- DL manuals

- Haier

- Air Conditioner

- AB242ACBEA

- Service manual

Haier AB242ACBEA Service manual

MANUAL CODE: SYJS-005 -03 Rev.0 .

Haier Group

Auto-Restart function

Group control(with a group controller)

Auto-changeover

The same outdoor unit can match with cassette \convertible\

duct type indoor unit

With new environment friendly refrigerant R407C

Weekly timing(with a weekly timer)

Features

Service Manual

Commercial Air Conditioning

24

28 Universal Outdoor Unit air conditioning

AC28NACBEA+AU28NAHBEA

AD28NAMBEA+AU28NAHBEA

AB28NACBEA+AU28NAHBEA

Remotoe control and Wired remote control(Optional)

AB242ACBEA+AU242AHBEA

AC242ACBEA+AU242AHBEA

AD242AMBEA+AU242AHBEA

AD242AHBE

A+ AU242AHBEA

AP242ACBE

A+ AU242AHBEA

AU282AHBEA

Summary of AB242ACBEA

Page 1

Manual code: syjs-005 -03 rev.0 . Haier group auto-restart function group control(with a group controller) auto-changeover the same outdoor unit can match with cassette \convertible\ duct type indoor unit with new environment friendly refrigerant r407c weekly timing(with a weekly timer) features ser...

Page 2: Contents

Contents 1. Description of products & features………………… ...…….2 2. Specifications…………………………. ……………… ...……8 3. Safety precaution…………………………..………………….12 4. Net dimensions of indoor and outdoor unit………………...14 5. Installation instructions ……………………. ………………. 16 6. Parts and functions …………………………..…… ..……….19...

Page 3

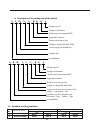

1 .Description of products & features products coding direction united outdoor unit: a u 24 2 a h b e a climate type: t1 (see table 1) design number e product type: a stands for heat pump type, refrigerant is r22 b stands for heat pump type, refrigerant is r407 m stands for cool only type, refrigera...

Page 4

A) description of the coding rule of the models a u 28 n a h b e a climate type:t1 design serial number air conditioner product series:one-to-one outdoor unit cooling capacity:28=28000btu/h adaptive voltage:380-400v/50hz appearance features product type: heat pump r407c a b 28 n a c b e a climate ty...

Page 5

C)brief introduction of the series: convertible type: ac242acbea ac28nacbea (1).Ceiling convertible,flexible installation,convenient maintenance,saving the users' expenditures (2)adopting single-phase & three-phase power supply,applicable for household and commercial usage (3).Dual air outlet design...

Page 6

Ab242acbea ab28nacbea products characteristic: completely invisible machine body: the whole machine body is completely concealed inside the ceiling. Due to its compact size it neither breaks the harmonization of indoor decoration nor occupies the indoor spaces. The stylish look of air conditioner al...

Page 7

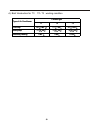

Climate type type of air conditioner t1 t2 t3 cool only 18 43 0 35 21 52 heat pump -7 43 -7 35 -7 52 electricity heating 43 35 52 d). Brief introduction for t1\ t2\ t3 working condition climate type type of air conditioner t1 t2 t3 cool only 18 43 10 35 21 52 heat pump -7 43 -7 35 -7 52 electricity ...

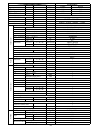

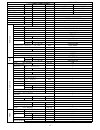

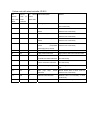

Page 8: 2 Specifications

2 specifications model item au242ahbea ac242acb ea ab242acbea ad242ambea e ad242ahb ea cooling capacity① btu/h 24000 24000 24000 24000 24000 heating capacity① btu/h 27000 27000 27000 27000 27000 power 1ph 220-230v 50hz cooling power(w) 2700 2700 2700 2700 2700 cooling eer(btu/w) 8.89 8.89 8.89 8.89 ...

Page 9

Function cooling heating capacity btu/h 24000 28000 capacity kw 7.1 7.9 w 2.7 2.7 w 3.2 3.2 eer or cop w/w 2.6 2.9 dehumidifying capacity 10‐³×m³/h power cable power source n,v,hz a / a 13.5/16 14.5/19.5 start current a fuse a unit model (color) type × number speed(h-m-l) r/min fan motor output powe...

Page 10

Function cooling heating capacity btu/h 28000 32000 w 3200 3300 w 4500 5500 eer or cop btu/w 8.75 9.7 dehumidifying capacity 10‐³×m³/h power cable power source n,v,hz a / a start current a unit model (color) fan type × number speed(h-m-l) r/min fan motor output power kw air-flow(h-m-l) m³/h heat exc...

Page 11

Function cooling heating capacity btu/h 28000 34000 capacity kw 8.2 10 sensible heat ratio 75% w 3400 3600 w 4300 4600 eer or cop w/w 2.41 2.77 dehumidifying capacity 10‐³×m³/h power cable power source n, v, hz a / a start current a unit model (color) model / manufacture type type × number speed r/m...

