- DL manuals

- Haier

- Air Conditioner

- AB122XCBAA

- Service Manual

Haier AB122XCBAA Service Manual - page 74

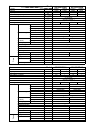

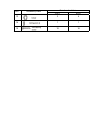

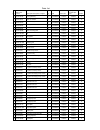

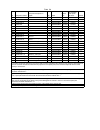

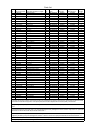

8 OFF ON ON ON

9

ON OFF OFF OFF

10 ON OFF OFF ON

11 ON OFF ON OFF

12 ON OFF ON ON

13 ON ON OFF

OFF

14 ON ON OFF ON

15 ON ON ON OFF

16 ON ON ON ON

If you use central control type, SW1, SW2 will be used simultaneously.

Wiring request in central control type: port A-B is connected with indoor port CN16

˄

A-B

˅

through 2-core shield wire. Requirements:

1. Port A connects with port CN16

˄

A

˅

of all indoor units.

2. Port B connects with port CN16

˄

B

˅

of all indoor units.

Address on

central

controller

Indoor unit

address

SW2-3 SW2-2 SW2-1 SW1-4 SW1-3 SW1-2 SW1-1

1

1

ON OFF OFF OFF OFF OFF OFF

2

2

ON OFF OFF OFF OFF OFF ON

3

3

ON OFF OFF OFF OFF ON OFF

4

4

ON OFF OFF OFF OFF ON ON

5

5

ON OFF OFF OFF ON OFF OFF

6

6

ON OFF OFF OFF ON OFF ON

7

7

ON OFF OFF OFF ON ON OFF

8

8

ON OFF OFF OFF ON ON ON

9

9

ON OFF

OFF

ON OFF

OFF

OFF

10

10

ON OFF

OFF

ON OFF

OFF

ON

11

11

ON OFF

OFF

ON OFF

ON OFF

12

12

ON OFF

OFF

ON OFF

ON ON

13

13

ON OFF

OFF

ON ON OFF

OFF

14

14

ON OFF

OFF

ON ON OFF

ON

15

15

ON OFF

OFF

ON ON ON OFF

16

16

ON OFF

OFF

ON ON ON ON

17

-------- ON OFF

ON OFF

OFF

OFF

OFF

18

-------- ON OFF

ON OFF

OFF

OFF

ON

19

-------- ON OFF

ON OFF

OFF

ON OFF

20

-------- ON OFF

ON OFF

OFF

ON ON

21

-------- ON OFF

ON OFF

ON OFF

OFF

22

-------- ON OFF

ON OFF

ON OFF

ON

23

-------- ON OFF

ON OFF

ON ON OFF

24

-------- ON OFF

ON OFF

ON ON ON

25

-------- ON OFF

ON ON OFF

OFF

OFF

Summary of AB122XCBAA

Page 1

Service manual commercial air conditioning 5hp fixed frequency free multi au422xibaa as122xabaa as122xcbaa ae122xcbaa ab122xcbaa af122xcbaa as142xcbaa ae142xcbaa ab142xcbaa af142xcbaa ae212xcbaa ab212xcbaa ƽ features ƽ auto-check function ƽ auto –restart function (optional ) ƽ group control function...

Page 2: Contents

Contents contents contents 1. Description of products & features 2. Specification 3. Safety precaution 4. Net dimension of indoor and outdoor 5. Installation instructions 6. Parts and functions 7. Remote controller functions 8. Refrigerant diagram 9. Electrical control functions 10. Diagnostic infor...

Page 3

1.Description of products & features 1.1. Products code explanation a u 42 2 x i b a a climate type: t1 (see table 1) design number (a stands for design sequence,fixed frequency type) product type: a stands for heat pump type, refrigerant is r22 b stands for heat pump type, refrigerant is r407c m st...

Page 4

1.4 product character 1.4.1 operating individually and operating simultaneously the unit can realize individual operation which can control one unit running, stop, and adjusting running mode. Also the unit can operate simultaneously which control multi indoor units at the same time. 1.4.2 variable q...

Page 5: 2. Specifications

—— cooling heating btu/h 42000 48000 w 12500 14000 w 5600 5600 w 6300 6300 w/w 2.30 2.50 10 ϋ ³×m³/h / / —— —— n, v, hz a / a 26.0 / 30.0 26.0 / 30.0 a a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output power w air-flows (h/m/l) m³/h type / di...

