- DL manuals

- Haier

- Air Conditioner

- HR18D2VAE

- Service Manual

Haier HR18D2VAE Service Manual

SERVICE MANUAL

●

Features

Models

Central Air Conditioning

Haier Hi-Efficiency aluminium fin and copper tube design

Benchmark hermetic compressor design

Powder coated full metal jacket

Efficient performance and economical operation

Durable construction

Quick, easy installation and service

HR18D2VAR

HR30D2VAR

HR36D2VAR

HR24D2VAR

Compact design

Manual code: SYJS-014-

07REV.0

Edition: 200

7-04-02

Heat pump, Value Series HR13-D2

Summary of HR18D2VAE

Page 1

Service manual ● features models central air conditioning haier hi-efficiency aluminium fin and copper tube design benchmark hermetic compressor design powder coated full metal jacket efficient performance and economical operation durable construction quick, easy installation and service hr18d2var h...

Page 2: Contents

2 contents 2. Physical and electrical specifications……………….. ...5 1. Description of products & features……………………...3 ! Warning ! The equipment detailed in this manual should be installed and serviced only by qualified technicians who are familiar with the safety procedures required for this work and ...

Page 3

3 1.2 nomenclature for model number model number explanation---indoor unit table 1-1 model number explanation---outdoor unit table 1-2 1.3 engineering features: haier system type nominal capacity in (1000) btuh seer designation design series electric designation body style h r 24 d v a r brand symbo...

Page 4

4 fig.1-1 fig.1-2 safe access to measure u nit nit pressures . Fig.1-3 valve in the cooling mode. Fig.1-4 accessories: cabinets: constructed of powder painted galvanized steel to provide a durable finish and protection for the outdoor coil. Fan guard and motor bracket: base pan: this deep-drawn base...

Page 5

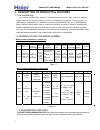

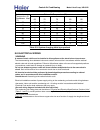

5 2. Physical and electrical specifications specifications subject to change without prior notice central air conditioning model: heat pump, hr13-d2 hr18d2var hr24d2var hr30d2var hr36d2var 1.5-ton outdoor hp 2-ton outdoor hp 2.5-ton outdoor hp 3-ton outdoor hp new model new model new model new model...

Page 6

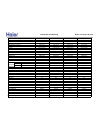

6 central air conditioning model: heat pump, hr13-d2 hr18d2var hr24d2var hr30d2var hr36d2var 1.5-ton outdoor hp 2-ton outdoor hp 2.5-ton outdoor hp 3-ton outdoor hp new model new model new model new model model number comments model status 1 1 2 2 0.87 x 0.75 0.87 x 0.75 0.87 x 0.75 0.87 x 0.75 21 2...

Page 7

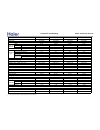

7 notes: 1- 120-second fan delay for air handler 2- r-22 charge for the outdoor unit with matching indoor unit and 25' line set. Central air conditioning model: heat pump, hr13-d2 hr18d2var hr24d2var hr30d2var hr36d2var 1.5-ton outdoor hp 2-ton outdoor hp 2.5-ton outdoor hp 3-ton outdoor hp new mode...

Page 8: Safety Precautions

3. Safety precautions 4. System components and functions this section describes the various air conditioning components, their purpose and operation. This section is only a guide and does not consider all components that could be found on an air conditioner in the field. Fig.4-1 generally, liquid re...

Page 9

Fan fig.4-2 fan and motor assembly fig4-3 flow-check pistons refrigerant metering device controlling refrigerant flow into the evaporator. Second, it acts as an open check valve when refrigerant flows in the opposite direction. Proper match of unit and piston sizes combinations for indoor and outdoo...

Page 10

Fig.4-5 service valves the stem or core is removable with a flexible seal at its base held closed with a spring. Schrader valves allow a technician to connect gages to the system with a minimum loss of charge. Use a cap with an 5.Electrical control devices protection devices protection for the unit ...

Page 11: 6. Application

Relays compreessor contactor contacts ,while others use 2-pole or 3-pole contacts. Compressor and outdoor fan. Optional delays and kits before re-starting the compressor. Defrost pcb start kits(optional) this special relay uses the emf generated by the compressor start windings to take a start capac...