Page 12

Function cooling heating capacity btu/h 28000 32000 w 3200 3300 w 4500 5500 eer or cop btu/w 8.75 9.7 dehumidifying capacity 10‐³×m³/h power cable power source n,v,hz a / a start current a unit model (color) fan type × number speed(h-m-l) r/min fan motor output power kw air-flow(h-m-l) m³/h heat exc...

Page 13

Function cooling heating capacity btu/h 28000 32000 w 3200 3300 w 4500 5500 eer or cop btu/w 8.75 9.7 dehumidifying capacity 10‐³×m³/h power cable power source n,v,hz a / a start current a unit model (color) fan type × number speed(h-m-l) r/min fan motor output power kw air-flow(h-m-l) m³/h heat exc...

Page 14

Function cooling heating capacity btu/h 28000 32000 w 3200 3300 w 4500 5500 eer or cop btu/w 8.75 9.7 dehumidifying capacity 10‐³×m³/h power cable power source n,v,hz a / a start current a unit model (color) fan type × number speed(h-m-l) r/min fan motor output power kw air-flow(h-m-l) m³/h heat exc...

Page 15: Warning

Warning caution warning caution this system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior environment such as engineering shop could cause equipment malfunction. Please entrust installation to either the company which sold you the equipment or to ...

Page 16: Warning

When setting up or moving the location of the air conditioner, do not mix air etc. Or anything other than the designated refrigerant (please see nameplate) within the refrigeration cycle. Rupture and injury caused by abnormal high pressure can result from such mixing. Always use accessory parts and ...

Page 17

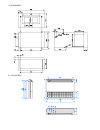

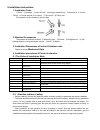

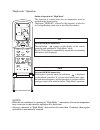

4.Net dimensions of indoor and outdoor unit indoor unit models 1) ab242acbea ab28nacbea 2) ad242ambea ad28nambea -14- 35 260 275 35 a-a a-a drainage pipe b-b fresh air outlet 655 liquid pipe gas pipe.

Page 18

3) ad242ahb ea 4) ac242acbea 6 5 5 24 0 2 0 0 9.

Page 19

-15- 185 185 55 70 70 screw hole (m10) 580 power wiring terminal power wiring distribution hole 70 1024 18 18 340 380 840 25 6)au242ahbea au28nahbea au282ahbea 11 0 1 8 0 6 0 8 5 100 30 5 55 6 3 0 6 9 0 105 195 300 600 600 3 1 0. 6 3 85 25 3 00 10 10 54 5 59 0 85 150 60 1200 15 0 23 5 1320 1 9 5 100...

Page 20

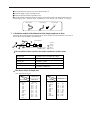

5. Installation instructions 1. Installation tools 1) driver 2) hacksaw 3) hole core drill 4)hexagon wrench(5mm) 5) spanner(14,17,19 and 24mm) 6) torque wrench(17,22,24mm) 7) pipe cutter 8) flaring tool for example: use two spanner to joint the pipe 2. Standard accessories the standard accessories i...

Page 21

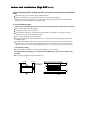

Edging (2) installation where the area with strong winds. Install the unit so that the air outlet section of the unit must not be faced toward wind direction. (1) open space requirement around the unit 2. Selection of the place of installation 1. Accessories "edging" for protection of electric wires...

Page 22

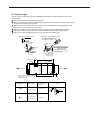

(1) outline piping 4. Refrigerant piping (2) piping size (3) limitations for one way piping length and vertical height difference. One way piping length: less than 15m (for 14,18 series), less than 30m (for 24,28 series), vertical height difference: less than 5m (for 14,18 series), less than 15m (fo...

Page 23

30ma 5. Electric wiring warning danger of bodily injury or death turn off electric power at circuit breaker or power source before making any electric connections. Ground connections must be completed before making line voltage connections. (1) selection of size of power supply and interconnecting w...

Page 24: 1. Accessories

Outdoor unit installation note : (1). Fix the parts with screws (2).Don't intake the strong wind directly to the outlet air-flow hole. 2. Selection of the place of installation (3).A one meter distance should be kept from the unit top 1. Accessories (4).Don't block the surroundings of the unit with ...

Page 25

One way piping length: less than 30m (for au242ahbea ). Vertical height difference: less than 20m (for au242ahbea ). (2) piping size au242ahbea install the removed flare nuts to the pipes to be connected, then flare the pipes. 90+0.5 pipe dia fastening torque liquid pipe 9.52mm gas pipe 15.88mm 42n....

Page 26

In the first to third test steps, if the pressure drops, check the leakage in each joint use sense of hearing, feeling and soap water, etc. Methods to find the leaking point. After confirming the leaking point, welding it again or tighten the nut tightly again. From pressurizing to 24 hours later, e...

Page 27

It shall use the vacuum p ump of (lower than -755mmhg)high vacuum degree and large air discharging (over 40l/min). The vacuumizing time depends on the length of the connecting pipe, generally is 1~2 hours. When vacuumizing, it shall be confirmed both gas and liquid side valves are closed. If after 2...

