- DL manuals

- IAI

- Controller

- PCON-CB series

- Instruction Manual

IAI PCON-CB series Instruction Manual

Summary of PCON-CB series

Page 1

Cb/cfb standard type cgb/cgfb safety category complied type pcon-cb series controller instruction manual first edition power con.

Page 3: Power Con

Power con pcon-cb/lc please read before use thank you for purchasing our product. This instruction manual describes all necessary information items to operate this product safely such as the operation procedure, structure and maintenance procedure. Before the operation, read this manual carefully an...

Page 4: Power Con

Power con pcon-cb/lc.

Page 5: Power Con

Power con pcon-cb/lc construction of instruction manual for each controller model and this manual pcon-cb/cfb pcon-cgb/cgfb z basic specifications • positioner operation pcon-cb/cfb (this manual) me0342 • serial communication serial communication 【 modbus 】 me0162 ★ types to select from • pio contro...

Page 6: Power Con

Power con pcon-cb/lc table of overall contents chapter 3 operation in this chapter, explains the comparison of operation patterns and details of each operation such as positioning and pressing operations. ☆ position number input operation ⇒ pg. 95 ☆ operation by pulse train control ⇒ pg.149 12 name ...

Page 7: Power Con

Power con pcon-cb/lc table of contents safety guide··································································································1 precautions in operation ··················································································8 international standards compliances ····...

Page 8: Power Con

Power con pcon-cb/lc 2.3 wiring method ............................................................................................................65 2.3.1 wiring layout of power supply connector...........................................................65 2.3.2 connection to actuator .................

Page 9: Power Con

Power con pcon-cb/lc 3.3.2 operation ready and auxiliary signals ..............................................................139 [1] system ready (pwr) .......................................................................................139 [2] emergency stop status (*emgs) ........................

Page 10: Power Con

Power con pcon-cb/lc chapter 9 troubleshooting .........................................................................................213 9.1 action to be taken upon occurrence of problem ....................................................213 9.2 fault diagnosis......................................

Page 11: Power Con

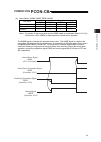

Power con pcon-cb/lc complete signal signal edit parameters of controller actuator controller command pulse plc enter an electronic gear ratio. Teaching tool completion signal signal signal edit position table of controller actuator position number + start signal plc enter a data including position,...

Page 12: Power Con

Power con pcon-cb/lc step 3 installation x external dimensions * check in 1.3 appearance as they differ for each type. Controller absolute battery unit (option for simple absolute type) x noise elimination grounding (frame ground) 1) screw fixed type 2) din rail fixed type x heat radiation and insta...

Page 13: Power Con

Power con pcon-cb/lc step 4 wiring refer to chapter 2 “wiring” [positioner operation] refer to sections 2.1 and 2.3 [pulse train control] refer to sections 2.2 and 2.3 [fieldbus specification] refer to chapter 4 step 5 operate unit how you should look in the instruction manuals will differ depending...

Page 14: Power Con

Power con pcon-cb/lc.

Page 15: Power Con

Power con pcon-cb/lc 1 safety guide “safety guide” has been written to use the machine safely and so prevent personal injury or property damage beforehand. Make sure to read it before the operation of this product. Safety precautions for our products the common safety precautions for the use of any ...

Page 16: Power Con

Power con pcon-cb/lc 2 no. Operation description description 2 transportation ● when carrying a heavy object, do the work with two or more persons or utilize equipment such as crane. ● when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follow...

Page 17: Power Con

Power con pcon-cb/lc 3 no. Operation description description (2) cable wiring ● use our company’s genuine cables for connecting between the actuator and controller, and for the teaching tool. ● do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not coil it around. Do not insert...

Page 18: Power Con

Power con pcon-cb/lc 4 no. Operation description description 4 installation and start (4) safety measures ● when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the worker...

Page 19: Power Con

Power con pcon-cb/lc 5 no. Operation description description 6 trial operation ● when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. ● after the teaching or ...

Page 20: Power Con

Power con pcon-cb/lc 6 no. Operation description description 8 maintenance and inspection ● when the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. ● perform the...

Page 21: Power Con

Power con pcon-cb/lc 7 alert indication the safety precautions are divided into “danger”, “warning”, “caution” and “notice” according to the warning level, as follows, and described in the instruction manual for each model. Level degree of danger and damage symbol danger this indicates an imminently...

Page 22: Power Con

Power con pcon-cb/lc 8 ■ precautions in operation ■ 1. Make sure to follow the usage condition, environment and specification range of the product. Not doing so may cause a drop of performance or malfunction of the product. 2. Use the following teaching tools. Use the pc software and the teaching pe...

Page 23: Power Con

Power con pcon-cb/lc 9 7. Attempt not to exceed the actuator specifications in the pulse train control mode. In pulse train control mode, the operation is performed corresponding to the input pulse. • input pulse value → moving distance • input pulse frequency → velocity • change in input pulse freq...

Page 24: Power Con

Power con pcon-cb/lc 10 10. Limitations on operation of rotary actuator in index mode rotary actuators of 360-degree specification can select the normal mode for finite rotations or the index mode enabling multi-rotation control by using parameter no.79 “rotational axis mode selection”. [refer to ch...

Page 25: Power Con

Power con pcon-cb/lc 11 12. Plc timer setting do not have the plc timer setting to be done with the minimum setting. Setting to “1” for 100msec timer turns on at the timing from 0 to 100msec while 10msec timer from 0 to 10msec for some plc. Therefore, the same process as when the timer is not set is...

Page 26: Power Con

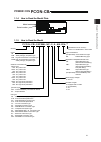

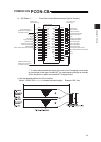

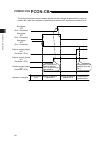

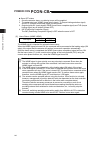

Power con pcon-cb/lc 12 ■ name for each parts and their functions ■ cb/cgb type cfb/cgfb type caution : in this manual, each type of cb/cgb/cfb/cgfb is stated as cb or cfb. 1) absolute battery connector (for simple absolute type) 2) absolute battery (for simple absolute type) 3) absolute battery sta...

Page 27: Power Con

Power con pcon-cb/lc 13 1) absolute battery connector [refer to chapter 7] it is the connector to plug in the enclosed battery if applicable for simple absolute type (option). 2) absolute battery [refer to chapter 7] it is enclosed if applicable for simple absolute type (option). Use unit by affixin...

Page 28: Power Con

Power con pcon-cb/lc 14 6) led for current/alarm monitoring in the ordinary use, it shows the command current percentage and shows the alarm code during an alarm being generated. Led operation status sts3 (gn) sts2 (gn) sts1 (gn) sts0 (gn) status display • during servo-off: it displays the current c...

Page 29: Power Con

Power con pcon-cb/lc 15 11) brake release switch (bk rls/nom) for the actuator equipped with a brake, the switch is used to release the brake forcibly. Bk rls ···· brake forcible release nom········ normal operation (brake is activated) 12) power supply connector [refer to 2.3.1 wiring layout of pow...

Page 30: Power Con

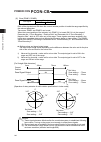

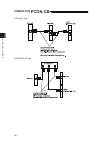

Power con pcon-cb/lc 16 ■ actuator axes ■ refer to the pictures below for the actuator axes that can be controlled. 0 defines the home position, and items in ( ) are for the home-reversed type (option). (1) rod type (2) slider type (3) table type (4) arm type caution : there are some actuators that ...

Page 31: Power Con

Power con pcon-cb/lc 17 (5) gripper type (3-finger gripper) note finger attachment is not included in the actuator package. Please prepare separately. (6) rotary type (330 ° rotation specification) (multiple rotation specification) for multiple rotation type with the origin reversed type, the direct...

Page 32: Power Con

Power con pcon-cb/lc 18.

Page 33: Power Con

Chapter 1 specifications check power con pcon-cb/lc 19 chapter 1 specifications check 1.1 product check 1.1.1 parts this product is comprised of the following parts if it is of standard configuration. If you find any fault in the contained model or any missing parts, contact us or our distributor. N...

Page 34: Power Con

Chapter 1 specifications check power con pcon-cb/lc 20 1.1.2 teaching tool a teaching tool such as pc software is necessary when performing the setup for position setting, parameter setting, etc. That can only be done on the teaching tool. Please prepare either of the following teaching tools. No. P...

Page 35: Power Con

Chapter 1 specifications check power con pcon-cb/lc 21 1.1.4 how to read the model plate 1.1.5 how to read the model p c o n - c b - 2 0 p wai - n p - 2 - 0 - a b - d n– ** cb : standard type cgb : safety category compliant type cfb : high thrust actuator connected type cgfb : high thrust actuator c...

Page 36: Power Con

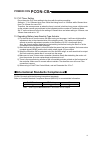

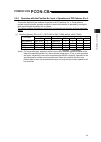

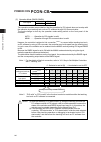

Chapter 1 specifications check power con pcon-cb/lc 22 1.2 list of basic specifications item pcon-cb/cgb pcon-cfb/cgfb number of controlled axes 1-axis power-supply voltage 24v dc ± 10% 20p, 28p, 28sp max. 1.0a 35p, 42p, 56p max. 2.2a rcp2 rcp3 motor type 60p, 86p max. 6a high-thrust function is dis...

