- DL manuals

- Haier

- Air Conditioner

- AC142ACNAC

- Service Manual

Haier AC142ACNAC Service Manual

HCFU-14CL03/R1 (AC142ACNAC+AU142ABNAC)

HCFU-18CL03/R1 (AC182ACNAC+AU182ABNAC)

HCFU-24CL03/R1 (AC242ACNAC+AU242ABNAC)

HCFU-28CM03/R1 (AC28NACNAC+AU28NABNAC)

HCFU-36CM03/R1 (AC36NACNAC+AU36NABNAC)

HCFU-42CM03/R1 (AC42NACNAC+AU42NABNAC)

MANUAL CODE: SYJS-006 EDITION:2002.12.31.

Haier Group

Super low outdoor ambient cooling at -15

Auto-restart function

Group control(with a group controller)

Auto-changeover

Compact design of indoor unit

Weekly timing(with a weekly timer)

With new environment friendly refrigerant R407C

Features

Service Manual

Commercial Air Conditioning

Convertible Type Low Ambient Cooling Series

Summary of AC142ACNAC

Page 1

Hcfu-14cl03/r1 (ac142acnac+au142abnac) hcfu-18cl03/r1 (ac182acnac+au182abnac) hcfu-24cl03/r1 (ac242acnac+au242abnac) hcfu-28cm03/r1 (ac28nacnac+au28nabnac) hcfu-36cm03/r1 (ac36nacnac+au36nabnac) hcfu-42cm03/r1 (ac42nacnac+au42nabnac) manual code: syjs-006 edition:2002.12.31. Haier group super low ou...

Page 2: Contents

Contents 1. Description of products & features………………… ...…….1 2. Specifications…………………………. ……………… ...……3 3. Safety precaution…………………………..………………….9 4. Net dimensions of indoor and outdoor unit………………...11 5. Installation instructions ……………………. ………………..17 6. Parts and functions …………………………..…… ..……….28 ...

Page 3

1 description of products & features 1.1 products coding direction old code h cfu – 42 c m 03 / r1 refers to hfc refrigerant power: 03(230v/50hz).04(240v/50hz).12(115v/60hz).13(230v/60hz) low ambient cooling “h” refer to cooling and heating, ”c” refer to cooling only nominal cooling capacity (btu/h)...

Page 4

1.4 products characteristic (2).Hfc refrigerant technology to protect the environment, we have adopted the hfc refrigerant. The hfc r407c is of zero odp for the purpose of environmental protection. (3).Ceiling/console convertible,flexible installation,convenient maintenance,saving the users' expendi...

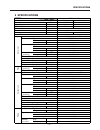

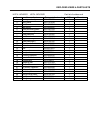

Page 5: 2 Specifications

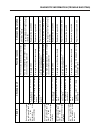

Function cooling heating capacity btu/h 14000 / w 2000 / eer or cop btu/w 7.00 / dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m...

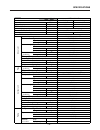

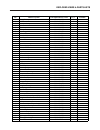

Page 6

Function cooling heating capacity btu/h 18000 / w 2000 / eer or cop btu/w 9.00 / dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m...

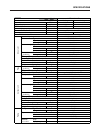

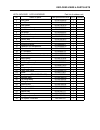

Page 7

Function cooling heating capacity btu/h 24000 / w 2800 / eer or cop btu/w 8.57 / dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m...

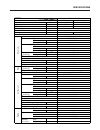

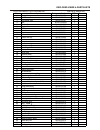

Page 8

Function cooling heating capacity btu/h 28000 / w 2800 / eer or cop btu/w 10.0 / dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m...

Page 9

Function cooling heating capacity btu/h 36000 / w 3600 / eer or cop btu/w 10.0 / dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m...

Page 10

Function cooling heating capacity btu/h 42000 / w 4600 / eer or cop btu/w 9.1 dehumidifying capacity 10‐³×m³/h power source ph-v-hz running current/starting current a power cable unit model (color) fan type × number speed r/min air-flow(h-m-l) m³/h heat exchanger type / diameter flow total area m² t...