Page 28

Warning · the distributing shop, where you brought the air conditioner, or the specified shops shall do the installation work. If you do the installation work by yourself, the improper installation will cause water leakage, electric shock fire and other accidents. · the installation work shall be in...

Page 29

5. 3 special work and main points in installation warning · during installation, if refrigerant leakage occurs, take ventilation measurement immediately. · as soon as the leaked refrigerant gas meets fire, poisonous gas will generate. · after finishing installation, confirm the refrigerant gas dose ...

Page 30: 5 Installation Instructions

5 .1 installation tools 1. Cross screwdriver 2 .Metal saw 3 .60,70mm drill 4. Inner hexagon spanner, shifting spanner 5 .Spanner(14, 17, 19,24,27mm diameter) 6. Pipe cutter 7. Pipe expander 8. Knife 9 .Pliers 10. Leak detector or soap liquor 11. Measuring tape 12 .Scraper 13. Refrigeration oil 14 .V...

Page 31

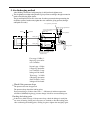

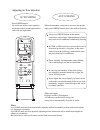

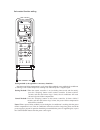

8 260 260 (2) ceiling height indoor unit can be installed on ceiling of 2.5-3m in height. (refer to foeld setting and installation manual of ornament panel.) (3) install suspending bolt. Check if the installation place is strong enough to hold weight. Take necessary measures in case it is not safe. ...

Page 32

50~100 roof anchor bolt long nut suspending bolt ceiling (2) cut an opening in ceiling for installation if necessary. (when ceiling already exists.) refer to paper pattern for dimension of ceiling hole. Connect all pipings (refrigerant, water drainage), wirings (inter unit cable) to indoor unit, bef...

Page 33

5.3.4 installation 4 5 7 (2) as for the dimensions of ceiling hole, see paper pattern. Ask your real estate dealer for details. Center of the hole is marked on the paper pattern. Center of the unit is marked on the card in the unit and on the paper pattern. Mount paper pattern onto unit using 3 scre...

Page 34

5.3.6 installation of drainage pipe 1-1.5m use the self-provided stiff pipe and clip with unit. Insert water pipe into water plug until it reaches the white tape. Tighten the clip until head of the screw is less than 4mm from hose. Wind the drain hose to the clip using seal pad 8 . Insulate drain ho...

Page 35

5.3.7 wiring terminal block clip a cover of control box 1 rubber tube a grounding lead cover of control box 2 terminal block connect with outdoor unit out in field wiring attach seal pad don't fail to seal it, or, water may come in. Rubber tube note: have it sealed, leaving no space. Seal pad (small...

Page 36

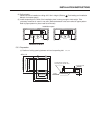

5 _ 8mm 3 2 2 1 4 holding ring piping hole position swing flap motor fig. 7 seal indoor unit ceiling material ornament panel (2) remove cover plate at corner tear off the adhesive tape, and slide it off. (refer to fig. 3) (1) (2) 2. Install ornament panel on indoor unit. As shown in fig . 7, match t...

Page 37

1 2 4. Installation of inlet grill and cover plate installation of inlet grill install in reversed order of “prepare ornament pandl”. Inlet grill can be adjusted into four directions by turning inlet grill. Inlet grill position can be adjusted as per customers request. (1) when installing inlet gril...

Page 38

Preparation before installing convertible type unit before installation of convertible type unit, please confirm which type will be selected: in the ceiling or on the floor. There is a dial switch k1 on the pcb, if you select d, that means the installation is in the ceiling. If you select l, that me...

Page 39

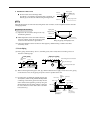

Installation procedure of convertible type unit caution! Installation procedure install the room air conditioning unit as follows: preparing indoor unit installation first remove the intake grill a. Floor mounting (ac36/42 only suitable for exposed ceiling mounting) 1. Drilling for piping the piping...

Page 40

68 16 21 28 381 232 26.5 26.5 2-r2.5 10 18 7.5 4-r5 68 16 21 28 381 232 26.5 26.5 2-r2.5 10 18 7.5 4-r5 wall 6mm 12.5mm fig. 11 fig. 12 fig. 13 spring washer special nut bracket caution hex bolt 8 to 13mm indoor unit fig. 14 fig. 16 remove the hole cover. Ok arrange the drain hose lower than this po...

Page 41: Wiring

Wiring caution (1) match the terminal block numbers and connection cable colours with those of the outdoor unit. Incorrect wiring may cause damage to the electrical parts. (2) connect the connection cables firmly to the terminal block. Incorrect installation may result in a fire. (3) always fasten t...

Page 42: Wiring

Wiring fig. 27 electrical component box fig. 28 base electrical component box cover caution be careful not to pinch the wiring between the electric component box and base. (1) ensure all wiring complies with current regulations. (2) it is recommended that a mcb of the correct rating is used to prote...

Page 43

Notice all wiring of this installation must comply with national, state and local regulations. These instructions do not cover all variations for every kind of installation circumstance. Should further information be desired or should particular problems occur, the matter should be referred to your ...

