- DL manuals

- HOLEMAKER

- Drill

- PRO 100

- Operator's Manual

HOLEMAKER PRO 100 Operator's Manual

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

WARNING!

BEFORE USE

,

ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL

.

e

s

a

h

c

r

u

P

f

o

e

t

a

D

#

l

a

ir

e

S

HOLEMAKER PRO 110

BEWARE OF

ROTATING

MACHINE PARTS

LINE VOLTAGE

PRESENT

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

HEARING PROTECTION

REQUIRED

EYE PROTECTION

REQUIRED

VER: 1.10 14/08/15

Summary of PRO 100

Page 1

Holemaker portable magnetic drilling machine operator’s manual warning! Before use , ensure everyone using this machine reads and understands all safety and operating instructions in this manual . E s a h c r u p f o e t a d # l a ir e s holemaker pro 110 beware of rotating machine parts line voltag...

Page 2

Holemaker pro 110 portable magnetic drilling machine congratulations on the purchase of your holemaker pro 110 portable magnetic drilling machine. Holemaker drilling machines are designed to deliver fast, efficient hole drilling performance in portable applications. Table of contents important safet...

Page 3

Important safety instructions warning! When using electrical tools , basic safety precautions should always be followed to reduce risk of fire , electric shock and personal injury . Read and save all instructions for future reference. 1. Keep work area clean • cluttered areas and benches increase ri...

Page 4

12. Maintain tools with care • keep tools sharp and clean for better and safer performance. • follow instructions for lubricating and changing accessories. • inspect tool cords periodically and if damaged, have repaired by authorized service facility. • inspect extension cords periodically and repla...

Page 5

Grounding instructions power supply requirements warning! Improperly connecting the grounding wire can result in the risk of electrical shock. Prior to use check condition of the power cord, which has to be free of any cuts, or similar damages. Attention!: this unit has a class one of insulation and...

Page 6

Technical data 6 supply voltage: ………………………………… 220-240v/ 50-60 hz. Motor power ……………………………………………………. 1650 w total power …………………………………………………….. 1800 w machine speeds (under load): ………………..... 85/135/160/250 rpm insulation class ………………………………………………….. First arbor bore ………………………………………………………. Mt 4 tool h...

Page 7

Special instructions 1. Read and follow operator’s manual thoroughly. If you cannot locate your operator’s manual, contact itms for an additional copy. 2. Do not touch rotating cutter or parts. 3. Always stop machine completely and unplug from power source before changing cutters, clearing swarf, re...

Page 8

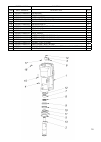

This drilling machine’s spindle has a 19mm weldon shank type and is specifically designed for use with annular cutters. Annular cutter (1) is located inside arbor body (2) and is fastened with grub screws (3). When fastening the cutter in the arbour, ensure that the grub screws are firmly tightened ...

Page 9

Before you cut before positioning the machine on work piece always make sure that: - work piece is made of ferrous material - thickness of work piece is adequate for secure magnetic adhesion (mild steel - 10mm is recommended) - ensure no part of magnet overhangs the steel workpiece - surface of stee...

Page 10

Fig. 1 cutting - choose a suitable lubricating fluid and fill the coolant tank. The cooling system is an integral part of the machine and should always be used. Warning: the cooling system works gravitationally, therefore it can be used only when in vertical position of the drilling machine. In othe...

Page 11

Maintenance and service 11 - every 250 hours of work check condition of carbon brushes. If their length is less than 5 mm they should be replaced with new genuine brushes. After replacement, new brushes should be run-in without load for about 20 min. Repair and service work is to be performed by aut...

Page 12

Basic troubleshooting 1. Magnetic base not holding securely • material is too thin. • surface of material being drilled must be free of chips, debris, rust and mill scale. • does size of cutter exceed machine’s rated capacity? • check magnet face for unevenness, nicks and burrs. 2. Drill motor runni...