Page 11: Warning

Warning caution warning caution this system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior environment such as engineering shop could cause equipment malfunction. Please entrust installation to either the company which sold you the equipment or to ...

Page 12: Warning

When setting up or moving the location of the air conditioner, do not mix air etc. Or anything other than the designated refrigerant (please see nameplate) within the refrigeration cycle. Rupture and injury caused by abnormal high pressure can result from such mixing. Always use accessory parts and ...

Page 13

Model: hcfu-14cl03/r1 hcfu-18cl03/r1 indoor unit model: hcfu-14cl03/r1 hcfu-18cl03/r1 outdoor unit 6 5 5 24 0 2 0 0 9 480 30 265 220 200 580 288 810 680 75 65 150 100 100 110 190 170 400 4 net dimensions of indoor and outdoor unit net dimensions of indoor and outdoor unit.

Page 14

Model: hcfu-24cl03/r1 hcfu-28cm03/r1 indoor unit 110 180 60 85 100 30 555 630 690 105 195 300 600 600 310 .63 85 25 300 10 10 545 590 85 150 60 12 0 0 150 235 13 2 0 40 195 100 85 45 65 r15 drainage pipe net dimensions of indoor and outdoor unit.

Page 15

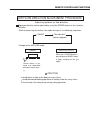

Note (1) fix the parts with screws (2)don't intake the strong wind directly to the outlet air-flow hole. (3)a one meter distance should be kept from the unit top (4)don't block the surroudings of the unit with sundries. Installation servicing space(at least) unit:mm installation i 300 100 0 0 150 0 ...

Page 16

Model: hcfu-36cm03/r1 hcfu-42cm03/r1 indoor unit r15 85 100 19 5 1920 1800 600 690 630 100 85 310 590 545 40 235 150 180 85 150 60 195 600 105 600 300 300 555 30 110 60 85 300 10 10 25 65 45 drainage pipe net dimensions of indoor and outdoor unit.

Page 17

185 185 30 52 88 screw hole (m10) 580 950 power wiring terminal 70 18 18 340 380 1250 25 note : (1). Fix the parts with screws (2).Don't intake the strong wind directly to the outlet air-flow hole. (3).A one meter distance should be kept from the unit top (4).Don't block the surroundings of the unit...

Page 18: Installation Instructions

(1) if possible, do not install the unit where it will be exposed to direct sunlight.(if necessary, install a blind that does not interfere with the air flow.) (2) install the outdoor unit in a place where it will be free from being dirty or getting wet by rain as much as possible. (3) install the u...

Page 19

Floor console fig. 1 15.88mm dia. 2 cm or more ceiling indoor unit 30 cm or more 30 cm or more left right 30 cm or more 30 cm or more 1.5m 1.5m 1.5m left right may be different for series24, 28 for series 36,42 note: for series 36, 42 no floor console type, the function below about floor console is ...

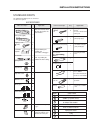

Page 20

Mark parts name adhesive tape saddle (l.S) with screws connecting electric cable for indoor and outdoor drain hose heat insulation material piping hole cover putty plastic clamp optional parts a b c d e f g h standard parts the following installation parts are furnished. Use them as required. Access...

Page 21

Installation procedure preparing indoor unit installation 1. Remove the intake grill install the room air conditioner as follows: open the intake grill and remove the three or four or six screws. (fig. 3) when the directions are selected, drill a 7 cm dia. Hole on the wall so that the hole is tilted...

Page 22

Installation template wall ceilling drilling position for piping drilling position for anchor bolt 200mm 900mm select piping and drain directions. For series 24,28,36,42 only rear side(fig.13) b. Under ceiling type using the installation template, drill holes for piping and anchor bolts(for holes).(...