Page 44

(5) installation of indoor unit fix the indoor unit to the hanger bolts.If required, it is possible to suspend the unit to the beam, etc. Directly by use of the bolts without using the hanger bolts. When the dimensions of main unit and ceiling holes does not match, it can be adjusted with the slot h...

Page 45

Vp 30 secure the elevation as high as possible (approx. 100 mm) a downhill grade of 1/100 or more drain hose joint for vp 25 (local procurement) 600 (maxi m um local drain up dimension) right overhead 290~325mm attached drain hose clamp drain piping main unit drain situation can be checked with tran...

Page 46

Exhaust hole state seeing from top of unit side fresh air inlet rear fresh air inlet fig.1 fig.2 (7) installation work for air outlet ducts calculate the draft and external static pressure and select the length, shape and blowout. A blowout duct 2-spot, 3-spot and 4-spot with 200 type duct are the s...

Page 47

1. Before installation [before finishing installation, do not throw the attached parts installation needs] confirm the way to move the unit to the installation place. Before moving the unit to the installation place, do not remove their packages. When have to remove the package, use a soft material ...

Page 48

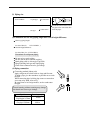

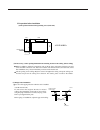

(1) the position relation among hoisting screw (unit: mm) (3) hanger bolts installation use care of the piping direction when the unit is installed. Hanging bolt m10 hole-in anchor hole-in plug insert concrete 370 250 910 603 628 590 down side up side (2) if necessary, cut the opening installation a...

Page 49

4. Installation of indoor unit fix the indoor unit to the hanger bolts. If required, it is possible to suspend the unit to the beam, etc. Directly by use of the bolts without using the hanger bolts. When the dimensions of main unit and ceiling holes does not match, it can be adjusted with the slot h...

Page 50

26 drainage test conduct a drainage test after completion of the electrical work. During the trial, make sure that drain flows properly through the piping and that no water leaks from connections. In case of a new building, conduct the test before it is furnished with the ceiling. Be sure to conduct...

Page 51

The calculation of duct resistance (the simple calculation is as follow table) straight part bend part air out part static pressure box air inlet grille (with air filter) calculate as per 1m length 1pa, 1pa/m each bend takes as a3~4m long straight duct calculate as 25pa calculate as 50pa/each calcul...

Page 52

8. The attentive matters in installation of air suction and discharging duct recommend to use anti-frost and sound-absorbing duct. (locally bought) the duct installation work should be finished before the fitment of ceiling. The duct must be heat insulated. The specific air-discharging outlet should...

Page 53

200 150 100 50 0 26 30 34 35 40 43 * * * * * * * * * * * * * * figure 1 figure 2 through the fan controller switch in the electric box, the air volume of this unit can be continuously adjusted. 10. The operation method of fan controller it is unnecessary to adjust air volume through the duct side wi...

Page 54

310 30 530 80 510 11. Refrigerant pipe [the air side pipe, liquid side pipe must be faithfully heat insulated, if no heat insulation, it may cause water leakage.] the outdoor unit has been charged with refrigerant. When connect the pipe to the unit or dismantling the pipe from the unit, please follo...

Page 55

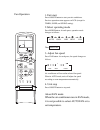

Drain hose swing fender refrigerant pipe cable line earthing line air filter outlet (located in the suction grill) in cooling operation,to discharge the water from inside the room. Discharge unit (built in) (located in the outlet) remote controller 6.Parts and functions 3 air inlet ab242acbea ab28na...

Page 56

Air outlet air inlet compressor (inside) fig.1 indoor unit 1 operating control panel (fig.2) 2 emergency switch 3 remote control signal receiver 4 power indicator lamp (red) 5 operation indicator lamp (green) 6 timer indicator lamp (yellow) 4 5 6 2 3 power oper timer emer fig.3 ac28nacbea parts and ...

Page 57

Remote controller functions 14.High/so button used to select high or soft operation. 21 22 31 29 32 fresh high/so timer set filter b a m d health reset lock sleep fan temp on off swing mode clock code light off a u t o 1 2 3 4 6 7 9 10 11 15 13 5 8 16 17 30 34 35 33 23 24 25 26 27 28 20 12 14 remote...

Page 58

Clock set displays when healthy run function is set. 22.Temperature display 34.Lock state display 33.Battery energy display notify the user when it is time to change the batteries. 24.High/so display 25.Signal sending display 26.Fresh air display 27.Electrical heating display 29.Health display 32.Sl...

Page 59

Fan operation 1.Unit start press on/off button to start your air conditioner. Previous operation status appears on lcd (except for timer, sleep, and swing setting). 2.Select operating mode press mode button. At each press, operation mode changes as follows: 3. Adjust fan speed press fan button. At e...

Page 60

Auto, cool , heat and dry operation 1. Unit start press on/off button,unit starts. Previous operation status appears on lcd (except for timer, sleep and swing setting) 3.Temperature setting then select auto run or select cool operation or select dry operation or select heat operation 2.Select operat...