Page 6

—— cooling heating cooling heating btu/h 12000 13000 14000 16000 w 3500 3900 4100 4600 10 ϋ ³×m³/h 1.6 / 1.6 / —— —— n, v, hz a / a 0.15 0.15 0.15 0.15 type × number —— speed r/min motor output power w air-flows (h-m-l) m³/h type / diameter mm total area m² temp. Scope ć external mm package mm drain...

Page 7

—— cooling heating btu/h 12000 13000 w 3500 3900 10 ϋ ³×m³/h 1.0 / —— n, v, hz a / a 0.25 0.25 a —— type × number —— speed r/min motor output power w air-flows (h-m-l) m³/h type / diameter mm total area m² temp. Scope ć external mm package mm drainage pipe material, diameter mm —— —— mm —— noise lev...

Page 8

—— cooling heating cooling heating btu/h 12000 13000 14000 16000 w 3500 3900 4100 4600 10 ϋ ³×m³/h 1.6 / 1.6 / —— —— n, v, hz a 0.20 0.20 0.20 0.20 type × number —— speed r/min motor output power w air-flows (h/m/l) m³/h type / diameter mm total area m² temp. Scope ć external mm package mm drainage ...

Page 9

—— cooling heating cooling heating btu/h 21000 24000 21000 24000 w 6150 7000 6150 7000 10 ϋ ³×m³/h 2.5 / 2.5 / —— —— n, v, hz a 1.35 1.35 0.80 0.80 type × number —— speed r/min motor output power w air-flows (h/m/l) m³/h type / diameter mm total area m² temp. Scope ć external mm package mm drainage ...

Page 10

Model part number part name characteristic 001a3900153 ambient temp sensor 1.R25=5k ȍ ±1% ˈ b25/50=3450k±1% 2.R25=5k ȍ ±1% ˈ b25/50=3450k±1% 0010450243 a system coil temp sensor r25=5k ȍ ±1% ˈ b25/50=3450k±1% 0010450398 a system discharging temp sensor r80=50k ȍ ±3% ˈ b25/80=4450k±3% 0010451344 b sy...

Page 11

4. Net dimension of indoor and outdoor 4.1 outdoor unit: au422xibaa 7huplqdoeorfn screw hole (m10).

Page 12

4.2 indoor units model: af122xcbaa model: as122xcbaa , as142xcbaa 783 440 225 q r s :kble >fk @jiafmfjibk ;>fbk > ? @ 462 /32 .5/.

Page 13

A b c model: wall mounted type model as122xabaa a b c 930 185 265.

Page 14

Model: ae122xcbaa , ae142xcbaa ǃ ae212xcbaa model: ab122xcbaa , ab142xcbaa a i e f g b c d type ae072xcbaa, a b c d e f g i 770 804 225 225 100 615 648 452 225 55 225 125 100 ae122xcbaa, 1064 1099 225 55 225 100 installation dimension: (unit: mm) ae092xcbaa ae142xcbaa ae212xcbaa 452 452 55 125 125 u...

Page 15

Model: ab212xcbaa :doorueduulhu %duulhu *urxqg (ceiling hole).

Page 16: Warning

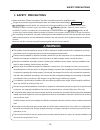

Warning caution warning caution this system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior environment such as engineering shop could cause equipment malfunction. Please entrust installation to either the company which sold you the equipment or to ...

Page 17: Warning

When setting up or moving the location of the air conditioner, do not mix air etc. Or anything other than the designated refrigerant (please see nameplate) within the refrigeration cycle. Rupture and injury caused by abnormal high pressure can result from such mixing. Always use accessory parts and ...

Page 18

The unit capacity and performance mode: (a stands for system a, b stands for system b) performance data of combination “au422xibaa+122x*baa h 4” as followings: performance mode a: af122*1 as122*1 ab122*1 ae122*1 b: af122*1 as122*1 ab122*1 ae122*1 a: af122*2 as122*2 ab122*2 ae122*2 b: af122*2 as122*2...

Page 19

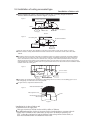

Pipe connections: 1 to 4 a1 a2 b1 b2 b2 a1 a2 b1 outdoor unit indoor units 1 to 3(except for 21000btu/h units) a1 a2 b1 b2 outdoor unit indoor units a2 b1 b2 1 to 2(except for 21000btu/h units) a1 a2 b1 b2 outdoor unit indoor units a2 b2.

Page 20

Communication wire connection: 1. The indoor unit whose liquid pipe is connected to a1 in a system is called unit a1, its communication wire of a1(3) ǃ a1(4) should be connected to a1(p) ǃ a1(q) respectively. 2. The indoor unit whose liquid pipe is connected to a2 in a system is called unit a2, its ...

