- DL manuals

- Holset

- Engine

- HE221W

- Service & Repair Manual

Holset HE221W Service & Repair Manual - Symbols

Symbole - Deutsch

In diesem Handbuch werden die folgenden Symbole verwendet, die wesentliche Funktionen hervorheben. Die

Symbole haben folgende Bedeutung:

WARNUNG - Unterhaltungs und Wartungsverfahren müssen genau befolgt werden, da ein

Nichtbeachten zu Personenschäden oder tödlichen Verletzungen führt.

ACHTUNG - Falls Unterhaltungs und Wartungsverfahren nicht genau beachtet werden, kann der

Turbolader dadurch beschädigt oder zerstört werden.

AUSBAU bzw. ZERLEGEN.

EINBAU bzw. ZUSAMMENBAU.

INSRPEKTION erforderlich.

Teil oder Baugruppe REINIGEN.

DIMENSION - oder ZEITMESSUNG.

Teil oder Baugruppe ÖLEN.

WERKZEUGGRÖSSE wird angegeben.

ANZUG auf vorgeschriebenes Drehmoment erforderlich.

Sicherstellen, daß die AUSWUCHTMARKEN an der Rotor-Baugruppe richtig ausgerichtet sind.

Elektrische MESSUNG DURCHFÜRHREN.

Weitere Informationen an anderer Stelle bzw. in anderen Handbüchern.

Schutzkleidung muß immer getragen werden.

Deutet an, daß Teile schwer sein können.

Website-Verzeichnis mit Ihrem nächsten Holset-Händler.

Gehe zu Inhalt

HX25/25W/27W Service Repair Manual

Introduction

Symbols

1:6

KG

Summary of HE221W

Page 1

Holset hx25/25w/27w service repair manual copyright 2007, cummins turbo technologies ltd. All rights reserved. Vgt, command valve and super mwe are trade marks of cummins turbo technologies ltd. Holset and the holset logo are registered trade marks of cummins turbo technologies ltd. Cummins and the ...

Page 2

Hx25/25w/27w service repair manual foreword foreword this publication was written to assist with turbocharger installation, maintenance and overhaul. It is not a warranty of any kind expressed or implied. The specifications and procedures in this manual are based on information in effect at the time...

Page 3: Table of Contents

Hx25/25w/27w service repair manual table of contents table of contents 1: introduction about the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1:1 how to use the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Hx25/25w/27w service repair manual introduction 1:1 about the manual the procedures in this manual were developed to instruct in the correct overhaul of the designated holset turbocharger range for optimum performance and minimum maintenance operation. How to use the manual the manual is split into ...

Page 5

Hx25/25w/27w service repair manual introduction description and operation of turbocharger 1:2 general information a turbocharger is a mechanical device which uses the engine’s exhaust gases to force more air into the engine cylinders. Hot exhaust gas energy is used to turn a turbine wheel and shaft....

Page 6

Note holset service receives many turbocharger returns that are no fault found. Before assuming the turbocharger is not performing to specification always refer to the engine diagnostic system and the troubleshooting diagnostic procedures of this manual. Hx25/25w/27w service repair manual introducti...

Page 7: Installation Data

Hx25/25w/27w service repair manual introduction installation data 1:4 1. Holset service receives many turbocharger returns that are no fault found. Before assuming the turbocharger is not performing to specification always refer to the engine diagnostic system and the fault finding chart of this man...

Page 8: Installation Checklist

Hx25/25w/27w service repair manual introduction installation checklist 1:5 1. Always understand why the original turbocharger needs replacing before fitting another unit. 2. Check the turbocharger dataplate to ensure the part no. Is correct for the engine/application. 3. Check the engine exhaust, in...

Page 9: Symbols

Symbole - deutsch in diesem handbuch werden die folgenden symbole verwendet, die wesentliche funktionen hervorheben. Die symbole haben folgende bedeutung: warnung - unterhaltungs und wartungsverfahren müssen genau befolgt werden, da ein nichtbeachten zu personenschäden oder tödlichen verletzungen fü...

