- DL manuals

- IAI

- Controller

- ACON-C

- Operation Manual

IAI ACON-C Operation Manual

Summary of ACON-C

Page 1

Ethernet/ip iai america inc. Operation manual, fourth edition acon-c/cg pcon-c/cg/ca/cfa scon-ca.

Page 3: Please Read Before Use

Please read before use thank you for purchasing our product. This operation manual explains the handling methods, structure and maintenance of this product, among others, providing the information you need to know to use the product safely. Before using the product, be sure to read this manual and f...

Page 5

Table of contents safety guide....................................................................................................................................................1 handling precautions ......................................................................................................

Page 6

3.6 communicating with the master station......................................................................................93 3.6.1 operation modes and corresponding plc i/o areas........................................................93 3.6.2 remote i/o mode (number of occupied bytes: 2) .........

Page 7

5.2 example of connection settings with keyence’s master ......................................................... 276 5.2.1 connection example ....................................................................................................... 276 5.2.2 setting the controller.......................

Page 9

1 safety guide “safety guide” has been written to use the machine safely and so prevent personal injury or property damage beforehand. Make sure to read it before the operation of this product. Safety precautions for our products the common safety precautions for the use of any of our robots in each...

Page 10

2 no. Operation description description 2 transportation Ɣ when carrying a heavy object, do the work with two or more persons or utilize equipment such as crane. Ɣ when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate...

Page 11

3 no. Operation description description (2) cable wiring Ɣ use our company’s genuine cables for connecting between the actuator and controller, and for the teaching tool. Ɣ do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not coil it around. Do not insert it. Do not put any h...

Page 12

4 no. Operation description description 4 installation and start (4) safety measures Ɣ when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. Ɣ when the product...

Page 13

5 no. Operation description description 6 trial operation Ɣ when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. Ɣ after the teaching or programming operation...

Page 14

6 no. Operation description description 8 maintenance and inspection Ɣ when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. Ɣ perform the work out of the safe...

Page 15: Alert Indication

7 alert indication the safety precautions are divided into “danger”, “warning”, “caution” and “notice” according to the warning level, as follows, and described in the operation manual for each model. Level degree of danger and damage symbol danger this indicates an imminently hazardous situation wh...

Page 16

8 handling precautions 1. It is recommended that the baud rate be set based on auto negotiation. Make sure the link setting of the ethernet/ip unit matches the communication mode set for the connected switching hub. If not, the link becomes unstable and communication cannot be performed properly. It...

Page 17

1. Overview 9 1. Overview ethernet/ip is an open field network. It is a standardized global open network specified by the iec 61158 series of international standards. You can connect acon, pcon and scon-ca controllers (hereinafter referred to as “the controllers”) to ethernet/ip to build a system wi...

Page 18

1. Overview 10 1.1 ethernet/ip specifications item specification communication standards iec61158 (ieee802.3) baud rate 10base-t/100 base-t (auto negotiation setting is recommended.) communication cable length refer to ethernet/ip specifications (the distance between the hub and each node must be wi...

Page 19

2. Acon-c/cg, pcon-c/cg 11 2. Acon-c/cg, pcon-c/cg 2.1 operation modes and functions acon and pcon controllers equipped with ethernet/ip can be operated in the following five operational modes: operation modes and main functions main functions remote i/o mode position/ simplified direct value mode h...

Page 20

2. Acon-c/cg, pcon-c/cg 12 [2] position/simplified direct value mode: in this operation mode, ethernet/ip communication is used to select and command movements that have been predefined in the controller’s position data table. Alternatively, this mode also allows the target position to be establishe...

Page 21

2. Acon-c/cg, pcon-c/cg 13 [4] full direct value mode: in this operation mode, all values regarding position control (“target position,” "speed” and "acceleration/deceleration,” etc.) are directly established. Number of occupied bytes: 32 bytes [5] remote i/o mode 2: in this operation method, ethern...

Page 22

2. Acon-c/cg, pcon-c/cg 14 2.2 model numbers the model numbers of acon and pcon applicable to ethernet/ip are described as follows. Ɣ acon-c/cg- -ep- Ɣ pcon-c/cg- -ep- front panel color printed series name y acon y pcon y acon: dark blue y pcon: dark green.

Page 23

2. Acon-c/cg, pcon-c/cg 15 2.3 ethernet/ip interface 2.3.1 names of the parts the names of each section related to ethernet/ip are described as follows. 05 .'& /5 .'& status indicator leds ethernet/ip port status leds.

Page 24

2. Acon-c/cg, pcon-c/cg 16 2.3.2 monitor led indications the slave condition (each controller), as well as network condition, can be checked using the two leds, ms and ns, provided on the front panel of the controller. The description of each is explained in the following table. ٤ : illuminating, ...

Page 25

2. Acon-c/cg, pcon-c/cg 17 8 1 2.4 wiring example 2.4.1 connection diagram * ethernet cable: straight cable of category 5e or above, 100 m max (aluminum tape and braided double-shielded cable are recommended.) (note) terminal processing is not required. 2.4.2 connector pin layout pin number signal n...

Page 26

2. Acon-c/cg, pcon-c/cg 18 2.5 setting using the teaching tool, set controller parameters. Set the mode toggle switch on the front panel of the controller to “manu” side. The versions of teaching tool compatible with ethernet/ip are as follows: x rc pc-compatible software: v8.02.00.00 or later x con...

Page 27

2. Acon-c/cg, pcon-c/cg 19 2.5.4 setting the subnet mask set parameter no. 141, “snmk: subnet mask.” set the same value you have set in the master unit and other slaves (on the same network). [refer to 2.9, “ethernet/ip parameters.”] settable range: 0.0.0.0 to 255.255.255.255 (the factory setting is...

Page 28

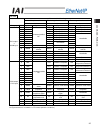

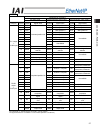

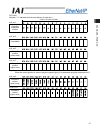

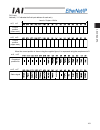

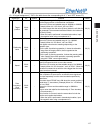

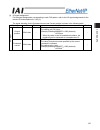

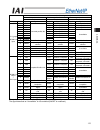

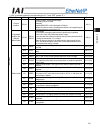

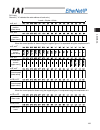

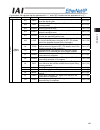

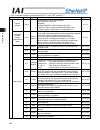

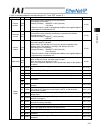

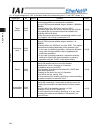

2. Acon-c/cg, pcon-c/cg 20 2.6 communicating with the master station 2.6.1 operation modes and corresponding plc i/o areas the addresses allocated for each operation mode are described as follows. X plc output o acon/pcon input (* “n” indicates the first output address of each axis.) di on the acon ...

Page 29

2. Acon-c/cg, pcon-c/cg 21 x acon/pcon outputoplc input side (* “n” indicates the first input address of each axis.) do on the acon or pcon side and output data register remote i/o mode position/simplified direct value mode half direct value mode full direct value mode remote i/o mode 2 plc input ar...

Page 30

2. Acon-c/cg, pcon-c/cg 22 2.6.2 remote i/o mode (number of occupied bytes: 2) in this operation method, ethernet/ip communications is used to mimic the operation of hardware pio (24v i/o). Set the position data using compatible teaching tools. The number of operable positions varies depending on th...

Page 31

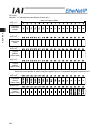

2. Acon-c/cg, pcon-c/cg 23 (1) plc address configuration (* “n” indicates the first address of each axis.) parameter no.84 acon/pcon side di (port no.) plc side output address (bytes) acon/pcon side do (port no.) plc side input address (bytes) 0 0 to 15 n+0, n+1 0 to 15 n+0, n+1 (note) be careful of...

