- DL manuals

- Haier

- Air Conditioner

- AP242ACAAA

- Technical Manual

Haier AP242ACAAA Technical Manual

HAIER

Machine Model No.:

1. Product coding explanation and product series brief instruction

2. Product technical parameter

3. Product specification

4. Name, dimension and function of primary component and accessory

5. Explosion illustration and structure details

6. Usage and setting of remote controller

7. Electric control instruction

8. Diagram circuit

9. Fault diagnosis

10. System flowchart

11. Mounting and maintenance

Contents

Cabinet air conditioner

Technical manual

AP242ACAAA/AU242AHAAA (HPU-24H03)

AP42NACAAA/AU42NAIAAA (HPU-42H03)

AP44NACAAA/AU44NAIAAA (HPU-44H03)

AP42NACABA/AU42NAIABA (HPU-42HB03)

Summary of AP242ACAAA

Page 1

Haier machine model no.: 1. Product coding explanation and product series brief instruction 2. Product technical parameter 3. Product specification 4. Name, dimension and function of primary component and accessory 5. Explosion illustration and structure details 6. Usage and setting of remote contro...

Page 2

1. Product coding explanation and product series instruction a. Model coding rule explanation h a a a a a c p n 42 p 4 2 h 0 3 u power type: triphase functional code: heating and cooling dual-purpose machine nominal cooling output (btu/h) the first two numbers based on thousand unit structured code ...

Page 3

2 model: outline dimension of indoor unit packing dimension of indoor unit: noise of indoor unit (cooling): noise of indoor unit (heating): net/gross weight of indoor unit: working voltage range working temperature range temperature regulating difference: maximum mounting drop height: maximum length...

Page 4

3 model: outline dimension of indoor unit: packing dimension of indoor unit: noise of indoor unit (cooling): noise of indoor unit (heating): net/gross weight of indoor unit: working voltage range working temperature range temperature regulating difference: maximum mounting drop height: maximum lengt...

Page 5

4 model: outline dimension of indoor unit: packing dimension of indoor unit: noise of indoor unit (cooling): noise of indoor unit (heating): net/gross weight of indoor unit: working voltage range working temperature range temperature regulating difference: maximum mounting drop height: maximum lengt...

Page 6

5 model: outline dimension of indoor unit: packing dimension of indoor unit: noise of indoor unit (cooling): noise of indoor unit (heating): net/gross weight of indoor unit: working voltage range working temperature range temperature regulating difference: maximum mounting drop height: maximum lengt...

Page 7

50000 100000 (zr3k4-pfj-552) (crnq-0500-tfd) 40000 80000 30000 60000 20000 40000 (btu) (btu) 0 0 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 60.0 60.0 48.9 48.9 37.9 37.9 14 14 ( ) ( ) 6.

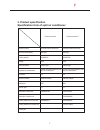

Page 8: 3. Product Specification

Model of product structural characteristic cooling capacity voltage series of product appearance characteristics certificate remote controller refrigerant climatic type dimension of indoor unit dimension of outdoor unit packing dimension of indoor unit packing dimension of outdoor unit packing list ...

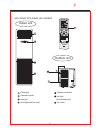

Page 9: Parts

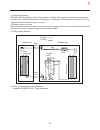

Parts indoor unit outdoor unit outlet grill operation panel inlet grill air filter remote-controller air inlet [ at side and rear] compressor [inside the unit ] air outlet piping and electric wire drain pipe c am temp swing mode clock timer sleep set reset lock fan on off 5 8.

Page 10

Am timer time temp temp time clock set sleep swing fan speed mode on off 1 2 3 outlet grill operation panel inlet grill air filter[inside the unit] remote-controller air inlet [at side and rear] air outlet indoor unit hpu-42h03 hpu-44h03 hpu-42hb03 outdoor unit c on off am pm am pm am pm auto temp s...

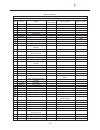

Page 12

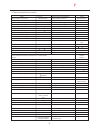

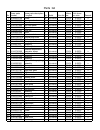

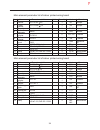

No. Spare parts number spare parts description in english qty. Model price list failure rate the proportion of the spare- part stock remark 1 001a1236028 front grille 1 hpu-24h03 0.00% 0.000% × 2 001a1436160 handle 2 hpu-24h03 0.00% 0.000% × 3 001a0100261 front panel 1 hpu-24h03 0.00% 0.000% × 4 001...