Page 37: Power Con

Chapter 1 specifications check power con pcon-cb/lc 23 item pcon-cb/cgb pcon-cfb/cgfb led display (mounted on front panel) sv (gn)/alm (rd) : servo on/alarm generated sts0 to 3 : status display rdy (gn)/alm (rd) : absolute function in normal / absolute function error (for the simple absolute type) 1...

Page 38: Power Con

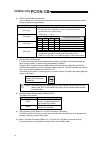

Chapter 1 specifications check power con pcon-cb/lc 24 1.3 appearance 1.3.1 cb type ・・・・・・ for incremental screw-fixed type 35 84.8 69.6 φ 5 170.5 178.5 5.

Page 39: Power Con

Chapter 1 specifications check power con pcon-cb/lc 25 1.3.2 cb type ・・・・・・ for incremental din rail-fixed type m3 35 178.5 185 (5) 93.3 78.1 8.5 4 104 from din rail center 35.4 (width of 35mm din rail) (for fg cable attachment).

Page 40: Power Con

Chapter 1 specifications check power con pcon-cb/lc 26 1.3.3 cb type ・・・・・・ for simple absolute screw-fixed type 35 84.8 69.6 φ 5 5 (40.5) (58) 170.5 178.5.

Page 41: Power Con

Chapter 1 specifications check power con pcon-cb/lc 27 1.3.4 cb type ・・・・・・ for simple absolute din rail-fixed type m3 35 178.5 185 (5) (58) 93.3 78.1 8.5 4 104 from din rail center 35.4 (width of 35mm din rail) (for fg cable attachment).

Page 42: Power Con

Chapter 1 specifications check power con pcon-cb/lc 28 1.3.5 cfb type ・・・・・ for incremental screw-fixed type 35 φ 5 5 84.8 69.6 190 170. 5 (7) (note) when using the attachment hole on the top of the controller, detach the fan unit temporarily..

Page 43: Power Con

Chapter 1 specifications check power con pcon-cb/lc 29 1.3.6 cfb type ・・・・・ for incremental din rail-fixed type (5) 93.3 78.1 115 from din rail center 8.5 4 35 .4 (width of 35mm din rail ) 35 190 (7) 196.5.

Page 44: Power Con

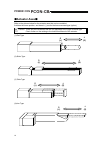

Chapter 1 specifications check power con pcon-cb/lc 30 1.3.7 absolute battery unit (option for simple absolute type) 1) din rail mounting type 30 100 (5) 110 35.4 (width of 35mm din rail) 72.2 66.2 50 from din rail center 2) screw mounting type 122 φ 5 30 15 5 130 73.5 66.2.

Page 45: Power Con

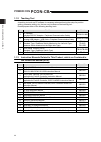

Chapter 1 specifications check power con pcon-cb/lc 31 1.4 i/o specifications 1.4.1 pio input and output interface input section output section input voltage 24v dc ± 10% load voltage 24v dc input current 5ma 1circuit peak load electric current 50ma 1circuit specification on/off voltage on voltage m...

Page 46: Power Con

Chapter 1 specifications check power con pcon-cb/lc 32 1.4.2 pulse train input output interface line driver input specification sends input pulse (differential voltage: approx. 4v) from the host unit that is installed with a line driver 26c31 or equivalent host unit positioning unit pcon pp /pp np /...

Page 47: Power Con

Chapter 1 specifications check power con pcon-cb/lc 33 1.5 options 1.5.1 pulse converter : ak-04 the pulse converter converts command pulses in the open collector mode to those in the differential mode. Use this converter if the host controller sends output pulses in the open collector mode. Item sp...

Page 48: Power Con

Chapter 1 specifications check power con pcon-cb/lc 34 1.6 installation and storage environment this product is capable for use in the environment of pollution degree 2 *1 or equivalent. *1 pollution degree 2 : environment that may cause non-conductive pollution or transient conductive pollution by ...

Page 49: Power Con

Chapter 1 specifications check power con pcon-cb/lc 35 1.7 noise elimination and mounting method (1) noise elimination grounding (frame ground) (2) precautions regarding wiring method 1) wire is to be twisted for the power supply. 2) separate the signal and encoder lines from the power supply and po...

Page 50: Power Con

Chapter 1 specifications check power con pcon-cb/lc 36 (4) heat radiation and installation design and build the system considering the size of the controller box, location of the controller and cooling factors to keep the surrounding temperature around the controller below 40 ° c. To fix the units i...

Page 51: Power Con

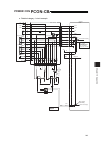

Chapter 2 wiring power con pcon-cb/lc 37 chapter 2 wiring 2.1 positioner mode (pio control) 2.1.1 wiring diagram (connection of devices) caution : make sure to turn the power to the controller off when inserting or removing the connector that connects the pc software or touch panel teaching to the c...

Page 52: Power Con

Chapter 2 wiring power con pcon-cb/lc 38 2.1.2 pio pattern selection and pio signal (1) pio pattern (control pattern) selection the controller provides 8 pio patterns (control patterns). Set the most suitable pio pattern with the actual use to parameter no. 25 “pio pattern select”. Refer to “3.2 ope...

Page 53: Power Con

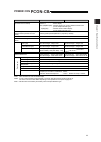

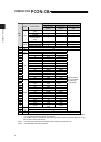

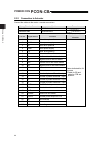

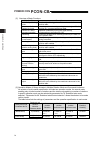

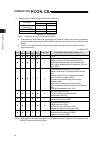

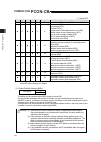

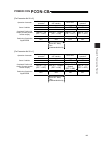

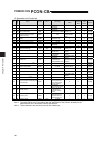

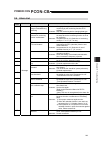

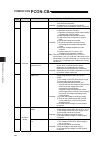

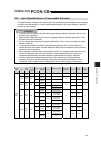

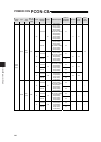

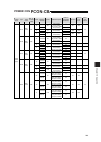

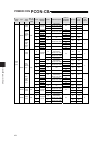

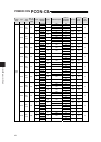

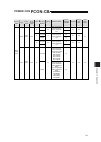

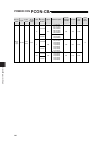

Chapter 2 wiring power con pcon-cb/lc 39 (2) pio patterns and signal assignment the signal assignment of i/o flat cable by the pio pattern is as shown below. Follow the following table to connect the external equipment (such as plc). Parameter no.25 “pio pattern” selection 0 1 2 3 category pio funct...

Page 54: Power Con

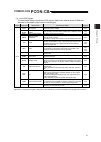

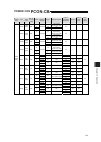

Chapter 2 wiring power con pcon-cb/lc 40 parameter no.25 “pio pattern” selection 4 5 6 or 7 category pio functions solenoid valve mode 1 solenoid valve mode 2 pulse train control mode number of positioning points 7 points 3 points – home return signal { × { jog signal × × × teaching signal (current ...

Page 55: Power Con

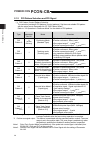

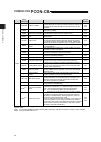

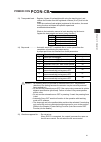

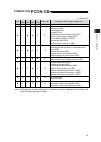

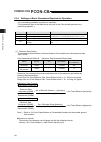

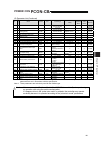

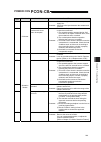

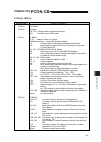

Chapter 2 wiring power con pcon-cb/lc 41 (3) list of pio signals the table below lists the functions of pio signals. Refer to the section shown in relevant sections for the details of the control of each signal. Category signal abbreviation signal name function description relevant sections cstr ptp...

Page 56: Power Con

Chapter 2 wiring power con pcon-cb/lc 42 category signal abbreviation signal name function description relevant sections pend/inp position complete turns on in the positioning band range after actuator operation. The inp signal will turn off if the position deviation exceeds the in-position range. P...

Page 57: Power Con

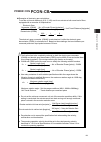

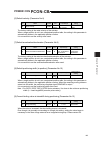

Chapter 2 wiring power con pcon-cb/lc 43 2.1.3 wiring [1] power supply connector (for power supply and emergency stop) as an example of a circuit, cases of 4 conditions are shown. Select from 3) or 4) for cgb type. 1) operate actuator without using the emergency stop input (emg-) 2) operate actuator...

Page 58: Power Con

Chapter 2 wiring power con pcon-cb/lc 44 2) example for wiring to operate actuator with the emergency stop input (emg-) activated the emergency stop gets released when +24v is supplied to emg- terminal on the controller, and emergency stop activates if the power supply is shut, and stops the actuato...

