- DL manuals

- IAI

- Power Supply

- PSA-24

- Instruction Manual

IAI PSA-24 Instruction Manual

Instruction Manual

First Edition

ME0379-1A

24V Power Supply Unit

PSA-24

Chapter

Specifications

1

Chapter

Installation

2

Chapter

Wiring

3

Chapter

Operation

4

Chapter

Preventive/Predictive

Maintenance

5

Chapter

Before Considering

Failure

6

Chapter

Maintenance and

inspection

7

Chapter

External Dimensions

8

Chapter

Life

9

Chapter

Warranty

10

Chapter

Appendix

11

Summary of PSA-24

Page 1

Instruction manual first edition me0379-1a 24v power supply unit psa-24 chapter specifications 1 chapter installation 2 chapter wiring 3 chapter operation 4 chapter preventive/predictive maintenance 5 chapter before considering failure 6 chapter maintenance and inspection 7 chapter external dimensio...

Page 2: Please Read Before Use

Please read before use thank you for purchasing our product. This instruction manual explains the handling methods, structure and maintenance of this product, providing the information you need in order to use the product safely. Before using the product, be sure to read this manual and fully unders...

Page 3: Psa-24 Power Supply Unit

Psa-24 power supply unit instruction manual configuration product name instruction manual name control number 24v power supply unit psa-24 first step guide me0380 24v power supply unit psa-24 instruction manual (this document) me0379.

Page 4: Contents

Contents safety guide ·················································································· intro-1 precautions for handling ···································································· intro-8 international standard compliance ···················································...

Page 5

Chapter 5 preventive/predictive maintenance 5.1 preventive maintenance function ··················································· 5-1 connection method ························································································· 5-1 status data ········································...

Page 7: Safety Guide

Safety guide intro-1 safety guide the safety guide is intended to permit safe use of the product and thus to prevent risks and property damage. Be sure to read it before handling the product. Safety precautions for our products common safety precautions for the use of robots in various operations ar...

Page 8

Safety guide intro-2 no. Operation precautions 2 transportation ● when transporting heavy objects, do the work with two or more persons or utilize equipment such as a crane. ● when working with two or more persons, make it clear who is to be in charge and communicate well with each other to ensure s...

Page 9

Safety guide intro-3 (2) cable wiring ● use iai genuine cables for connecting the actuator and controller, and for the teaching tools. ● do not scratch cables, bend them forcibly, pull them, coil them, snag them, or place heavy objects on them. Otherwise, this may lead to fire, electric shock, or ab...

Page 10

Safety guide intro-4 4 installation and startup (4) safety measures ● when working with two or more persons, make it clear who is to be in charge and communicate well with each other to ensure safety. ● when the product is operating or in the ready mode, take safety measures (such as the installatio...

Page 11

Safety guide intro-5 6 trial operation ● when working with two or more persons, make it clear who is to be in charge and communicate well with each other to ensure safety. ● after teaching or programming, carry out trial operation step by step before switching to automatic operation. ● when trial op...

Page 12

Safety guide intro-6 8 maintenance and inspection ● when working with two or more persons, make it clear who is to be in charge and communicate well with each other to ensure safety. ● perform the work outside the safety/protection fence, if possible. If operation must be performed within the safety...

Page 13: Precaution Indications

Safety guide intro-7 precaution indications the safety precautions are divided into "danger", "warning", "caution" and "notice" according to the warning level, as follows, and described in the instruction manual for each model. Level degree of risk to persons and property symbol danger this indicate...

Page 14: Precautions For Handling

Precautions for handling intro-8 precautions for handling the safety guide attached with the product is intended to permit safe use of the product and thus to prevent risks and property damage. Be sure to read it before handling the product. Do not attempt any handling or operation that is not indic...

Page 15

International standard compliance intro-9 international standard compliance emc specifications this power supply unit satisfies the following emc specifications. Item condition specifications noise-resistance ability (impulse noise test) ±2000 v pulse width (100/1000 ns, repeating cycle 30-100hz, no...

Page 16

International standard compliance intro-10 safety standard specifications this power supply unit meets the following safety standards. Item standards ul/cul ul61010-1 ce marking lvd: en61010 / emc: en55011.

Page 17: Part Names

Part names intro-11 part names psa-24 (204w / without fan) psa-24l (330w / with fan).

Page 18

Part names intro-12 din tab screw mounting hole left side right side rear fan connector communication connector communication address switch fan unit fan alarm notification led normal operation notification led power terminal block top front.

Page 19

Part names intro-13 functions of each part [fan alarm notification led / normal operation notification led] this power supply unit is equipped with the following two kinds of led. Name panel notation display color status description fan alarm notification led fan orange light on fan rotation speed a...