Page 10

Symbols - english the following group of symbols have been used in this manual to help communicate the intent of the instructions. When one of the symbols appears, it conveys the meaning defined below. Warning - serious personal injury or extensive property damage can result if the warning instructi...

Page 11

Simbolos - español los simbolos siguientes son usados en estes manual para clarificar el proceso de las instrucciones. Cuado aparece uno de estos simbolos, su significado se espcifica en la parte inferior. Advertencia – procedimientos de mantenimiento o servicio que al no seguirse resultarán en daño...

Page 12

Symboles - français les symboles suivants sont utilisés dans ce manuel pour aider à communiquer le but des instructions. Quand l’un de ces symboles apparait, il évoque le sens défini ci-dessous: attention danger - procédures de maintenance ou d’entretien qui, si elles ne pas observées correctement, ...

Page 13

Hx25/25w/27w service repair manual introduction 1:10 símbolos - português os símbolos a seguir serão utilizados neste manual para facilitar a comunicação das instruções e seue significados estão déscritos abaixo. AtenÇÃo - os procedimentos de manutenção ou serviços que não forem seguidos correctamen...

Page 14: Turbocharger Identification

Turbocharger identification hx25/25w/27w service repair manual component identification 2:1 dataplate center housing rotating assembly (chra) (2) 35xxxxx xyymmxxxxx hx27w note dataplates will be fitted to the compressor housing (8). The information from the dataplate must be quoted for service and p...

Page 15

Hx25/25w/27w service repair manual component identification 2:2 installation options type a hx27w type b hx25 type c hx25w.

Page 16

Hx25/25w/27w service repair manual component identification 2:3 installation options type d - hx25w type e - hx25 type f - hx25w.

Page 17

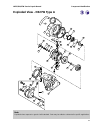

Hx25/25w/27w service repair manual component identification exploded view - hx27w type a 2:4 74 106 60 73 76 75 75 77 96 81 28 43 113 114 4 7 61 66 33 38 60 12 11 64 11 91 53 41 36 6 13 31 16 32 62 5 8 note exploded views represent a generic build standard. Parts may be added or subtracted in specif...

Page 18: Exploded View - Hx25 Type B

Hx25/25w/27w service repair manual component identification 2:5 exploded view - hx25 type b 113 114 4 7 61 66 16 38 60 12 11 64 11 91 41 36 53 6 13 5 8 31 33 32 43 28 62 96 note exploded views represent a generic build standard. Parts may be added or subtracted in specific applications..

Page 19

Hx25/25w/27w service repair manual component identification component list - hx25/25w/27w 2:6 item no. Description quantity all applications 1 repair kit chra (core)* 1 2 chra (core) 1 4 bearing housing 1 5 turbine housing 1 6 assembly, turbine wheel 1 7 compressor wheel 1 8 compressor housing 1 11 ...

Page 20

Hx25/25w/27w service repair manual component identification component list - hx25/25w/27w 2:7 item no. Description quantity wastegate applications 74 wastegate kit comprising: 1 73 actuator 1 75 hose clip 2 76 end link, assembly 1 77 retaining ring, end link 1 106 screw, actuator 2 60 plain washer 2...

Page 21: Purchasable Service Tools

Hx25/25w/27w service repair manual component identification purchasable service tools 2:8 the following special tools can be purchased from your local authorised repair location. The use of these tools is recommended and where necessary they are shown in the appropriate service procedure. Service to...

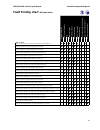

Page 22: Fault Finding Chart

Hx25/25w/27w service repair manual troubleshooting and diagnosis fault finding chart - all applications engine lacks power black exhaust smoke blue exhaust smoke high oil consumption t urbocharger noisy engine running hot poor t ransient response smoke cyclic sound from the t urbocharger oil leak fr...