Page 21

Special installation guide to 21000btu indoor units on free multi system only for outdoor unit au422xibaa working with 21000btu indoor units 1. Special accessory pipes for 21000btu indoor units: a b changing pipe (1/2-5/8) collecting pipe (1/4-3/8) ¶ 12.7 ¶ 15.88 ¶ 6.35 ¶ 9.52 ¶ 6.35 2. Pipe install...

Page 22

5. Installation instructions 5.1 installation of outdoor unit 5.1.1 connection of pipes ƽ coat the flaring seal face with refrigerant oil. ƽ to bend a pipe, give the roundness as large as possible not to crash the pipe. ƽ to connect a pipe, fit the centers and tighten the nut hand tight, then use sp...

Page 24

Place where it is easy to route drainage pipe and outdoor piping. Place ,away from heat source and with less direct sunlight. Place where cool and warm air could be delivered evently to every corner of the room. Place near power supply socket.Leave enough space around the unit. Place ,robust not cau...

Page 25: Fixing of The Unit

Fixing of the unit 1.Position of the wall hole wall hole should be decided according to installation place and piping direction.(refer to installation drawings). 2. Making a wall hole drill a hole of 120x70mm dia. With a little slope towards outside. 3. Piping connection indoor side outdoor side thi...

Page 26

Piping connection of the indoor unit 1. Arrangement of piping and drainage pipe after opening inlet grill,you will see a control box. Remove the cover before working. Cut away, with a hammer or a saw, the lid for piping according to piping direction. According to the piping method, connect the pipin...

Page 27

When connecting indoor and outdoor wire, check the number on indoor and outdoor terminal blocks. Terminals of same number and same color shall be connected by the same wire. Incorrect wiring may damage air conditioner's control or cause operation failure. Note: wiring diagram: w:white b : black y/g:...

Page 28: 5.3

5.3 installation instructions of wall mounted type installation tools 1) screw driver 2) hacksaw 3) hole core drill 4) hexagon wrench (5mm) 5) spanner (14,17,19 and 24mm) 6) torque wrench (17,22,24mm) 7) pipe cutter 8) flaring tool standard accessories the standard accessories includes: 1) measuring...

Page 29

Number of articles no. Accessory parts 3 by 1 4 by 1 13 3 4 14 1 1 15 12 16.

Page 30

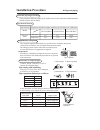

1 fitting of the mounting plate and positioning of the wall hole 1 carry out,based on the neighboring pillars or lintels, a proper leveling for the plate to be fixed against the wall,then temporarily fasten the plate with one steel nail. 2 make sure once more the proper level of the plate,by hanging...

Page 31

3 lnstallation of the lndoor unit drawing of pipe [rear piping] draw pipes and the drain hose, then fasten them and connecting electric cable for indoor and outdoor with the adhesive tape. Drain hose should be placed under. Right piping left piping under piping adhesive tape b heat insulation materi...

Page 32

5.4 installation of ceiling concealed type installation of indoor unit each air return and supply duct should fix to the floor precast slab by using an iron stand. Use glue to seal the interface closely. Recommend the distance between the air return duct and the wall is more than 150mm. The distance...

Page 33

Indoor unit flexible joint or static pressure box transitive air duct circular air duct joint of air diffuser air diffuser fig1: duct connected indoor unit air return shutter rivet air return duct galvanized board glue nail insulating fabric tinfoil adhesive tape glue nail cover 2 . Installation for...

Page 34

Iron reinforcement knife embedded part foundation bolt guide plate embedded part pipe suspension foundation bolt original concrete slab use hole hinge, hole plunger or hole bolt. Steel reinforcement structure use steel angle or new support steel angle directly. Hanging bolt suspension screw support ...

Page 35

Installation of remote controller 5. Replace the upper cover of wire controller note try as far as possible a flat surface for installation. Don't use excessive force when tightening screws, or lower part might got deformed. Pcb is mounted on lower part of wire controller, be careful not to damage i...

Page 36

Drain pipe ! Caution in order to drain water normally, the drain pipe shall be processed as specified in the installation manual and shall be thermal insulated to avoid dew generation. Improper hose connection may cause indoor water leakage. Requirements the indoor drain pipe shall be thermal insula...

