- DL manuals

- HOLEMAKER

- Drill

- 35

- Operator's Manual

HOLEMAKER 35 Operator's Manual

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

WARNING!

BEFORE USE

,

ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL

.

e

s

a

h

c

r

u

P

f

o

e

t

a

D

#

l

a

ir

e

S

HOLEMAKER 35

PNEUMATIC

BEWARE OF

ROTATING

MACHINE PARTS

LINE VOLTAGE

PRESENT

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

HEARING PROTECTION

REQUIRED

EYE PROTECTION

REQUIRED

Summary of 35

Page 1

Holemaker portable magnetic drilling machine operator’s manual warning! Before use , ensure everyone using this machine reads and understands all safety and operating instructions in this manual . E s a h c r u p f o e t a d # l a ir e s holemaker 35 pneumatic beware of rotating machine parts line v...

Page 2

Holemaker 35 pneumatic magnetic drilling machine congratulations on the purchase of your holemaker 35 pneumatic magnetic drilling machine. Holemaker drilling machines are designed to deliver fast, efficient hole drilling performance in portable applications. Table of contents important safety instru...

Page 3

Important safety instructions warning! Read and save all instructions for future reference. 1. Keep work area clean 3. Check the state of the air lines, connections and machine before beginning operation 4. Ensure the drill is powered by cleaned and oiled air 5. Do not allow the drill to be submerge...

Page 4

12. Maintain tools with care • keep tools sharp and clean for better and safer performance. • follow instructions for lubricating and changing accessories. • inspect tool periodically and if damaged, have repaired by authorized service facility. • inspect air supply hose periodically and replace if ...

Page 5

Technical data 5 operating pressure 85 psi air consumption 1400 l/min 800watt motor power arbor size 3/4” weldon /19,05 mm/ hole capacity with holemaker cutter 35mm (1.38 in) maximum drilling depth 25mm (0.98 in) stroke 39mm (1.54 in) magnet force on 25mm plate 6,500 n 500 rpm free speed 240 rpm loa...

Page 6

Special instructions 1. Read and follow operator’s manual thoroughly. 2. Do not touch rotating cutter or parts. 3. Always stop machine completely and unplug from air supply before changing cutters, clearing swarf, refilling lubrication or performing adjustments. 4. Never wear loose clothing or glove...

Page 7

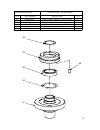

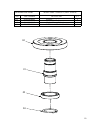

This drilling machine’s spindle has a 19mm weldon shank type and is specifically designed for use with annular cutters. Annular cutter (1) is located inside arbor body (2) and is fastened with grub screws (3). When fastening the cutter in the arbour, ensure that the grub screws are firmly tightened ...

Page 8

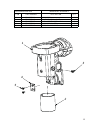

On magnet off off on motor fig. 4 8 cutting - choose a suitable lubricating fluid and fill the coolant tank. The cooling system is an integral part of the machine and should always be used. Warning: the cooling system works gravitationally, therefore it can be used only when in vertical position of ...

Page 9

- regularly grease the pinion and the teeth on the pinole sleeve. - all component parts should be cleaned and maintained with a thin oil film. - use only clean, detergent-free oil with a density compliant with sae 10 (90ssu) or lower. - when working with a pneumatic motor, it is necessary to use an ...

Page 10

Basic troubleshooting 1. Magnetic base not holding securely • material is too thin. • surface of material being drilled must be free of chips, debris, rust and mill scale. • does size of cutter exceed machine’s rated capacity? • check magnet face for unevenness, nicks and burrs. 2. Drill motor runni...

Page 11

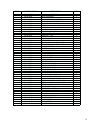

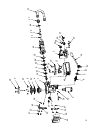

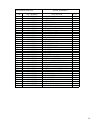

11 item part number description qty 1 1 main body assembly valve assembly quill assembly bevel gear t=39 assembly, gear box cover assembly, bearing nut holder, sleeve pinion driver main body bracket motor hose assy gearshft t=11, head assembly, spoke handle including 35406 knob d-ring strap straight...

Page 12

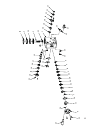

12 1 2 3 4 5 6 7 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 25 26 27 28 48 30 31 32 33 34 35 36 37 37 38 39 40 41 42 43 44 45 46 47 29 49.

Page 13

13 item part number description qty 1.1 1 main body bushing permaglide hex. Insert screw m8x6 main body plate scr, m4 x 10 fhscs spmp350101 spmp350102 spmp350103 spmp350104 spmp350105 1.2 1.3 1 1.4 1 1.5 2 part number:spmp3501 main body assembly 1 3 4 5 2.

Page 14

14 item part number description qty 2.1 0201 0202 0203 0204 0205 0206 0207 0208 0209 0210 0211 0212 0213 0214 0215 0216 0217 0218 0219 0220 0221 0222 0223 0224 0225 0226 0227 0228 0229 0230 0231 0232 0233 0234 0235 0236 0237 spmp35 spmp35 spmp35 spmp35 spmp35 spmp35 spmp35 spmp35 spmp35 spmp35 spmp3...

Page 15

15 1 2 3 4 7 5 6 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 22 22 23 24 25 25 25 25 26 27 28 29 30 31 32 33 33 34 35 36 36 36 36 37.

Page 16

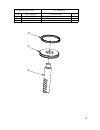

16 item part number description qty 2.2.1 spmp35020201 spmp35020202 spmp35020203 piston piston gear rack o-ring 39,2x3 1 2.2.2 1 2.2.3 1 part number:spmp350202 piston assy 1 2 3.

Page 17

17 y t q n o i t p i r c s e d r e b m u n t r a p m e t i 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 spmp3503 01 02 03 04 05 06 07 08 09 10 11 12 13 quill carrier spindle distanc...

Page 18

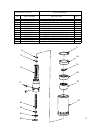

18 y t q n o i t p i r c s e d r e b m u n t r a p m e 4.1 4.2 4.3 4.4 4.5 4.6 spmp350401 spmp350402 spmp350403 spmp350404 spmp350405 spmp350406 bevel gear t=39 assy / incl. Sleeve bearing nut bearing ball 61805 2rs external retaining ring 25z type a internal retaining ring 37w hex set screw m5x10 1...

Page 19

19 y t q n o i t p i r c s e d r e b m u n t r a p m e t i 1 4.1.1 4.1.2 4.1.3 4.1.4 spmp35040101 spmp35040102 spmp35040103 spmp35040104 sleeve bevel gear t=39 bearing ball 6806 llu external retaining ring 30z 1 1 1 part number:spmp350401 bevel gear t=39 assy / incl. Sleeve 01 02 03 04.

Page 20

20 y t q n o i t p i r c s e d r e b m u n t r a p m e t i 1 r e v o c x o b r a e g 1 . 5 spmp350501 spmp350502 spmp350503 1 r e p m u j 2 . 5 1 9 1 - h - 2 t m a r u f l e p p i n s s u l h c s n a 3 . 5 part number:spmp3505 gear box cover assembly 01 02 03.