Page 12

. After the proper equipment combination has been selected, satisfying both sensible and latent ● outdoor unit location ● proper equipment evacuation ● outdoor unit refrigerant charge ● indoor unit air flow ● indoor unit blower speed ● supply and return air duct design and sizing ● system air balanc...

Page 13: 8. Installation Instructions

Table 6-2 piston size and humidity control depend on the correct balance between indoor load and outdoor unit capacity. High air conditioning requires a specified air flow. Each ton of air conditioning requires 400 cubic feet of air per minute (400cfm/ton). Of 3°in the return duct and 4°in the suppl...

Page 14

Figure 7 heat pump refrigerant circuit 14 central air conditioning model: heat pump, hr13-d2.

Page 15

. This product is designed and manufactured to permit installation in accordance with national codes. It is prevailing local codes and regulations. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations. The united states environmental protection ...

Page 16

Power supply and wiring. Provide gutters or other shielding at roof level. Locate unit on a level concrete slab or prefabricate pad. To prevent transmission of noise or vibration, slab should not be connected to building structure. Some sort of sound-absorbing material such as rubber and cork pad sh...

Page 17

8.5 refrigerant piping 1. Figure a figure b figure c fig. 8-2 only refrigeration-grade copper piping (dehydrated and sealed) should be used. Take extreme care to refrigerant piping should be as short as possible, with a minimum of elbows or bends, to avoid capacity allow the strapping to directly co...

Page 18

. Refrigerant line sizing check the following table (table 8-1) for correct suction and liquid line sizes for any combination of the unit size and the maximum refrigerant line length . Refrigerant line sizing refrigerant line length (ft) 0 – 24 25 – 49 50 – 74 line outside diameter (in) unit size (t...

Page 19

1.Tubing should be cut square. Make sure it is round and free of burrs at the connecting ends. Clean the tubing to prevent contamination from entering the system. 2.Make sure that both refrigerant shutoff valves at the outdoor unit are closed. 3.Push the tubing into the fitting until it stops. This ...

Page 20

System superheat return air temperature ( ) ℉ ambient temperature at condenser inlet ( ) ℉ 65 70 75 80 85 60 17 25 30 33 37 65 13 19 26 32 35 70 5 14 20 28 32 75 5 10 17 25 29 80 5 12 21 26 85 5 10 17 20 90 7 12 18 95 5 5 5 100 5 5 ! Warning a means of strain relief must be installed to this applian...

Page 21

100 ampacity. Copper wire size - awg (1% voltage drop) supply wire length - ft supply circuit ampacity 50 100 150 200 15 14 10 8 6 20 12 8 6 4 25 10 8 6 4 30 10 6 4 4 35 8 6 4 3 40 8 6 4 2 45 6 4 3 2 50 6 4 3 1 table8-3: minimum wire size based on n.E.C. For 60 c type copper conductors below the ins...

Page 22

8.10.System startup 1.Turn thermostat to "off", turn on power supply at disconnect switch. 3.Turn fan switch to "on". Indoor blower should run. Be sure it is running in the right direction. 4.Turn fan switch to "auto". Turn system switch to "cool" and turn temperature setting below room temperature....

Page 23: 9.Maintenance Instructions

9.Maintenance instructions filters warning: disconnect main electrical power to the unit before attempting any 1. Attention until dust and fibers from the construction is removed. 2. Replace glass fiber filters when dirty. 3. Clean semi-permanent plastic impregnated fiber filters : caution: do not o...

Page 24

Recovery means to collect the refrigerant in a special holding container. Recycling means to run the refrigerant through a filtering system to remove most particles and moisture. Reclaiming means to chemically reprocess the refrigerant to return it to its original purity. Recovering and recycling re...

Page 25

Outdoor unit installation ………….Unit level with proper clearances for air flow and service …………..Proper elevation of outdoor unit …………..Solid pad refrigerant lines ………….Proper length according to manufacturer’s instructions …………..Proper size according to manufacturer’s instructions …………..Large vapor ...

Page 26

Run capacitor fig.10-2 warning:disconnect all power to the outdoor unit before beginning this test . Electrical the motors in both the outdoor unit and indoor unit are similar .Outdoor motors have one speed while the fan motor has both “run” and “start “windings .Extended run windings furnish a choi...