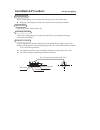

Page 37: Installation Procedure

Supplementary refrigerant the refrigerant supplementation shall be as specified in the installation instructions attached with the outdoor unit. The added refrigerant shall be r22. The adding procedure shall be aided with a measuring meter for a specified amount of supplemented refrigerant requireme...

Page 38: Installation Procedure

R efrigerant piping vacuum pumping with a vacuum pump, create vacuum from the stop valve of the outdoor unit. L emptying with refrigerant sealed in the outdoor unit is absolutely forbidden. Open all valves open all the valves on the outdoor unit. Gas leakage detection check with a leakage detector o...

Page 39: Installation Procedure

Electric wiring the electric wiring work shall be conducted by qualified electricians according to the installation instructions. A separate power circuit shall be used. Insufficient power cord amperage or improper wiring will cause danger of electric shock or fire. During wiring connection, the pow...

Page 40

Wire connection for built-in indoor unit insert from outside the connection wire and signal transmission wire through the wall hole with pipeline already arranged. Pull out the front ends of connection wire and signal wire and make a circle on the signal wire. Connect the connection wire according t...

Page 41

5. 5 installation of cassette type (ab122~ab142xcbaa).

Page 46

1.Before installation do not discard any accessories until installation completed ● determine the best way to carry the unit to its installation place. ● do not remove the packing until the unit reaches the installation place. 2.Selection of installation position (1) installation place shall meet th...

Page 47

Level spirit level screws at the piping outlet are fixed at the corner of drain pan. Center of ceiling hole paper pattern [fix the paper pattern] (2) cut an opening in the ceiling for installation if necessary. (when ceiling already exists.) ● refer to paper pattern for dimension of ceiling hole. (3...

Page 48

5. Refrigerant piping ● the outdoor unit is precharged with r407c refrigerant. ● refer to fig.1, when connecting and removing piping from unit. ● for the size of the flare nut, please refer to table 1. ● apply refrigerant oil at both inside and outside of flare nut. Tighten by hand 3-4 turns then ti...

Page 49

Warning observe the following when connecting power supply terminal block: do not connect wires of different specifications to the same terminal block. (loose wire may cause overheating of circuit) connect wires of same specifications as shown in right fig. Charge water from air outlet charge water ...

Page 50

6. Parts and functions 6.1 outdoor unit 6.2 indoor unit / 1 2 3 0 / -= a@; 8 @ 0-7= @? = ; >6 ; 1- : ; 8 @ 2 -9 :;@ 8 ? + d ef d b c , 3 -= a@; 8 @ air outlet air inlet maintenance plat e valve plate terminal block.

Page 51

Air inlet grille haier air filter(inside) signal receiver window louver air outlet grille motor inside fan inside electric control box evaporator ceiling concealed type indoor unit wall mounted type indoor unit:as122xcbaa, as142xcbaa air duct inlet grill air filter vertical flap for multi-split type...

Page 52

Drain swing louvre refrigerant pipes air filter outlet suction grille (located in the suction grille) in cooling operation,to discharge the water from inside the room. Pump unit (built in) (located in the outlet) cassette type indoor unit swing louver (air flow direction can be adjusted by using the...

Page 53

14.High/so button used to select high or soft operation. 21 22 31 29 32 fresh high/so timer set filter b a m d health reset lock sleep fan temp on off swing mode clock code light off a u t o 1 2 3 4 6 7 9 10 11 15 13 5 8 16 17 30 34 35 33 23 24 25 26 27 28 20 12 14 remote controller 1.Temp setting b...

Page 54

Clock set displays when healthy run function is set. 22.Temperature display 34.Lock state display 33.Battery energy display notify the user when it is time to change the batteries. 24.High/so display 25.Signal sending display 26.Fresh air display 27.Electrical heating display 29.Health display 32.Sl...

Page 55

Fan operation 1.Unit start press on/off button to start your air conditioner. Previous operation status appears on lcd (except for timer, sleep, and swing setting). 2.Select operating mode press mode button. At each press, operation mode changes as follows: 3. Adjust fan speed press fan button. At e...

Page 56

Auto, cool , heat and dry operation 1. Unit start press on/off button,unit starts. Previous operation status appears on lcd (except for timer, sleep and swing setting) 3.Temperature setting then select auto run or select cool operation or select dry operation or select heat operation 2.Select operat...

Page 57

Press swing button. Up and down airflow varies upwards and downwards. Left and right airflow varies left and right sides. Always use swing button on the remote controller to adjust flaps. Adjusting them by hand may result in air conditioner's abnormally running. Displays on the lcd disappear. All in...