Page 23

1. Flare processing (1) cut the connection pipe with pipe cutters so that the pipe is not deformed. (2) holding the pipe downward so that cuttings cannot enter the pipe, remove the burrs. (3) remove the flare nut from the indoor unit pipe and outdoor unit and assemble as shown in(table1) and insert ...

Page 24

Note (1)place the concrete foundation deep enough. Connecting method apply refrigerant oil at half union as large and flare nut. To bend a pipe, give the roundness as possible not to crush the pipe. When connecting pipe, hold the pipe centre to centre then screw nut on by hand, refer to fig. Be care...

Page 25

Detach the charge hose from the service port, open 2-way valve and 3-way. Turn the valve rod anticlockwise until hitting lightly. 6 if it does not stop gas leakage, discharge whole refrigerants from the serice port. After flaring work again and vacuumize, fill up prescribed refrigerant from the gas ...

Page 26

Gas leakage inspection after connecting the piping, check the joints for gas leakage with gas leakage detector. Caution how to connect wiring to the terminals a. For solid core wiring (or f-cable)(fig.28a) (1) cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about...

Page 27

1. Indoor unit side (1) remove the electric component box. Indoor unit side (2) pull out the electric component box. Fig. 32 (3) remove the electric component box cover. Fig. 33 (1) remove the cord clamp. (2) process the end of the connection cords to the dimensions shown in fig.34. (3) connect the ...

Page 28

Test running customer guidance explain the following to the customer in accordance with the operating manual: (1) starting and stopping method, operation switching, temperature adjustment, timer, air flow switching, and other remote control unit operations. (2) air filter removal and cleaning, and h...

Page 29: Parts and Functions

6 .1 drawings fig.1 indoor unit 1 operating control panel (fig.2) 2 emergency switch 3 remote control signal receiver 4 power indicator lamp (red) 5 operation indicator lamp (green) 6 timer indicator lamp (yellow) 7 compressor run lamp (green) 8 intake grill (fig.3) 9 air filter 10 up/down air direc...

Page 30: Remote Controller Functions

Introduction to spare parts buttons and display of the remote controller. Clock mode swing power on/off temp fan sleep set hour reset lock timer used for unit start and stop. Used to set auto fan direction. Used to select auto run, cool,dry,heat and fan operation. Used to set correct time. Used to s...

Page 31

Introduction to spare parts hints lo mid hi auto auto buttons and display of the remote controller. Dry cool auto swing fan speed sleep clock set timer on timer off lock clock temp. Signal sending fan operation heat when unit is started for the first time and after replacing batteries in remote cont...

Page 32

Remote controller operation remote controller's operation when in use, put the signal transmission head directly to the receiver hole on the indoor unit. The distance between the signal transmission head and the receiver hole should be within 7m without any obstacle as well. Don't throw the controll...

Page 33

Guide to operation fan operation remote controller can memorize settings in each operation mode. To run it next time just select the operation mode and it will start with the previous setting. No reselecting is needed.(timer on/off needs reselecting) hints (1) unit start (2) select operation mode (3...

Page 34

Guide to operation auto run, cool,heat and dry operation use cool in summer. Use heat in winter. Use dry in spring,autumn and in damp climate. (1) unit start (2) select operation mode (3) select temp.Setting press on/off button, unit starts. Previous operation status appears on display.(not timer se...

Page 35

Guide to operation press fan button. For each press, fan speed changes as follows: (4) fan speed selection unit runs at the speed displayed on lcd. In heat mode, warm air will blow out after a short period of time due to cold-draft prevention function. In dry mode, when room temp. Becomes 2 c higher...

Page 36

Guide to operation timer operation hints set clock correctly before starting timer operation(refer to page 6) you can let unit start or stop automatically at following times: before you wake up in the morning, or get back from outside or after you fall asleep at night. Timer on/off (1)after unit sta...

Page 37

Guide to operation temp swing fan on off mode sleep set clock timer lock reset on am 2 1 6 3 5 off pm 4 every time the button is pressed, time increases 10min. If button is kept depressed, time will change quickly. Every time the button is pressed, time decreases 10min. If button is kept depressed, ...