Page 20

Part names intro-14 [power terminal block] terminal block for ac power supply input, frame ground, and output voltage wire connections. Connector name: dt-5c-b84w-6717-07 (dinkle) pin no. Signal description 1 +24 v 24v output terminal (pins 1 and 2 are internally connected) 2 +24 v 3 0 v 0v output t...

Page 21

Part names intro-15 [communication connector] connector for monitoring status data inside the power supply by communication. In order to enable communication of multiple power sources by multi-drop, two connection ports are provided. The differential signal of each connection port is short-circuited...

Page 22

Part names intro-16 [fan connector] fan connector used when continuous rated output is at 330 w. Board-side connector name: df11-4dp-2ds(24) (hirose) pin no. Signal description 1 24 v fan power supply 2 connect connection recognition signal (connected: h / not connected: l) 3 gnd fan gnd 4 pulse fan...

Page 23: Power Supply Unit

Specifications 1.1 product configuration ············································· 1-1 components ·································································· 1-1 how to read the model nameplate ····································· 1-1 model name ··········································...

Page 24

1.1 product configuration 1-1 1. S pec ific at ions 1.1 product configuration the standard configuration of this product is comprised of the following parts. In the unlikely case that any model number errors or missing parts come to light, contact your local iai distributor. Components no. Part name...

Page 25

1.1 product configuration 1-2 1. S pec ific at ions model name series type option with fan psa - 24 blank l psa - fu (1) (2) (1) type · 24: 24 v power supply unit · fu: fan unit (single) (2) option with fan · blank: standard specification (204w) · l: unit with fan specification (330w) * if the fan u...

Page 26

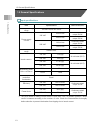

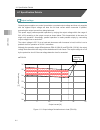

1.2 general specifications 1-3 1. S pec ific at ions 1.2 general specifications input specifications item specifications terms of use, etc. Power input voltage range 100 vac to 230 vac ±10% power supply current 100 vac 2.5a or less continuous rated output 204 w 3.9a or less continuous rated output 3...

Page 27

1.2 general specifications 1-4 1. S pec ific at ions output specifications item specifications terms of use, etc. Rated output voltage 24 v output voltage range *1 24v ±10% continuous rated output 204 w 8.5a without fan continuous rated output 330 w 13.8a with fan peak output *2 17a (408w) default i...

Page 28

1.2 general specifications 1-5 1. S pec ific at ions protective function specifications item specifications overcurrent protection operation output is cut off when a current exceeding the peak capacity flows (including short circuits) refer to "output voltage" on page 4-1 protection method intermitt...

Page 29

1.2 general specifications 1-6 1. S pec ific at ions * 2: when fan connection is detected at startup, it can be used at continuous rated output 330 w by switching the overload protection level. The overload protection level is decreased in case of fan malfunction, so the continuous rated output is r...

Page 30

1.2 general specifications 1-7 1. S pec ific at ions.

Page 31: Power Supply Unit

Installation 2.1 environmental conditions ········································ 2-1 2.2 heat dissipation and mounting ································· 2-3 power supply unit chapter 2.

Page 32

2.1 environmental conditions 2-1 2. Ins ta llat ion 2.1 environmental conditions item specifications terms of use, etc. Ambient operating temperature 0°c~+55°c (with derating) natural air cooling (204 w/without fan) forced cooling (330 w/with fan) ambient operating humidity 85% rh or less non-conden...

Page 33

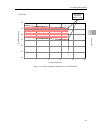

2.1 environmental conditions 2-2 2. Ins ta llat ion reduce the output power in accordance with the following derating curve at high temperatures. Figure 2.1.1 derating with regard to ambient temperature *however, when using the fan at 40°c or more, the fan life is excluded from the above derating. T...

Page 34

2.2 heat dissipation and mounting 2-3 2. Ins ta llat ion class d grounding construction (former class 3 grounding: grounding resistance 100 Ω or less) grounding wires should not be connected in common with other devices and separate power supplies should be installed. Controller other devices other ...

Page 35

2.2 heat dissipation and mounting 2-4 2. Ins ta llat ion *3: the minimum distance to the control panel wall or the minimum distance for power supply spacing when operating in parallel is as below. Note that control panels should be designed and manufactured such that the power supply ambient operati...

Page 36

2.2 heat dissipation and mounting 2-5 2. Ins ta llat ion.

Page 37: Power Supply Unit

Wiring 3.1 connection to peripheral devices (overall electrical wiring diagram) ····· 3-1 3.2 connection cables ················································· 3-2 communication cable ······················································ 3-2 power supply cable ····································...

