot gas discharge via an internal slide assembly. The valve has a line voltage solenoid that is en- ergized when heat mode operation is desired. The solenoid will direct the internal slide to send the hot gas t...

Testing page 28 english outdoor unit testing procedures temperature sensor testing the temperature sensors are negative coefficient type. These sensors will reduce their electrical resistance as temperature decreases. Should the sensors fail, the ecu will generate an appropriate error code. To check...

Error codes page 29 english error code 10 this code indicates an electrical failure of the sensor that is used to sense the temperature of the outdoor coil during heat mode operation. This sensor is connected to the ecu via a connection at plug cn-14. Error code 11 this code indicates an electrical ...

Error codes page 30 english outdoor unit pressure switch error codes there are two pressure switches in the outdoor unit, a low pressure switch and a high pressure switch. They connect to the ecu via plugs cn-12 and cn-13. The low pressure switch is connected at cn-12 and the high pressure switch at...

Error codes page 31 english outdoor unit error codes indoor unit and outdoor unit communication errors error code 15 this error indicates the indoor unit and outdoor unit are having a problem communicating information. The wiring path for the data signal is between terminals 3 to 1 on the terminal b...

Error codes page 32 english outdoor unit error codes error codes related to the module board operation error codes related to the module board operation error code 2 the module board detected excessive instantaneous current compressor , ipm hardware automatically stopped the module board output to p...

Error codes page 33 english outdoor unit error codes error codes related to module board operation error code 26 cpu module reset indicates possible drive module power anomalies. Usually when the low line voltage conditions are present. Check for line voltage problems. Error code 27 compressor curre...

Technical overview page 34 english indoor unit technical overview indoor wall mount unit components indoor unit technical overview the wall mounted units act as evaporator coils during cooling mode and condenser coils during heating mode. These units have gravity condensate drain systems. If a conde...

Technical overview page 35 english indoor unit technical overview the indoor unit circuit board communicates with the outdoor unit ecu via a connection at terminal block screw 3. The data pulse that sends the communi- cation information can be measured with a voltmeter placed to dcv range. From the ...

Technical overview page 36 english the blower assembly consists of a plastic blower wheel that is connected to a variable speed indoor blower motor. A set screw holds the blower wheel to the blower motor. The indoor blower motor is a dc fan motor that is connected to the indoor unit control board vi...

Testing page 37 english indoor wall mount unit technical overview accessing components/removing cover 1. To access components for service, first disconnect power to the outdoor unit. This will de-energize the indoor unit. 2. Lift the front cover by prying on the two indented finger holds at each end...

Technical overview page 38 english indoor wall mount unit technical overview if the indoor fan motor does not run. 1. Remove the front cover and access the circuit board connection cn-9. 2. Reset power and turn the remote control fan command to fan on mode. Motor test 1. If the motor doesn’t run, ch...

Technical overview page 39 english indoor wall mount unit technical overview step 6. Remove 6 screws that hold the motor bracket and evaporator coil. Step 7. Lift the evaporator coil and remove the motor bracket. Step 8 loosen the motor shaft set screw. Phillips head screw. Step 9. Unplug the motor ...

Testing page 40 english indoor wall mount unit section testing temperature sensors the easiest problems to solve will involve codes that are related to potential failure of temperature sensors. Common problems may include loose connections, open electrically, and out of calibration. Checking the con...

Testing page 41 english indoor wall mount unit section testing communication circuit testing communication circuit if an error e7 occurs, perform the following test to determine if the indoor control board is functioning properly to send data to the outdoor unit. Perform this test with the unit powe...

Error codes page 42 english indoor wall mount unit indoor unit error codes indoor unit error codes (hsu218vhg only) the error codes that are displayed on the indoor units may vary from the outdoor unit codes. The information communicated by the error code will be the same for both indoor and outdoor...

Error codes page 43 english indoor unit error codes indoor wall mount unit error code f4 this code indicates the temperature of the compressor hot gas is too high. This error would have occurred despite the ecu attempt at reducing operating frequency. Causes of this type of condition are typically a...