Page 61

Press swing button. Up and down airflow varies upwards and downwards. Left and right airflow varies left and right sides. Always use swing button on the remote controller to adjust flaps. Adjusting them by hand may result in air conditioner's abnormally running. Displays on the lcd disappear. All in...

Page 62

Sleep function before going to bed you can press down the sleep button and the air conditioner will run so as to make you sleep more comfortably. Before using this function, the clock must be set. Use of sleep function after the unit's start, set running mode and then press sleep button once to make...

Page 63

Every time the button is pressed, time increases 10 minuts. If the button is kept pressed, time changes quickly. Timer on/off function set clock correctly before starting timer operation 1.Unit start after unit start, select your desired operation mode (operation mode will be displayed on lcd) 2.Tim...

Page 64

Timer on-off function set clock correctly before starting timer operation 1.Unit start after unit start, select your desired operation mode (operation mode will be displayed on lcd) 2.Timer mode selection press timer button on the remote controller to change timer mode. Every time the button is pres...

Page 65

After the air conditioner has operated for a certain period, dust has accumulated on the filter, and the filter up/down function can be used to clean it. 1.Whether unit starts or stops, continuously press filter button for 3 seconds, and enter the filter up/down waiting status (when unit stops, the ...

Page 66

Press the high/so button twice notice: when the air conditioner is operating in " high mode " , unevenness of room air temperature may occur due to the intensive operation in a short time. Anyway, operation in "high mode", does not last for more than 15 minutes, then regular operation is automatical...

Page 67

Press the high/so button twice notice: when the air conditioner is operating in " high mode " , unevenness of room air temperature may occur due to the intensive operation in a short time. Anyway, operation in "high mode", does not last for more than 15 minutes, then regular operation is automatical...

Page 68

Auto restart function setting setting method (to be applied for a necessary situation) : setting method: when the remote controller is on (excluding timer mode and fan mode), press the "sleeping" button on the remote controller 10 times within 5 seconds, and after the buzzer rings 4 times, the air c...

Page 69

C health set recovery check f cautions: on cooling only unit, heating mode is not available. Note: the above information is the explanation of the displayed information therefore varies with those displayed in actual operation. Clock used to adjust time. Timer used to set timer mode. Stands for time...

Page 70

Buttons function: mode:used for select indoor operation mode. Fan:used for select indoor air flow. Swing:used for setting indoor swing mode. Health:used for setting indoor health function. Temp + -:used for changing set temperature. Clock:used to adjust time. +、-:stands for time plus/minus, used to ...

Page 71

[fan] [high]:high fan speed [fan] [med]: medium fan speed [fan] [low]: low fan speed [fan] [fix]: fixed fan speed, it will display only when fixed fan speed is requested to main indoor unit. [central]: central control mode [operation] :running mode [stand by] : waiting mode [pre-heat] : pre-heating ...

Page 72

Auto operation, cooling, heating and dehumidification operation 1) start up operation: press the button of on/off, the system will start up, and will display [mode][auto];[fan][auto];[room temp.]+“24℃”;[clock]+”12:00”. 2) select mode: press the mode button, then you will see in the display section [...

Page 73

Timer on, press [timer]. [timer][on] will be constant on. Then [timer] [off] flashes, press the clock +/- button to adjust the time of timer off, press [set]. The time sequence of timer on and timer off will determine the mode is [timer] [on] →[off] or [timer] [off] → [on]. If you want the current t...

Page 74

Central control function when the central controller selects [central] mode, the buttons in the wired controller except for [check] will be invalid. Ventilation mode (only for the unit with fresh air function or heat recovery function) press [recovery] button, then the unit will switch over the vent...

Page 75

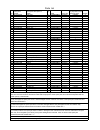

G preset ――― h outdoor total capacity actual value, decimal in check mode, press [check] to quit the check mode, and go into normal running mode. How to change the function switches? No. Type state of switch function description connected central controller j01 changeover of wired controller and cen...

Page 76

Controller, if the central controller is set to “central”, the buttons in the wired controller will be invalid, or the buttons will be valid. Failure code: for remote type, flash times failure code on wired controller for central control, failure code failure description reason remarks 10 08(08h) 21...

Page 77

2m continuously 13 13(0dh) 31d solenoid valve abnormal solenoid valve act incorrectly 3 times continuously ○ 14 76(4ch) 15d discharging temp. Sensor abnormal sensor broken down or short circuit for more than 2m continuously ○ 15 05(05h) 17d eeprom abnormal eeprom data missing run as the default valu...

Page 78

8 off on on on 9 on off off off 10 on off off on 11 on off on off 12 on off on on 13 on on off off 14 on on off on 15 on on on off 16 on on on on if you use central control type, sw1, sw2 will be used simultaneously. Wiring request in central control type: port a-b is connected with indoor port cn16...

Page 79

26 -------- on off on on off off on 27 -------- on off on on off on off 28 -------- on off on on off on on 29 -------- on off on on on off off 30 -------- on off on on on off on 31 -------- on off on on on on off 32 -------- on off on on on on on 33 -------- on on off off off off off 34 -------- on ...