Page 58

Sleep function before going to bed you can press down the sleep button and the air conditioner will run so as to make you sleep more comfortably. Before using this function, the clock must be set. Use of sleep function after the unit's start, set running mode and then press sleep button once to make...

Page 59

Every time the button is pressed, time increases 10 minuts. If the button is kept pressed, time changes quickly. Timer on/off function set clock correctly before starting timer operation 1.Unit start after unit start, select your desired operation mode (operation mode will be displayed on lcd) 2.Tim...

Page 60

Timer on-off function set clock correctly before starting timer operation 1.Unit start after unit start, select your desired operation mode (operation mode will be displayed on lcd) 2.Timer mode selection press timer button on the remote controller to change timer mode. Every time the button is pres...

Page 61

After the air conditioner has operated for a certain period, dust has accumulated on the filter, and the filter up/down function can be used to clean it. 1.Whether unit starts or stops, continuously press filter button for 3 seconds, and enter the filter up/down waiting status (when unit stops, the ...

Page 62

Press the high/so button twice notice: when the air conditioner is operating in " high mode " , unevenness of room air temperature may occur due to the intensive operation in a short time. Anyway, operation in "high mode", does not last for more than 15 minutes, then regular operation is automatical...

Page 63

Press the high/so button twice notice: when the air conditioner is operating in " high mode " , unevenness of room air temperature may occur due to the intensive operation in a short time. Anyway, operation in "high mode", does not last for more than 15 minutes, then regular operation is automatical...

Page 64

Auto restart function setting setting method (to be applied for a necessary situation) : setting method: when the remote controller is on (excluding timer mode and fan mode), press the "sleeping" button on the remote controller 10 times within 5 seconds, and after the buzzer rings 4 times, the air c...

Page 65

C health set recovery check f cautions: on cooling only unit, heating mode is not available. Note: the above information is the explanation of the displayed information therefore varies with those displayed in actual operation. Clock used to adjust time. Timer used to set timer mode. Stands for time...

Page 66

Buttons function ˖ mode ˖ used for select indoor operation mode. Fan ˖ used for select indoor air flow. Swing ˖ used for setting indoor swing mode. Health ˖ used for setting indoor health function. Temp + - ˖ used for changing set temperature. Clock ˖ used to adjust time. + ǃ - ˖ stands for time plu...

Page 67

[fan] [high] ˖ high fan speed [fan] [med] ˖ medium fan speed [fan] [low] ˖ low fan speed [fan] [fix] ˖ fixed fan speed, it will display only when fixed fan speed is requested to main indoor unit. [central] ˖ central control mode [operation] ˖ running mode [stand by] ˖ waiting mode [pre-heat] ˖ pre-h...

Page 68

Auto operation, cooling, heating and dehumidification operation 1) start up operation: press the button of on/off, the system will start up, and will display [mode][auto] ˗ [fan][auto] ˗ [room temp.]+ Ā 24 ćā˗ [clock]+”12 ˖ 00”. 2) select mode: press the mode button, then you will see in the display...

Page 69

Timer on, press [timer]. [timer][on] will be constant on. Then [timer] [off] flashes, press the clock +/- button to adjust the time of timer off, press [set]. The time sequence of timer on and timer off will determine the mode is [timer] [on] » [off] or [timer] [off] » [on]. If you want the current ...

Page 70

Central control function when the central controller selects [central] mode, the buttons in the wired controller except for [check] will be invalid. Ventilation mode (only for the unit with fresh air function or heat recovery function ) press [recovery] button, then the unit will switch over the ven...

Page 71

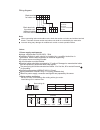

G preset ̣̣̣ h outdoor total capacity actual value, decimal in check mode, press [check] to quit the check mode, and go into normal running mode. How to change the function switches? No. Type state of switch function description connected central controller j01 changeover of wired controller and cen...

Page 72

Controller, if the central controller is set to “central”, the buttons in the wired controller will be invalid, or the buttons will be valid. Failure code: for remote type, flash times failure code on wired controller for central control, failure code failure description reason remarks 10 08(08h) 21...

Page 73

2m continuously 13 13(0dh) 31d solenoid valve abnormal solenoid valve act incorrectly 3 times continuously ƻ 14 76(4ch) 15d discharging temp. Sensor abnormal sensor broken down or short circuit for more than 2m continuously ƻ 15 05(05h) 17d eeprom abnormal eeprom data missing run as the default valu...

