- DL manuals

- Holset

- Engine

- HE341Ve

- Service Manual

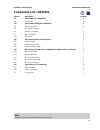

Holset HE341Ve Service Manual - Component List - He341Ve

HE341Ve Service Manual

Component Identification

Component List - HE341Ve

2:4

Item No.

Description

Quantity

121

VG Actuator Kit comprising:

1

126

VG Actuator

1

122

VG Actuator Fittings Kit comprising:

1

120

Screw, Cap Head

3

151

Coverplate, Actuator

1

46

Gasket, Coverplate

1

67

Bolt, Coverplate

4

154

Pivot Block

1

152

VG Position Sensor Kit comprising:

1

153

Position Sensor

1

106

Screw, Socket Head

2

105

Connector Male, Water

2

123

VG Bearing Housing Seals and Adapter Kit (Water & Oil) comprising:

1

053

Gasket, Oil Outlet

1

113

Adapter, Oil Inlet

1

114

O Ring Seal, Oil Inlet

1

105

Connector Male, Water

2

115

O Ring Seal, Water

2

124

Speed Sensor Kit comprising:

1

112

Speed Sensor

1

120

Screw, Cap Head

1

27

O Ring Seal

1

Note

Exploded views may not contain all listed components.

Summary of HE341Ve

Page 1

Holset he341ve service manual copyright 2007, cummins turbo technologies ltd. All rights reserved. Vgt, command valve and super mwe are trade marks of cummins turbo technologies ltd. Holset and the holset logo are registered trade marks of cummins turbo technologies ltd. Cummins and the cummins logo...

Page 2

He341ve service manual foreword foreword this publication was written to assist with turbocharger installation, maintenance and overhaul . The specifications and procedures in this manual are based on information in effect at the time of publication. Holset service reserves the right to make any cha...

Page 3: Table of Contents

He341ve service manual table of contents table of contents 1: introduction about the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1:1 how to use the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

He341ve service manual introduction 1:1 about the manual the procedures in this manual were developed to instruct in the correct overhaul of the holset he341ve turbocharger for optimum performance and minimum maintenance operation. How to use the manual the manual is split into sections designed to ...

Page 5

He341ve service manual introduction description and operation of turbocharger 1:2 general information a turbocharger is a mechanical device which uses the engine’s exhaust gases to force more air into the engine cylinders. Hot exhaust gas energy is used to turn a turbine wheel and shaft. At the othe...

Page 6

He341ve service manual introduction 1:3 the advantages of a variable geometry (vg) turbocharging system you may already have experience of the effect of a wastegate turbocharger on the performance of your vehicle. The advantage of variable geometry over a wastegate system is that all the exhaust gas...

Page 7

He341ve service manual introduction 1:4 notes, cautions and warnings notes, cautions and warnings are used in this manual to emphasise important or critical instructions. Note information which is essential to highlight. Caution maintenance or service procedures which if not strictly followed, will ...

Page 8: Installation Data

He341ve service manual introduction installation data 1:5 1. Holset service receives many turbocharger returns that are no fault found. Before assuming the turbocharger is not performing to specification always refer to the engine diagnostic system and the fault finding chart of this manual to make ...

Page 9: Installation Checklist

He341ve service manual introduction installation checklist 1:6 1. Always understand why the original turbocharger needs replacing before fitting another unit. 2. Check the turbocharger dataplate to ensure the part no. Is correct for the engine/application. 3. Check the engine exhaust, intake and aft...

Page 10: Symbols

Symbole - deutsch in diesem handbuch werden die folgenden symbole verwendet, die wesentliche funktionen hervorheben. Die symbole haben folgende bedeutung: warnung - unterhaltungs und wartungsverfahren müssen genau befolgt werden, da ein nichtbeachten zu personenschäden oder tödlichen verletzungen fü...

Page 11

He341ve service manual introduction 1:8 symbols - english the following group of symbols have been used in this manual to help communicate the intent of the instructions. When one of the symbols appears, it conveys the meaning defined below. Warning - serious personal injury or extensive property da...

Page 12

Simbolos - español los simbolos siguientes son usados en estes manual para clarificar el proceso de las instrucciones. Cuado aparece uno de estos simbolos, su significado se espcifica en la parte inferior. Advertencia – procedimientos de mantenimiento o servicio que al no seguirse resultarán en daño...

Page 13

Symboles - français les symboles suivants sont utilisés dans ce manuel pour aider à communiquer le but des instructions. Quand l’un de ces symboles apparait, il évoque le sens défini ci-dessous: attention danger - procédures de maintenance ou d’entretien qui, si elles ne pas observées correctement, ...