Page 80

-------- on off off off on off off -------- on off off off on off on -------- on off off off on on off -------- on off off off on on on -------- on off off on off off off -------- on off off on off off on -------- on off off on off on off -------- on off off on off on on -------- on off off on on of...

Page 81

-------- on on off on on on on -------- on on on off off off off -------- on on on off off off on -------- on on on off off on off -------- on on on off off on on -------- on on on off on off off -------- on on on off on off on -------- on on on off on on off -------- on on on off on on on -------- ...

Page 82

Electrical functions of wired controller: 1.Function difference between master wired controller and slave one: contrastive items master wired controller slave wired controller function all of functions only with below functions: on/off, mode, fan speed, set temp., swing 2. Wiring connections of wire...

Page 83

B. One wired controller controls one indoor unit, and the indoor unit connects with the wired controller through 3 pieces of polar wire. C. Two wired controllers control one indoor unit. The wired controller connected with indoor unit is called master one, the other is called slave one. Master wired...

Page 84: Refrigerant Diagram

8 . Refrigerant diagram heating operation cooling operation air-liquid departor compressor 4-way vavle outdoor unit muffler one way vavle heat exchanger of indoor unit indoor unit -44-.

Page 85

9. Electrical control functions flow chart for operation 1) turn on/off unit on/off trouble mode determinati heating operation cooling operation fan motor turn off, electronic expansion valve close, louver motor turn off dehumidifying operation a power indicator turn off, operation indicator turn of...

Page 86

2) cooling operation electronic expansion valve: overheat control,swing flap: cooling standard position , fan motor: rated speed close open no no yes yes no yes electronic expansion valve: close, send turning off unit signal to outdoor unit according to the state of thermostat electronic expansion v...

Page 87

Note: ① when abnormal phenomenon occur, the indoor unit indicator will indicate abnormality according to the abnormal parts. ② when temperature of the evaporator inlet is lower than 0℃ and keeps for 5 minutes, unit will operate in anti-icing mode. 3)dehumidifying operation -47- swing no swing flap i...

Page 88

4) heating operation -48- or unit heating operation no swing flap in set fan speed position swing yes swing action on side: wind off, expansion valve steady off side: electronic expansion valve totally open yes defrosting no no rated according to temperature sensor to adjust state and valve open deg...

Page 89

10. Diagnostic information 10.1 failure code remote control type unit: failure description indoor running lamp flash times indoor ambient temp. Sensor failure 1 indoor coil temp.Sensor failure 2 outdoor ambient temp. Sensor failure or 4-way valve broken down in heating mode 3 outdoor coil temp. Sens...

Page 90

Failure code with wired controller yr-e12: for remote type, flash times failure code on wired controller for central control, failure code failure description reason 10 08 21 drainage system failure float switch broken down for more than 25m continuously 1 01 01 indoor ambient temp. Sensor failure s...

Page 91

10.2 trouble shooting - detailed for engineer malfunction flow chart: analyze and diagnose if the air-condition fails to cooling or heating function and other functions, please check the system as follows: 1.Cooling y change the designed temp. Replacing compressor superaddition condensate cl...

Page 92

2. Heating y change the designed temp. Replacing compressor superaddition condensate clear the filter enact fan speed of high or middle speed airiness circle improperly heat insulation of condensate pipeline between indoor unit and outdoor unit is normal n n compressor fault quantity of condensate c...

Page 93

3 malfunction and solution of wired controller 1) there is nothing on display of wire control organ, and the air-conditioner failure to operate if the diode on indoor unit is lumines if there ' s voltage on the primary side of tranaformer if the fuse of indoor unit pcb.Is normal if the primary side ...

Page 94

2) the wire control organ displays the alarm signal with “e0” “e0” means the floater switch of indoor unit is abnormal replacing the switch if the function of the floater is normal if the floater swith is orientated correctly the alarm signal of wire control organ is e0 begining amend the oritatio...

Page 95

4) the wire control organ displays the alarm signal with “e2” “e2” means indoor piping temperature sensor is abnormal the alarm signal of wire control organ is e2 replacing the sensor if the resistance of the sensor is right n y amend the position of sensor n begining if the position of pip...

Page 96: 11.

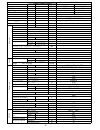

11. Electrical data 11 .1 wiring diagram 11 .1.1 outdoor unit 2. Dashed parts is optional for low ambient temp. Cooling,and there is no relay in only cooling type note: 1. Dashed parts is not available for only cooling type single phase outdoor wiring diagram 3. Dashed parts is optional for low ambi...

Page 97

11 .1.2 indoor unit note: 1. Dashed parts are not availble in convertible type 2. Dashes part is not avaliable below cooling capacity 42000btu type 3. Remote central controller is optional 4. P16 and p17 are used for room card function over 24000btu/h convertible type wiring diagram note: 1. Parts i...

Page 98

2. Dashed part is ont avaliable below cooling capacity 28000btu type over 24000btu/h mid esp duct type wiring diagram note: 1.Dashed parts are not available in duct type. 3.Remote central controller is optional. 4.P16 and p17 are used for room card function w y r.