Page 38

Air flow direction adjustment procedure caution adjusting up/down air flow direction up/down direction can be adjusted by using the swing button on the remote c ontroller. Each time pressing this button, the mode changes in the following sequence. Swing no indication (louver stopped) change to the a...

Page 39

At night, before going to bed you can press down the sleep button on the controller and the air-conditioner will run by the comfortable sleeping mode to make you sleep more comfortable. One hour after sleeping operation start, the temp. Is 1 c higher than the setting one. After another hour the temp...

Page 40

15 power failure resume (to be applied for a necessary situation): setting method: when the remote controller is on (excluding timer mode and fan mode), press the "sleeping" button on the remote controller 10 times within 5 seconds, and after the buzzer rings 4 times, the air conditioner will enter ...

Page 41: Refrigerant Diagram

Swing on off temp fan 18 0 58 22 after six minutes disorder and reload new's when the remote controller 3.Please remove the batteries batteries in the polarity of different types together 2.Insert correctly 2 two r-03 ries and do not use batteries 1.Do not mix old with new batte remote control uint ...

Page 42: Electrical Control Functions

9.1 control features the brief introduction includes those for each item of various types of air conditioners and their electric control functions. The brief introduction includes those for each item of various types of air conditioners and their electric control functions. 7.1 brief introduction of...

Page 43

(2) auto selection of wind speed in the following, tr means room temperature while ts means setting temperature. A. During cooling program conversion of wind speed from the low to high won’t work until the present speed has continued for 3 minutes while conversion from the high to low needs no time ...

Page 44

Blowing fan runs at setting wind speed. This working area is defined as area a. (2) ts tr ts + 2 , the compressor and outdoor blowing fan run for 10 minutes then pause for 6 minutes, while indoor blowing fan runs at low wind speed. This working area is defined as area b. (3) tr fan runs at low wind ...

Page 45

Setting wind speed. (6) afterheat blowing during heating program during heating program, the compressor will stop running (except overheat protection or frost removal) while the indoor blowing fan will firstly run for 50 seconds at low speed then stop. (7) frost removal control (applicable for cooli...

Page 46

Restarted until 3 minutes later after it is reenergized. 10 power breakdown memory if the machine suddenly loses power while running, or stops for maintenance or trouble shooting, it will restart running as the status when it stops after the power is restored. Note: 1. Function setting: continuously...

Page 47

9.2 introduction to the fan speed controller 210v 60v 27 35 39 42 the low ambient temperature cooling system realizes starting normally at the temperature -15 by the method of: the sensor collects the coil temperature to change the voltage of the outdoor fan motor, thus to change the fan speed. As a...

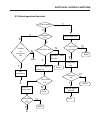

Page 48

Return return 9.3 defrost operation flow chart return condition for compress or off off compressor open outdoor fun compressor off or 55s? 4-way value on compressor on ? Clear the sign of defrosts return operation indoor fun motor return come to defrost compressor on e-heat off for 30s? Turn off com...

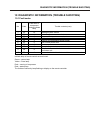

Page 49

No. Code flash time of compressor running indicate lamp trouble contents (new) 1 e0 10 drainage system trouble 2 e1 1 indoor temperature sensor broken 3 e2 2 indoor coil temperature sensor broken 4 e3 3 outdoor temperature sensor broken 5 e4 4 outdoor coil temperature sensor broken 6 e5 5 over curre...

Page 50

10.2 trouble shooting - detailed for engineer tr ouble checkup result possible reasons corresponding solution unavailable voltage at input part o f circuit board the powe r supply coil isn’t plugged well plug the supply coil properly damaged wave filtering component return to the controller manufact...

Page 51

Tr ouble checkup result possible reasons corresponding solution no output at 15 pin of 2803 damaged 2803 replace with a good 2803 no voltage a t com of relay jk3 on oor board ind damaged relay jk3 replace with a good jk3e indoor bl owi ng fan cannot generat e medium wind no output at relay jk2 on in...