Technical overview page 44 english cassette unit components component overview the indoor cassette type units act as evaporator coils during cooling mode and condenser coils during heating mode. These units have a built in condensate pump with an associated condensate level switch. The condensate pu...

Technical overview page 45 english cassette unit technical overview the indoor unit circuit board controls the switching functions of the indoor unit. All control decisions are made by the outdoor unit ecu. The indoor board has some limited diagnostic capability which will be covered in this manual....

Technical overview page 46 english cassette unit technical overview cassette unit components the blower assembly the blower assembly consists of a plastic blower wheel that is connected to a psc indoor blower motor. A set screw holds the blower wheel to the blower motor. The indoor blower motor is a...

Technical overview page 47 english cassette unit technical overview accessing the blower motor and condensate pump a1. Disconnect power to the outdoor unit. A2. Remove the louver assembly. A3. Disconnect the main power wire to the indoor unit. A4. Unplug the condensate pump and float switch from wir...

Testing page 48 english cassette unit technical overview cassette unit testing procedures: accessing components/removing cover indoor fan motor test procedure if the indoor fan motor does not run. 1. Disconnect power to the system. 2. Remove the return air cover and access the circuit board connecti...

Testing page 49 english cassette unit technical overview cassette unit sensor testing procedures testing temperature sensors the easiest problems to solve will involve codes that are related to potential failure of temperature sensors. Common problems may include loose connections, open electrically...

Testing page 50 english cassette unit technical overview cassette unit testing procedures: louver motor testing louver motors if the louver does not operate with command from the remote control, either the indoor board is bad, or the louver motor is defective. It is more likely the motor is defectiv...

Testing page 51 english testing communication circuit if an error e7 occurs, perform the following test to determine if the indoor control board is functioning properly to send data to the outdoor unit. Perform this test with the unit powered and all wiring connected between indoor and outdoor unit....

Technical overview page 52 english slim duct slim duct unit technical overview the slim duct indoor unit will act as evaporator coils during cooling mode and condenser coils during heating mode. This unit can operate with a motorized supply air louver or it can have a limited amount of ducting added...

Technical overview page 53 english slim duct overview the indoor unit features a multi speed blower motor that will change speed to match the capacity demand from the outdoor unit. The motor is a dual shaft type that powers two individual blower assemblies. Separate motors located in the accessory s...

Technical overview page 54 english indoor unit circuit board the indoor unit circuit board controls the switching functions of the indoor unit. All control decisions are made by the outdoor unit ecu. The indoor board has some limited diagnostic capability which will be covered in this manual. The in...

Technical overview page 55 english sw1 dip switches there are two sets of dip switches on the circuit board. Sw3 is for factory use only. Sw1 is used to set the configuration of the indoor unit operation. The first three switches sw1-1, sw1-2 and sw1-3 select the indoor unit capacity. Air delivery p...

Testing page 56 english test condensate pump and associated float switch if the internal condensate pump does not operate, the pump may be bad or the float switch may be defective. Perform the following test: float switch and condensate pump 1. Access the electrical control box. 2. Unplug the float ...

Testing page 57 english slim duct testing procedures testing communication circuit if an error e7 occurs, perform the following test to determine if the indoor control board is functioning properly to send data to the outdoor unit. Perform this test with the unit powered and all wiring connected bet...

Remote controls page 58 english user friendly: back light; room temperature display functions: clock; timer; sleep function; heat reclaim ventilation; eco; filter cleaning; error code display; child lock; parameter inquiry; unit no. Setting; static pressure grade inquiry; temp. Compensation setting;...

Page 59 english remote controls remote controls wired controller installation 1. Put communication wire through the hole in the back cover as shown. 2. Mount the back cover in the desired location, making sure not to pinch the communication wire. Then connect the com- munication wire to con1 port of...

Remote controls page 60 english dip switch wired controller wiring instructions wired controller installation dimensions unit: inch (mm) dip switch on/off function default setting sw1-1 on set as the slave controller off off set as the master controller sw1-2 on ambient temp. Display available off o...

