- DL manuals

- Holman

- Toaster

- QT14C

- Installation And Operation Instructions Manual

Holman QT14C Installation And Operation Instructions Manual

Summary of QT14C

Page 1

1 il1336 ® conveyor sandwich toaster model qt14c, qt14cr installation and operation instructions 2m-z10368 rev. B 7/11/07 qt14c.

Page 2

2 2 these symbols are intended to alert the user to the presence of important operating and maintenance instructions in the manual accompanying the appliance. Retain this manual for future reference notice using any part other than genuine star factory supplied parts relieves the manufacturer of all...

Page 3

3 specifications qt14c, qt14cr rating/connection: 8,300 watts plug: twist lock, 2 pole, 3 wire, 50 amp 250v california style or equivalent electrical supply: separate service per toaster - 39.9 amp, 208 vac, 1 phase, 60 hz separate service per toaster - 34.6 amp, 240 vac, 1 phase, 60/50 hz separate ...

Page 4

4 general installation data this equipment is designed and sold for commercial use only by personnel trained and experienced in its operation and is not sold for consumer use in and around the home nor for use directly by the general public in food service locations. Before using your new equipment,...

Page 5

5 assembly and installation continued electrical connection have an electrician connect input power to the unit(s) in accordance with local electrical codes. Cord & plug is provided. Verify the ground (earth) connection is properly wired. Never connect unit to power without proper ground connections...

Page 6

6 control panel controls stacking toasters when stacking two holman qt14/qt14c conveyor sandwich toasters a qt14 stacking legs kit (part no. Ps-z8977) must be used to prevent overheating of the control box of the top toaster. 1. Unplug both unit power cords from the wall receptacle, and allow to coo...

Page 7

7 daily operation 1. Turn main on/off switch to the on position and variable speed control to the desired setting. Allow 30-40 minutes for complete machine warm up. 2. Adjust speed as required during operation to achieve a good bake. 3. When done for the day, turn the on/off switch to the off positi...

Page 8

8 cleaning preventive maintenance for your toaster consists of the following recommended cleaning procedures. To keep your unit in its top operating condition, these steps should be performed on a daily, weekly or as indicated. Turn power off and allow cooling fans to run until the control box is co...

Page 9

9 cleaning continued weekly 1.Turn main power switch to the off position, allow cooling fans to run until the control box is cooled off. Disconnect unit from power source and allow to cool. 2. Perform daily cleaning procedures. 3. Using a damp cloth, wipe clean the fan guard located on the control b...

Page 10

10 cleaning continued monthly 1.Turn main power switch to the off position, allow cooling fans to run until the control box is cooled off. Disconnect unit from power source and allow to cool. 2. Perform daily & weekly cleaning procedures. 3. Working from the power supply side of the oven, locate the...

Page 11

11 maintenance & repairs a. Replacing element note: replace one element at a time. 1) disconnect power source. 2) remove both the left and right side panels, by removing the truss head screws. Pull the top of each panel out slightly and lift up. 3) remove the wire terminal from the each end of the e...

Page 12

12 maintenance procedures continued 7) install sprocket on motor shaft & chain after aligning them. See sprocket alignment illustration. Note: the two sprockets must line up flush with each other, so the chain does not twist during operation. Also the hub is installed closest to the motor. 8) slide ...

Page 13

13 troubleshooting guide a. Unit will not heat, conveyor belt will not move. 1) be sure the main circuit breaker is switched to the on position and there is power to the outlet. 2) check to see if the toaster is plugged in and all controls are turned to the on position. 3) be sure the hi-limit reset...

Page 14

14 part# 2m-4497-2 12/06 rms the foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty. For assistance should you need any assistance regarding the operation or maintenance of any star equipment; write, phone, fax or email our service ...

Page 15

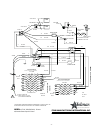

15 fan drive motor: use blk/wht for 208v use blk/blu for 240v diode 500 ohm pot fan top heaters (5 parallel sets of 2 in series) bottom heaters (3 parallel sets of 2 in series) 6 awg/3 cord set 50 amp twist loc plug (california standard) fan switch pilot light on/off fuse 2 fuse 1 4 3 13 14 15 17 18...

Page 16

Star manufacturing 10 sunnen drive, st. Louis, mo 63143 u.S.A. (800) 807-9054 (314) 781-2777 parts & service (800) 807-9054 www.Star-mfg.Com.