Page 14

He341ve service manual introduction 1:11 símbolos - português os símbolos a seguir serão utilizados neste manual para facilitar a comunicação das instruções e seue significados estão déscritos abaixo. AtenÇÃo - os procedimentos de manutenção ou serviços que não forem seguidos correctamente resultarã...

Page 15: Turbocharger Identification

Turbocharger identification he341ve service manual component identification 2:1 dataplate he341ve 35xxxxx xyymmxxxxx he341ve note dataplates may be fitted to the dc motor of the vg actuator (126) or to the compressor housing (8). The information from the dataplate must be quoted for service and part...

Page 16

He341ve service manual component identification 2:2 installation options type a.

Page 17: Exploded View - He341Ve

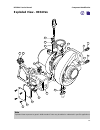

He341ve service manual component identification exploded view - he341ve 2:3 67 151 46 112 120 53 27 126 120 154 105 115 105 115 114 113 153 106 105 105 note exploded views represent a generic build standard. Parts may be added or subtracted in specific applications..

Page 18: Component List - He341Ve

He341ve service manual component identification component list - he341ve 2:4 item no. Description quantity 121 vg actuator kit comprising: 1 126 vg actuator 1 122 vg actuator fittings kit comprising: 1 120 screw, cap head 3 151 coverplate, actuator 1 46 gasket, coverplate 1 67 bolt, coverplate 4 154...

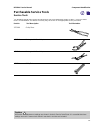

Page 19: Purchasable Service Tools

He341ve service manual component identification purchasable service tools 2:5 the following special tools can be purchased from your local authorised repair location. The use of these tools is recommended and where necessary they are shown in the appropriate service procedure. Service tools part no....

Page 20: Fault Finding Chart

He341ve service manual troubleshooting and diagnosis fault finding chart - all applications engine lacks power black exhaust smoke blue exhaust smoke high oil consumption t urbocharger noisy engine running hot poor t ransient response smoke cyclic sound from the t urbocharger oil leak from compresso...

Page 21: Fault Finding Chart

He341ve service manual troubleshooting and diagnosis 3:2 fault finding chart - variable geometry intermittent low power engine does not run smoothly low power at low engine speed t urbocharger noisy poor acceleration engine lacks power engine overheats intermittent engine braking reduced braking coo...

Page 22: Fault Finding Chart

He341ve service manual troubleshooting and diagnosis 3:3 fault finding chart - variable geometry intermittent low power engine does not run smoothly low power at low engine speed t urbocharger noisy poor acceleration engine lacks power engine overheats intermittent engine braking reduced braking coo...

Page 23: Fault Finding Chart

He341ve service manual troubleshooting and diagnosis fault finding chart - variable geometry 3:4 intermittent low power engine does not run smoothly low power at low engine speed t urbocharger noisy poor acceleration engine lacks power engine overheats intermittent engine braking reduced braking coo...

Page 24: Service Tools

Dial gauge and dial gauge adapter -0+ 10 10 20 20 30 30 40 40 50 mercer type 20 steel rule vernier caliper allen key stopwatch 60 5 10 15 20 25 30 35 40 45 50 55 he341ve service manual component testing and replacement service tools 4:1 the following special tools are recommended to perform procedur...

Page 25: Service Tools

He341ve service manual component testing and replacement service tools 4:2 the following special tools are recommended to perform procedures in this manual. The use of these tools is shown in the appropriate procedure. These tools can be purchased from your local authorised repair location. Part no....

Page 26: On Engine Checks

Oil leakage m12 x 1.5 replacement seals and adapters should be fitted without sealant as this can contaminate the oil. Torque tighten adapter to value specified by engine manufacturer. It is important to avoid kinked or worn pipes during servicing and subsequent operation. He341ve service manual com...

Page 27

Visual checks make visual check for damaged or bent blades. Replace turbocharger if damaged or bent. He341ve service manual component testing and replacement 4:4 make visual check for damaged and fouling of impeller blades. Replace turbocharger if damaged or bent. M10 x 1.0 (16 mm) repair actuator c...

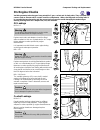

Page 28

Check speed sensor, position sensor and actuator wiring and connectors for damage and bad connections. Remake connections and if fault persists repair wiring by replacement. M6 x 1.0 (8 mm) where it is not possible to remove 4-bolt actuator coverplate on engine due to space claim constraints, it mig...