Page 59: Power Con

Chapter 2 wiring power con pcon-cb/lc 45 3) example for wiring to stop supplying external motor power at emergency stop input the emergency stop gets released when +24v is supplied to emg- terminal on the controller, and emergency stop activates if the power supply is shut, and stops the actuator op...

Page 60: Power Con

Chapter 2 wiring power con pcon-cb/lc 46 4) refer to below when shutting the motor power off externally by the emergency stop input when using two or more units of controllers. 24v 0v 0v 0v emergency stop reset switch emergency stop switch cr1 cr1 cr2 s1 s2 mpi mpo 24v emg- bkls s1 s2 mpi mpo 24v em...

Page 61: Power Con

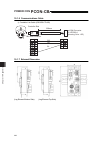

Chapter 2 wiring power con pcon-cb/lc 47 [2] motor • encoder circuit 1) connection to rcp2 series 2) connection to rcp3, rcp4, rcp5 and rcp6 series note 1 applicable connection cable model codes □□□ : cable length example) 030 = 3m model name cable reference rcp2 (for cb type) cb-psep-mpa □□□ robot ...

Page 62: Power Con

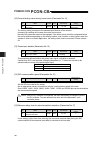

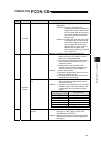

Chapter 2 wiring power con pcon-cb/lc 48 [4] pio circuit 1) pio pattern 0 ··········· positioning mode (standard type) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is normally on in the power-on ...

Page 63: Power Con

Chapter 2 wiring power con pcon-cb/lc 49 2) pio pattern 1 ············ teaching mode (teaching type) 0v(npn type) 24v dc supply 1a p24 pm1 1b 0v supply 24v dc(npn type) 24v dc(pnp type) 2a p24 pm2 2b 0v(pnp type) command position no.1 3a pc1 pm4 3b completed position no.1 command position no.2 4a pc...

Page 64: Power Con

Chapter 2 wiring power con pcon-cb/lc 50 3) pio pattern 2 ············ 256-point mode (number of positioning points : 256-point type) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is normally on i...

Page 65: Power Con

Chapter 2 wiring power con pcon-cb/lc 51 4) pio pattern 3 ············ 512-point mode (number of positioning points : 512-point type) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is normally on i...

Page 66: Power Con

Chapter 2 wiring power con pcon-cb/lc 52 5) pio pattern 4 ············· solenoid valve mode 1 (7-point type) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is normally on in the power-on status and...

Page 67: Power Con

Chapter 2 wiring power con pcon-cb/lc 53 6) pio pattern 5 ············· solenoid valve mode 2 (3-point type) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is normally on in the power-on status and...

Page 68: Power Con

Chapter 2 wiring power con pcon-cb/lc 54 2.2 pulse train control mode 2.2.1 wiring diagram (connection of devices) caution : make sure to turn the power to the controller off when inserting or removing the connector that connects the pc software or touch panel teaching. Inserting or removing the con...

Page 69: Power Con

Chapter 2 wiring power con pcon-cb/lc 55 2.2.2 i/o signals in pulse train control mode [1] pio pattern 6 (incremental type for actuator) the table below shows the signal assignment of the flat cable in the “pulse train control mode” to pio pattern 6. Follow the following table to connect the externa...

Page 70: Power Con

Chapter 2 wiring power con pcon-cb/lc 56 [2] pio pattern 7 (incremental type for actuator) the table below shows the signal assignment of the flat cable in the “pulse train control mode” to pio pattern 6. Follow the following table to connect the external equipment (such as host unit). Pin no. Categ...

Page 71: Power Con

Chapter 2 wiring power con pcon-cb/lc 57 2.2.3 wiring [1] power supply connector (for power supply and emergency stop) as an example of a circuit, cases of 4 conditions are shown. Select from 3) or 4) for cgb type. 1) operate actuator without using the emergency stop input (emg-) 2) operate actuator...

Page 72: Power Con

Chapter 2 wiring power con pcon-cb/lc 58 2) example for wiring to operate actuator with the emergency stop input (emg-) activated the emergency stop gets released when +24v is supplied to emg- terminal on the controller, and emergency stop activates if the power supply is shut, and stops the actuato...

Page 73: Power Con

Chapter 2 wiring power con pcon-cb/lc 59 3) example for wiring to stop supplying external motor power at emergency stop input the emergency stop gets released when +24v is supplied to emg- terminal on the controller, and emergency stop activates if the power supply is shut, and stops the actuator op...

Page 74: Power Con

Chapter 2 wiring power con pcon-cb/lc 60 4) refer to below when shutting the motor power off externally by the emergency stop input when using two or more units of controllers. 24v 0v 0v 0v emergency stop reset switch emergency stop switch cr1 cr1 cr2 s1 s2 mpi mpo 24v emg- bkls s1 s2 mpi mpo 24v em...

Page 75: Power Con

Chapter 2 wiring power con pcon-cb/lc 61 [2] motor • encoder circuit 1) connection to rcp2 series 2) connection to rcp3, rcp4, rcp5 and rcp6 series note 1 applicable connection cable model codes □□□ : cable length example) 030 = 3m model name cable reference rcp2 (for cb type) cb-psep-mpa□□□ robot c...

Page 76: Power Con

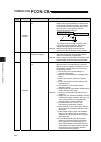

Chapter 2 wiring power con pcon-cb/lc 62 [3] pio circuit 1) pio pattern 6·············· pulse train control mode (incremental type for actuator) “*” in codes above shows the signal of the active low. Processing occurs when an input signal of the type is turned off. An output signal of the type is no...

Page 77: Power Con

Chapter 2 wiring power con pcon-cb/lc 63 0v(npn type) 24v dc br- 1 1a p24 pwr 1b br- 3 0v 24v dc(npn type) 24v dc(pnp type) rd- 1 2a p24 sv 2b rd- 3 0v(pnp type) or- 1 3a son inp 3b or- 3 system ready yw- 1 4a res hend 4b yw- 3 servo on status gn- 1 5a home tlr 5b gn- 3 bl- 1 6a tl 6b bl- 3 pl- 1 7a...

Page 78: Power Con

Chapter 2 wiring power con pcon-cb/lc 64 pcon pio connector 3a 4a 17b 18b 19b 20b host unit positioning unit pulse command (line driver: 26c31 or equiv.) pp /pp np 0v 0v 0v /np it is recommended that pp and /pp and also np and /np are twisted with each other so the system can be run safely. [4] circ...

Page 79: Power Con

Chapter 2 wiring power con pcon-cb/lc 65 2.3 wiring method 2.3.1 wiring layout of power supply connector the wires of the power supply and the emergency stop circuit are to be connected to the controller enclosed connector (plug). Strip the sheath of the applicable wires for 10mm and insert them to ...

Page 80: Power Con

Chapter 2 wiring power con pcon-cb/lc 66 2.3.2 connection to actuator connect the cables to the motor • encoder connectors. Motor • encoder connector model remarks cable side padp-24v-1-s controller side s24b-padss-1 pin no. Signal name contents applicable cable diameter 1 φ a motor drive phase a 2 ...

Page 81: Power Con

Chapter 2 wiring power con pcon-cb/lc 67 2.3.3 connection of pio conduct the connection of i/o to the controller is to be carried out using the dedicated i/o cable. The cable length is shown in the model code of the controller. Please check the controller model code. There are 2m for standard, 3m an...

Page 82: Power Con

Chapter 2 wiring power con pcon-cb/lc 68 2.3.4 connection of pulse train signal pulse train is input to pio connector. Insert the wires to the indicated pin numbers. [refer to 2.2.3 [4] circuits for pulse train control] if the output pulse of the host controller is open collector type, use the follo...

Page 83: Power Con

Chapter 2 wiring power con pcon-cb/lc 69 2.3.5 sio connector connection sio connectors can be used not only for the connection of teaching tool, but also for the connection of the host controller (plc, touch panel and pc). For the operation, refer to the instruction manual of each module. [refer to ...

Page 84: Power Con

Chapter 2 wiring power con pcon-cb/lc 70

Page 85: Power Con

Chapter 3 operation power con pcon-cb/lc 71 chapter 3 operation 3.1 basic operation 3.1.1 basic operation methods there are two types, positioner mode and pulse train control mode, for the operation. Select the suitable one considering the system function. There are various types of actuators includ...

Page 86: Power Con

Chapter 3 operation power con pcon-cb/lc 72 • procedure 3 : turn the servo on, and have a home-return operation. • procedure 4 : define the destination (position) of the slider or rod of the actuator. The destination can be defined by using the following two methods: 1) read out the coordinate value...

Page 87: Power Con

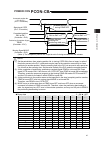

Chapter 3 operation power con pcon-cb/lc 73 (2) pulse train control mode complete signal signal edit parameters of controller actuator controller command pulse host controller enter an electronic gear ratio. Teaching tool ● operation ・・・・ example for when the parameter settings at delivery • procedu...

Page 88: Power Con

Chapter 3 operation power con pcon-cb/lc 74 3.1.2 parameter settings parameter data should be set to be suited to the system or application. Parameters are variables to be set to meet the use of the controller in the similar way as settings of the ringtone and silent mode of a cell phone and setting...