Page 74

8 off on on on 9 on off off off 10 on off off on 11 on off on off 12 on off on on 13 on on off off 14 on on off on 15 on on on off 16 on on on on if you use central control type, sw1, sw2 will be used simultaneously. Wiring request in central control type: port a-b is connected with indoor port cn16...

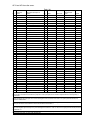

Page 75

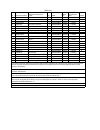

26 -------- on off on on off off on 27 -------- on off on on off on off 28 -------- on off on on off on on 29 -------- on off on on on off off 30 -------- on off on on on off on 31 -------- on off on on on on off 32 -------- on off on on on on on 33 -------- on on off off off off off 34 -------- on ...

Page 76

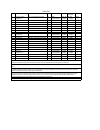

-------- on off off off on off off -------- on off off off on off on -------- on off off off on on off -------- on off off off on on on -------- on off off on off off off -------- on off off on off off on -------- on off off on off on off -------- on off off on off on on -------- on off off on on of...

Page 77

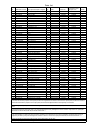

-------- on on off on on on on -------- on on on off off off off -------- on on on off off off on -------- on on on off off on off -------- on on on off off on on -------- on on on off on off off -------- on on on off on off on -------- on on on off on on off -------- on on on off on on on -------- ...

Page 78

Electrical functions of wired controller: 1.Function difference between master wired controller and slave one: contrastive items master wired controller slave wired controller function all of functions only with below functions: on/off, mode, fan speed, set temp., swing 2. Wiring connections of wire...

Page 79

Terminal a ǃ b ǃ c of wired controller respectively. The communication wiring is 4 meter long; if the actual length is more than it, please distribute wiring according to below table: communication wiring length ˄ m ˅ dimensions of wiring 2 x3-core shielded wire ı 100 and 0.5mm 2 x3-core shielded wi...

Page 80

Refrigerant diagram h e a ti n g o p e ra ti o n c o o lin g o p e ra ti o n h e a t e x c h a n g e r o u td o o r u n it in d o o r u n it o il s e p a ra to r s to p v a lv e c o m p re s s o r a ir -l iq u id s e p a ra to r fo u r- w a y v a lv e liq u id re c e iv e r c a p ill a ry c a p ill ...

Page 81: Electrical Control Functions

Electrical control functions no function description of function 1 auto over 23 cooling and set 26 less 23 2 cooling set temperature between 16 and 30 3 drying set temperature between 16 and 30 4 fan temperature can not be adjusted 5 emergence run over 23 cooling and set 26 less 23 6 test run set fo...

Page 82

Haier 2) cooling operation loide vavle is not energized compressor and outdoor fan stop led of operation goes on /('srzhujrhvrq loide valve energized frost prevent n y n compressor and outdoor fans run led of power goes on does the room temp.Exceed the temp. Setting y lo mid lo mid manual auto hi hi...

Page 83

Haier 3) dehumidifying operation dehumidifying solenoid valves open, indoor unit fan motor weak wind solenoid valves open, indoor unit fan motor weak wind electronic expansion valve totally open a send indoor unit operation state to outdoor unit determine if dehumidify according to air temperature n...

Page 84

10. Diagnostic information (trouble shooting) 10.1 failure code resumable failures are marked with “ Ĵ ”, the others are not resumable failures. Resumable failure will disappear when the failure is eliminated and its failure code will disappear automatically within 30 seconds. But the other failure ...

Page 85

Failure code of wall mounted units no. Failure contents flash times of timer lamp on indoor unit 1 room temperature sensor problem 1 2 pipe temperature sensor problem of indoor unit 2 3 fan motor problem of indoor unit 3 4 high pressure problem of the system 17 5 communication problem between indoor...

Page 86

Trouble shooting - detailed for engineer malfunction flow chart: analyze and diagnose if the air-condition fails to cooling or heating function and other functions, please check the system as follows: ҏ 1. Cooling y change the designed temp. Replacing compressor superaddition condensate clear the fi...

Page 87

2. Malfunction of air-conditioner units 1) fan of indoor unit faulty on abnormal functioning if the cmos chip of control panel has signal output y if capacitator of fan motor is normal if cmos chip of control pcb.Is normal replacing the control pcb. N if pressure sensor resistence throughing replaci...

Page 88

3) there is nothing on display of remote control organ, and the air-conditioner failure to operate if there's ac 13v on transformer subside of indoor unit pcb. If the transform of pcb.Socket is normal replacing the transformer n y redo the connection work check the port row of power supply if power ...