Page 13

41 001a4400511 wire assy. 1 hpu-24h03 0.00% 0.000% × 4,not need provided :the spare-part which is seldom damaged or the maintenance man could not maitmains.The spare parts may be air freighted by the factory if they were damaged.The customer nees not stock in the spare-part warehouse,should be marke...

Page 14

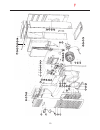

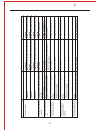

9 41 42 43 1 2 3 4 5 6 7 8 9 10 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 11 12.

Page 15

10 bristol compressor detailed statement of explosion figure model no. Ap42nacaaa/au42naiaaa outdo r unit o no. Specific number name single consumption type of material weight of material 580 6040 1245 2550 255 1810 2330 3740 1610 6 19 7.5 250 400 1920 19 4 2 5 1 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 6 1 2 ...

Page 16

No. Spare parts number spare parts description in english qty. Model price list failure rate the proportion of the spare- part stock remark 1 001a5002108 screw 4 hpu-42hb03 0.00% 0.000% × 2 001a1236028 front guard web 2 hpu-42hb03 0.00% 0.000% × 3 001a5002005 screw 1 hpu-42hb03 0.00% 0.000% × 4 001a...

Page 17

43 001a1436160 handle 1 hpu-42hb03 0.00% 0.000% × 5,above should be improved accord with the reply of the market half a year per time. 6.The spare parts price on net is fob qingdao term. 1,the failer rate and the proportion of the spare-part stock are regarded as the reference of the stock for spare...

Page 18

No. Spare parts number spare parts description in english qty. Model price list failure rate the proportion of the spare- part stock remark 1 001a5002108 screw 4 hpu-44h03 0.00% 0.000% × 2 001a1236028 front guard web 2 hpu-44h03 0.00% 0.000% × 3 001a5002005 screw 1 hpu-44h03 0.00% 0.000% × 4 001a130...

Page 19

43 001a1436160 handle 1 hpu-44h03 0.00% 0.000% × 5,above should be improved accord with the reply of the market half a year per time. 6.The spare parts price on net is fob qingdao term. 1,the failer rate and the proportion of the spare-part stock are regarded as the reference of the stock for spare-...

Page 20

10 26 34 35 36 37 38 40 39 41 42 43 44 45 46 47 48 49 50 51 52 10 9 8 7 6 5 4 3 2 1 11 12 13 14 15 16 25 24 23 53 54 55 56 57 58 59 30 29 28 27 21 17 18 19 20 22 33 32 31.

Page 21

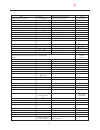

No. Spare parts number spare parts description in english qty. Model price list failure rate the proportion of the spare- part stock remark 1 001a1231233 inlet grill 1 hpu-24h03 0.00% 0.000% × 2 001a1301502 inlet grill insert 2 hpu-24h03 0.00% 0.000% × 3 001a0100384 front panel 1 hpu-24h03 0.00% 0.0...

Page 22

38 0010200026 air ring 1 hpu-24h03 0.00% 0.000% × 39 001a0100385 down shell 1 hpu-24h03 0.00% 0.000% × 40 001a2400102 filter 1 hpu-24h03 0.00% 0.000% × 41 001a0100075 door lock 1 hpu-24h03 0.00% 0.000% × 42 001a1734967 sealing plate 1 hpu-24h03 0.00% 0.000% × 43 001a17621241 sealing plate 1 hpu-24h0...

Page 23

No. Spare parts number spare parts description in english qty. Model price list failure rate proportion of the spare- part stock remark 1 001a1231233 inlet grill 1 hpu-42hb03 0.00% 0.000% × 2 001a1301502 inlet grill insert 2 hpu-42hb03 0.00% 0.000% × 3 001a0100384 front panel 1 hpu-42hb03 0.00% 0.00...

Page 24

40 001a2400102 filter 1 hpu-42hb03 0.00% 0.000% × 41 001a0100075 door lock 1 hpu-42hb03 0.00% 0.000% × 42 001a1734967 sealing plate 1 hpu-42hb03 0.00% 0.000% × 43 001a17621241 sealing plate 1 hpu-42hb03 0.00% 0.000% × 44 001a1757833 cushion rubber 1 hpu-42hb03 0.00% 0.000% × 45 001a3000016a synchro-...

Page 25

No. Spare parts number spare parts description in english qty . Model price list failure rate proportion of the spare- part stock remark 1 001a1231233 inlet grill 1 hpu-44h03 0.00% 0.000% × 2 001a1301502 inlet grill insert 2 hpu-44h03 0.00% 0.000% × 3 001a0100384 front panel 1 hpu-44h03 0.00% 0.000%...