Page 52

Tr ouble checkup result possible reasons corresponding solution three minutes’ protection for compressor the compressor will wo rk normal after three minutes too low temperature o f indoor coil pipe causes overcoo ling protection it will restor e automatically when the temperature of indoo r coil pi...

Page 53

Tr ouble checkup result possible reasons corresponding solution during h eating progr a m , the compressor work while outdoor blo w ing fan do es not too high te mperature of indoor coil pipe causes overheat protection it will automatically resto re whe n the temperature of indoor coil pipe falls to...

Page 54: Electrical Data

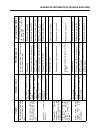

11 .1 wiring diagram hcfu-14cl03/r1 hcfu-18cl03/r1 11 electrical data electrical data.

Page 55

Hcfu-24cl03/r1 3.15a/250v transformer indoor wiring diagram the part in the dashed frame is optional element louver motor fan motor y/g: yellow/green capacitor w: white b: black r: red note: remote control to outdoor unit fuse signal receiver indoor pcb board detector piping temp. Sensor ambient sen...

Page 56

Hcfu-28cm03/r1 3.15a/250v transformer indoor wiring diagram the part in the dashed frame is optional element louver motor fan motor y/g: yellow/green capacitor w: white b: black r: red note: remote control to outdoor unit fuse signal receiver indoor pcb board detector piping temp. Sensor ambient sen...

Page 57

3.15a/250v indoor pcb indoor wiring diagram louver motor fan motor capacitor capacitor fan motor transformer fuse to outdoor unit signal receiver piping temp. Sensor sensor temp. Ambient board remote control detector note: the part in the dashed frame is optional element w: white b: black r: red y/g...

Page 58

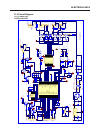

Hcfu-14cl03/r1 +5 c12 4.7uf/50v l1 101k l 3 331k r15 20k-1% r13 10k +12 +12 ic7 lm358 c20 104 c21 104 r33 10k r32 10k r31 10k i8 1 i7 2 i6 3 i5 4 i4 5 i3 6 i2 7 i1 8 gnd 9 vcc 10 q1 11 q2 12 q3 13 q4 14 q6 15 q5 16 q8 18 q7 17 ic3 2803 osc c23 104 jk5 c6 104 c5 100uf/16v c3 2200uf/35v c4 104 t1 +5 v...

Page 59: Ic1

1 2 3 4 5 6 7 8 a b c d 8 7 6 5 4 3 2 1 d c b a +5 r32 10k +5 +5 c8 4.7uf/50v c9 102 l1 101k l2 331k r13 20k r14 10k +5 c7 104 +5 +12 +12 +12 +12 ic5 lm358 q4 9014 q3 9014 c20 104 c21 104 r28 10k r22 10k r29 10k r27 10k r30 1k r31 5.6k +12 c22 0.01uf/275 r23 47 i8 1 i7 2 i6 3 i5 4 i4 5 i3 6 i2 7 i1 ...

Page 60

1 +5 +5 +5 +5 +5 +12 +12 +12 +12 +5 +5 +5 +5 +5 +5 +5 +5 +5 +12 1 2 3 4 5 6 7 8 a b c d 8 7 6 5 4 3 2 d c b a b c23 104 lx c2 0.1uf/275v r27 5.6k q2 9014 r28 330 ic4 tlp371 r24 33k c11 103 led d5 4007 ic5 tlp521 r22 1k r21 5.6k c19 103 c10 103 r23 2.2k fuse 3.15a/250v c1 0.1uf/275v vin 1 gn d 2 vout...

Page 61

11 .2.2 outdoor unit 1 2 3 4 5 6 7 8 a b c d 8 7 6 5 4 3 2 1 d c b a c19 103 c9 104 c5 100uf/16v jk4 jk2 jk3 rw 101 db1 r7 560 c13 470uf/16v 1 2 cn4 4pin 1 2 cn1 4pin c2 0.1uf/275v c8 10uf/16v r5 1k r6 1k r3 5.1k r4 5.1k r18 2.2k c4 104 c3 2200uf/35v vin 1 gnd 2 vout 3 2 voltreg fus2 c6 104 a1 1 a2 ...