Page 89: Power Con

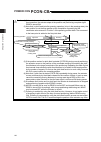

Chapter 3 operation power con pcon-cb/lc 75 3.2 operation in positioner mode this controller can switch over the mode between positioner mode and pulse train control mode with the parameters. In the positioner mode, the following 6 types of pio pattern can be selected with a proper parameter. This o...

Page 90: Power Con

Chapter 3 operation power con pcon-cb/lc 76 [2] overview of major functions major functions description number of positioning points number of positioning points which can be set in the position table. Operation with the position no. Input normal operation started by turning the start signal on afte...

Page 91: Power Con

Chapter 3 operation power con pcon-cb/lc 77 3.2.1 set of position table (this section is not required in selection of pulse train control mode.) the values in the position table can be set as shown below. For only positioning, only the position data may be written if specifying the speed, accelerati...

Page 92: Power Con

Chapter 3 operation power con pcon-cb/lc 78 3) velocity [mm/s] ······· set the velocity in the operation. Do not attempt to input a value more than the maximum velocity [refer to the caution note below] or minimum velocity (note 1) . Note 1 the minimum velocity differs depending on the type of the a...

Page 93: Power Con

Chapter 3 operation power con pcon-cb/lc 79 8) positioning width [mm] ·····for positioning in pio patterns *1 0 to 4, the positioning complete signal is output if the remaining moving distance is entered within the zone set here. For pressing, the actuator is moved at the setup velocity and accelera...

Page 94: Power Con

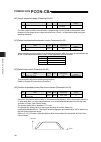

Chapter 3 operation power con pcon-cb/lc 80 11) acceleration / deceleration mode ······select a proper acceleration/deceleration pattern depending on the load. Set value acceleration/ deceleration pattern operation 0 trapezoid 1 s-motion (refer to caution at s-shaped motion) set the s-motion rate wi...

Page 95: Power Con

Chapter 3 operation power con pcon-cb/lc 81 13) transported load ···· register 4 types of load weights with using the teaching tool, and choose the number from the registered numbers (0 to 3) that is to be used. From the numbers (load weights) registered in this section, the smart tuning function ca...

Page 96: Power Con

Chapter 3 operation power con pcon-cb/lc 82 3.2.2 control of input signal the input signal of this controller has the input time constant of 6ms considering the prevention of wrong operation by chattering and noise. Therefore, input each input signal for 6ms or more (note 1) continuously. The signal...

Page 97: Power Con

Chapter 3 operation power con pcon-cb/lc 83 [2] operation mode (rmod, rmds) input output pio signal rmod rmds common to patterns 0 to 5 { { { : available, × : unavailable two operation modes are provided so that the operation by pio signals does not overlap with the operation by a teaching tool such...

Page 98: Power Con

Chapter 3 operation power con pcon-cb/lc 84 [3] servo on (son, sv, pend) input output pio signal son sv son other than pattern 5 { { { pattern 5 { { × { : available, × : unavailable 1) servo on signal son is the input signal making the servo motor of the actuator operable. 2) if the servo-on is perf...

Page 99: Power Con

Chapter 3 operation power con pcon-cb/lc 85 [4] home return (home, hend, pend, move) input output pio signal home hend pend move patterns 0 and 1 { { { { patterns 2 to 4 { { { × pattern 5 × (note1) { × × { : available, × : unavailable note 1: for pattern 5, the home return by the home signal is not ...

Page 100: Power Con

Chapter 3 operation power con pcon-cb/lc 86 [operation of slider type/rod type actuator] 1) with the home signal being on, the actuator moves toward the mechanical end at the home return speed. The moving speed is 20mm/s for most actuators but less than 20mm/s for some actuators. Refer to the instru...

Page 101: Power Con

Chapter 3 operation power con pcon-cb/lc 87 (2) multi-rotation specification 1) once the home-return command is issued, the actuator rotates in ccw (counterclockwise) direction from the view point of the load side. The velocity is 20deg/s. 2) home sensor turns on. 3) starts reversed rotation. 4) goe...

Page 102: Power Con

Chapter 3 operation power con pcon-cb/lc 88 [operation of actuator of gripper type] + + + 1) 2) 2) finger attachment finger attachment 1) 2) 1) 2) 1) 2) (note 1) (note 1) 1) if the home signal is turned on, the actuator moves toward the mechanical end (to end side) at the home return speed (20mm/s)....

Page 103: Power Con

Chapter 3 operation power con pcon-cb/lc 89 [5] zone signal and position zone signal (zone1, zone2, pzone) output pio signal zone1 zone2 (note 2) pzone (note 2) pattern 0 { { { pattern 1 { (note 2) × { pattern 2 { (note 2) × { pattern 3 (note 1) × × × pattern 4 { { { pattern 5 { { { { : available, ×...

Page 104: Power Con

Chapter 3 operation power con pcon-cb/lc 90 (2) position zone signal (pzone) no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode 0 1 ...

Page 105: Power Con

Chapter 3 operation power con pcon-cb/lc 91 [6] alarm, alarm reset (*alm, res) input output pio signal res *alm common to patterns 0 to 5 { { { : available, × : unavailable 1) alarm signal *alm is set to on in the normal status but turned off at the occurrence of an alarm at a level equal to or high...

Page 106: Power Con

Chapter 3 operation power con pcon-cb/lc 92 [7] binary output of alarm data output (*alm, pm1 to 8) output pio signal *alm pm1 to 8 common to patterns 0 to 3 { { pattern 4 (note 1) { × pattern 5 (note 1) { × { : available, × : unavailable note 1 patterns 4 and 5 do not have this function. 1) if an a...

Page 107: Power Con

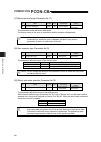

Chapter 3 operation power con pcon-cb/lc 93 { : on z : off *alm alm8 (pm8) alm4 (pm4) alm2 (pm2) alm1 (pm1) binary code description: alarm code is shown in ( ). Z { z z z 8 actual speed excessive (0c0) z { z z { 9 regenerative electric discharge circuit error (0c7) overcurrent (0c8) overvoltage (0c9...

Page 108: Power Con

Chapter 3 operation power con pcon-cb/lc 94 [8] brake release (bkrl) input pio signal bkrl pattern 0 { pattern 1 (note 1) × pattern 2 to 5 { { : available, × : unavailable note 1 pattern 1 does not have this feature the brake can be released while bkrl signal is set to on. If a brake is installed in...

Page 109: Power Con

Chapter 3 operation power con pcon-cb/lc 95 3.2.4 operation with the position no. Input = operations of pio patterns 0 to 3 this section describes the methods of operations of pio patterns 0 to 3. These patterns provide normal controller operation methods in which the controller is operated by turni...

Page 110: Power Con

Chapter 3 operation power con pcon-cb/lc 96 sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode 0 1 70.00 100.00 0.20 0.20...

Page 111: Power Con

Chapter 3 operation power con pcon-cb/lc 97 (note 1) the completion position no. Output is set to 0 during movement of the actuator. Caution: (1) set the period taken from entering position no. To turning cstr on to 6ms or larger. In spite of 6ms timer process in the plc, commands may be input to th...

Page 112: Power Con

Chapter 3 operation power con pcon-cb/lc 98 [shortcut control of rotary actuator of multi-rotation specification] (1) set of shortcut selection the shortcut selection can be made valid/invalid by parameter no.80 “shortcut selection during rotation”. If the shortcut selection is made valid, the actua...

Page 113: Power Con

Chapter 3 operation power con pcon-cb/lc 99 (2) infinite rotation control making the shortcut selection valid and moving the actuator in a specific direction continuously allows the actuator to be rotated continuously as a motor. The continuous operation can be done as described below. [operation ex...

Page 114: Power Con

Chapter 3 operation power con pcon-cb/lc 100 [2] speed change during the movement sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported loa...

Page 115: Power Con

Chapter 3 operation power con pcon-cb/lc 101 [3] pitch feeding (relative movement = incremental feed) sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- me...

Page 116: Power Con

Chapter 3 operation power con pcon-cb/lc 102 caution: (1) if the actuator reaches the software limit corresponding to the stroke end in the pitch feed operation, the actuator stops at the position and positioning complete signal pend is turned on. (2) note that, in pitch feed just after pressing ope...

Page 117: Power Con

Chapter 3 operation power con pcon-cb/lc 103 [4] pressing operation sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode 0 ...

Page 118: Power Con

Chapter 3 operation power con pcon-cb/lc 104 note 1 set the period taken from entering the position number to turning cstr on to 6ms or longer. Because 6ms timer process on the plc is also entered to the controller, positioning at another position may occur. Take the plc scan time into account. Note...

Page 119: Power Con

Chapter 3 operation power con pcon-cb/lc 105 caution: (1) the speed during pressing operation is set in parameter no.34. Check the 10.6 list of specifications of connectable actuators for the pressing operation speed. Do not set any value larger than the value in the list. If the speed set in the po...

Page 120: Power Con

Chapter 3 operation power con pcon-cb/lc 106 judging completion of pressing operation the operation monitors the torque (current limit value) in percent in “pressing” of the position table and turns pressing complete signal pend on when the load current satisfies the condition shown below during pre...