Page 32

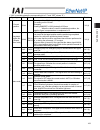

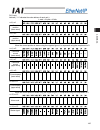

2. Acon-c/cg, pcon-c/cg 24 (3) i/o signal assignment the controller's i/o port signal varies depending on the parameter no. 25 setting. (refer to operation manual for the controller main body for more information.) acon parameter no. 25 setting positioning mode teaching mode 256-point mode 0 1 2 cat...

Page 33

2. Acon-c/cg, pcon-c/cg 25 acon parameter no. 25 setting 512-point mode electromagnetic valve mode 1 electromagnetic valve mode 2 3 4 5 category port no. Symbol signal name symbol signal name symbol signal name 0 pc1 st0 start position 0 st0 start position 0 1 pc2 st1 start position 1 st1 start posi...

Page 34

2. Acon-c/cg, pcon-c/cg 26 pcon parameter no. 25 setting positioning mode teaching mode 256-point mode 0 1 2 category port no. Symbol signal name symbol signal name symbol signal name 0 pc1 pc1 pc1 1 pc2 pc2 pc2 2 pc4 pc4 pc4 3 pc8 pc8 pc8 4 pc16 pc16 pc16 5 pc32 command position no. Pc32 command po...

Page 35

2. Acon-c/cg, pcon-c/cg 27 pcon parameter no. 25 setting 512-point mode electromagnetic valve mode 1 electromagnetic valve mode 2 3 4 5 category port no. Symbol signal name symbol signal name symbol signal name 0 pc1 st0 start position 0 st0 start position 0 1 pc2 st1 start position 1 st1 start posi...

Page 36

2. Acon-c/cg, pcon-c/cg 28 2.6.3 position/simplified direct value mode (number of occupied bytes: 8) in this operation mode, ethernet/ip communication is used to select and command movements that have been predefined in the controller’s position data table. Alternatively, through use of a pmod signa...

Page 37

2. Acon-c/cg, pcon-c/cg 29 (2) i/o signal allocation for each axis the i/o signals of each axis consist of four input words (4 words = 8 bytes) and four output words in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current posit...

Page 38

2. Acon-c/cg, pcon-c/cg 30 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits current position (lower word) current position (upper word) n+0, n+1...

Page 39

2. Acon-c/cg, pcon-c/cg 31 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and ...

Page 40

2. Acon-c/cg, pcon-c/cg 32 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit - current position: 32-bit signed integer. The setting unit is 0.01mm. (example) reading:000003ff h =1023 (decimal)=10.23mm * when ...

Page 41

2. Acon-c/cg, pcon-c/cg 33 2.6.4 half direct value mode (number of occupied bytes: 16) this is the operation mode with the target position, positioning band, speed, acceleration/deceleration and pressing current value set up in the plc. Set each value in the i/o areas. When the zone function is used...

Page 42

2. Acon-c/cg, pcon-c/cg 34 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (8 words = 16 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position...

Page 43

2. Acon-c/cg, pcon-c/cg 35 plc output address (* “n” indicates the first output address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits target position (lower word) target position (upper word) n+2, n+3 ...

Page 44

2. Acon-c/cg, pcon-c/cg 36 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complemen...

Page 45

2. Acon-c/cg, pcon-c/cg 37 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and ...

Page 46

2. Acon-c/cg, pcon-c/cg 38 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details pressing current-limiting value 16-bit data - 16-bit integer specify the current-limiting value to be used during pressing operation. The allowable specifi...

Page 47

2. Acon-c/cg, pcon-c/cg 39 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading: 000003ff h =1023 (decim...

Page 48

2. Acon-c/cg, pcon-c/cg 40 2.6.5 full direct value mode (number of occupied bytes: 32) this is the operation mode with all the values (target position, speed, etc.) set up directly using values from plc. Set each value in the i/o area. The robot cylinder's effective main functions that can be contro...

Page 49

2. Acon-c/cg, pcon-c/cg 41 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (16 words = 32 bytes) and one output word in the i/o areas. Z control signals 1 and 2 and status signals are on/off bit signals. Z the target position and current position are ex...

Page 50

2. Acon-c/cg, pcon-c/cg 42 plc output address (* “n” indicates the first output address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. When the zone boundary is shown using the negative figure, it is expressed using the compleme...

Page 51

2. Acon-c/cg, pcon-c/cg 43 address (* “n” indicates the first output address of each axis.) when the zone boundary is shown using the negative figure, it is expressed using the complement of 2. (*1) signal assignment for b10 of n+28, n+29 (*2) signal assignment for b7 and b6 of n+28, n+29 symbol sym...

Page 52

2. Acon-c/cg, pcon-c/cg 44 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complemen...

Page 53

2. Acon-c/cg, pcon-c/cg 45 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer indicating the current position set the target position on the absolute coord...

Page 54

2. Acon-c/cg, pcon-c/cg 46 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) address bit symbol function details acceleration 16-bit data - deceleration 16-bit data - 16-bit integer specify the acceleration and deceleration at which to move the actuator. The unit is 0.01g...

Page 55

2. Acon-c/cg, pcon-c/cg 47 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) address bit symbol function details b5 b4 - unavailable - b3 inc incremental command: absolute position commands are issued when this signal is off, and incremental position commands are issued w...

Page 56

2. Acon-c/cg, pcon-c/cg 48 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading:000003ff h =1023 (decima...

Page 57

2. Acon-c/cg, pcon-c/cg 49 2.6.6 remote i/o mode 2 (number of occupied bytes: 12) in this operation method, ethernet/ip communications is used to mimic the operation of hardware pio (24v i/o). Set the position data using the teaching tools. The number of operable positions varies depending on the pa...

Page 58

2. Acon-c/cg, pcon-c/cg 50 (1) plc address configuration (* “n” indicates the first address of each axis.) parameter no.84 acon/pcon side di and input register plc side output address (bytes) acon/pcon side do and output register plc side input address (bytes) port no.0 to 15 n, n+1 port no.0 to 15 ...

Page 59

2. Acon-c/cg, pcon-c/cg 51 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits controller output port number unavailable current position (lower wo...

Page 60

2. Acon-c/cg, pcon-c/cg 52 (3) i/o signal assignment for the signal assignments corresponding to each pio pattern, refer to the i/o signal assignments for the remote i/o mode explained in 2.6.2 (3). The signal allocation for the command current and current position is shown in the following table. S...

Page 61

2. Acon-c/cg, pcon-c/cg 53 2.6.7 i/o signal controls and function * on indicates that the applicable bit signal is “1”, while off indicates that the bit signal is “0”. The i/o control and functions used in the position/simplified direct value mode, half direct value mode and full direct value mode, ...

Page 62

2. Acon-c/cg, pcon-c/cg 54 (5) servo on command (son) plc output signal operation preparation end (sv) plc input signal when the son signal is turned on, the servo will turn on. When “son” signal is turned “on”, the servo-motor is turned “on”. When the servo-motor is turned on, the status indicator ...

Page 63

2. Acon-c/cg, pcon-c/cg 55 (6) home return (home) plc output signal home return completion (hend) plc input signal under home return operation (ghms) plc input signal when the “home” signal is turned “on”, this command is processed at the startup (on edge), and the home return operation is performed...

Page 64

2. Acon-c/cg, pcon-c/cg 56 (7) positioning start (cstr): used in the position/simple direct mode plc output signal this signal is processed at the startup (on edge) and the positioning is performed to the target position with the specified position no. Or set using the plc's target position register...

Page 65

2. Acon-c/cg, pcon-c/cg 57 travel speed positioning band time target position timing at which the position complete signal turns on (10) positioning completion signal (pend) plc input signal this signal is turned “on” when the actuator is moved to the target position and reaches the positioning band...

Page 66

2. Acon-c/cg, pcon-c/cg 58 zone signal + direction actuator operation home zone setting - zone setting + (12) zone 1 (zone1) plc input signal zone 2 (zone2) plc input signal position zone (pzone) plc input signal these signals are turned on when the current position of the actuator is within the set...