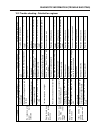

Page 62

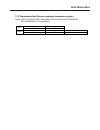

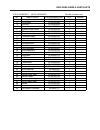

Model: h cfu-14cl03/r1 hcfu-18cl03/r1 hcfu-24cl03/r1 hcfu-28cm03/r1 ambient temperature sensor coil temperature sensor 23k 10k ambient temperature sensor coil temperature sensor fan speed controller sensor 5k 5k 5k indoor outdoor h cfu-36cm03/r1 hcfu-42cm03/r1 electrical data 11 .3 thermostat chart ...

Page 63

R/t chart of sensor r 25 = 23k 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 -20 -18 -16 -14 -12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 resistance k electrical data.

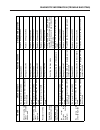

Page 64

R/t chart of sensor r25 =5k 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 -20 -19 -18 -17 -16 -15 -14 -13 -12 -11 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22...

Page 65

R/t chart of sensor r 25 = 10k 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 76 78 80 82 84 86 88 90 92 94 96 -20 -18 -16 -14 -12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 ...

Page 66

12 exploded views & part lists 12.1 model hcfu-14cl03/r1 hcfu-18cl03/r1 indoor unit exploded views & parts lists.

Page 67

Hcfu-14cl03/r1 hcfu-18cl03/r1 part list of indoor unit no. Name of part specialized number qty. Remark 1 air filter 001a2400087 2 2 inlet grill assy 001a0100330 1 3 fixing plate 001a1301398 2 4 strengthen tendon 001a1301395 1 5 pinch plate 001a1301399 2 6 wiring assembly 001a4400509 1 7 fan motor ca...

Page 68

Model hcfu-14cl03/r1 hcfu-18cl03/r1 outdoor unit exploded views & parts lists.

Page 69

Hcfu-14cl03/r1 hcfu-18cl03/r1 part list of outdoor unit no. Name of parts part specialized code qty. Remark 1 front guard assy. 001a0100122 1 2 front panel 001a1101038 1 3 axial fan 001a2331024 1 4 fan mortor 001a3000026 1 5 motor mounting plate 001a1301133 1 6 condenser assy. 001a0400130 1 7 slide ...

Page 70

12.2 model hcfu-24cl03/r1 hcfu-28cm03/r1 indoor unit exploded views & parts lists.

Page 71

Exploded views & parts lists no. Name of parts part specialized code qty. Remark 1 inlet grill assy 001a1231278 2 2 air filter 001a2400108 2 3 front panel assy 001a1101174 1 4 pad 001a17341062 1 5 pipe temperature sensor 001a3900006 1 6 drain pan assy 001a1200185 1 7 mounting plate 001a1101179 1 8 l...

Page 72

Model hcfu-24cl03/r1 hcfu-28cm03/r1 outdoor unit exploded views & parts lists.

Page 73

H cfu-24cl03/r1 hcfu-28cm03/r1 part list of outdoor unit no name of parts part specialized code qty. Remark 1 front grille 001a1236028 1 2 handle 001a1436160 2 3 front panel 001a1101078 1 4 service panel assy 001a0100524 1 5 axial fan 001a5402022 1 6 fan motor 001a3000082 1 7 bracket for fan motor 0...

Page 74

12.3 model hcfu-36cm03/r1 hcfu-42cm03/r1 indoor unit exploded views & parts lists.

Page 75

H cfu-36cm03/r1 hcfu-42cm03/r1 part list of indoor unit no. Name of parts part specialized code qty. Remark 1 inlet grill assy 001a1231278 3 2 air filter 001a2400108 3 3 front panel assy 001a1101167 1 4 pad 001a17341009 1 5 eletrical box 001a13011280 1 6 eletrical box cover 001a1301379 1 7 pcb 00104...