Page 121: Power Con

Chapter 3 operation power con pcon-cb/lc 107 command torque level detection at pressing this is a function to detect whether the specified load is applied to the actuator by checking the torque while in press-fitting operation when having a press-fitting process with the pressing operation. If there...

Page 122: Power Con

Chapter 3 operation power con pcon-cb/lc 108 [5] tension operation image diagram no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode ...

Page 123: Power Con

Chapter 3 operation power con pcon-cb/lc 109 3) first define the positioning in position no.1. Next, the operation in position no.2 moves the actuator to the position of 80mm at the setting speed and rating torque and change to the tension operation. The actuator moves by 50mm in the negative direct...

Page 124: Power Con

Chapter 3 operation power con pcon-cb/lc 110 [6] multi-step pressing image diagram no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mod...

Page 125: Power Con

Chapter 3 operation power con pcon-cb/lc 111 [7] teaching by pio (mode, modes, pwrt, wend, jisl, jog+, jog-) input output pio signal mode jisl jog+ jog- pwrt modes wend other than pattern 1 × × × × × × × pattern 1 { { { { { { { { : existence of signal, × : no signal (note) the feature is available o...

Page 126: Power Con

Chapter 3 operation power con pcon-cb/lc 112 warning: (1) in home return incomplete state, software limit cannot stop the actuator. Take interlock and prohibit the operation or perform the operation carefully. (2) if the jisl signal is changed during inching operation, the inching being operated is ...

Page 127: Power Con

Chapter 3 operation power con pcon-cb/lc 113 caution: (1) set the period taken from entering position no. To turning the pwrt on to 6ms or longer. In spite of 6ms timer process in the plc, commands may be input to the controller concurrently to cause writing to another position. Take the scanning ti...

Page 128: Power Con

Chapter 3 operation power con pcon-cb/lc 114 control method pause is possible during movement. In addition, the remaining moving distance can be cancelled to interrupt the operation. The pause signal is an input signal always set to on. So, it is normally used to remain on. Use this function for int...

Page 129: Power Con

Chapter 3 operation power con pcon-cb/lc 115 3.2.5 direct position specification (solenoid valve mode 1) = operation of pio pattern 4 the start signal is provided for every position number. Only turning on the relevant input signal according to the table shown below allows the operation based on the...

Page 130: Power Con

Chapter 3 operation power con pcon-cb/lc 116 control method 1) when start signal st* is turned on, the actuator starts acceleration based on the data in the specified position table for positioning to the target position. 2) at the completion of positioning, positioning complete signal pend is turne...

Page 131: Power Con

Chapter 3 operation power con pcon-cb/lc 117 [2] pitch feeding (relative movement = incremental feed) sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- me...

Page 132: Power Con

Chapter 3 operation power con pcon-cb/lc 118 caution: (1) because pitch feed is repeated, turning on the st* signal of the same position after completion of positioning causes both the pe* and pend signals to be turned off at operation start and turned on again at completion of positioning in the sa...

Page 133: Power Con

Chapter 3 operation power con pcon-cb/lc 119 [3] pressing operation sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode 0 ...

Page 134: Power Con

Chapter 3 operation power con pcon-cb/lc 120 caution: (1) the speed during pressing operation is set in parameter no.34. Check the 10.6 list of specifications of connectable actuators for the pressing operation speed. Do not set any value larger than the value in the list. If the speed set in the po...

Page 135: Power Con

Chapter 3 operation power con pcon-cb/lc 121 judging completion of pressing operation the operation monitors the torque (current limit value) in percent in “pressing” of the position table and turns pressing complete signal pend on when the load current satisfies the condition shown below during pre...

Page 136: Power Con

Chapter 3 operation power con pcon-cb/lc 122 command torque level detection at pressing this is a function to detect whether the specified load is applied to the actuator by checking the torque while in press-fitting operation when having a press-fitting process with the pressing operation. If there...

Page 137: Power Con

Chapter 3 operation power con pcon-cb/lc 123 [4] tension operation image diagram no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mode ...

Page 138: Power Con

Chapter 3 operation power con pcon-cb/lc 124 3) first define the positioning in position no.1. Next, the operation in position no.2 moves the actuator to the position of 80mm at the setting speed and rating torque and change to the tension operation. The actuator moves by 50mm in the negative direct...

Page 139: Power Con

Chapter 3 operation power con pcon-cb/lc 125 [5] multi-step pressing image diagram no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load stop mod...

Page 140: Power Con

Chapter 3 operation power con pcon-cb/lc 126 [6] pause and operation interruption (st*, *stp, res, pe*, pend) pause is possible during movement. In this mode, the following two methods are possible for pause. 1) use of pause signal *stp turning reset signal res on during the pause allows the remaini...

Page 141: Power Con

Chapter 3 operation power con pcon-cb/lc 127 caution: (1) at occurrence of an alarm in the release level note 1 , res can reset the alarm. Cancel the remaining moving distance after confirmation that alarm signal *alm (being on in normal state and off at occurrence of an alarm) is set to on. Note 1:...

Page 142: Power Con

Chapter 3 operation power con pcon-cb/lc 128 3.2.6 direct position specification (solenoid valve mode 2) = operation of pio pattern 5 the start signal is provided for every position number. Only turning on the relevant input signal according to the table shown below allows the operation based on the...

Page 143: Power Con

Chapter 3 operation power con pcon-cb/lc 129 [operation of slider type/rod type actuator] 1) with the st0 signal being on, the actuator moves toward the mechanical end at the home return speed. The moving speed is 20mm/s for most actuators but less than 20mm/s for some actuators. Check the instructi...

Page 144: Power Con

Chapter 3 operation power con pcon-cb/lc 130 (2) multi-rotation specification 1) once the home-return command is issued, the actuator rotates in ccw (counterclockwise) direction from the view point of the load side. The velocity is 20deg/s. 2) home sensor turns on. 3) starts reversed rotation. 4) go...

Page 145: Power Con

Chapter 3 operation power con pcon-cb/lc 131 [operation of actuator of gripper type] + + + 1) 2) 2) finger attachment finger attachment 1) 2) 1) 2) 1) 2) (note 1) (note 1) 1) if the home signal is turned on, the actuator moves toward the mechanical end (to end side) at the home return speed (20mm/s)...

Page 146: Power Con

Chapter 3 operation power con pcon-cb/lc 132 [2] features of ls signals (ls0 to 2) the ls* signals are not complete signals for positioning commands such as those for other pio patterns. Despite the specified position no., the corresponding ls* signal is turned on when the actuator is entered into t...

Page 147: Power Con

Chapter 3 operation power con pcon-cb/lc 133 [3] positioning [basic] (st0 to st2, ls0 to ls2) position no. Input output 0 st0 ls0 1 st1 ls1 2 st2 ls2 (note) pressing and pitch feed are unavailable. Sample use no. Position [mm] velocity [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh...

Page 148: Power Con

Chapter 3 operation power con pcon-cb/lc 134 (example) repetition of st1 → st2 → st1 → ・・・ insert timer Δ t if necessary. Δ t : time required to certainly reach the target position after the position sensing output ls1 or 2 is turned on. [example of stop position when the st* signal is turned off by...

Page 149: Power Con

Chapter 3 operation power con pcon-cb/lc 135 [4] speed change during the movement sample use no. Position [mm] velcoty [mm/s] accele- ration [g] decele- ration [g] pressing [%] thresh- old [%] positioning width [mm] zone+ [mm] zone- [mm] acceleration/ deceleration mode incre- mental transported load...

Page 150: Power Con

Chapter 3 operation power con pcon-cb/lc 136 the timing chart shown below indicates that the actuator changes its speed while it moves to position no.1 after the completion of positioning at position no.2 and moves to position no.0. Start signal st0 (plc → controller) position sensing output ls0 (co...

Page 151: Power Con

Chapter 3 operation power con pcon-cb/lc 137 [5] pause and operation interruption (st*, *stp, res, pe*, pend) turning start signal st* off allows the actuator to be paused while it is moved. To restart it, turn the same st* signal on. Control method if start signal st* is turned off during movement,...

Page 152: Power Con

Chapter 3 operation power con pcon-cb/lc 138 3.3 pulse train control mode (for pulse train type) this controller can switch over the mode between positioner mode and pulse train control mode with the parameters. In pulse train mode, there are 2 types, incremental type for actuator (pio pattern 6) an...

Page 153: Power Con

Chapter 3 operation power con pcon-cb/lc 139 3.3.1 i/o signal controls the input signals of this controller incorporate an input time constant to prevent malfunction due to chattering, noise, etc. Make sure to input the signals continuously for 6ms or more. (note) command pulse train inputs (pp, /pp...

Page 154: Power Con

Chapter 3 operation power con pcon-cb/lc 140 [3] operation mode (rmod, rmds) input output pio signal rmod rmds two operation modes are provided so that the operation by pio signals does not overlap with the operation by a teaching tool such as pc software through sio communication. The mode change i...

Page 155: Power Con

Chapter 3 operation power con pcon-cb/lc 141 [4] compulsory stop (cstp) input pio signal cstp this signal is used to forcibly stop the actuator. Input the cstp signal continuously for 16ms or longer. Once the cstp signal is received, the actuator decelerates and stops with the maximum torque, and th...