Page 26

38 0010200026 air ring 1 hpu-44h03 0.00% 0.000% × 39 001a0100385 down shell 1 hpu-44h03 0.00% 0.000% × 40 001a2400102 filter 1 hpu-44h03 0.00% 0.000% × 41 001a0100075 door lock 1 hpu-44h03 0.00% 0.000% × 42 001a1734967 sealing plate 1 hpu-44h03 0.00% 0.000% × 43 001a17621241 sealing plate 1 hpu-44h0...

Page 27

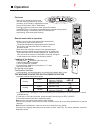

Remote controlled operation power on/off temp dry cool auto sleep swing fan speed low mid high auto heat fan operation signal sending temp clock timer off timer on fan sleep set hour reset used for unit start and stop. Used to select your desired temp. Used to select fan speed: low,mid, high,auto. U...

Page 28: Operation

Clock set remote contronller's operation loading of the battery the machine is adaptive in following situation when unit is started for the first time and after replacing batteries in remote controller, clock should be adjusted as follows: press clock button,"am"or "pm"flashes. Press or to set corre...

Page 29: Operation

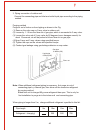

Remote-controlled operation press on/off button unit starts running. The previous status appears on the display (except. Timer, sleep and swing mode) press mode button. For each press, operation mode changes as follows: note: during auto run operation, temp. Setting will not be shown in lcd display,...

Page 30: Operation

Manual operation remote-controlled operation press on/off button unit starts running. The previous status appears on the display (except. Timer, sleep and swing mode) press mode button. For each press, operation mode changes as follows: press fan button. For each press, fan speed changes as follows:...

Page 31: Operation

Manual operation dry remote-controlled operation am timer time temp temp time clock set sleep swing fan speed mode on off low set temp c 2 3 1 5 4 press on/off button unit starts running. The previous status appears on the display (except. Timer, sleep and swing mode) press mode button. For each pre...

Page 32: Operation

Heating manual operation note:for cooling only type, this function is invalid. Remote-controlled operation press on/off button unit starts running. The previous status appears on the display (except. Timer, sleep and swing mode) press mode button. For each press, operation mode changes as follows: s...

Page 33: Operation

Fan manual operation remote-controlled operation press on/off button unit starts running. The previous status appears on the display (except. Timer, sleep and swing mode) press mode button. For each press, operation mode changes as follows: press fan button. For each press, fan speed changes as foll...

Page 34: Operation

Remote-controlled operation before sleeping you can press the sleep button. The conditioner will run under comfort sleep mode, and give you a comfort sleep. Usage of the sleep function after starting, set the run mode and press the sleep button. Run mode 1.In cooling and dry after starting of the sl...

Page 35: Operation

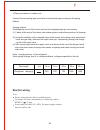

Timer on/off operation manual operation remote controlled operation timer operation timer on/off set clock correctly before starting timer operation(refer to page 3) you can let unit start or stop automatically at following times: before you wake up in the morning, or get back from outside or after ...

Page 36: Operation

Manual operation remote controlled operation timer on-off (1) after unit start,select your desired operation mode. Operation mode will be displayed on lcd. (2)timer mode selection press timer button to change timer mode. Every time the button is pressed, display changes as follows: (3) timer setting...

Page 37: Operation

Swing louvers (vertical louvers) horizontal louvers (adjust by hand) up and down adjust the louvers by hand to proper position. Side from side swing press the swing again to fix the vertical louvers at your desired position. Press swing " " or " " appears on the display, the vertical louvers move fr...

Page 38

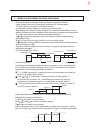

7. Electric controllable function instruction 7.1 brief instruction of electric controllable function (1) automatic running (applies to cooling and heating model) after starting the machine, system changes over automatic mode. Before running , system will determine firstly operation mode according t...

Page 39

(4) warm start (avoid of cool air at the beginning of heating , applies to cooling and heating model ) at the just beginning of heating, indoor fan motor will delivery air as follows: if indoor coiled temperature 28 ,start low fan speed; if indoor coiled temperature 38 or operation of compressor 4 m...

Page 40

45 53 45 56 53 59 70 63 2min -2 7 7 1 -1 (7) auxiliary electric heater control auxiliary electric heater starts work on condition that the following conditions are met simultaneously (tr is room temperature, st is setting temperature in the following selectable conditions): note: after starting elec...

Page 41

30 (11) power failure compensating function in the case that power failure, down maintenance or troubleshooting occurs during operating of machine, if only the current is remade, machine will restart on the original condition. Note: 1. Function setting: push 10 times sleeping button with remote cont...