Page 67

2. Acon-c/cg, pcon-c/cg 59 (13) +jog (jog+) plc output signal –jog (jog–) plc output signal this signal is the command for the jog operation startup or inching operation startup. If a + command is issued, the actuator will operate in the direction opposite home. When a – command is issued, the actua...

Page 68

2. Acon-c/cg, pcon-c/cg 60 (14) jog-speed/inch-distance switching (jvel) plc output signal this change-over signal is used for the parameters specifying the jog speed when the jog operation is selected or the inching distance when the inching operation is selected. The relationship is as follows. Jv...

Page 69

2. Acon-c/cg, pcon-c/cg 61 (16) teaching mode command (mode) plc output signal teaching mode signal (modes) plc input signal when the mode signal is turned “on”, the normal operation mode is changed to the teaching mode. When the mode for the controllers for each actuator is changed to the teaching ...

Page 70

2. Acon-c/cg, pcon-c/cg 62 speed travel positioning band positioning band positioning band dir = off target position dir = on (19) operating mode selector (rmod) plc output signal operation mode status (rmds) plc input signal the operation mode is selected with the rmod signal and the mode switch lo...

Page 71

2. Acon-c/cg, pcon-c/cg 63 (23) pressing and a miss (psfl) plc input signal in the case that the pressing operation was performed, and the actuator moved the travel distance set in the controller position table positioning band or set using the plc's positioning band register, but it was not pushed ...

Page 72

2. Acon-c/cg, pcon-c/cg 64 (26) load output judgment (load) plc input signal dedicated pcon function this signal is available only in the pressing operation. When this signal is used for pressing-in purpose, it should be known if the set load threshold is reached during the pressing operation. The l...

Page 73

2. Acon-c/cg, pcon-c/cg 65 target position travel speed position where the actuator is pushed against the work part and the pressing completion is judged so the positioning completion signal is turned “on” range where the trqs signal is output. Positioning band (max. Pressing level) (27) torque leve...

Page 74

2. Acon-c/cg, pcon-c/cg 66 (28) stopping control mode (smod) plc output signal dedicated pcon function one of the pulse motor general characteristics is that that the holding current in the stop mode is larger than that for the ac servo-motor. Because of this, when the stop time is longer at the sta...

Page 75

2. Acon-c/cg, pcon-c/cg 67 setting: 50 setting: 100 setting: 10 (29) acceleration/deceleration mode (mod1ޔmod0) plc output signal dedicated acon function this signal is used to select the acceleration/deceleration pattern characteristics. Select one of them before the actuator movement command. Mod1...

Page 76

2. Acon-c/cg, pcon-c/cg 68 caution: [1] even if a position command or direct value command with s-shaped motion setting is issued when the actuator is running, s-shaped motion control will not be executed. Issue these commands when the actuator is stopped. [2] when the index mode is set on the rotar...

Page 77

2. Acon-c/cg, pcon-c/cg 69 (30) stop mode selection (aso1, aso0) plc output signal select the stop mode for the duration before the movement to the next position after a positioning is completed. If the duration for a stop is long, the system automatically turns the servo off to reduce the power con...

Page 78

2. Acon-c/cg, pcon-c/cg 70 plc sequence program control signal status signal acon, pcon control signal status signal master station o slave transmission delay time (yt) slave o master station transmission delay time (xt) command processing time 2.7 i/o signal timings when any of the control signal i...

Page 79

2. Acon-c/cg, pcon-c/cg 71 2.8 operation the timings for the basic operation examples in the position/simplified direct value mode, half direct value mode and full direct value mode, are described. For the remote i/o mode and remote i/o mode 2, refer to the controller’s operational manual. (in remot...

Page 80

2. Acon-c/cg, pcon-c/cg 72 * t1: considering the scanning time of the host controller, set it so that “t1 0ms”. * yt+xt tdpf yt+xt+3 (msec) [7] [1] [2] [3] [4] [5] [6] * set value of target position data specific position number positioning start positioning completion current position moving ...

Page 81

2. Acon-c/cg, pcon-c/cg 73 (2) operation in the half direction mode it is operated with the data set in the plc's target position register, positioning band register, setup speed register, acceleration/deceleration register and pressing current-limiting setup register. Z example of operation (pressi...

Page 82

2. Acon-c/cg, pcon-c/cg 74 *t1: considering the scanning time of the host controller, set it so that “t1 0ms”. *yt+xt tdpf yt+xt+3(msec) positioning band [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [14] [13] set value of target position data set value of positioning band data set value ...

Page 83

2. Acon-c/cg, pcon-c/cg 75 (3) operation in the full direct mode the actuator is operated by specifying all conditions required for positioning such as the target position resister and positioning band resister of the plc. Z example of operation (pressing operation) [1] set the target position data ...

Page 84

2. Acon-c/cg, pcon-c/cg 76 [1] [2] [3] [4] [5] [6] [7] [8] set value of target position data set value of positioning band data set value of speed data set value of position zone boundary data set value of acceleration data set value of deceleration data set value of pressing current-limiting value ...

Page 85

2. Acon-c/cg, pcon-c/cg 77 *t1: considering the scanning time of the host controller, set it so that “t1 0ms”. *yt+xt tdpf yt+xt+3 (msec) [9] [10] [11] [12] [13] [17] [16] [15] [14] pressing specification push direction specification positioning command positioning completion/ pressing and a m...

Page 86

2. Acon-c/cg, pcon-c/cg 78 [1] [2] [3] actuator speed speed n2 speed n3 set value of speed or acceleration/deceleration (4) data change during movement in the half direct mode or full direct mode, the value currently set to a given resister among the resisters for target position data, acceleration/...

Page 87

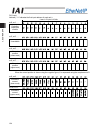

2. Acon-c/cg, pcon-c/cg 79 2.9 ethernet/ip related parameters parameters relating to ethernet/ip are no. 84, no. 86 to 87, no. 90 and no. 140 to 142. Category: c: external interface parameter no. Category symbol name default value set in the factory before delivery 1 ~ 83 refer to operation manual f...

Page 88

2. Acon-c/cg, pcon-c/cg 80 z network type (no.87 ntyp) the network module type is set for the parameter no. 87. Do not change the default value. Z field i/o format (no.90 fmio) addresses in the plc are assigned in units of 16 points (2 bytes) based on the node address set in the controller and the o...

Page 89

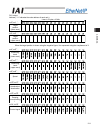

2. Acon-c/cg, pcon-c/cg 81 (example ii) set value = “1” z indicates on, while c indicates off acon, pcon input resister acon, pcon output resister hexadecimal data hexadecimal data hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 90

2. Acon-c/cg, pcon-c/cg 82 (example iii) set value = “2” z indicates on, while c indicates off acon, pcon input resister acon, pcon output resister hexadecimal data hexadecimal dat a hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 91

2. Acon-c/cg, pcon-c/cg 83 (example iv) set value = “3” z indicates on, while c indicates off acon, pcon input resister acon, pcon output resister hexadecimal data hexadecimal data hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 92

2. Acon-c/cg, pcon-c/cg 84 z ip address (no. 140: ipad) specify the ip address in parameter no. 140. Setting range: 0.0.0.0 to 255.255.255.255 (factory setting: 192.168.0.1) (note) when this parameter is set to 0.0.0.0, dhcp is enabled. Manual setting is recommended. Z subnet mask (no. 141: snmk) sp...

Page 93

3. Scon-ca/cf a 85 3. Pcon-ca/cfa 3.1 operation modes and functions pcon-ca/cfa controllers equipped with ethernet/ip can be operated in the following five operational modes: operation modes and main functions main functions remote i/o mode position/ simplified direct value mode half direct value mo...

Page 94

3. Scon-ca/cf a 86 [2] position/simplified direct value mode: in this operation mode, ethernet/ip communication is used to select and command movements that have been predefined in the controller’s position data table. Alternatively, this mode also allows the target position to be established direct...