Page 156: Power Con

Chapter 3 operation power con pcon-cb/lc 142 z servo off status 1. Once the actuator stops, no retaining torque will be supplied. 2. The pulse train input, home (home return signal), tl (torque-limiting selection signal) and cstp (external forced stop signal) are all ignored. 3. Output signals sv (r...

Page 157: Power Con

Chapter 3 operation power con pcon-cb/lc 143 [operation of slider type/rod type actuator] 1) with the home signal being on, the actuator moves toward the mechanical end at the home return speed. The moving speed is 20mm/s for most actuators but less than 20mm/s for some actuators. Check the instruct...

Page 158: Power Con

Chapter 3 operation power con pcon-cb/lc 144 (2) multi-rotation specification 1) once the home-return command is issued, the actuator rotates in ccw (counterclockwise) direction from the view point of the load side. The velocity is 20deg/s. 2) home sensor turns on. 3) starts reversed rotation. 4) go...

Page 159: Power Con

Chapter 3 operation power con pcon-cb/lc 145 [operation of actuator of gripper type] + + + 1) 2) 2) finger attachment finger attachment 1) 2) 1) 2) 1) 2) (note 1) (note 1) 1) if the home signal is turned on, the actuator moves toward the mechanical end (to end side) at the home return speed (20mm/s)...

Page 160: Power Con

Chapter 3 operation power con pcon-cb/lc 146 [8] zone (zone1, zone2) output pio signal zone1 zone2 each of the signals turns on when the current actuator position is inside the range specified by the relevant parameter. Two zones, zone1 and zone2, can be set. When the current position of the actuato...

Page 161: Power Con

Chapter 3 operation power con pcon-cb/lc 147 [9] alarm, alarm reset (*alm, res) input output pio signal res *alm 1) alarm signal *alm is set to on in the normal status but turned off at the occurrence of an alarm at a level equal to or higher than the operation release level. 2) turning reset signal...

Page 162: Power Con

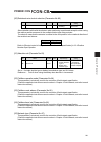

Chapter 3 operation power con pcon-cb/lc 148 { : on z : off *alm alm8 alm4 alm2 alm1 binary code description: alarm code is shown in ( ). Z { z z z 8 actual velocity excessive (0c0) z { z z { 9 overcurrent (0c8) overvoltage (0c9) overheat (0ca) current sensor offset adjustment error (0cb) control po...

Page 163: Power Con

Chapter 3 operation power con pcon-cb/lc 149 3.3.3 pulse train input operation [1] command pulse input (pp•/pp, np•/np) in the differential type, it is able to have 200 kpps of pulse train input at maximum. When the host controller possesses only the pulse output func tion of the open collector, it ...

Page 164: Power Con

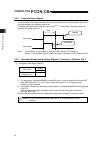

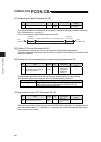

Chapter 3 operation power con pcon-cb/lc 150 time constant motor rotation caution: consider the electric gear ratio of the host side and that of the controller side via the following calculation. (reference) acceleration/deceleration settings of general positioning device 1g = 9800mm/s 2 : accelerat...

Page 165: Power Con

Chapter 3 operation power con pcon-cb/lc 151 [3] torque limit select (tl, tlr) input output pio signal tl tlr this signal is used to limit the torque of the motor. While the tl signal is on, the actuator thrust (motor torque) can be limited to the torque set in parameter no.57 “torque limit”. With t...

Page 166: Power Con

Chapter 3 operation power con pcon-cb/lc 152 3.3.4 settings of basic parameters required for operation it is a mandatory parameter to perform an operation. (the parameters listed in the table below may only be set if the actuator performs only positioning operation.) parameter no. Parameter name det...

Page 167: Power Con

Chapter 3 operation power con pcon-cb/lc 153 examples of electronic gear calculations: to set the unit travel distance to 0.01 (1/100) mm for an actuator a ball screw lead of 3mm, equipped with an encoder of 800pulses/rev. The electronic gear numerator (cnum) is calculated as 8, while the electronic...

Page 168: Power Con

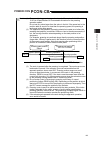

Chapter 3 operation power con pcon-cb/lc 154 [2] format settings of command pulse train set the format of command pulse train in parameter no.63 and active high/low in no.64. (1) command pulse mode no. Name symbol unit input range initial value 63 command pulse input mode mod - 0 to 2 1 pp • /pp np ...

Page 169: Power Con

Chapter 3 operation power con pcon-cb/lc 155 3.3.5 parameter settings required for advanced operations depending on systems and/or loads, set the following parameters if necessary. [1] position command primary filter time constant no. Name symbol unit input range initial value 55 position command pr...

Page 170: Power Con

Chapter 3 operation power con pcon-cb/lc 156 [4] error monitor during torque limiting no. Name symbol unit input range initial value 59 error monitor during torque limiting fstp – 0 to 1 0 you can select whether to enable or disable the function to monitor deviation while torque is being limited (th...

Page 171: Power Con

Chapter 4 field network power con pcon-cb/lc 157 chapter 4 field network applicable for the fieldbus shown in the list below. Except for rs485 (modbus), it is the option which can be selected when purchasing. It cannot be changed after the product is delivered. Also, for the fieldbus other than rs48...

Page 172: Power Con

Chapter 4 field network power con pcon-cb/lc 158 [reference] wiring layout of fieldbus (for fieldbus type) follow the instruction manual of the master unit and plc consists of each fieldbus for the details of how to perform connections. 1) devicenet type 2) cc-link type 3) profibus-dp type.

Page 173: Power Con

Chapter 4 field network power con pcon-cb/lc 159 4) componet type 5) ethernet/ip type 6) mechatrolink- Ⅰ / Ⅱ type.

Page 174: Power Con

Chapter 4 field network power con pcon-cb/lc 160 7) ethercat type 8) profinet-io type.

Page 175: Power Con

Chapter 5 collision detection feature power con pcon-cb/lc 161 chapter 5 collision detection feature this controller is equipped with a feature to stop immediately when the actuator is hit on an object during operation. Understand this chapter well to avoid any trouble in operation and safety. Colli...

Page 176: Power Con

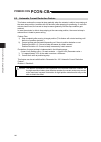

Chapter 5 collision detection feature power con pcon-cb/lc 162 5.2 settings have the following settings established when using following function. 1) select to use feature setting can be established in the parameters. Setting of parameter ” no.168 collision detection feature” setting value operation...

Page 177: Power Con

Chapter 6 power-saving function power con pcon-cb/lc 163 chapter 6 power-saving function 6.1 automatic servo-off and full servo functions this controller possesses automatic servo-off and full servo functions to reduce the power consumption while the actuator is stopped. Read the description in this...

Page 178: Power Con

Chapter 6 power-saving function power con pcon-cb/lc 164 (1) setting of periods taken until automatic servo-off three periods from completion of positioning to automatic servo-off can be set in the following parameters in seconds [sec]. Parameter no. Description 36 auto servo motor off delay time 1 ...

Page 179: Power Con

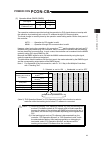

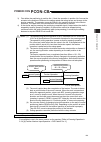

Chapter 6 power-saving function power con pcon-cb/lc 165 [for parameter no.39 = 0] operation of actuator positioning operation automatic servo off standby servo off positioning operation servo condition on on off on completed position no. Output (current position number output) pm1 to ** =0 (pe** = ...

Page 180: Power Con

Chapter 6 power-saving function power con pcon-cb/lc 166 6.2 automatic current reduction feature this feature reduces the current at stop gradually when the actuator is able to keep staying at the same stop position (condition with no deviation) after stopping for positioning. In case the actuator h...

Page 181: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 167 chapter 7 absolute reset and absolute battery 7.1 absolute reset in simple absolute type and battery-less absolute type, the encoder position information is retained even when the power is off. For those types, it is unnecessary ...

Page 182: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 168 (2) for teaching pendant (tb-02/tb-03) press alarm reset. Press trial operation on the menu 1 screen. Press jog inching on test run screen. Touch servo to turn the servo on and touch homing in jog inching screen. 1 2 3 4.

Page 183: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 169 (3) for teaching pendant (tb-01) press reset alm. Press trial operation on the menu 1 screen. Press jog_inching on trial operation screen. Touch sv off to turn the servo on and touch home in jog screen. 1 2 3 4.

Page 184: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 170 [2] absolute reset using pio 1) turn the reset signal res from off to on. (processed with on edge.) 2) check that the alarm signal *alm is on (controller’s alarm (note 1) is cancelled). (note 1) if the cause of the alarm is not r...

Page 185: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 171 [absolute reset process] note 1 turn on 24v power supply for pio (and 24v power supply for brake if the actuator is equipped with a brake) prior to turn on the control power supply or motor power supply. Note 2 have the control p...

Page 186: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 172 7.2 absolute battery (for simple absolute type) [1] for the type to attach battery to controller side absolute battery and fabric hook-and-loop faster are enclosed in the simple absolute type controllers. The absolute battery is ...