Page 76

Hbu-36cm03/r1 hbu-42cm03/r1 outdoor units exploded views & parts lists.

Page 77

Hcfu-36cm03/r1 hcfu-42cm03/r1 part list of indoor unit no. Name of parts part specialized code qty. Remark 1 front grille 001a1236028 2 2 front panel 001a0100492 1 3 axial fan 001a5402022 2 4 fan motor 001a3000244 2 5 bracket for fan motor 001a0100740 1 6 ac contactor 001a3900161 1 7 capacitor for f...

Page 78: Performance Curves

13 performance curves hcfu-14cl03/r1 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 -15 -10 -5 5 15 25 35 43 outdoor temperatur( ) cooling c apacity(kw) 20 22 25 27 30 32 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) eer 20 22 25 ...

Page 79

Hcfu-18cl03/r1 cool ing capacity graph eer graph a b 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) cooling c apacity(kw) 20 22 25 27 30 32 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) eer 20...

Page 80

Hcfu-24cl03/r1 cool ing capacity graph eer graph a b 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) cooling capacity(kw) 20 22 25 27 30 32 outdoor temperature( ) 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 -15 -10 -5 5 15 25 35 43 eer 20...

Page 81

Hcfu-28cm03/r1 cool ing capacity graph eer graph a b 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) cooling capacity(kw) 20 22 25 27 30 32 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 -15 -10 -5 5 15 25 35 43 outdoor temp...

Page 82

Hcfu-36cm03/r1 cool ing capacity graph eer graph a b 0.00 1.50 3.00 4.50 6.00 7.50 9.00 10.50 12.00 13.50 15.00 16.50 18.00 -15 -10 -5 5 15 25 35 43 outdoor temperature( ) cooling capacity(kw) 20 22 25 27 30 32 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 -15 -10 -5 5 15 25 35 43 outdoor temper...

Page 83

Cool ing capacity graph eer graph a b 0.0 2.5 5.0 7.5 10.0 12.5 15.0 17.5 20.0 -15 -10 -5 5 15 25 35 43 20 22 25 27 30 32 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 -15 -10 -5 5 15 25 35 43 eer 20 22 25 27 30 32 indoor db( ) indoor db( ) outdoor db( ) outdoor db( ) cooling capacity(kw) hcfu-42cm03/r1 perfo...

Page 84: Noise Level Test Chart

14 noise level test chart noise level test chart.

Page 85

Model: hcfu-14cl03/r1 hcfu-18cl03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 2.4 5.5 0 15.1 floor type / s 1.0 / s 0.5 / s 0 2.4 22 25 27 5.5 1.0m/s 1.5m/s 0.5m/s 1...

Page 86

Model: hcfu-24cl03/r1 hcfu-28cm03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 0 2.4 5.5 1.0m/s 1.5m/s 0.5m/s 25 0 2.4 22 27 5.5 air velocity distribution.

Page 87

Model: hcfu-36cm03/r1 hcfu-42cm03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 0 2.4 5.5 27 0 2.4 22 25 5.5 1.0m/s 1.5m/s 0.5m/s air velocity distribution.

Page 88

15.2 ceiling type model: hcfu-14cl03/r1 hcfu-18cl03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 5.5 0 2.4 m/s 1.0m/s 0.5m/s 0 2.4 22 25 27 5.5 air velocity distribut...

Page 89

0 m/s 0.5m/s 1.0m/s 5.5 2.4 model: hcfu-24cl03/r1 hcfu-28cm03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 0 2.4 22 27 25 5.5 air velocity distribution.

Page 90

Model: hcfu-36cm03/r1 hcfu-42cm03/r1 air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 0.5m/s m/s 0 1.0m/s 2.4 5.5 27 5.5 0 2.4 22 25 air velocity distribution.

Page 91

Sincere forever tel: 86-532-8938356 web site: http: //www.Haier.Com.