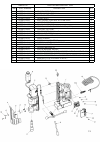

Page 13

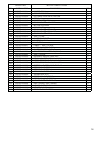

V 0 3 2 o r p e n i h c a m g n i l l i r d hmpro110 item part number qty n o i t p i r c s e d sppro11001 sppro11002 sppro11003 sppro11004 sppro11005 sppro11006 sppro11007 sppro11008 sppro11009 sppro11010 sppro1101004 sppro11011 sppro11012 sppro11013 sppro11014 sppro11015 sppro11016 sppro11017 sppr...

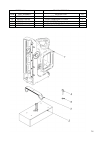

Page 14

14 qty y l b m e s s a e m a r f 1 0 0 1 1 o r p p s item part number description 1.1 1.2 1.3 1.4 1.5 sppro1100101 sppro1100102 sppro1100103 sppro1100104 sppro1100105 main body assy electromagnetic base d-ring strap hex. Socket bolt m8x35, spring washer 8,2 1 1 1 4 4.

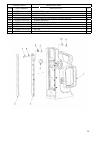

Page 15

15 main body assy sppro1100101 item part number qty n o i t p i r c s e d sppro110010101 sppro110010102 sppro110010103 sppro110010104 sppro110010105 sppro110010106 sppro110010107 sppro110010108 sppro110010109 sppro110010110 main body pressure plate slide insert self lubricating sleeve 28,05h7x32x16,...

Page 16

V 0 3 2 e t e l p m o c r o t o m 2 0 0 1 1 o r p p s item part number qty n o i t p i r c s e d sppro1100201 sppro1100202 sppro1100203 sppro1100204 sppro1100205 sppro1100206 sppro1100207 sppro1100208 sppro1100210 sppro1100211 sppro1100212 sppro1100213 sppro1100214 sppro1100215 sppro1100216 sppro110...

Page 17

17.

Page 18

V 0 3 2 r o t o m 1 0 2 0 0 1 1 o r p p s item part number qty n o i t p i r c s e d sppro110020101 sppro110020102 sppro110020103 sppro110020104 sppro110020105 sppro110020106 sppro110020107 sppro110020108 sppro110020109 sppro110020110 sppro110020111 motor cover guide fan armature assy 230v armature ...

Page 19

X o b r a e g 2 0 2 0 0 1 1 o r p p s item part number qty n o i t p i r c s e d sppro110020201 sppro110020202 sppro110020203 sppro110020204 sppro110020205 sppro110020206 sppro110020207 sppro110020208 sppro110020209 sppro110020210 sppro110020211 sppro110020212 sppro110020213 sppro110020214 sppro1100...

Page 20

Qty 0 2 = z y l b m e s s a t f a h s n o i n i p 6 0 2 0 0 1 1 o r p p s item part number description 2.6.1 2.6.2 2.6.3 2.6.4 sppro110020601 sppro110020602 sppro110020603 sppro110020604 gearshaft, 20t gear, 29t helical input gear z45 key,woodruff #403 1 1 1 1 qty t 4 1 y l b m e s s a t f a h s n o...

Page 21

3 2 4 qty 4 1 = z y l b m e s s a t f a h s n o i n i p 2 1 2 0 0 1 1 o r p p s item part number description 2.12.1 2.12.2 2.12.3 2.12.4 sppro110021201 sppro110021202 sppro110021203 sppro110021204 gearshaft 14-1.5 mm gear, 33t square key 5x5x12 external retaining ring- 18z 1 1 1 1 qty 5 2 / 9 1 y l ...

Page 22

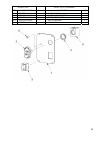

Qty y l b m e s s a e t a l p l e n a p 3 0 0 1 1 o r p p s item part number description 3.1 3.3 3.4 3.5 3.6 sppro1100301 sppro1100303 sppro1100304 sppro1100305 sppro1100306 panel plate switch start-stop start-stop wire switch magnet light pipe 1 1 1 1 1 22.

Page 23

Electrical diagram 23.