Page 187: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 173 (example) from monday to friday ; charge for 8 hours per day, discharge for 16 hours, saturday and sunday ; use with discharge 1) if the upper limit setting for the number of encoder revolution is 800 [prm]; full charge amount : ...

Page 188: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 174 7.2.4 replacement of absolute battery when replacing the battery, leave the power to the controller on, remove the battery connector and replace with a new battery. [1] for the type to attach battery to controller side [removal] ...

Page 189: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 175 [2] when using absolute battery unit 1) detach the absolute battery connector first, and then remove the absolute battery unit cover retaining screws (2 places) to detach the cover. At this time, pull out the battery cables from ...

Page 190: Power Con

Chapter 7 absolute reset and absolute battery power con pcon-cb/lc 176.

Page 191: Power Con

Chapter 8 parameter power con pcon-cb/lc 177 chapter 8 parameter parameters are the data to set up considering the system and application. When a change is required to the parameters, make sure to back up the data before the change so the settings can be returned anytime. With using pc software, it ...

Page 192: Power Con

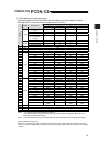

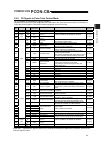

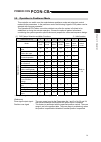

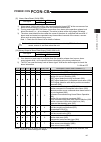

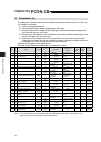

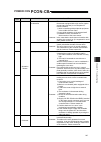

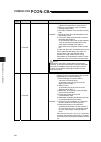

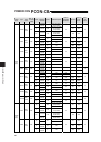

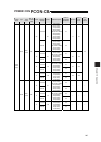

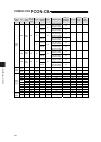

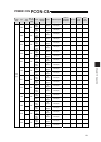

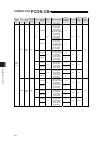

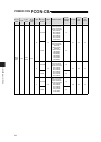

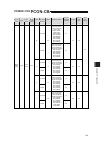

Chapter 8 parameter power con pcon-cb/lc 178 8.1 parameter list the categories in the table below indicate whether parameters should be set or not. There are five categories as follows: a : check the settings before use. B : use parameters of this category depending on their uses. C : use parameters...

Page 193: Power Con

Chapter 8 parameter power con pcon-cb/lc 179 i/o parameter list (continued) no. C at eg or y name symbol unit (note1) input range default factory setting for positioner mode for pulse train mode relevant sections 27 b movement command type fpio – 0: level 1: edge 0 { 8.2 [20] 28 b default movement d...

Page 194: Power Con

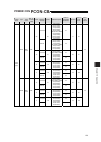

Chapter 8 parameter power con pcon-cb/lc 180 i/o parameter list (continued) no. C at eg or y name symbol unit (note1) input range default factory setting for positioner mode for pulse train mode relevant sections 60 b deviation counter clear input dclr – 0: enabling 1: disabling 0 { 3.3.5 [5] 61 b t...

Page 195: Power Con

Chapter 8 parameter power con pcon-cb/lc 181 i/o parameter list (continued) no. C at eg or y name symbol unit input range default factory setting for positioner mode for pulse train mode relevant sections 140 b ip address ipad – 0.0.0.0 to 255.255.255.255 separate volume { { separate volume 141 b su...

Page 196: Power Con

Chapter 8 parameter power con pcon-cb/lc 182 8.2 detail explanation of parameters caution: • if parameters are changed, provide software reset or reconnect the power to reflect the setting values. • the unit (deg) is for rotary actuator and lever type gripper. Pay attention that it is displayed in m...

Page 197: Power Con

Chapter 8 parameter power con pcon-cb/lc 183 [2] soft limit+, soft limit- (parameter no.3, no.4) no. Name symbol unit input range default factory setting 3 soft limit + limm mm (deg) -9999.99 to 9999.99 actual stroke on + side 4 soft limit - liml mm (deg) -9999.99 to 9999.99 actual stroke on - side ...

Page 198: Power Con

Chapter 8 parameter power con pcon-cb/lc 184 [4] press & hold stop judgment period (parameter no.6) no. Name symbol unit input range default factory setting 6 press & hold stop judgment period pswt msec 0 to 9999 255 judging completion of pressing operation (1) for standard type (pio pattern 0 to 3)...

Page 199: Power Con

Chapter 8 parameter power con pcon-cb/lc 185 [6] default velocity (parameter no.8) no. Name symbol unit input range default factory setting 8 default velocity vcmd mm/s (deg/s) 1 to actuator’s max. Verocity rated actuator speed the factory setting is the rated velocity of the actuator. When a target...

Page 200: Power Con

Chapter 8 parameter power con pcon-cb/lc 186 [10] current-limiting value during home return (parameter no.13) no. Name symbol unit input range default factory setting 13 current-limiting value during home return odpw % 1 to 100 in accordance with actuator the factory setting conforms to the standard...

Page 201: Power Con

Chapter 8 parameter power con pcon-cb/lc 187 [14] home position check sensor input polarity (parameter no.18) no. Name symbol unit input range default factory setting 18 home position check sensor input polarity ls – 0 to 2 in accordance with actuator the home sensor is an option. Set value descript...

Page 202: Power Con

Chapter 8 parameter power con pcon-cb/lc 188 [17] zone boundary 2+, zone boundary 2- (parameter no.23, no.24) [refer to 8.2 [1].] [18] pio pattern selection (parameter no.25) no. Name symbol unit input range default factory setting 25 pio pattern selection iopn – 0 to 7 0 (standard type) 6 (pulse tr...

Page 203: Power Con

Chapter 8 parameter power con pcon-cb/lc 189 [19] pio jog velocity (parameter no.26) no. Name symbol unit input range default factory setting 26 pio jog velocity iojv mm/s (deg/s) 1 to actuator’s max. Speed (note1) 100 this is the jog operation velocity setting with pio signal (jog input command) wh...

Page 204: Power Con

Chapter 8 parameter power con pcon-cb/lc 190 [21] default movement direction for excitation-phase signal detection (parameter no.28) no. Name symbol unit input range default factory setting 28 default movement direction for excitation-phase signal detection phsp – 0 : reversed direction 1 : forward ...

Page 205: Power Con

Chapter 8 parameter power con pcon-cb/lc 191 [24] velocity loop proportional gain (parameter no.31) no. Name symbol unit input range default factory setting 31 velocity loop proportional gain vlpg – 1 to 27661 in accordance with actuator this parameter determines the response of the speed control lo...

Page 206: Power Con

Chapter 8 parameter power con pcon-cb/lc 192 [26] torque filter time constant (parameter no.33) no. Name symbol unit input range default factory setting 33 torque filter time constant trqf – 0 to 2500 in accordance with actuator this parameter decides the filter time constant for the torque command....

Page 207: Power Con

Chapter 8 parameter power con pcon-cb/lc 193 [29] auto servo motor off delay time 1, 2, 3 (parameter no.36, no.37, no.38) no. Name symbol unit input range default factory setting 36 auto servo motor off delay time 1 aso1 sec 0 to 9999 0 37 auto servo motor off delay time 2 aso2 sec 0 to 9999 0 38 au...

Page 208: Power Con

Chapter 8 parameter power con pcon-cb/lc 194 [32] operating-mode input disable (parameter no.41) no. Name symbol unit input range default factory setting 41 operating-mode input disable fpio – 0 : enabling 1 : disabling 0 this parameter defines whether the operation mode input signal is disabled or ...

Page 209: Power Con

Chapter 8 parameter power con pcon-cb/lc 195 [36] velocity override (parameter no.46) no. Name symbol unit input range default factory setting 46 velocity override ovrd % 0 to 100 100 when move commands are issued from the plc, the moving speed set in the “velocity” field of the position table can b...

Page 210: Power Con

Chapter 8 parameter power con pcon-cb/lc 196 [40] torque inspected range (parameter no.51) no. Name symbol unit input range default factory setting 51 torque inspected range trqz – 0 : enabling 1 : disabling 0 the load output (load) turns on when it exceeds the current [%] set as the position table ...

Page 211: Power Con

Chapter 8 parameter power con pcon-cb/lc 197 [44] s-motion rate (parameter no.56) no. Name symbol unit input range default factory setting 56 s-motion rate scrv % 0 to 100 0 this parameter is used when the value in the “acceleration/deceleration mode” field of the position table is set to “1 [s-moti...

Page 212: Power Con

Chapter 8 parameter power con pcon-cb/lc 198 [45] torque limit (parameter no.57) this parameter is exclusively used for the pulse-train control mode. [refer to 3.3.5 parameter settings required for advanced operations.] [46] deviation clear at servo off & alarm stop (parameter no.58) this parameter ...

Page 213: Power Con

Chapter 8 parameter power con pcon-cb/lc 199 [56] position feed forward gain (parameter no.71) no. Name symbol unit input range default factory setting 71 feed forward gain plfg – 0 to 100 0 this parameter defines the level of feed forward gain to be applied to position control. Setting this paramet...