Page 95

3. Scon-ca/cf a 87 [4] full direct value mode: in this operation mode, all values regarding position control (“target position,” "speed” and "acceleration/deceleration,” etc.) are directly established. Number of occupied bytes: 32 bytes [5] remote i/o mode 2: in this operation method, ethernet/ip co...

Page 96

3. Scon-ca/cf a 88 3.2 model numbers the model numbers of pcon-ca/cfa applicable to ethernet/ip are described as follows. Ɣ pcon-ca- -ep- Ɣ pcon-cfa- -ep- front panel color printed series name y pcon y pcon-ca : dark green y pcon-cfa : light green.

Page 97

3. Scon-ca/cf a 89 3.3 ethernet/ip interface 3.3.1 names of the parts the names of each section related to ethernet/ip are described as follows. 3.3.2 monitor led indications the slave condition (each controller), as well as network condition, can be checked using the two leds, ms and ns, provided o...

Page 98

3. Scon-ca/cf a 90 8 1 3.4 wiring example 3.4.1 connection diagram * ethernet cable: straight cable of category 5e or above, 100 m max (aluminum tape and braided double-shielded cable are recommended.) (note) terminal processing is not required. 3.4.2 connector pin layout pin number signal name sign...

Page 99

3. Scon-ca/cf a 91 3.5 setting using the teaching tool, set controller parameters. Set the mode toggle switch on the front panel of the controller to “manu” side. Refer to the instruction manual for each teaching tool for the applicable version of the teaching tool that can be applied to ethernet/ip...

Page 100

3. Scon-ca/cf a 92 3.5.4 setting the subnet mask set parameter no. 141, “snmk: subnet mask.” set the same value you have set in the master unit and other slaves (on the same network). [refer to 3.9, “ethernet/ip parameters.”] settable range: 0.0.0.0 to 255.255.255.255 (the factory setting is 255.255...

Page 101

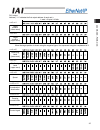

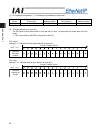

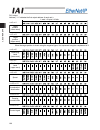

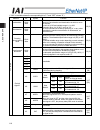

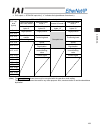

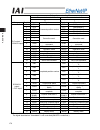

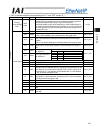

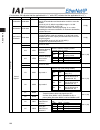

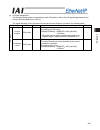

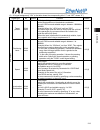

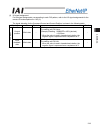

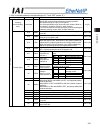

3. Scon-ca/cf a 93 3.6 communicating with the master station 3.6.1 operation modes and corresponding plc i/o areas the addresses allocated for each operation mode are described as follows. X plc output o pcon-ca/cfa input (* “n” indicates the first output address of each axis.) di on the pcon-ca/cfa...

Page 102

3. Scon-ca/cf a 94 x pcon-ca/cfa outputoplc input side (* “n” indicates the first input address of each axis.) do on the pcon-ca/cfa side and output data register remote i/o mode position/simplified direct value mode half direct value mode full direct value mode remote i/o mode 2 plc input area (byt...

Page 103

3. Scon-ca/cf a 95 3.6.2 remote i/o mode (number of occupied bytes: 2) in this operation method, ethernet/ip communications is used to mimic the operation of hardware pio (24v i/o). Set the position data using compatible teaching tools. The number of operable positions varies depending on the parame...

Page 104

3. Scon-ca/cf a 96 (1) plc address configuration (* “n” indicates the first address of each axis.) parameter no.84 pcon-ca/cfa side di (port no.) plc side output address (bytes) pcon-ca/cfa side do (port no.) plc side input address (bytes) 0 0 to 15 n+0, n+1 0 to 15 n+0, n+1 (note) be careful of usi...

Page 105

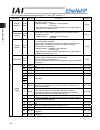

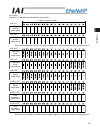

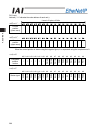

3. Scon-ca/cf a 97 (3) i/o signal assignment the controller's i/o port signal varies depending on the parameter no. 25 setting. (refer to operation manual for the controller main body for more information.) parameter no. 25 setting positioning mode teaching mode 256-point mode 0 1 2 category port no...

Page 106

3. Scon-ca/cf a 98 parameter no. 25 setting 512-point mode electromagnetic valve mode 1 electromagnetic valve mode 2 3 4 5 category port no. Symbol signal name symbol signal name symbol signal name 0 pc1 st0 start position 0 st0 start position 0 1 pc2 st1 start position 1 st1 start position 1 2 pc4 ...

Page 107

3. Scon-ca/cf a 99 3.6.3 position/simplified direct value mode (number of occupied bytes: 8) in this operation mode, ethernet/ip communication is used to select and command movements that have been predefined in the controller’s position data table. Alternatively, through use of a pmod signal, this ...

Page 108

3. Scon-ca/cf a 100 (2) i/o signal allocation for each axis the i/o signals of each axis consist of four input words (4 words = 8 bytes) and four output words in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are...

Page 109

3. Scon-ca/cf a 101 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits current position (lower word) current position (upper word) n+0, n+1 n+2, n...

Page 110

3. Scon-ca/cf a 102 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settabl...

Page 111

3. Scon-ca/cf a 103 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit - current position: 32-bit signed integer. The setting unit is 0.01mm. (example) reading:000003ff h =1023 (decimal)=10.23mm * when the val...

Page 112

3. Scon-ca/cf a 104 3.6.4 half direct value mode (number of occupied bytes: 16) this is the operation mode with the target position, positioning band, speed, acceleration/deceleration and pressing current value set up in the plc. Set each value in the i/o areas. When the zone function is used, set i...

Page 113

3. Scon-ca/cf a 105 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (8 words = 16 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are ex...

Page 114

3. Scon-ca/cf a 106 plc output address (* “n” indicates the first output address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits target position (lower word) target position (upper word) n+2, n+3 n+0, n+...

Page 115

3. Scon-ca/cf a 107 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complement of 2....

Page 116

3. Scon-ca/cf a 108 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settabl...

Page 117

3. Scon-ca/cf a 109 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details pressing current-limiting value 16-bit data - 16-bit integer specify the current-limiting value to be used during pressing operation. The allowable specification ...

Page 118

3. Scon-ca/cf a 110 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading: 000003ff h =1023 (decimal) =10...

Page 119

3. Scon-ca/cf a 111 3.6.5 full direct value mode (number of occupied bytes: 32) this is the operation mode with all the values (target position, speed, etc.) set up directly using values from plc. Set each value in the i/o area. The robot cylinder's effective main functions that can be controlled us...

Page 120

3. Scon-ca/cf a 112 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (16 words = 32 bytes) and one output word in the i/o areas. Z control signals 1 and 2 and status signals are on/off bit signals. Z the target position and current position are expressed...

Page 121

3. Scon-ca/cf a 113 plc output address (* “n” indicates the first output address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. When the zone boundary is shown using the negative figure, it is expressed using the complement of 2...

Page 122

3. Scon-ca/cf a 114 address (* “n” indicates the first output address of each axis.) when the zone boundary is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits control signal 2 acceleration deceleration pressing current-limiti ng value load curren...

Page 123

3. Scon-ca/cf a 115 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complement of 2....

Page 124

3. Scon-ca/cf a 116 address (* “n” indicates the first input address of each axis.) 1 word = 2 bytes = 16 bits n+20, n+21 b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0 total moving count (slave word) 32 ,7 68 16 ,3 84 8, 19 2 4, 09 6 2, 04 8 1, 02 4 51 2 25 6 12 8 64 32 16 8 4 2 1 n+22, n+23...

Page 125

3. Scon-ca/cf a 117 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer indicating the current position set the target position on the absolute coordinates....

Page 126

3. Scon-ca/cf a 118 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) address bit symbol function details acceleration 16-bit data - deceleration 16-bit data - 16-bit integer specify the acceleration and deceleration at which to move the actuator. The unit is 0.01g and se...