Page 89

11. Electrical data: outdoor unit: ::klwh%5%urzq %%odfn%/%oxh 55hg *d v 3l sl qj 6h qv ru $ *d v 3l sl qj 6h qv ru % %5 %5 5 note: 1.The communication terminal block to indoor cannot be connected to ht eletricity, or pcb will be damaged. 2.Heater is optional according to different outdoor unit. 3.Ox...

Page 90

Console type: indoor wiring diagram bottom louver motor top louver motor optional board receiving board ambient temp. Sensor piping temp. Sens0r bottom fan motor top fan motor remote control detector power supply board terminal block sw3 and sw4 are used to choose the working state of the wired cont...

Page 91

Wall mounted type: as122xcbaa, as142xcbaa ignore the state on the controller and power off the controller is able to be controlled ignore the state on the controller and power off if the controller power on, the indoor unit run according to the state on the controller; if the controller power off, t...

Page 92

Model: as122xabaa remote control detector grouding grouding:to grouding of power note:remote control detector is optional y/g wiring diagram of indoor unit transformer signal receiver display cn3 cn1 cn7 m cn9 cn2 cn8 s901 cn4 cn6 cn5 cn16 emergency switch bl b m y/g: yellow/green br: brown r: red b...

Page 93

Ceiling concealed type 3. P16 and p17 are used for room card function &1 75$16 &1 2 ; 6:,1* circuit diagram of indoor unit / + 80, 3 3 803 1 / & 200 0 + )8 6( 31 &1 5(&(,9(%2$5' 21 &1 6: 21 6: 3 3 '225 &1 )/2 $7 % $ $/$ 50 &1 5(027( &1 &1 5(027( &(175$/,=(' &21752//(5 :,5(' &21752//(5 5(027( &21752/...

Page 94

Cassette type &1 2 ; 6 :, 1* 3. P16 and p17 are used for room card function circuit diagram of indoor unit transformer filter motor wired controller remote controller receiver central controller receive board float switch swing motor pump motor fan motor fan capacitor room temp. Sensor piping temp. ...

Page 95

Out door unit wiring circuit:.

Page 96

Circuit diagram: w a ll mounted type: as122xcbaa, as142xcbaa c 2 1 102 c9 104 c20 102 c17 102 low er sw ing m o tor r36 10k 1 220vl 1 220vn fu se1 t 3 .15a c2 0.1uf /275v e1 2200u/25v e8 220u/16v +5 vi n 1 gnd 2 vou t 3 w1 7805 c7 104 rv1 s 14k 350 pt c 4 1 ir q 2 rs t 3 pt f 0 /t a c h2 4 pt f 1 /t...

Page 97

Circuit diagram indoor uni t m odel :a s 092xabaa, as122xabaa.

Page 98

Console type (power board): 1 2 3 4 56 a b c d 6 5 4 3 2 1 d c b a + 12v vi n 1 gnd 2 vo u t 3 ic 3 7805 c1 1 100uf /16v +5 le d 1 g r een ic 4 p 521 g nds c3 2. 2nf /1 k v c4 0. 1uf /50v c5 2. 2nf y 1 d5 u f 4005 d6 m u r 410 100v 4a 1 2 3 4 t 135-265v a c c2 22uf 400v c6 1000uf 25v c8 470uf /25v l...

Page 99

1 2 3 4 56 a b c d 6 5 4 3 2 1 d c b a + 12v vin 1 gnd 2 vout 3 ic 3 7805 c1 1 100u f /16v +5 le d 1 g r een ic 4 p 521 g nds c3 2. 2n f /1k v c4 0. 1u f /50v c5 2. 2n f y 1 d5 u f 4005 d6 m u r 410 100v 4a 1 2 3 4 t 135- 265v a c c2 22u f 400v c6 1000u f 25v c8 470u f /25v l2 3. 3u h 2a c1 0. 1u f ...

Page 100

Console type (select board): 1 2 3 4 5 6 7 8 cn1 con8 r1 10k r 2 10k r 3 10k r4 220 r5 220 r6 220 r7 10k q1 9013 q2 9013 q3 9013 +5 sw 1 r8 10k r9 330 c2 4.7u f /50v out vcc gnd ic 3 led1 led2 led3 led c1 102 indication board circuit diagr a 1 2 cn2 +5 sw2 sw3 r11 5.1k r12 10k r13 20k selection boar...

Page 101

Cassette type and ceiling concealed type:.

Page 102

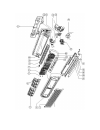

Exploded views: outdoor unit:.