Page 23: Fault Finding Chart

Hx25/25w/27w service repair manual troubleshooting and diagnosis fault finding chart - wastegate applications 3:2 engine lacks power black exhaust smoke blue exhaust smoke high oil consumption t urbocharger noisy engine running hot poor t ransient response smoke cyclic sound from the t urbocharger o...

Page 24: Service Tools

Dial gauge and dial gauge adaptor -0+ 10 10 20 20 30 30 40 40 50 mercer type 20 pressure gauge regulated air supply max 300 kpa (45 lbf/in 2 ) hx25/25w/27w service repair manual component testing and replacement service tools 4:1 the following special tools are recommended to perform procedures in t...

Page 25: On Engine Checks

Oil leakage bearing housing m10 x 1.25 pipe fitting 11/16-16 un (19 mm) replacement seals and adapters should be fitted without sealant as this can contaminate the oil. Torque tighten adaptor to value shown in service data sheet . It is important to avoid kinked pipes during servicing and subsequent...

Page 26

Exhaust gas leakage turbine housing flange leakage will cause soot formation on the flange. Check exhaust manifold to flange seal ensuring fastener torque meets engine manufacturer’s recommendation. Check flange for cracks and ensure flatness is within 0.1 mm (0.004 in). Check turbine housing gasket...

Page 27

To check for wastegate actuator rod movement and air leakage on engine, follow the checking procedure described in wastegate actuator checks . Hx25/25w/27w service repair manual component testing and replacement 4:4 warning never attempt to check actuator using air supplied from a running engine..

Page 28: Bearing Clearance

Secure the turbine housing and check the thrust clearance using a dial gauge. Ensure clearance is within min/max values shown on service data sheet . If axial clearance does not meet specification refer to turbocharger service and overhaul to strip and rebuild the chra (core). Hx25/25w/27w service r...

Page 29

Hx25/25w/27w service repair manual component testing and replacement turbine and compressor housings 4:6 compressor housing mark compressor housing, bearing housing and retaining ring to record correct orientation. This action assists in re-assembling the pinned components and defines orientation of...

Page 30

Remove the o-ring seal, compressor housing (41) and discard. Hx25/25w/27w service repair manual component testing and replacement 4:7 inspect internal profile of compressor housing for scoring damage due to possible contact with compressor wheel. Check compressor cover retaining ring groove is free ...

Page 31

Gently remove the chra (core) assembly from the turbine housing. If necessary use a soft hammer to free the joint. Hx25/25w/27w service repair manual component testing and replacement 4:8 cracking of the turbine housing inlet flange and inlet duct generally requires turbine housing replacement. Acce...

Page 32: Cleaning of Housings

Visually inspect the parts to detect signs of burning and other conditions in order to obtain as much information as possible before washing. Hx25/25w/27w service repair manual component testing and replacement cleaning of housings 4:9 soak the housings in a non-corrosive low flash point metal clean...

Page 33

Hx25/25w/27w service repair manual component testing and replacement 4:10 it is permissible to bead blast the turbine housing if chemical and brush cleaning is not effective. Warning do not bead blast aluminium and cast iron components together. Caution prevent the bead spray impinging directly on t...

Page 34: Reassembly of Housings

Turbine housing align marks applied to turbine housing, bearing housing and v-band clamp to establish component orientation. This action assists in re-assembling the pinned components. Hx25/25w/27w service repair manual component testing and replacement reassembly of housings 4:11 install chra (core...

Page 35

Compressor housing lubricate new o-ring seal with clean engine oil and insert into bearing housing groove. Hx25/25w/27w service repair manual component testing and replacement 4:12 position retaining ring, compressor housing over the bearing housing with the chamfered face towards the turbine housin...

Page 36

Check for free rotation of the rotor assembly. Hx25/25w/27w service repair manual component testing and replacement 4:13.

Page 37: Wastegate Actuator Checks

Place the turbocharger on a suitable workbench. Using a small flat screwdriver, carefully remove the hose clip (75) and discard. Pull the flexible hose from the actuator spigot. Hx25/25w/27w service repair manual component testing and replacement wastegate actuator checks 4:14 connect and secure the...