Page 127

3. Scon-ca/cf a 119 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) address bit symbol function details b2 dir pressing direction specification: “off” for the direction reducing the positioning band from the target position “on” for the direction adding the positioning ...

Page 128

3. Scon-ca/cf a 120 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading:000003ff h =1023 (decimal) =10....

Page 129

3. Scon-ca/cf a 121 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details b15 emgs emergency stop: an emergency stop is actuated when this signal turns on. 3.6.7 (2) b14 pwr controller ready : this signal turns on when the controller be...

Page 130

3. Scon-ca/cf a 122 3.6.6 remote i/o mode 2 (number of occupied bytes: 12) in this operation method, ethernet/ip communications is used to mimic the operation of hardware pio (24v i/o). Set the position data using the teaching tools. The number of operable positions varies depending on the parameter...

Page 131

3. Scon-ca/cf a 123 (1) plc address configuration (* “n” indicates the first address of each axis.) parameter no.84 pcon-ca/cfa side di and input register plc side output address (bytes) pcon-ca/cfa side do and output register plc side input address (bytes) port no.0 to 15 n, n+1 port no.0 to 15 n, ...

Page 132

3. Scon-ca/cf a 124 plc input address (* “n” indicates the first input address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits controller output port number unavailable current position (lower word) cur...

Page 133

3. Scon-ca/cf a 125 (3) i/o signal assignment for the signal assignments corresponding to each pio pattern, refer to the i/o signal assignments for the remote i/o mode explained in 3.6.2 (3). The signal allocation for the command current and current position is shown in the following table. Signal t...

Page 134

3. Scon-ca/cf a 126 3.6.7 i/o signal controls and function * on indicates that the applicable bit signal is “1”, while off indicates that the bit signal is “0”. The i/o control and functions used in the position/simplified direct value mode, half direct value mode and full direct value mode, are des...

Page 135

3. Scon-ca/cf a 127 (5) servo on command (son) plc output signal operation preparation end (sv) plc input signal when the son signal is turned on, the servo will turn on. When “son” signal is turned “on”, the servo-motor is turned “on”. When the servo-motor is turned on, the status indicator led (re...

Page 136

3. Scon-ca/cf a 128 (6) home return (home) plc output signal home return completion (hend) plc input signal under home return operation (ghms) plc input signal when the “home” signal is turned “on”, this command is processed at the startup (on edge), and the home return operation is performed automa...

Page 137

3. Scon-ca/cf a 129 (7) positioning start (cstr): used in the position/simple direct mode plc output signal this signal is processed at the startup (on edge) and the positioning is performed to the target position with the specified position no. Or set using the plc's target position register. Wheth...

Page 138

3. Scon-ca/cf a 130 travel speed positioning band time target position timing at which the position complete signal turns on (10) positioning completion signal (pend) plc input signal this signal is turned “on” when the actuator is moved to the target position and reaches the positioning band and th...

Page 139

3. Scon-ca/cf a 131 zone signal + direction actuator operation home zone setting - zone setting + (12) zone 1 (zone1) plc input signal zone 2 (zone2) plc input signal position zone (pzone) plc input signal these signals are turned on when the current position of the actuator is within the set area a...

Page 140

3. Scon-ca/cf a 132 (13) +jog (jog+) plc output signal –jog (jog–) plc output signal this signal is the command for the jog operation startup or inching operation startup. If a + command is issued, the actuator will operate in the direction opposite home. When a – command is issued, the actuator wil...

Page 141

3. Scon-ca/cf a 133 (14) jog-speed/inch-distance switching (jvel) plc output signal this change-over signal is used for the parameters specifying the jog speed when the jog operation is selected or the inching distance when the inching operation is selected. The relationship is as follows. Jvel sign...

Page 142

3. Scon-ca/cf a 134 (16) teaching mode command (mode) plc output signal teaching mode signal (modes) plc input signal when the mode signal is turned “on”, the normal operation mode is changed to the teaching mode. When the mode for the controllers for each actuator is changed to the teaching mode, t...

Page 143

3. Scon-ca/cf a 135 speed travel positioning band positioning band positioning band dir = off target position dir = on (19) operating mode selector (rmod) plc output signal operation mode status (rmds) plc input signal the operation mode is selected with the rmod signal and the mode switch located o...

Page 144

3. Scon-ca/cf a 136 (23) pressing and a miss (psfl) plc input signal in the case that the pressing operation was performed, and the actuator moved the travel distance set in the controller position table positioning band or set using the plc's positioning band register, but it was not pushed against...

Page 145

3. Scon-ca/cf a 137 (26) load output judgment (load) plc input signal this signal is available only in the pressing operation. When this signal is used for pressing-in purpose, it should be known if the set load threshold is reached during the pressing operation. The load threshold and check range a...

Page 146

3. Scon-ca/cf a 138 target position travel speed position where the actuator is pushed against the work part and the pressing completion is judged so the positioning completion signal is turned “on” range where the trqs signal is output. Positioning band (max. Pressing level) (27) torque level (trqs...

Page 147

3. Scon-ca/cf a 139 (28) stopping control mode (smod) plc output signal one of the pulse motor general characteristics is that that the holding current in the stop mode is larger than that for the ac servo-motor. Because of this, when the stop time is longer at the standby position, the measure to r...

Page 148

3. Scon-ca/cf a 140 setting: 50 setting: 100 setting: 10 (29) acceleration/deceleration mode (mod1ޔmod0) plc output signal this signal is used to select the acceleration/deceleration pattern characteristics. Select one of them before the actuator movement command. Mod1 mod0 pattern name remarks off ...

Page 149

3. Scon-ca/cf a 141 caution: [1] even if a position command or direct value command with s-shaped motion setting is issued when the actuator is running, s-shaped motion control will not be executed. Issue these commands when the actuator is stopped. [2] when the index mode is set on the rotary actua...

Page 150

3. Scon-ca/cf a 142 (30) stop mode selection (aso1, aso0) plc output signal select the stop mode for the duration before the movement to the next position after a positioning is completed. If the duration for a stop is long, the system automatically turns the servo off to reduce the power consumptio...

Page 151

3. Scon-ca/cf a 143 plc sequence program control signal status signal pcon control signal status signal master station o slave transmission delay time (yt) slave o master station transmission delay time (xt) command processing time 3.7 i/o signal timings when any of the control signal is turned on t...

Page 152

3. Scon-ca/cf a 144 3.8 operation the timings for the basic operation examples in the position/simplified direct value mode, half direct value mode and full direct value mode, are described. For the remote i/o mode and remote i/o mode 2, refer to the operation manual for the controller main body. (i...

Page 153

3. Scon-ca/cf a 145 * t1: considering the scanning time of the host controller, set it so that “t1 0ms”. * yt+xt tdpf yt+xt+3 (msec) [7] [1] [2] [3] [4] [5] [6] * set value of target position data (plc o pcon) specific position number (plc o pcon) positioning start cstr (plc o pcon) positionin...

Page 154

3. Scon-ca/cf a 146 (2) operation in the half direction mode it is operated with the data set in the plc's target position register, positioning band register, setup speed register, acceleration/deceleration register and pressing current-limiting setup register. Z example of operation (pressing oper...

Page 155

3. Scon-ca/cf a 147 *t1: considering the scanning time of the host controller, set it so that “t1 0ms”. *yt+xt tdpf yt+xt+3(msec) positioning band [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [14] [13] set value of target position data set value of positioning band data set value of spee...

Page 156

3. Scon-ca/cf a 148 (3) operation in the full direct mode the actuator is operated by specifying all conditions required for positioning such as the target position resister and positioning band resister of the plc. Z example of operation (pressing operation) [1] set the target position data in the ...

Page 157

3. Scon-ca/cf a 149 [1] [2] [3] [4] [5] [6] [7] [8] set value of target position data set value of positioning band data set value of speed data set value of position zone boundary data set value of acceleration data set value of deceleration data set value of pressing current-limiting value set val...