Page 42

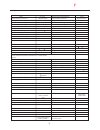

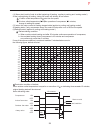

32 7.2 element layout and main element parameter list of printed-wiring board element layout of indoor printed-wiring board d 1 7 d 1 8 d 1 9 d 2 0 c 1 2 c 1 8 0 x t 1 c 3 0 r 1 4 r 1 1 r 3 5 r 4 1 r 1 3 r 1 2 r 1 2 c 3 2 c 2 7 c 2 6 x t 2 c 3 1 2 5 3 0 2 0 1 5 o s c r 3 0 c14 c19 c 1 3 1 0 c 2 5 5 ...

Page 43

L n s c 2 2 r 2 7 r 3 0 ic 2 c 2 0 d 8 t 3 d9 cn10 cn8 cn9 cn6 c t 1 j k 1 j k 2 j k 3 j k 4 j k 5 c 1 7 l x c 1 8 d 6 r 2 6 c 1 9 ic 4 t 2 t 1 c 2 5 c 3 c 2 1 r 2 9 r 3 1 r 2 1 r 2 0 r 2 2 r 1 8 t 7 t 9 t 1 0 r 2 8 c n 3 l 2 c 1 4 r 8 ic 5 c 8 d 5 c 9 c 1 3 r 1 3 d 1 9 d 1 8 c 6 r 1 c x 1 c 5 c 4 c...

Page 44

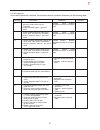

34 main element parameter list of indoor printed-wiring board main element parameter list of indoor printed-wiring board no. No. Name name element model no. Element model no. Unit unit quantity quantity label label remarks remarks philipe philipe mulata toshiba toshiba american st northland machushi...

Page 45

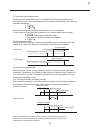

35 + 5 r t 2 (p )r t (s ) r 2 8 c 3 2 0 k r 2 5 r 2 6 2 0 k r 2 7 c 1 3 1 0 4 d 1 6 d 1 4 d 1 3 + 5 d 1 1 c 2 8 c 2 5 c t 2 d 2 1 r 2 c n 6 0 .1 4 1 4 8 d 2 4 d 2 3 d 2 2 r 6 2 2 0 v c n 5 c n 3 2 2 0 v c n 4 l n c 8 c 9 5 + 5 c 1 2 c 1 8 l x 1 0 2 z r 1 1 7 8 0 5 d 1 9 d 1 8 c3 3 c1 7 c2 7 c3 1 c 5...

Page 46

36 r 1 0 4 7 0 l d 1 1 2 + 5 1 2 c 2 3 1 0 3 r 2 1 0 0 k 1 0 0 k r 3 l 1 2 2 0 u h 5 4 3 r 1 0 d 5 2 8 1 i c 3 u l n 2 0 0 3 in 1 in 2 in 3 in 4 in 5 in 6 in 3 g n d o u t 1 o u t 2 o u t 3 o u t 4 o u t 5 o u t 6 o u t 7 v c c 1 6 1 2 3 cn 10 l x r v 5 6 0 1 jk 4 jk 5 2 2 1 fu se cn 9 cn 6 c 17 10 ...

Page 47

37 fault coding fault cause resolution remarks 1. Indoor ambient temperature sensor get out of order, short circuit or shutdown 2. Indoor computer plate l1 get out of order replace indoor ambient temperature sensor of computer plate replace indoor coiled temperature sensor of computer plate replace ...

Page 48

38 (1) usage of refrigerant take fleon r22 as refrigerant, factory filling quantity is 3520g. If the length of connecting line is less than or equal to 5m, additional refrigerant is unnecessary. If the length of connecting line is more than 5m, 50g refrigerant shall be added for every 1 m more. (2) ...

Page 49

(1) usage of refrigerant take fleon r22 as refrigerant, factory filling quantity is 2380g. If the length of connecting line is less than or equal to 5m, additional refrigerant is unnecessary. If the length of connecting line is more than 5m, 50g refrigerant shall be added for every 1 m more. (2) sys...

Page 50

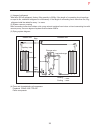

40 over 10c m over 10c m o v e r 1 0 c m ove r 1 00 cm ove r 10c m ove r 15c m ove r 1 0c m ove r 6 0c m left power cable length pipe direction rear approx 2m approx 1.5m right bottom indoor & outdoor unit connection.