Page 99

High esp duct type wiring diagram note: 1.Dashed parts are not available in duct type 2.Dashed part is fan speed controller kit. 3.Remote central controller is optional 4.P16 and p17 are used for room card function w y r.

Page 100: Cabinet Unit Wiring Diagram:

Cabinet unit wiring diagram: wiring diagram for 24000/42000btu/h cabinet unit terminal block to outdoor u n it y/g r b w y/g r b w t3.15a/250vac fuse trans. Piping temp controller cn3 cn12 cn11 cn8 door switch cn5 cn6 cn7 swing motor fan motor fan motor cap. Cn1 n s(n-w) cn9 room temp..

Page 101

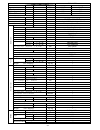

0010451167 pcb information – circuit diagram 1 2 3 4 5 6 7 8 10 11 12 13 14 15 16 9 ic1 2003 c32 104 1 p2-p6 187 e6 4.7uf in out w1 7812 rl1 jq1ap-1 rl3 jq1ap-a rl6 jq1ap-a rc3 0.033uf+120 n8 9013 7 6 5 1 2 3 4 8 ic5 24c01a xt1 8.00m 1 7 cn13 1 4 cn14 升降控制 1 2 cn16 1 2 3 4 5 6 7 8 10 11 12 13 14 15 ...

Page 102

0010451167 pcb information – characters on board(horizontal).

Page 103

0010451167 characters on board(vertical).

Page 104

Condition for the pcb data: 1.Working ambient temperature:-10℃~70℃, relative humidity:30%~95% 2.Preserved ambient temperature:-20℃~80℃,relative humidity:30%~95% 3.Power supply:220vac、50/60hz,voltage range:160v~250v 4.Precise of temperature control: ±1℃ 0010451167 pcb information – port and definitio...

Page 105

Lamp 0vdc,6. Signal output of power lamp 0vdc, 7. Signal output of water pump running lamp 0vdc) cn14——control external load, auto elevating function (1. Signal of door switch close, 2. Output of elevating direction control 0vdc, 3. Output of elevating power control 0vdc, 4. Power supply 12vdc) cn15...

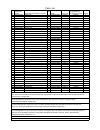

Page 106

0010451167 pcb information – function selection(on is 1, off is 0) the standard condition for pcb in factory sw1:4 bits are off sw2:4 bits are off sw3:4 bits are on sw4:2 bits are on sw5:4 bits are on sw1-sw2: used for indoor unit to set unit address from 1 to 16’ sw3-sw5: used for indoor unit to se...

Page 107

0010451167 pcb information- control type control type selection between remote and wired: select by dip switch j1, sw3-1(1 means remote control; 0means wired control). For remote control type, please use remote controller yr-h71, and a remote receiver is equipped with indoor unit. For wired control ...

Page 108

Units sets: 128×16 can be controller. Address setting of central controller can be met firstly, and then modulate the address setting of slave unit wired controlled. Led in indoor pcb: 1. Led1:is the state lamp for remote receiver as well as failure lamp. If indoor unit is normal, led1 is on, or if ...

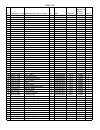

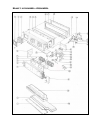

Page 109: Exploded Views & Part Lists

12 exploded views & part lists 12 .1 outdoor units-24\28.

Page 110

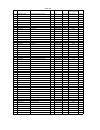

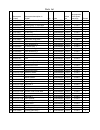

No. Spare parts number spare parts description in english qty . Model failure rate the proportion of the spare-part stock remark 1 001a0100122 front grille 1 au242ahbea 0.0000% 0.0000% x 2 001a1436160 handle 2 au242ahbea 0.0000% 0.0000% x 3 001a0100261 front panel 1 au242ahbea 0.0000% 0.0000% x 4 00...

Page 111

No. Spare parts number spare parts description in english qty . Model failure rate the proportion of the spare-part stock remark 1 001a0100122 front grille 1 au28nahbea 0.0000% 0.0000% x 2 001a1436160 handle 2 au28nahbea 0.0000% 0.0000% x 3 001a0100261 front panel 1 au28nahbea 0.0000% 0.0000% x 4 00...

Page 112

No. Spare parts number spare parts description in english qty . Model failure rate the proportion of the spare-part stock remark 1 001a0100122 front grille 1 au282ahbea 0.0000% 0.0000% x 2 001a1436160 handle 2 au282ahbea 0.0000% 0.0000% x 3 001a0100261 front panel 1 au282ahbea 0.0000% 0.0000% x 4 00...

Page 113

Model 2: ac242acbea.

Page 114

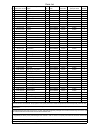

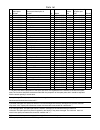

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 001a2400087 air filter 2 ac242acbea 0.00% 0.000% × 2 001a0100330 inlet grill assy 1 ac242acbea 0.00% 0.000% × 3 001a1301398 fixing plate 2 ac242acbea 0.00% 0.000% × 4 00...

Page 115

Model 2: ac28nacbea.