Page 158

3. Scon-ca/cf a 150 *t1: considering the scanning time of the host controller, set it so that “t1 0ms”. *yt+xt tdpf yt+xt+3 (msec) [9] [10] [11] [12] [13] [17] [16] [15] [14] pressing specification push direction specification positioning command positioning completion/ pressing and a miss pen...

Page 159

3. Scon-ca/cf a 151 [1] [2] [3] actuator speed speed n2 speed n3 set value of speed or acceleration/deceleration (4) data change during movement in the half direct mode or full direct mode, the value currently set to a given resister among the resisters for target position data, acceleration/deceler...

Page 160

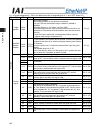

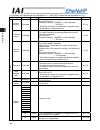

3. Scon-ca/cf a 152 3.9 ethernet/ip related parameters parameters relating to ethernet/ip are no. 84, no. 86 to 87, no. 90, no. 140 to 142 and no. 159. Category: c: external interface parameter no. Category symbol name default value set in the factory before delivery 1 ~ 83 refer to operation manual...

Page 161

3. Scon-ca/cf a 153 z network type (no.87 ntyp) the network module type is set for the parameter no. 87. Do not change the default value. Z field i/o format (no.90 fmio) addresses in the plc are assigned in units of 16 points (2 bytes) based on the node address set in the controller and the occupied...

Page 162

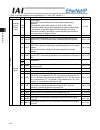

3. Scon-ca/cf a 154 (example ii) set value = “1” z indicates on, while c indicates off pcon input resister pcon output resister hexadecimal data hexadecimal data hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 163

3. Scon-ca/cf a 155 (example iii) set value = “2” z indicates on, while c indicates off pcon input resister pcon output resister hexadecimal data hexadecimal dat a hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 164

3. Scon-ca/cf a 156 (example iv) set value = “3” z indicates on, while c indicates off pcon input resister pcon output resister hexadecimal data hexadecimal data hexadecimal data hexadecimal data plc: output ch plc: input ch.

Page 165

3. Scon-ca/cf a 157 z ip address (no. 140: ipad) specify the ip address in parameter no. 140. Setting range: 0.0.0.0 to 255.255.255.255 (factory setting: 192.168.0.1) (note) when this parameter is set to 0.0.0.0, dhcp is enabled. Manual setting is recommended. Z subnet mask (no. 141: snmk) specify t...

Page 166

4. Scon-ca 158 4. Scon-ca 4.1 operation modes and functions scon-ca controllers supporting ethernet/ip can be operated in a desired operation mode selected from the following nine modes. Operation modes and key functions key function remote i/o mode position/ simple direct mode half direct mode full...

Page 167

4. Scon-ca 159 [2] position/simple direct mode: in this mode, the actuator is operated by specifying position numbers. You can select whether to specify the target position directly as a value, or use a value registered in the position data table, by switching a control signal. For the speed, accele...

Page 168

4. Scon-ca 160 [4] full direct mode: in this mode, the actuator is operated by specifying all values relating to position control (target position, speed, acceleration/deceleration, etc.) directly as values. Number of occupied bytes: 32 bytes [5] remote i/o mode 2: in this mode, the actuator is oper...

Page 169

4. Scon-ca 161 [7] half direct mode 2: in this mode, the actuator is operated by specifying the speed, acceleration/deceleration and pressing current, in addition to the target position, directly as values. Unlike in mode [3], command current cannot be read in this mode. However, load cell data can ...

Page 170

4. Scon-ca 162 4.2 model numbers the model numbers of scon-ca controller supporting ethernet/ip are indicated as follows, respectively: z scon-ca- -ep- .

Page 171

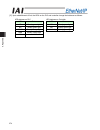

4. Scon-ca 163 4.3 ethernet/ip interface 4.3.1 names of the parts the names of each section related to ethernet/ip are described as follows. Ns led ethernet/ip port.

Page 172

4. Scon-ca 164 4.3.2 monitor led indications the slave condition (each controller), as well as network condition, can be checked using the two leds, ms and ns, provided on the front panel of the controller. The description of each is explained in the following table. ٤ : illuminating, : off, ڏ : f...

Page 173

4. Scon-ca 165 4.4 wiring 4.4.1 connection diagram * ethernet cable: straight cable of category 5e or above, 100 m max (aluminum tape and braided double-shielded cable are recommended.) (note) terminal processing is not required. 4.4.2 connector pin layout pin number signal name signal abbreviation ...

Page 174

4. Scon-ca 166 4.5 setting using the teaching tool, set controller parameters. Set the mode toggle switch on the front panel of the controller to “manu” side. The versions of teaching tool compatible with ethernet/ip are as follows: x rc pc-compatible software: v8.01.01.00 or later x con-t/tg: v1.10...

Page 175

4. Scon-ca 167 4.5.3 setting the ip address set parameter no. 140, “ipad: ip address.” [refer to 4.9, “ethernet/ip parameters.”] settable range:0.0.0.0 to 255.255.255.255 (it is set to “192.168.0.1” when the machine is delivered from the factory.) (note 1) exercise caution to avoid ip address duplic...

Page 176

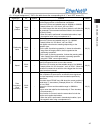

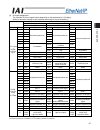

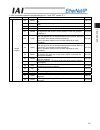

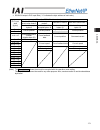

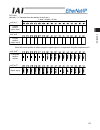

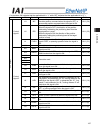

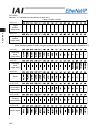

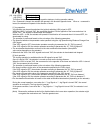

4. Scon-ca 168 4.6 communicating with the master station 4.6.1 operation modes and corresponding plc i/o areas the channels allocated for each operation mode are described as follows. X plc output o scon-ca input (* “n” indicates the byte address of each axis.) di on the scon-ca side and input data ...

Page 177

4. Scon-ca 169 x plc output o scon-ca input side (* “n” indicates the byte address of each axis.) do on the scon-ca side and output data register position/simplified direct value mode 2 half direct value mode 2 remote i/o mode 3 half direct value mode 3 plc input area (bytes) number of occupied byte...

Page 178

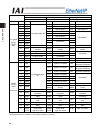

4. Scon-ca 170 x scon-ca output o plc input (* “n” indicates the byte address of each axis.) do on the scon-ca side and output data register remote i/o mode position/ simplified direct value mode half direct value mode full direct value mode remote i/o mode 2 plc output area (bytes) number of occupi...

Page 179

4. Scon-ca 171 x scon-ca outputoplc input side (* “n” indicates the byte address of each axis.) do on the scon-ca side and output data register position/simplified direct value mode 2 half direct value mode 2 remote i/o node 3 half direct value node 3 plc input area (bytes) number of occupied bytes:...

Page 180

4. Scon-ca 172 4.6.2 remote i/o mode (number of occupied bytes: 2) this is the operation mode with the position no. Set up as the same as using pio (24v i/o). Set the position data using the teaching tools such as pc software. The number of operable positions varies depending on the parameter no. 25...

Page 181

4. Scon-ca 173 (1) plc address configuration (* “n” indicates the node address of each axis.) parameter no.84 scon-ca side di(port no.) plc side output address (bytes) scon-ca side do(port no.) plc side input address (bytes) 0 0 to 15 n+0, n+1 0 to 15 n+0, n+1 (note) be careful of using duplicated n...

Page 182

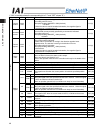

4. Scon-ca 174 (3) i/o signal assignment the controller's i/o port signal varies depending on the parameter no. 25 setting. (refer to operation manual for the controller main body for more information.) parameter no. 25 setting positioning mode teaching mode 256-point mode 0 1 2 category port no. Sy...

Page 183

4. Scon-ca 175 parameter no. 25 setting 512-point mode electromagnetic valve mode 1 electromagnetic valve mode 2 3 4 5 category port no. Symbol signal name symbol signal name symbol signal name 0 pc1 st0 start position 0 st0 start position 0 1 pc2 st1 start position 1 st1 start position 1 2 pc4 st2 ...