Page 61 english remote controls wired controller operation 1 2 3 note: this function requires the on/off key led to be turned off and the screen backlight to be illuminated. Press and hold the mode key for 5 seconds, the number of the mode currently being used will display in the upper left corner o...

Remote controls page 62 english note: the display backlight must be illumi- nated before proceeding. To turn the back- light on, press any key (mode, fan, pq, time, or set) located at the bottom of the display, or press the on/off key located at the top of the display. Timer on press the timer key o...

Page 63 english remote controls wired controller operation note: this function requires the screen backlight to be illuminated. The on/off key led can be either on or off. Press and hold the set key for 10 seconds. The wired control- ler address and communication address between the indoor and outdo...

Remote controls page 64 english press the set key. The swing louver function icon will be displayed. Press the pq keys to advance through the functions to select the sleep func- tion. The sleep and sleep “off” time icons will be displayed. (the sleep icon will be flashing) press the time key, the “o...

Page 65 english remote controls 3 8 6 19 4 17 18 14 13 10 9 7 5 16 2 15 11 12 1 1 power button press the on/off button on the remote control to start the unit. 2 turbo/quiet button the turbo function is used for fast heating or cooling. Press the turbo/quiet button once and the remote control will d...

Remote controls page 66 english 9 louver swing button - vertical air flow direction adjustment press the swing up/down button to choose the position of the vertical airflow louvers. Status display of air flow cool/dry: heat: caution: • it is advisable not to keep the vertical louver in the down- war...

Page 67 english remote controls the time. After replacing batteries or a power failure occurs, the time setting will need to be reset. According to the time setting sequence of timer on or timer off, either start-stop or stop-start can be achieved. 13 sleep button sleep mode press the extra function...

Remote controls page 68 english 15 health button feature not available on this series. 16 confirm/cancel button function: setting and canceling timer and other functions. 17 lock button used to lock buttons and lcd display 18 light button turns indoor unit display on and off 19 reset button if the r...

References page 69 english references troubleshooting timer lamp flash time running lamp flash time 1 faulty of outdoor unit eeprom 15 2 1 f12 2 ipm overcurrent or short circuit 16 2 2 f1 4 communication failure between module and ecu 18 2 4 f3 5 module operated overload 19 2 5 f20 6 module low or h...

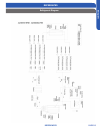

References page 70 english references yellow blue white black red yellow infinity Ω 345k Ω 238k Ω infinity Ω blue 4.7k Ω 4.54m Ω infinity Ω white 107k Ω infinity Ω black infinity Ω red wall mount fan motor resistance values blue violet yellow orange red blue 383 Ω 388 Ω 390 Ω 195 Ω violet 381 Ω 385 ...

References page 71 english references the led flashes when any of the following errors are detected: 1. When a protection device of the indoor or the outdoor unit activated or when the thermistor malfunctions, disabling equipment operation 2. When a signal transmission error occurs between the indoo...

References page 72 english problem problems & solutions length limits piping length limits references.

References page 73 english component ratings references.

References page 74 english references duct work installation duct work installation roof installation ceiling air supply unit return air return air box roof air outlet grill air supply unit return air box return air use rivet to connect the air return duct on the air return inlet of the indoor unit,...

References page 75 english references cover plate of the outdoor unit to expose the terminal block connections. Line voltage from circuit breaker/disconnect to outdoor unit wire terminal always follow local and national codes when installing electrical wiring. The required fuse size can be found in ...

References page 76 english wiring references.

References page 77 english wiring references.

References page 78 english wiring references.

References page 79 english wiring references.

References page 80 english wiring references.

References page 81 english 2u wiring references.

References page 82 english cn20 connector for room card wiring references.

References page 83 english swi wiring references.

References page 84 english wiring references.

References page 85 english cn1 cn2 cn3 cn11 cn36 cn10 cn15 cn25 cn23 cn24 cn22 cn28 cn9 cn16 cn17 cn18 cn19 cn20 cn21 pcb(1) wiring references.

References page 86 english circuit diagrams references.

References page 87 english circuit diagrams references.

References page 88 english wiring diagrams references.

References page 89 english wiring diagrams references.

References page 90 english 2u - piping installation dimensions references.