Page 103

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 001a0100122 front guard assy 2 au422xibaa 0.0000% 0.0000% x 2 001a1301971 plate for maintain 1 au422xibaa 0.0000% 0.0000% x 3 001a1301640 front panel(left) 1 au422xibaa 0...

Page 104

35 001a3900161 ac contactor 2 au422xibaa 0.2000% 0.2400% * 36 0010150084 electric box (horizontal) 1 au422xibaa 0.0000% 0.0000% x 37 001a3600018 fan capacitor 2 au422xibaa 0.2000% 0.2400% * 38 0010150138 electric box (vertical) 1 au422xibaa 0.0000% 0.0000% x 39 001a4000110 power wiring block 1 au422...

Page 106

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 001a0100543 front grill 1 as122xabaa 0.00% 0.000% × 2 001a0100943 front panel 1 as122xabaa 0.00% 0.000% × 3 001a2400080 air filter 1 as122xabaa 0.00% 0.000% × 4 001a24000...

Page 107

* + * , * -.

Page 108

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010202192 front grill 1 as122xcbaa 0.00% 0.000% × 2 0010802130 front panel 1 as122xcbaa 0.00% 0.000% × 3 0010202204 air filter (left) 1 as122xcbaa 0.00% 0.000% × 4 00102...

Page 109

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010202192 front grill 1 as142xcbaa 0.00% 0.000% × 2 0010802130 front panel 1 as142xcbaa 0.00% 0.000% × 3 0010202204 air filter (left) 1 as142xcbaa 0.00% 0.000% × 4 00102...

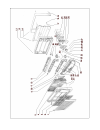

Page 111

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010800954 front grill 1 af122xcbaa 0.0000% 0.0000% x 2 0010201169 air filter 1 af122xcbaa 0.0000% 0.0000% x 3 0010201288 button 1 af122xcbaa 0.0000% 0.0000% x 4 00108009...

Page 112

Exploded view 20 21.

Page 113

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 *0010851501.1 fan 2 ae122xcbaa 0.0200% 0.0240% * 2 *0010851501.2 scroll case 2 ae122xcbaa 0.0000% 0.0000% x 3 *0010851501.3 fan motor 1 ae122xcbaa 0.0200% 0.0240% * 4 00...

Page 114

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 *0010851502.1 fan 2 ae142xcbaa 0.0200% 0.0240% * 2 *0010851502.2 scroll case 2 ae142xcbaa 0.0000% 0.0000% x 3 *0010851502.3 fan motor 1 ae142xcbaa 0.0200% 0.0240% * 4 001...

Page 115

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 *0010851572.1 fan 2 ae212xcbaa 0.0200% 0.0240% * 2 *0010851572.2 scroll case 2 ae212xcbaa 0.0000% 0.0000% x 3 *0010851572.3 fan motor 1 ae212xcbaa 0.0200% 0.0240% * 4 00...

Page 117

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010851179 guard assembly 1 ab122xcbaa 0.0000% 0.0000% x 2 0010400705 indoor fan motor 1 ab122xcbaa 0.0200% 0.0240% * 3 0010100531 motor fix plate 1 ab122xcbaa 0.0000% 0....

Page 118

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010851179 guard assembly 1 ab142xcbaa 0.0000% 0.0000% x 2 0010400705 indoor fan motor 1 ab142xcbaa 0.0200% 0.0240% * 3 0010100531 motor fix plate 1 ab142xcbaa 0.0000% 0....

Page 119

Exploded view model ab212xcbaa.

Page 120

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part remark 1 001a0100708 bottom plate assy. 1 ab212xcbaa 0.00% 0.000% h 2 001a1301741 swing 4 ab212xcbaa 0.00% 0.000% h 3 001a1301743 motor holder 1 ab212xcbaa 0.00% 0.000% h 4 001a1301668 ...

Page 121

Performance curves indoor temp. D.B. / w.B. 18 ć 20 ć 25 ć 32 ć 35 ć /24 ć 40 ć 43 ć 46 ć 18/14 ć 11.6 11.4 10.9 10.4 9.8 9.3 8.8 8.4 20/15 ć 12.0 11.7 11.4 10.9 10.2 9.8 9.3 8.8 22/16 ć 12.4 12.1 11.7 11.5 11.0 10.1 9.8 9.3 25/18 ć 13.3 12.9 12.7 12.3 11.8 11.0 10.7 10.2 27/19 ć 13.8 13.4 13.2 12.9...