Page 184

4. Scon-ca 176 setting of parameter no. 25 force control mode 1 force control mode 2 6 7 category port no. Symbol signal name symbol signal name 0 pc1 st0 start position 0 1 pc2 st1 start position 1 2 pc4 st2 start position 2 3 pc8 st3 start position 3 4 pc16 command position number st4 start positi...

Page 185

4. Scon-ca 177 4.6.3 position/simplified direct value mode (number of occupied bytes: 8) this is the operation mode with the position no. Set up. Whether the target position is set directly the control signals (pmod signals), or the value registered on the position data is used can be selected. For ...

Page 186

4. Scon-ca 178 (2) i/o signal allocation for each axis the i/o signals of each axis consist of four input words (4 words = 8 bytes) and four output words in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are expr...

Page 187

4. Scon-ca 179 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. N+4ޔn+5 n+6ޔn+7 completed position number status signal n+6, n+7 n+4, n+5 1 word = 2 bytes =16 bits n+0ޔn+1 n+2ޔn...

Page 188

4. Scon-ca 180 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settable ran...

Page 189

4. Scon-ca 181 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit - current position: 32-bit signed integer. The setting unit is 0.01mm. (example) reading:000003ff h =1023 (decimal)=10.23mm * when the value is...

Page 190

4. Scon-ca 182 4.6.4 half direct value mode (number of occupied bytes: 16) this is the operation mode with the target position, positioning band, speed, acceleration/deceleration and pressing current value set up in the plc. Set each value in the i/o areas. When the zone function is used, set it usi...

Page 191

4. Scon-ca 183 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (8 words = 16 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are express...

Page 192

4. Scon-ca 184 plc output address (* “n” indicates the node address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 bytes =16 bits target position (lower word) target position (upper word) n+2, n+3 n+0, n+1 positioning...

Page 193

4. Scon-ca 185 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2 ...

Page 194

4. Scon-ca 186 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settable ran...

Page 195

4. Scon-ca 187 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details pressing current-limiting value 16-bit data - 16-bit integer specify the current-limiting value to be used during pressing operation. The allowable specification range...

Page 196

4. Scon-ca 188 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading: 000003ff h =1023 (decimal) =10.23mm...

Page 197

4. Scon-ca 189 4.6.5 full direct value mode (number of occupied bytes: 32) this is the operation mode with all the values (target position, speed, etc.) set up directly using values from plc. Set each value in the i/o area. The robot cylinder's effective main functions that can be controlled using t...

Page 198

4. Scon-ca 190 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (16 words = 32 bytes) and one output word in the i/o areas. Z control signals 1 and 2 and status signals are on/off bit signals. Z the target position and current position are expressed usin...

Page 199

4. Scon-ca 191 plc output address (* “n” indicates the node address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. When the zone boundary is shown using the negative figure, it is expressed using the complement of 2. N+4ޔn+5 n+6...

Page 200

4. Scon-ca 192 address (* “n” indicates the node address of each axis.) when the zone boundary is shown using the negative figure, it is expressed using the complement of 2. N+20ޔn+21 n+22ޔn+23 n+24ޔn+25 n+26ޔn+27 n+28ޔn+29 n+30ޔn+31 acceleration deceleration pressing current-limiting load current t...

Page 201

4. Scon-ca 193 plc input channel (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the current speed is shown using the negative figure, it is expressed using the complement of 2. N+12ޔn+13 n...

Page 202

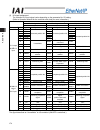

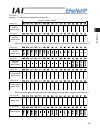

4. Scon-ca 194 b15 n+18, n+19 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0 32,768 16,384 8,192 4,096 2,048 1,024 512 256 128 64 32 16 8 4 2 1 b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0 b15 n+20, n+21 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0 ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ 524,288 26...

Page 203

4. Scon-ca 195 (3) i/o signal assignment (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer indicating the current position set the target position on the absolute coordinates. The ...

Page 204

4. Scon-ca 196 (* in the table, on indicates that the applicable bit is “1,” while off indicates that the applicable bit is “0.”) address bit symbol function details acceleration 16-bit data - deceleration 16-bit data - 16-bit integer. Specify the acceleration and deceleration at which to move the a...

Page 205

4. Scon-ca 197 (* in the table, on indicates that the applicable bit is “1,” while off indicates that the applicable bit is “0.”) address bit symbol function details b3 inc incremental specification: absolute position command when the signal is off, or incremental position command when the signal is...

Page 206

4. Scon-ca 198 (* in the table, on indicates that the applicable bit is “1,” while off indicates that the applicable bit is “0.”) signal type bit symbol description details current position 32 bit data - 32-bit signed integer indicating the current position. The unit is 0.01 mm. (example) reading: 0...

Page 207

4. Scon-ca 199 (* in the table, on indicates that the applicable bit is “1,” while off indicates that the applicable bit is “0.”) signal type bit symbol description details b15 emgs emergency stop: an emergency stop is being executed when the signal is on. 4.6.11 (2) b14 pwr controller ready: the si...

Page 208

4. Scon-ca 200 4.6.6 remote i/o mode 2 (number of occupied bytes: 12) this is the operation mode with the position no. Set up as the same as using pio (24v i/o). Set the position data using the teaching tools such as rc pc software. The number of operable positions varies depending on the parameter ...

Page 209

4. Scon-ca 201 (1) plc address configuration (* “n” indicates the node address of each axis.) parameter no. 84 scon-ca side di and input register plc side output address (bytes) scon-ca side do and output register plc side input address (bytes) port number 0 to 15 n+0, n+1 port number 0 to 15 n+0, n...

Page 210

4. Scon-ca 202 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. Command current (lower word) command current (upper word) n+8ޔn+9 n+10ޔn+11 n+10, n+11 n+8, n+9 controller output...

Page 211

4. Scon-ca 203 (3) i/o signal assignment for the signal assignments corresponding to each pio pattern, refer to the i/o signal assignments for the remote i/o mode explained in 4.6.2 (3). The signal allocation for the command current and current position, is shown in the following table. Signal type ...

Page 212

4. Scon-ca 204 4.6.7 position/simplified direct value mode2 (number of occupied bytes: 8) in this mode, the actuator is operated by means of force control (pressing operation based on feedback of load cell values) and also by specifying position numbers. Whether the target position is set directly t...

Page 213

4. Scon-ca 205 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (4 words = 8 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are expresse...

Page 214

4. Scon-ca 206 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. B15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0 completed position number ʊ ʊ ʊ ʊ ʊ ʊ pm512 pm256 pm128 pm6...

Page 215

4. Scon-ca 207 (3) i/o signal assignments(* in the table, on indicates that the applicable bit is “1,” while off indicates that the applicable bit is “0.”) signal type bit symbol description details target position 32-bit data - 32-bit signed integer. Specify the target position on the absolute coor...

Page 216

4. Scon-ca 208 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit - current position: 32-bit signed integer. The setting unit is 0.01mm. (example) reading:000003ff h =1023 (decimal)=10.23mm * when the value is...

Page 217

4. Scon-ca 209 4.6.8 half direct value mode 2 (number of occupied bytes: 16) in this mode, the actuator is operated by means of force control (pressing operation based on feedback of load cell values) and also by specifying the target position, positioning band, speed, acceleration/deceleration and ...

Page 218

4. Scon-ca 210 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (8 words = 16 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are express...

Page 219

4. Scon-ca 211 plc output address (* “n” indicates the node address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. Target position (lower word) target position (upper word) 1 word = 2 bytes =16 bits n+0ޔn+1 n+2ޔn+3 n+2, n+3 n+0,...

Page 220

4. Scon-ca 212 plc input address (* “n” indicates the node address of each axis.) when the current position is a negative figure, it is expressed using the complement of 2. When the force feedback data is a negative value, it is expressed using the complement of 2. When the current speed is a negati...