Page 214: Power Con

Chapter 8 parameter power con pcon-cb/lc 200 [57] ball screw lead length (parameter no.77) no. Name symbol unit input range default factory setting 77 ball screw lead length lead mm 0.01 to 999.99 in accordance with actuator this parameter set the ball screw lead length. The factory setting is the v...

Page 215: Power Con

Chapter 8 parameter power con pcon-cb/lc 201 [60] rotational axis shortcut selection (parameter no.80) no. Name symbol unit input range default factory setting 80 rotational axis shortcut selection atyp – 0: disabling 1: enabling in accordance with actuator select whether valid/invalid the shortcut ...

Page 216: Power Con

Chapter 8 parameter power con pcon-cb/lc 202 [67] software limit margin (parameter no.88) no. Name symbol unit input range default factory setting 88 software limit margin slma mm (deg) 0 to 9999.99 in accordance with actuator this is the parameter to set the position of over error detection against...

Page 217: Power Con

Chapter 8 parameter power con pcon-cb/lc 203 [71] calendar function (parameter no.111) no. Name symbol unit input range default factory setting 111 calendar function frtc – 0: unused 1: use 1 this parameter defines whether the calendar function (rtc) is used or not. Set the current time with using a...

Page 218: Power Con

Chapter 8 parameter power con pcon-cb/lc 204 [74] ip address (parameter no.140) no. Name symbol unit input range default factory setting 140 ip address ipad mm 0.0.0.0 to 255.255.255.255 192.168.0.1 it is the parameter dedicated for fieldbus (ethernet/ip). [refer to ether net/ip instruction manual (...

Page 219: Power Con

Chapter 8 parameter power con pcon-cb/lc 205 [79] gs velocity loop proportional gain (parameter no.145) no. Name symbol unit input range default factory setting 145 gs velocity loop proportional gain gspc – 1 to 30000 750 when the gain scheduling upper multiplying rate (parameter no.144) is set to 1...

Page 220: Power Con

Chapter 8 parameter power con pcon-cb/lc 206 [84] light malfunction alarm output select (parameter no.151) no. Name symbol unit input range default factory setting 151 select of light failure alarm output oall – 0: overload warning output 1: message lebel alarm output 0 it can be selected whether ou...

Page 221: Power Con

Chapter 8 parameter power con pcon-cb/lc 207 [88] absolute battery retention time (parameter no.155) no. Name symbol unit input range default factory setting 155 absolute battery retention time aip – 0: 20 days 1: 15 days 2: 10 days 3: 5 days 0 for simple absolute type, set how long the encoder posi...

Page 222: Power Con

Chapter 8 parameter power con pcon-cb/lc 208 [92] delay time after shutdown release (parameter no.165) no. Name symbol unit input range default factory setting 165 delay time after shutdown release sddt msec 0 to 100 0 it is used in purpose to scatter the in-rush current when the power is supplied t...

Page 223: Power Con

Chapter 8 parameter power con pcon-cb/lc 209 [94] pulse train datum position (parameter no.167) no. Name symbol unit input range default factory setting 167 pulse train datum position rpos mm -9999.99 to 9999.99 0 when the pulse train control mode (pio pattern 7) is selected, operation is made with ...

Page 224: Power Con

Chapter 8 parameter power con pcon-cb/lc 210 8.3 servo adjustment the parameters are preset at the factory before shipment so that the actuator operates stably within the rated (maximum) transportable weight. However, the preset setting cannot always be the optimum load condition in the actual use. ...

Page 225: Power Con

Chapter 8 parameter power con pcon-cb/lc 211 no. Situation that requires adjustment how to adjust 4 abnormal noise is generated. Especially, when stopped state and operation in low speed (less than 50mm/sec), comparatively high noise is generated. ● input the “torque filter time constant”. Try to in...

Page 226: Power Con

Chapter 8 parameter power con pcon-cb/lc 212.

Page 227: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 213 chapter 9 troubleshooting 9.1 action to be taken upon occurrence of problem upon occurrence of a problem, take an appropriate action according to the procedure below in order to ensure quick recovery and prevent recurrence of the problem. 1) status ...

Page 228: Power Con

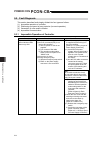

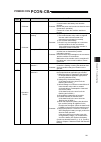

Chapter 9 troubleshooting power con pcon-cb/lc 214 9.2 fault diagnosis this section describes faults largely divided into four types as follows: (1) impossible operation of controller (2) positioning and speed of poor precision (incorrect operation) (3) generation of noise and/or vibration (4) impos...

Page 229: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 215 situation possible cause check/treatment alm in the status display leds turns on when the power is supplied. (1) occurrence of alarm (2) during emergency-stop. 1) was the emergency-stop switch. 2) emg- on the power supply connector is not connected....

Page 230: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 216 [in the case of positioner mode] situation possible cause check/treatment both position no. And start signal are input to the controller, but the actuator does not move. There is a problem either in pio signal treatment, position table setting or op...

Page 231: Power Con

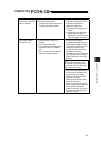

Chapter 9 troubleshooting power con pcon-cb/lc 217 [startup adjustment with teaching tool when control circuit incomplete] situation possible cause check/treatment operation is not performed even though the teaching tool is connected, and power to the controller motor and control circuit is supplied...

Page 232: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 218 9.2.2 positioning and speed of poor precision (incorrect operation) situation possible cause check/treatment completion of operation on the way to home return in the home return of our standard specification, the actuator is first pressed to the mec...

Page 233: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 219 [in the case of pulse train control mode] situation possible cause check/treatment the actuator does not stop at the command position. Pio signal processing or parameter setting is incorrect. 1) incorrect electronic gear ratio 2) acceleration/decele...

Page 234: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 220 9.2.3 generation of noise and/or vibration situation possible cause check/treatment generation of noise and/or vibration from actuator itself noise and vibration are generated by many causes including the status of load, the installation of the actu...

Page 235: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 221 9.2.4 impossible communication situation possible cause check/treatment • not connectable with host machine 1) communication rates do not match. 2) the machine number (station number) is set to be duplicate with that of another unit or out of the ra...

Page 236: Power Con

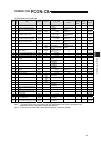

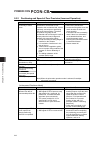

Chapter 9 troubleshooting power con pcon-cb/lc 222 9.3 alarm level the alarms are classified to 3 types of levels by the content of the error. Alarm level alm lamp *alm signal status when an error occurred cancellation method message (note 1) off no output no stop alarm of maintenance output such as...

Page 237: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 223 9.4 alarm list alarm code alarm level alarm name cause/treatment 02c monitoring data type change command during monitoring cause : changing data type was directed during monitoring by the monitoring function of pc software. Treatment : stop the moni...

Page 238: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 224 alarm code alarm level alarm name cause/treatment 080 move command in servo off cause : a move command was issued when the servo is off. Treatment : issue a movement command after confirming the servo is on (servo on signal (sv) or position complete...

Page 239: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 225 alarm code alarm level alarm name cause/treatment 0a1 cold start parameter data error cause : the data input range in the parameter area is not appropriate. Example 1) this error occurs when the magnitude relationship is apparently inappropriate suc...

Page 240: Power Con

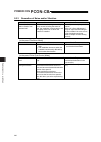

Chapter 9 troubleshooting power con pcon-cb/lc 226 alarm code alarm level alarm name cause/treatment 0a7 operation release command deceleration error cause : because there is not enough deceleration distance when the deceleration is changed to a lower setting during the operation, the actuator excee...

Page 241: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 227 alarm code alarm level alarm name cause/treatment 0ba home sensor non-detection cause : this indicates that the home-return operation of the actuator equipped with origin sensor (option except rotary actuator) is not completed in normal condition. 1...

Page 242: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 228 alarm code alarm level alarm name cause/treatment 0c9 overvoltage cause : the voltage of the power regenerative circuit has risen above the threshold. Treatment : a malfunction of a component inside the controller can be considered. Please contact i...

Page 243: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 229 alarm code alarm level alarm name cause/treatment 0d4 drive source error cause : overcurrent is generated on the motor power supply line. Treatment : check the wire layout between the actuator and controller. 0d5 cold start differential counter over...

Page 244: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 230 alarm code alarm level alarm name cause/treatment 0e0 cold start overload cause : 1) the work piece weight exceeds the rating, or load has increased due to external force. 2) brake is not released in case of actuator (equipped with brake). 3) the sl...

Page 245: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 231 alarm code alarm level alarm name cause/treatment 0e6 cold start encoder count error cause : error status was received in initial communication with battery-less absolute encoder treatment : reboot the power and conduct an absolute reset (home-retur...

Page 246: Power Con

Chapter 9 troubleshooting power con pcon-cb/lc 232 alarm code alarm level alarm name cause/treatment 0ef absolute encoder error detection 3 the encoder for the simple absolute applicable type cannot detect the position information properly. (encoder overspeed error) cause : the current position chan...

Page 247: Power Con

Chapter 10 appendix power con pcon-cb/lc 233 chapter 10 appendix 10.1 way to set multiple controllers with 1 teaching tool it is usually necessary to connect the teaching tool to the controllers one by one when making a setup to multiple controllers with one unit of teaching tool. In this section, e...

Page 248: Power Con