Page 38: Actuator Removal

Carefully remove the actuator clip using point nose pliers. Hx25/25w/27w service repair manual component testing and replacement actuator removal 4:15 gently apply a small amount of air to the actuator and when/if the rod end moves, carefully slide the end link off the valve lever arm. If the actuat...

Page 39: Wastegate Mechanism Check

Carefully move the lever arm up and down. If the arm moves freely by hand, then re-check for movement of actuator rod. Apply an air pressure of 300 kpa (45 lbf/in 2 ) to the actuator spigot inlet. If the rod does not move, replace the actuator with a pre-set replacement kit (74). If the lever arm is...

Page 40

Radial cracks can occur around the valve seat when the turbocharger has been abused or overheated. Hx25/25w/27w service repair manual component testing and replacement 4:17 lever arm pin can be worn by partial seizure of the valve mechanism. Scoring may be caused by arduous local environmental condi...

Page 41

Hx25/25w/27w service repair manual component testing and replacement wastegate actuator replacement 4:18 thread new end link several turns on to the shaft of the new pre-set actuator assembly. Hold the actuator assembly with the spine of the spacer piece upright. Rotate the valve mechanism lever arm...

Page 42

M8 (12 mm) fit actuator mounting fasteners with washers and torque tighten to the value shown in the service data sheet . Hx25/25w/27w service repair manual component testing and replacement 4:19 fit new spring clip to retain end link on pin. (10 mm) loosen spacer piece by turning jam-nut anti-clock...

Page 43

Refit the air supply hose with new clips (75). Clips should be crimped closed using pinsers. Crimp gap will vary due to spring back and hose type but will not be less than 0.6 mm (0.025 in). Suitable alternative hose clamps can be used. Hx25/25w/27w service repair manual component testing and replac...

Page 44: Service Tools

Hx25/25w/27w service repair manual turbocharger service and overhaul service tools 5:1 the following special tools are recommended to perform procedures in this manual. The use of these tools is shown in the appropriate procedure. These tools can be purchased from your local authorised repair locati...

Page 45: Disassembly

Hx25/25w/27w service repair manual turbocharger service and overhaul disassembly 5:2 locate the chra (2) on to a 12 mm 12 point socket located in a suitable fixture. M5 x 0.8 l.H. (8mm) remove the locknut, compressor wheel (62). Remove compressor wheel (7). Note left hand thread. Caution this turboc...

Page 46

Remove remaining chra from fixture taking care to hold assembly, turbine wheel in place. Gently slide bearing housing (4) off the assembly, turbine wheel (6). It is permissible to tap the protruding turbine shaft gently with a soft hammer if the split ring seal is stuck in its bore. The turbine end ...

Page 47

Remove oil seal plate (43) using two screw drivers under the exposed lip to prise out seal plate. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:4 remove oil slinger (31) and baffle sub-assembly from oil seal plate. Using a precision screwdriver, remove split ring seal, compr...

Page 48

Turn bearing housing over so that thrust bearing (12) * , thrust collar (36) and the compressor end journal bearing (11) * drop out of assembly under own weight. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:5 inboard bearing retaining rings are intended to remain in the hou...

Page 49: Component Cleaning

Visually inspect all parts to detect signs of burning and other fault conditions in order to obtain as much information as possible before washing. Hx25/25w/27w service repair manual turbocharger service and overhaul component cleaning 5:6 soak the components in a non-corrosive low flash point metal...

Page 50

It is permissible to bead blast the turbine housing if chemical and brush cleaning is not effective. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:7 it is important that the oil chamber of the bearing housing is free of carbon before re-building. If heavy deposits persist af...

Page 51: Inspection and Testing

Major components assembly turbine wheel place assembly, turbine wheel (6) on a vee block. Position a dial gauge on the turned surface of the shaft at the threaded end. Check dial gauge reading. Where shaft bend is greater than the recommended maximum of 0.015 mm (0.0006 in) replace the assembly. -0+...