Page 221

4. Scon-ca 213 (3) i/o signal assignment(* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settable rang...

Page 222

4. Scon-ca 214 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details pressing current- limiting value 16-bit data - 16-bit integer specify the current-limiting value to be used during pressing operation. The allowable specification rang...

Page 223

4. Scon-ca 215 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading: 000003ff h =1023 (decimal) =10.23mm...

Page 224

4. Scon-ca 216 4.6.9 remote i/o mode 3 (number of occupied bytes: 12) in this mode, force control (feedback pressing of load cell values) is used in addition to the remote i/o mode 2 function for operation. Set the position data using the teaching tools such as rc pc software. The number of operable...

Page 225

4. Scon-ca 217 (1) plc address configuration (* “n” indicates the node address of each axis.) parameter no. 84 scon-ca side di and input register plc side output address (bytes) scon-ca side do and output register plc side input address (bytes) port number 0 to 15 n+0, n+1 port number 0 to 15 n+0, n...

Page 226

4. Scon-ca 218 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2. When the force feedback data is shown using the negative figure, it is expressed using the complement of 2. 1 wor...

Page 227

4. Scon-ca 219 (3) i/o signal assignment for the signal assignments corresponding to each pio pattern, refer to the i/o signal assignments for the remote i/o mode explained in 4.6.2 (3). The signal allocation for the command current and current position, is shown in the following table. Signal type ...

Page 228

4. Scon-ca 220 4.6.10 half direct value mode 3 (number of occupied bytes: 16) in this mode, the jog function in the half direct numerical mode is not available, but the vibration damping parameter set can be changed. Set each value in the i/o areas. When the zone function is used, set it using the p...

Page 229

4. Scon-ca 221 (2) i/o signal allocation for each axis the i/o signals of each axis consist of one input word (8 words = 16 bytes) and one output word in the i/o areas. Z the control signals and status signals are on/off signals in units of bit. Z the target position and current position are express...

Page 230

4. Scon-ca 222 plc output address (* “n” indicates the node address of each axis.) when the target position is shown using the negative figure, it is expressed using the complement of 2. Target position (lower word) target position (upper word) 1 word = 2 bytes =16 bits n+2, n+3 n+0, n+1 positioning...

Page 231

4. Scon-ca 223 plc input address (* “n” indicates the node address of each axis.) when the current position is shown using the negative figure, it is expressed using the complement of 2 . When the current speed is shown using the negative figure, it is expressed using the complement of 2. 1 word = 2...

Page 232

4. Scon-ca 224 (3) i/o signal assignment(* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details target position 32-bit data - 32-bit signed integer. Set the target position on the absolute coordinates. The unit is 0.01mm and settable rang...

Page 233

4. Scon-ca 225 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol description details pressing current-limiting value 16-bit data - 16-bit integer. Specify the current-limiting value during pressing operation. The specified range is 0 (0%) to 255 (10...

Page 234

4. Scon-ca 226 (* “on” in the table shows the corresponding bit of “1” and “off” shows “0”.) signal type bit symbol contents details current position 32-bit data - 32-bit signed integer indicating the current position the setting unit is 0.01mm. (example) reading: 000003ff h =1023 (decimal) =10.23mm...

Page 235

4. Scon-ca 227 4.6.11 i/o signal controls and function * on indicates that the applicable bit signal is “1”, while off indicates that the bit signal is “0”. The i/o control and functions used in the position/simplified direct value modes 1 and 2, half direct value modes 1 to 3 and full direct value ...

Page 236

4. Scon-ca 228 (5) servo on command (son) plc output signal operation preparation end (sv) plc input signal when the son signal is turned on, the servo will turn on. When “son” signal is turned “on”, the servo-motor is turned “on”. When the servo-motor is turned on, the status indicator led (refer t...

Page 237

4. Scon-ca 229 (6) home return (home) plc output signal home return completion (hend) plc input signal under home return operation (ghms) plc input signal when the “home” signal is turned “on”, this command is processed at the startup (on edge), and the home return operation is performed automatical...

Page 238

4. Scon-ca 230 (7) positioning start (cstr):used in the position/simple direct mode plc output signal this signal is processed at the startup (on edge) and the positioning is performed to the target position with the specified position no. Or set using the plc's target position register. Whether if ...

Page 239

4. Scon-ca 231 (10) positioning completion signal (pend) plc input signal this signal is turned “on” when the actuator is moved to the target position and reaches the positioning band and the pressing is completed. When the servo-motor is turned on from off condition, the positioning is performed wi...

Page 240

4. Scon-ca 232 (12) zone 1 (zone1) plc input signal zone 2 (zone2) plc input signal position zone (pzone) plc input signal these signals are turned on when the current position of the actuator is within the set area and turned off when the current position is out of the set area. [1] zone 1, zone 2 ...

Page 241

4. Scon-ca 233 (13) +jog (jog+) plc output signal –jog (jog–) plc output signal this signal is the command for the jog operation startup or inching operation startup. If a + command is issued, the actuator will operate in the direction opposite home. When a – command is issued, the actuator will ope...

Page 242

4. Scon-ca 234 (14) jog-speed/inch-distance switching (jvel) plc output signal this change-over signal is used for the parameters specifying the jog speed when the jog operation is selected or the inching distance when the inching operation is selected. The relationship is as follows. A jog operatio...

Page 243

4. Scon-ca 235 (16) teaching mode command (mode) plc output signal teaching mode signal (modes) plc input signal when the mode signal is turned “on”, the normal operation mode is changed to the teaching mode. When the mode for the controllers for each actuator is changed to the teaching mode, the mo...

Page 244

4. Scon-ca 236 (19) operating mode selector (rmod) plc output signal operation mode status (rmds) plc input signal the operation mode is selected with the rmod signal and the mode switch located on the front surface of the controller. Also, which mode is currently set, auto or manu, can be confirmed...

Page 245

4. Scon-ca 237 (23) pressing and a miss (psfl) plc input signal in the case that the pressing operation was performed, and the actuator moved the travel distance set in the controller position table positioning band or set using the plc's positioning band register, but it was not pushed against the ...

Page 246

4. Scon-ca 238 (26) load output judgment (load) plc input signal this signal is available only in the pressing operation. When this signal is used for pressing-in purpose, it should be know whether if the set load threshold is reached during the pressing operation. The load threshold and check range...

Page 247

4. Scon-ca 239 (27) torque level (trqs) plc input signal this signal is available only in the pressing operation. When the motor current reaches the load threshold during the pressing operation (moving up to the positioning band), this signal is turned “on”. Because the current level is monitored, w...

Page 248

4. Scon-ca 240 (28) absolute battery voltage low 2arning (balm) plc input signal with an absolute system, this signal is off when the absolute battery voltage is normal. It remains off with an incremental system. This balm signal turns on when the absolute battery voltage drops to 3.1 v. If the cont...

Page 249

4. Scon-ca 241 (30) acceleration/deceleration mode (mod1, mod0) plc output signal this signal is used to select the acceleration/deceleration pattern characteristics. Select one of them before the actuator movement command. Mod1 mod0 pattern name remarks off off trapezoid pattern factory setting off...

Page 250

4. Scon-ca 242 first-order lag filter this describes much gentle acceleration/deceleration curve than that for the linear acceleration/deceleration (trapezoid pattern). Use it when it is not desired to give any slight vibration to the work part in acceleration/deceleration operation. * the first-ord...

Page 251

4. Scon-ca 243 (31) standstill mode selection (aso0, aso1) plc output signals select the stop mode to be applied while the actuator is standing by to move to the next position after completing a positioning. If the actuator remains standstill for a long time, the servo is turned off automatically to...

Page 252

4. Scon-ca 244 (32) load cell calibration command (clbr) plc output signal load cell calibration complete (cend) plc input signal the factory setting for the load cell is 0 n when no load is applied. If you want to use the loaded condition as the reference (0 n), perform the following calibration. A...

Page 253