Page 51: Tools Necessary

41 tools necessary 1. Screw driver 2. Hacksaw 3. 70mm dia. Hole core drill 4. Spanner (dia.17,27mm) 5. Spanner (14,17,27mm) 6. Pipe cutter 7. Flaring tool 8. Knife 9. Nipper 10. Gas leakage detector or soap water 11. Measuring tape 12. Reamer 13. Refrigerant oil parts in the following list are acces...

Page 52: Installation Procedures

42 try to bring the packed unit to the installation place. When it is inevitable to unpack the unit, be careful not to damage the unit. Wrap it with nylon etc. After unpacking, be sure to put it with the front side of the unit facing up. Note: when delivering, don't hold plastic parts like inlet and...

Page 53: Installation Procedures

43 selection of installation place place where it is easy to route drainage pipe and outdoor piping. Place away from heat source and with less direct sunlight. Place where cool and warm air could be delivered evenly to every corner of the room. Place near power supply socket.Leave enough space aroun...

Page 54

44 fix the fitting metal to the wall by screws so that there is no clearance between them. With the unit set up vertically, fix the fitting metal to the unit with screws while making an adjustment at the long portion of the hole so that there is no clearance between the upper surface and the fitting...

Page 55

45 2. Piping connection of indoor unit arrangement of piping and drainage pipe after opening inlet grill, you will see a control box as shown in the fig. Remove the cover before working. Connecting electric cable for indoor and outdoor unit drain hose copper tube insulation material cut away, with a...

Page 56

46 3. Piping connection of outdoor unit. Connect the connecting pipe and inlet and outlet liquid pipe according to the piping method. Purging method purge air out of indoor unit and piping as shown in the fig. (1) remove the valve cap on 2-way valve in outdoor unit. (2) loosen by 1-1.5 turn the flar...

Page 57

47 note: electric wiring must be done by qualified person. Use copper wire only, the parameter of connecting cable is 2 h07rn-f4 0.75mm . Ok no terminal block table clanip wiring of indoor unit insert the cable from outside the wall hole where piping already exist. Pull it out from front. Loosen ter...

Page 58

48 1. Power supply air conditioner must use an exclusive line (over 30a) when installation air conditioner in a wet place, try to use a circuit breaker against current leakage. For installation in other places, use circuit breaker as far as possible. 2. Pipe cutting and flaring be sure to carry out ...

Page 59: Electric Wiring

49 3.Piping connection of outdoor unit. Connect the connecting pipe and inlet and outlet liquid pipe according to the piping method. Purging method discharge the air out of the indoor unit and the refrigerant pipe by vacuumizing. (1) fasten all the nuts of the indoor and outdoor pipes to make these ...

Page 60

50 wiring of indoor unit insert the cable from outside the wall hole where piping already exist. Pull it out from front. Loosen terminal screws and insert cable end fully into terminal block, then tighten it. Pull the cable gently to make sure it is tight. Replace cover after wiring. Wiring of outdo...

Page 61

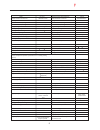

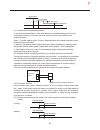

51 in d o o r a m b ie n t te m p e ra tu re s e n s o r s h o rt o u t o r s h u td o w n in d o o r c o ile d t e m p e ra tu re s e n s o r s h o rt o u t o r s h u td o w n o u td o o r a m b ie n t te m p e ra tu re s e n s o r s h o rt o u t o r s h u td o w n o u td o o r c o ile d t e m p e ...

Page 62

52 p o w e r c ir c u it i s n 't w e ll in s e rt e d f ilt e r c ir c u it d e v ic e i s b ro k e n f u s e i s b ro k e n t ra n s fo rm e r is n 't w e ll in s e rt e d o r b ro k e p o w e r d e v ic e o n i n d o o r p la te i s b ro k e n c o n n e c ti n g p ie c e b e tw e e n p a n e l a ...

Page 63

53 in d o o r a n d o u td o o r c o n n e c to r is n 't p ro p e rl y i n s e rt e d p o w e r c o rd i s n 't p ro p e rl y i n s e rt e d f u s e o n o u td o o r p la te b ro k e t ra n s fo rm e r is n 't p ro p e rl y i n s e rt e d p o w e r c ir c u it o n o u td o o r p la te i s a t fa u ...

Page 64

54 3 m in u te s p ro te c ti o n f o r c o m p re s s o r in d o o r c o ile d t e m p e ra tu re i s t o o h ig h ,o v e rh e a ti n g p ro te c ti o n 2 0 0 3 i s b ro k e n r e la y j k 5 i s b ro k e n c o n n e c ti n g l in e i s n 't w e ll in s e rt e d i n s o c k e t c n 6 o n o u td o o ...