- DL manuals

- Haier

- Dishwasher

- HDW101 Series

- Service Manual

Haier HDW101 Series Service Manual - 2.Features

- 4 -

Features / Specifications

2.Features

2.1 This product is provided with economic washing mode that users can select

optionally.

2.2 This product can contain 12 sets of eating utensils, applicable to big family.

2.3 Knife and fork can be separated by net and cleaned more easily

2.4 Detergent and rinse aid automatic dispenser is provided and can add them properly

that ensured the brightness and cleanness of eating utensils.

2.5 Water overflow protection is provided

.

Summary of HDW101 Series

Page 1

Hdw101** dishwasher service manual models: hdw101wh hdw101ss l features l two stars for energy consumption of autralian/new zealand standard l economic washing l overflow protection function l net for separating forks or knives l super-capacity for 12 settings haier group manual code:0120502831/0120...

Page 2: Contents

- 2 - contents 1. Product code illumination and series introduction …………..………….………...3 2. Features………………………………………………… ……………………………….4 3. Specifications…………………………………………… ……………………..….…….5 4. Safety precaution………………………………………… …………………….….…...8 5. Warning and cautions………………………………… ……………………...……….10 6. Net...

Page 3

- 3 - product code illumination and series introduction 1.Product code illurmination and series introduction model identification hdw 101 □□ a b c a: abbreviation of haier dishwasher b: series of factory design c: colour of dishwasher’s appearance wh: white ss: stainless steel bk: black example: hdw...

Page 4: 2.Features

- 4 - features / specifications 2.Features 2.1 this product is provided with economic washing mode that users can select optionally. 2.2 this product can contain 12 sets of eating utensils, applicable to big family. 2.3 knife and fork can be separated by net and cleaned more easily 2.4 detergent and...

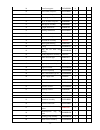

Page 5: 3.Specifications

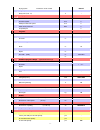

- 5 - 3.Specifications dish washer free last update 2003-10-30 2003-10-30 revision 00.01 00.01 supplier type n°. Hdw101wh/hdw101ss suppliers bar code n°. Ean sales brand / model gxch sales bar code n°. Ean 1. Key-features energy efficiency class ★★ washing efficiency class - drying efficiency class ...

Page 6

- 6 - drying system condenser / turbo vented natural height adjustable feet n°. / max. Mm 4/20 delay timer (from - to) h - 3. Safety systems child resistant door lock cdl - anti flood system afs l waterproof anti leak system als l water return protection wrp l acqua stop kit l 4. Programs normal c° ...

Page 7

- 7 - max. Failure rate (12 months after sales to end customer) pc/% - 11. Packing materials / recycling symbols rs rezy carton (weight) g 4,600 polistyren(weight) g 1,518 polyetylenefoil (weight) g 65 other packing materials (weight) g 55 wood (weight) kg 0.15 12 delivery time of first batch 10. 20...

Page 8: 4. Safety Precaution

- 8 - safety precaution / warning and cautions 4. Safety precaution.

Page 9

- 9 - safety precuation.

Page 10: 5.Warning and Cautions

- 10 - 5.Warning and cautions 1.Shelf(the container which dishes are put in is called shelf) 2.Put the shelf into the washing box 3.Put in detergent 4.End of cycle.

Page 11

- 11 - warning and cautions 5.Weekly maintenance -.

Page 12: Net Dimension

- 12 - net dimension / installations and accessory parts 6 . Net dimension 7. Installations and accessory parts 7.1 positioning the appliance position the appliance in the desired location. The back should rest against the wall behind it, and the sides, along the adjacent cabinets or wall. The dishw...

Page 13

- 13 - installation and accessory parts 7.3 cold water connection connect the cold water supply hose to a threaded 3/4(gas) connector, inserting the small filter supplied with the dishwasher and making sure that it is fastened tightly in place (see fig.1) if the water pipes are new or have not been ...

Page 14

- 14 - parts and functions 8. Parts and functions.

Page 15

- 15 - parts and functions detergent detergent specifically intended for use with dishwashers must be used.The dispenser must be refilled before the start of each wash cycle following the instructions provided in the "wash cycle table." the detergent dispenser is located on the inside panel the door...

Page 16

- 16 - parts and functions.

Page 17

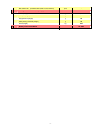

- 17 - function schedule 9. Function schedule 1、 intensive wash 2、 normal wash 3、 rinse wash 4、 glasses wash 5、 pre-wash(soak) 6、 intensive wash and economic button 7、 normal wash and economic button 8、 rinse wash and economic button 9、 glasses wash and economic button 10、 glasses wash and rapid but...

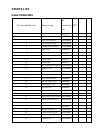

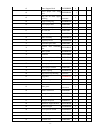

Page 18: 10. Program Diagram

- 18 - program diagram 10. Program diagram.

Page 19

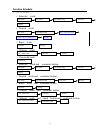

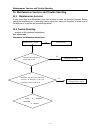

- 19 - cable or program controller is broken dismantle the door case and using avometer to measure if the two terminals of door switch is on. Open the door and check if door flap is ok maintenances services and trouble shooting 11. Maintenances services and trouble shooting 11.1 maintenances service...