References page 91 english 2u - piping installation dimensions in case elevation b is more than 16 feet, the oil trap should be installed every 16 to 23 feet. In case the total pipe length (b1+b2) is more than 66 feet, the refrigerant should be charged according to 66 g/ft (20g/m) references.

References page 92 english refrigerant diagram references.

References page 93 english refrigerant diagram references.

References page 94 english 3u - piping installation dimensions references.

References page 95 english 4u - piping installation dimensions references.

References page 96 english flow charts check the connector connection caution: be sure to turn power off before connecting or disconnecting the connector, or parts may sustain damage. Check the connector connection correct the connection is it normal? Thermistor resistance check is it normal? Replac...

References page 97 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Indoor eeprom error when the data of the eeprom is in error or the eeprom is damaged outdoor eeprom error; outdoor led flashes 1 time replac...

References page 98 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. When the detection rotation signal is not received in 2 minutes note: when the a/c is charging do not remove or insert plugs in order to avo...

References page 99 english flow charts does fan rotate smoothly? Turn off the power supply and rotate the fan by hand replace fan motor turn power on and operate fan does it run? Yes no no yes is motor power voltage dc310v generated? Check output of fan motor connector replace indoor unit pcb is the...

References page 100 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Check to see that the terminal on the outdoor main board is properly inserted. Is it normal? Reinsert the terminals. No no no no yes yes us...

References page 101 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. No turn on the unit with the remote control. Is an error indicated before the compressor starts? Ipm module is damaged and needs to be repl...

References page 102 english flow charts flow charts caution: be sure to turn power switch off before connecting or disconnecting connector, or parts may sustain damage. The current of the compressor is too high caution: be sure to turn power switch off before connecting or disconnecting the connecto...

References page 103 english flow charts flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Yes yes no no 1. Check whether terminals cn23 and cn24 and terminals cn10 and cn 11 on the ipm module are securely connected ar...

References page 104 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Turn on the unit with the remote control. Check to see if the compressor starts normally. Does it start normally? Test the outdoor power su...

References page 105 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Yes yes no no turn on the unit with the remote control. Measure the temperature at the exhaust temperature sensor of the compressor on the ...

References page 106 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Yes yes restart the system does it start up normally but the error occurs again after a short period of time? Check whether the wiring betw...

References page 107 english flow charts no yes yes yes no check the indoor main board test the outdoor power supply if 230vac is available but 310vdc is not, the power module is damaged. Replace it. Measure the voltage between jumpers 3 and 4 of ic1 on the indoor main board with a multimeter is the ...

References page 108 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. Within 3 minutes after the unit is supplied with power and turned on with the remote control, check to see if the compressor starts up. Yes...

References page 109 english flow charts caution: be sure to turn power switch off before connecting or disconnecting the connector, or parts may sustain damage. No no yes use the remote control to turn on the unit. Check whether the ambient temperature is below 149°f did the unit malfunction after i...

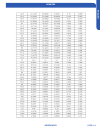

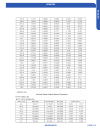

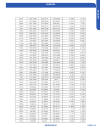

References page 110 english sensors value of thermistor - indoor unit.

References page 111 english sensors.

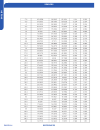

References page 112 english sensors.

References page 113 english sensors.

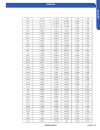

References page 114 english sensors.

References page 115 english sensors.

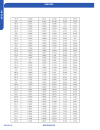

References page 116 english sensors.

References page 117 english sensors.

References page 118 english sensors.

References page 119 english sensors.

References page 120 english sensors.

References page 121 english sensors.

Model #: 2u18ms2vh, 3u24ms2vh, 4u36ms2vh, ab09sc2vh, ab12sc2vh, ab18sc2vh, aw07lc2vh, aw09lc2vh, aw12lc2vh, aw18lc2vh, ad07sl2vh, ad09sl2vh, ad12sl2vh, ad18sl2vh issued date: august 2015 www.Haier.Com haier america, wayne, nj 07470 ©2015 haier america trading, llc..