Page 52

Compressor wheel inspect compressor wheel (7), for cracked, bent or damaged blades. Replace with new if any damage found. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:9 compressor housing inspect internal profile of compressor housing (8), for scoring damage due to possible...

Page 53

After washing and bead blasting the wastegate valve mechanism may remain seized or stiff to operate. If so, soak the mechanism in penetrating oil for approximately 20 minutes or a period of time recommended by the oil manufacturer. Access to the valve mechanism via the turbine housing outlet can be ...

Page 54

Wastegate actuator inspect the actuator rod end bore which locates on the lever arm pin for elongation. Ovalisation must not exceed 0.50 mm (0.020 in). Hx25/25w/27w service repair manual turbocharger service and overhaul 5:11 bearing housing inspect journal bearing bores for wear and score marks. Re...

Page 55

Heat shield check and replace if the heat shield (38) is distorted or if signs of rubbing or cracking are visible. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:12 thrust collar check and replace if thrust collar (36) is scored on thrust face or if any cracks are visible..

Page 56: Reassembly

Core balance hx25/25w/27w service repair manual turbocharger service and overhaul reassembly 5:13 small high speed turbochargers require a new standard of balancing process using a proprietary vibration sorting rig (vsr). As the results of vibration based tests are rig specific, the balance limits s...

Page 57

Place bearing housing compressor face on a clean surface. Place heat shield (38) on shaft and insert assembly, turbine wheel (6) into assembled turbine end journal bearing. Ensure wheel spins freely by hand rotation. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:14 turn over...

Page 58

Loosely assemble oil baffle (33) to oil slinger (31). Complete sub-assembly by fitting new split ring seal, turbine (13) * to oil slinger/ oil baffle loose assembly. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:15 insert oil slinger assembly into oil seal plate (43). Lightl...

Page 59

Use suitable circlip pliers to install the retaining ring, insert (66). Hx25/25w/27w service repair manual turbocharger service and overhaul 5:16 tap ends of retaining ring (66) lightly with hammer and drift to ensure that the retaining ring is properly located into its groove in the bearing housing...

Page 60

M7 lh (10 mm) install the new locknut, compressor wheel (61) and tighten in two stages to the values shown in the service data sheet . Hx25/25w/27w service repair manual turbocharger service and overhaul 5:17 place turbine housing (5) on a clean surface. Place v- band (28) loosely into position on t...

Page 61

Check compressor end radial movement using a dial gauge. Ensure clearance lies within min/max tir (total indicator reading) values shown on service data sheet . Hx25/25w/27w service repair manual turbocharger service and overhaul 5:18 remove locknut, v-band clamp and carefully extract core for balan...

Page 62

Place retaining ring, compressor housing (91) around bearing housing. Carefully locate the compressor housing over the compressor wheel and locate on the bearing housing spigot. Hx25/25w/27w service repair manual turbocharger service and overhaul 5:19 caution the compressor wheel blades can be easil...

Page 63

Thread new end link (76) several turns on to the shaft of the new pre-set actuator assembly (73). Hold the actuator assembly with the spine of the spacer piece upright. Rotate the valve mechanism lever arm to close the wastegate valve (pushed towards the compressor end). Fit end link (76) over the l...

Page 64

Hx25/25w/27w service repair manual turbocharger service and overhaul 5:21 (10 mm) loosen spacer piece by turning jam-nut anti-clockwise (counter-clockwise). Remove and discard tie wrap and spacer piece. Continue turning jam-nut in the same direction, and torque tighten against end link to value show...

Page 65: Holset Holset Hx25/25W/27W

Holset holset hx25/25w/27w service repair manual copyright 2007, cummins turbo technologies ltd. All rights reserved. Vgt, command valve and super mwe are trade marks of cummins turbo technologies ltd. Holset and the holset logo are registered trade marks of cummins turbo technologies ltd. Cummins a...