Page 20

- 20 - whether water level switch is ok check whether the water intake veloscity is too slow whether solenoid valve is working cable or the program controller is broken maintenances services and trouble shooting analysis of the common breakdowns water supply trouble phenomenon: water level cannot re...

Page 21

- 21 - maintenances services and trouble shooting analysis of the common breakdowns drain pump trouble phenomenon: water cannot be drained n n whether drain pump is working whether drain pump is electrifyed circuit is damaged y y drain pump is broken drain hose is too high y whether pipeline is ok i...

Page 22

- 22 - connect it well replace the heater replace the temperature limiting device whether socket connector is connected well the cable or the controller board is suspected damaged check whether the circuit between the two teminals is open check the resistence between the heater resistor maintenances...

Page 23

- 23 - maintenances services and trouble shooting analysis of the common breakdowns water overflow trouble phenomenon: drain pump keep on working y n y n n n y y n y maintenances services and trouble shooting whether the water overflow swich is ok whether water is deposited is the bottom case whethe...

Page 24

- 24 - power supply indicator or circuit is broken measure whether power supply switch is ok analysis of the common breakdowns power supply trouble phenomenon: water cannot be heated check: check whether the power connector n is in position y n y connect it properly check whether the power connector...

Page 25

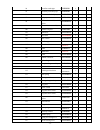

- 25 - circuit diagram 12. Circuit diagram c l 1 e.

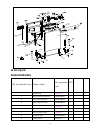

Page 26: 13.Exploded View

- 26 - list of parts 13.Exploded view model:hdw101ss 1 exploded view.

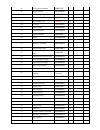

Page 27: 14 List of Parts

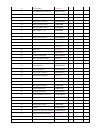

- 27 - 14 list of parts model:hdw101ss no. In exploded view name of part part specialized code qty . . . 1 complete top 0120803797 1 2 shelf fastening small block 012g2150035 3 3 upper front crosspiece 012g1310022 1 4 right upright assembly 012g9350003 1 5 painted right side pannel 0120104772 1 6 up...

Page 28

- 28 - 10 lower basket 0120801993 1 11 rear intermediate crosspiece 012g1310023 1 12 drain hose stop 012g2160204 1 13 lower rear crosspiece 012g1310028 1 14 terminal box assembly 012g2150046 1 15 wheel for lower basket 0120200964 8 16 wheel for upper basket 0120200963 8 17 wheel support pin 01202009...

Page 29

- 29 - 45 upper sprayer assembly 0120801726 1 46 support for float 012g2160206 1 47 float for acquastop 012g2110049 1 48 micro switch elbi type s3 012g6050040 1 49 power supply cable 0120400028 1 50 air outlet 012g2160197 3 51 thermo limiter 012g6010009 1 52 induction contact 012g1450902 1 53 elasti...

Page 30

- 30 - 79 rubber coupling 012g4050152 2 80 ring nut for cup fastening 0120201292 1 81 cup gasket 012g4050151 1 82 overflow ring 0120300283 1 83 water gutter 012g2160191 1 84 handle small block 0120200640 1 85 door gasket 012g4050243 1 86 electric wave filter 0120400001 1 87 inlay stainless steel pie...

Page 31

138 suction condenser group 0120201282 1 139 condenser support 0120201283 1 140 o-ring gasket for condenser 0120300464 1 -31-.

Page 32

- 32 -.

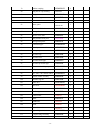

Page 33: 2 Parts List

- 33 - 2 parts list model:hdw101wh no. In exploded view name of part part specialized code qty. . . . . 1 complete top 0120803796 1 2 shelf fastening small block 012g2150035 3 3 upper front crosspiece 012g1310022 1 4 right upright assembly 012g9350003 1 5 painted right side pannel 012g1020068 1 6 up...

Page 34

- 34 - 28 front foot support 012g1451091 2 29 lower front crosspiece 012g1310027 1 30 painted left side pannel 012g1020066 1 31 left upright assembly 012g9350002 1 32 cover for front crosspiece 0120200065 2 33 rail support assembly 0120200966 4 34 upright small block 0120200124 2 35 hooking small bl...

Page 35

- 35 - 61 heater support block 012g1020032 1 62 lower sprayer base fixing piece 012g2160193 1 63 ring nut for lower spayer fastening 0120201006 1 64 o-type sealing ring 012g4050153 1 65 lower sprayer base 0120201004 1 66 breather assembly 012g2160196 1 67 air outlet nut 0120201008 1 68 duct coupling...

Page 36

- 36 - 94 overflow outlet pipe 0120300281 1 95 overflow protection pipe 0120300282 1 96 connection for 3rd sprayer 012g2160200 1 97 3rd sprayer 0120201003 1 98 pvc tube + 40% nitrilic rubber 012g4050253 1 99 thermo limiter assembly 0120800830 1 100 breather ring nut 0120201008 2 101 outer duct 012g2...

Page 37

128 closing lever 012g2150050 1 138 suction condenser group 0120201282 1 139 condenser support 0120201283 1 140 o-ring gasket for condenser 0120300464 1 -37-.

Page 38

- 38 -.