Page 116

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 001a1231278 inlet grill assy 2 ac28nacbea 0.00% 0.000% × 2 001a2400108 air filter 2 ac28nacbea 0.00% 0.000% × 3 001a1101174 front panel assy 1 ac28nacbea 0.00% 0.000% × 4...

Page 117

Model 3: ad242ambea ad28nambea.

Page 118

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 0010800086 guard plate 1 1 ad242ambea 0.000% 0.000% x 2 0010100228 guard plate 2 1 ad242ambea 0.000% 0.000% x 3 0010752516 evaporator assembly 1 ad242ambea 0.010% 0.012% ...

Page 119

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 0010800086 guard plate 1 1 ad28nambea 0.000% 0.000% x 2 0010100228 guard plate 2 1 ad28nambea 0.000% 0.000% x 3 0010752957 evaporator assembly 1 ad28nambea 0.010% 0.012%...

Page 120

Model 4: ad242ahbea and ad28nahbea are the same..

Page 121

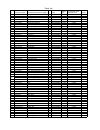

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 0010150130 connection frame of inlet air 1 ad242ahbea 0.00% 0.000% × 2 0010151123 hanging 4 ad242ahbea 0.00% 0.000% × 3 0010851049 boarding assy. Of liquid pipe 1 ad242a...

Page 122

Cassette type -ab242acbea ab28nacbea.

Page 123

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 001a0100708 bottom plate assy. 1 ab242acbea 0.00% 0.000% × 2 001a1301741 swing 4 ab242acbea 0.00% 0.000% × 3 001a1301743 motor holder 1 ab242acbea 0.00% 0.000% × 4 001a13...

Page 124

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare- part stock remark 1 001a0100708 bottom plate assy. 1 ab28nacbea 0.00% 0.000% × 2 001a1301741 swing 4 ab28nacbea 0.00% 0.000% × 3 001a1301743 motor holder 1 ab28nacbea 0.00% 0.000% × 4 001a1...

Page 126

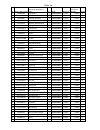

No. Spare parts number spare parts description in english qty. Model failure rate the proportion of the spare-part stock remark 1 001a1231233 inlet grill 1 ap242acbea 0.00% 0.000% × 2 001a1301502 inlet grill insert 2 ap242acbea 0.00% 0.000% × 3 001a1231234 front panel 1 ap242acbea 0.00% 0.000% × 4 0...

Page 127: 13.

13. Performance curves 1 cooling when air conditioner operate on cooling status, the indoor air humid ball and outdoor air dry ball which means humid degree of indoor and dry degree of outdoor unit make important mean on cooling capacity. 1) chart of humid ball of indoor unit air ℃ modify coefficien...

Page 128

2 heating when air conditioner operate on heating status,the outdoor air humid ball and indoor air dry ball which means humid degree of outdoor and dry degree of indoor unit also make important mean on heating capacity. 1)chart of humid ball of outdoor unit air ℃ modify coefficient 2)chart of dry ba...

Page 129

Model: ad28nambea performance curves cool capacity graph 0 2 4 6 8 10 12 -7 5 15 25 35 43 outdoor db( ) capacity(kw) 20 22 25 27 30 32 indoor db( ) eer graph 1 2 3 4 5 -7 5 15 25 35 43 outdoor db( ) eer 20 22 25 27 30 32 indoor db( ).

Page 130

Heat capacity graph 4 5 6 7 8 9 10 11 12 -7 -5 0 7 10 15 outdoor db( ) capacity(kw) 16 18 20 22 24 26 28 indoor db( ) cop graph 1 2 3 4 -7 -5 0 7 10 15 outdoor db( ) cop 16 18 20 22 24 26 28 ).

Page 131

Ac28nacbea performance curves cool capacity graph 0 2 4 6 8 10 12 -7 5 15 25 35 43 outdoor db( ) capacity(kw) 20 22 25 27 30 32 indoor db( ) eer graph 1 2 3 4 5 -7 5 15 25 35 43 outdoor db( ) eer 20 22 25 27 30 32 indoor db( ).

Page 132

Ab28nacbea eer graph performance curves 0 2 4 6 8 10 12 -5 5 15 25 35 43 outdoor db( ) capacity(kw) 20 22 25 27 30 32 indoor db( ) 1 2 3 4 5 - 5 5 15 25 35 43 outdoor db( ) eer 20 22 25 27 30 32 indoor db( ).

Page 133: Noise Level Charts

Noise level charts.

Page 134

Model: ac28nacbea air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 15.Air velocity distribution 0 2.4 5.5 25 0 2.4 22 27 5.5.

Page 135

Model: ab28nacbea air velocity distribution cooling blowy angle:40 temperature distribution cooling blowy angle:40 a. Cooling / air velocity distribution b. Cooling / temperature distribution 4 2 1 0 1 2 0 4 m/s m/s 2 4 2 1 27 25 22 27 1 0 2 25 22 0 4 2 air velocity distribution.

Page 136

Ad28nambea cooling cooling air discharge angle 5 air velocity distribution temperature distribution 0 1.8 2.4 0.5 5.5 air discharge angle 5 1.8 0 22 25 27 5.5 2.4 air velocity distribution.