Page 27

Condenser fan blade location dimension “a” will be from 2” to 4” depending on the unit model number. Be sure to check this dimension before removing the fan blade. Note: when parts combination results in motor /blade interference ,the fan blade should be located to provide 1/8” motor /blade clearanc...

Page 28

They indicate the cubic feet of air per minute(cfm) moving through the coil. An inclined manometer or magnehilic guage can be used for measurement. A velometer measures the velocity of the air in feet per minute(fpm). If the area of duct is known, ▼ 1.08 × temp rise compressor and system fault diagn...

Page 29

Example: start to common -4.0 ohms start to run -3.0 ohms start to run -3.0 ohms start to common -∞ ohms open compressor start winding---replace the compressor . 7.The resistance from one winding terminal to any other terminal should be the same with three phase compressors. Note: on larger 208/230 ...

Page 30

4. Causes :leaking liquid line valve, leaking discharge check valve (scroll compressors only ), refrigerant is leaking from the condenser coil . Causes :leaking liquid line valve, leaking discharge check valve (scroll compressors only ), leaking compressor valves. Action: determine the causes and co...

Page 31

4. Remove the failed compressor. A. Unsolder the suction and discharge lines at the compressor stubs. B. Remove the compressor hold down bolts. C. Place the failed compressor on a smooth surface to remove the mounting grommets and sleeves for use with the new compressor . D. Prevent any contaminatio...

Page 32: 10.

7. Other check points a. Verify the operating voltage is within the specified range. E. Inspect all the other electrical components for proper operation. F. I. 10. 2 troubleshooting guide ! Warning – disconnect all electrical power to the unit before servicing. Disconnect power to both the indoor an...

Page 33

Run or start capacitor defective replace loose connection check and tighten all connections. Compressor stuck, grounded or open motor winding, open internal overload wait for 2 hours for overload to reset. Replace compressor if still open. Low voltage condition at compressor terminals, voltage must ...

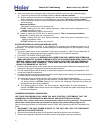

Page 34

1. Failure code 1.1 outdoor coil temp. Sensor failure: flash once 1.2 compressor discharging temp. Sensor failure: flash twice 1.3 pressure switch failure: three times 1.4 over current protection: four times indicator function: when led is used as failure indication, refer to the failure code. Elect...

Page 35

When led is used as a status indicator, the following codes will be shown: 1.5 in defrost, the led will flash 2 seconds on, 2 senconds off. 1.6 in the normal operation state and the compressor is running – outdoor pcb led will be in the on state. 1.7 in normal state, if compressor not running – outd...

Page 36

3.2 outdoor discharging temp. Sensor: r80=50k±3%, b25/80=4450k±3%, with copper terminal 3.5 signal continueous detecting time: pressure switch 30seconds sensor value 20seconds sensor failure (short circuit/open circuit) 2minutes 4. Pcb port function 4.1 cn1——1,2,3,4 are corresponding to the input si...

Page 37

4.6 cn7 — — discharging temp. Sensor connector; the discharging temp. Sensor connected /disconnected failure: 30seconds later alarm; the failure can be resumable. When compressor is running, if the discharging temp. >248℉, compressor will stop; if the discharging temp. For 3 minutes, compressor will...

Page 38

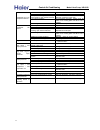

5. Defrosting operation note: the defrost action will be end when defrost has worked for 10 minutes or when the piping temp. Arrives at or more than 50 . No no no no no the compressor runtime>180min yes go to defrost go to defrost yes yes 180 min>the compressor runtime>120min go to defrost yes yes 1...

Page 39

Yes no replace reversing valve does reversing valve work ok? Check the resistance of pipe sensor,whether at normal range) refer to other fault solution no check system whether lack r22 yes no replace pipe sensor yes short the xt port,see whether defrost replace pcb no yes yes no does the dip switch ...

Page 40: 11. Wiring Diagram

Note : the diagram wiring of the fan motor maybe have some difference from the real parts due to different types of fan motor ,the detailed information can refer to the fan motor nameplate. 47 11. Wiring diagram 40 bk optional tl rd tl bk rd rd rd l1 brk indoor unit bk rd l2 bk electric heater kit f...

Page 41: Sincere Forever

Sincere forever haier group haier industrial park, no.1, haier road 266101, qingdao, china http://www.Haier.Com central air conditioning model: heat pump, hr13-d2.