Page 29

He341ve service manual component testing and replacement 4:6 if actuator rod travel is within permissible range shown in service data sheet check pivot block is free to rotate and move axially on cross shaft pin. If pivot block is seized or if force is required to move pivot block on pin remove bloc...

Page 30

M6 x 1 (8 mm) where ecm indicates a speed sensor fault and no wiring or connector problems are found refer to speed sensor check and removal for further health checks. Replace sensor by refering to speed sensor replacement . He341ve service manual component testing and replacement 4:7 caution never ...

Page 31: Bearing Clearance

Secure the turbine housing and check the axial clearance at compressor impeller nose using a dial gauge. Ensure clearance is within min/max values shown on service data sheet . If axial clearance does not meet specification replace the turbocharger. He341ve service manual component testing and repla...

Page 32

Where space claim allows, position sensor checks and removal should be done on engine. If this is not possible, remove actuator by reference to actuator check and removal . If actuator removal is not possible, remove turbocharger from engine. He341ve service manual component testing and replacement ...

Page 33

M4 x 0.7 (3 mm) where an electrical fault is diagnosed or correct actuation is confirmed, use a socket wrench and rachet to loosen and remove 2 socket head screws. He341ve service manual component testing and replacement 4:10 extract the position sensor and refer to position sensor replacement . App...

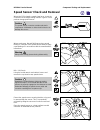

Page 34: Position Sensor Replacement

The sensor flange features a mechanical baulk (tab) to ensure correct sensor orientation. First ensure o ring seal is greased and in position. Engage sensor on to flatted shaft then locate flange baulk into housing face location. He341ve service manual component testing and replacement position sens...

Page 35: Actuator Check and Removal

The engine control module (ecm) features a key-on calibration check of the vg actuation system. When combined with electro-mechanical checks, it will potentially detect faults in: • vg mechanism • vg actuator • position sensor turbocharger speed exhaust outlet pressure actuator position actuator con...

Page 36

Carefully slide actuator rod from slot location with pivot block. He341ve service manual component testing and replacement 4:13 remove actuator. Apply system voltage to actuator motor through on/off switch. If actuator travel is outside range shown in service data sheet , remove actuator. 20 10 actu...

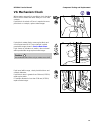

Page 37: Vg Mechanism Check

If pin travel within range, check pivot block bore and crankpin diameter. If pivot block bore is greater than 6.04 mm (0.238 in) replace pivot block. If crankpin diameter is less than 5.99 mm (0.236 in) replace turbocharger. He341ve service manual component testing and replacement vg mechanism check...

Page 38: Remote Actuator Check

Apply system voltage to actuator motor through on/off switch. Switch voltage to retract and extend actuator rod. Check actuation cycle can be completed in 5 seconds. He341ve service manual component testing and replacement remote actuator check 4:15 if any of three test results are outside specified...

Page 39: Actuator Replacement

He341ve service manual component testing and replacement actuator replacement 4:16 assemble three fasteners loosely in sequence. 1 2 3 actuator service kits are available (121). Used actuators may be refitted depending on ecm fault diagnostics and confirmatory turbocharger investigations using the p...

Page 40

Use a calibrated torque wrench to tighten three screws in sequence to value specified in service data sheet . 1 2 3 he341ve service manual component testing and replacement 4:17 at this stage, prior to fitting coverplate. It is possible to verify correct actuator movement. Apply system voltage to ac...

Page 41

Ensure rotor assembly freely rotates prior to engine mounting. He341ve service manual component testing and replacement 4:18 caution ensure dataplate label is transferred from old to new actuator to maintain record of essential turbocharger information..

Page 42

Where the ecm signals a speed signal error, check the connection to the engine wiring harness is good. If error persists change speed sensor. He341ve service manual component testing and replacement speed sensor check and removal 4:19 m6 x 1.0 (8 mm) using the socket wrench and ratchet, loosen and r...

Page 43: Speed Sensor Replacement

Speed sensor kits (124) are available. Prior to inserting speed sensor ensure it is clean and unable to collect magnetic particles as it is inserted. Ensure the o-ring seal is in position on the sensor body. The o-ring moves automatically into its fitted position during insertion. He341ve service ma...

Page 44: Holset He341Ve

Holset he341ve service manual cummins turbo technologies ltd. Aftermarket division croset avenue huddersfield west yorkshire hd1 6se www.Holsetaftermarket.Com copyright 2007, cummins turbo technologies ltd. All rights reserved. Vgt, command valve and super mwe are trade marks of cummins turbo techno...