Page 38

3.1 connection to peripheral devices (overall electrical wiring diagram) 3-1 3. W irin g 3.1 connection to peripheral devices (overall electrical wiring diagram) *1: mixing units with and without fans for parallel operation is not possible rcon (prepared by user) fan unit *1 common terminal block to...

Page 39

3.2 connection cables 3-2 3. W irin g 3.2 connection cables communication cable this shows the applicable wire and strip length that can be used for the cable connector. Use twisted pair cables for differential signal lines. Item specifications compatible wire awg22 ~ 20 strip length 10.0mm cable si...

Page 40

3.2 connection cables 3-3 3. W irin g power supply cable the following shows the specifications for terminals and wiring for connections. Item specifications terminal block screw diameter m3.5 rated torque 1.1 [n·m] applicable round terminal (applicable wire size) 1.25-m3.5 (awg22 ~ 16) 2-m3.5 (awg1...

Page 41: Power Supply Unit

Operation 4.1 specification details ············································· 4-1 output voltage ······························································· 4-1 parallel operation ··························································· 4-3 power on/off sequence ··························...

Page 42

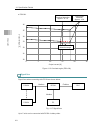

4.1 specification details 4-1 4. O per at io n 4.1 specification details output voltage general power supplies use control to maintain a constant output voltage and thus only supplies with the highest output voltage will bear the full load current when connected in parallel, preventing the output cu...

Page 43

4.1 specification details 4-2 4. O per at io n ● psa-24l 20 21 22 23 24 25 26 0 5 10 15 20 25 output current [a] figure 4.1.2 output voltage fluctuation due to load (psa-24l) overcurrent detection approx. 18 a o ut put v ol tag e [v].

Page 44

4.1 specification details 4-3 4. O per at io n parallel operation parallel operation is possible under the following conditions. ■ parallel operation should be limited to 5 units. Do not connect power supply units other than psa-24 in parallel. ■ do not operate psa-24 (204 w) and psa-24 l (330 w) in...

Page 45

4.1 specification details 4-4 4. O per at io n ● for one load take out to the common terminal block and configure for parallel connection. The common terminal block is used to connect all power supply lines in this case, eliminating the need to run cables between power supply units. Variations in th...

Page 46

4.1 specification details 4-5 4. O per at io n if one load is connected without using the terminal block as shown in the figure below, the load current for the power supply unit closer to the load increases and the voltage drop due to the cables becomes larger, creating an unbalanced output current....

Page 47

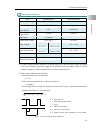

4.1 specification details 4-6 4. O per at io n power on/off sequence the startup time and output retention time stipulated in "output specifications" on page 1-4 define the following times. Item specifications startup time the time until the output voltage rises to 90% after the input voltage is app...

Page 48

4.1 specification details 4-7 4. O per at io n inrush current prevention circuit this power supply unit uses a thermistor to suppress inrush current at startup. The thermistor has high resistance at low temperatures and low resistance at high temperatures. Therefore, when the power is turned on, the...

Page 49

4.1 specification details 4-8 4. O per at io n overload detection this power supply unit handles peak current values, so energization above the rated current for a short period of time is possible. However, if continuous current continues to flow beyond the rated current, there is a significant risk...

Page 50

4.1 specification details 4-9 4. O per at io n ● psa-24l figure 4.1.6 overload region (psa-24l) signal line signal lines when connecting with rcon are shown below. Up to 5 units can be connected with rcon via daisy chain. Psa-24 rcon pc plc fig. 4.1.7 signal lines modbus fieldbus modbus psa-24 20 21...

Page 51: Power Supply Unit

Preventive/predictive maintenance 5.1 preventive maintenance function ····························· 5-1 connection method ························································ 5-1 status data ··································································· 5-2 fan installation ················...

Page 52

5.1 preventive maintenance function 5-1 5. P rev ent ive / p re dic tiv e m ai nt ena nc e 5.1 preventive maintenance function this power supply unit is equipped with a communication function that enables monitoring of status data from the host as a preventive maintenance function aimed at improving...

Page 53

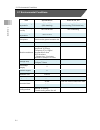

5.1 preventive maintenance function 5-2 5. P rev ent ive / p re dic tiv e m ai nt ena nc e status data the status data that can be monitored is as follows. Item content output voltage ad conversion value of output voltage. This power supply fluctuates the output voltage according to the load, so the...

Page 54

5.1 preventive maintenance function 5-3 5. P rev ent ive / p re dic tiv e m ai nt ena nc e ● switch overload error threshold the rated current changes depending on whether a fan is connected or not, so the internal overload error threshold is also switched after detecting the fan connection. If fan ...

Page 55: Power Supply Unit

Before considering failure 6.1 before considering failure ······································ 6-1 power supply unit chapter 6.

Page 56

6.1 before considering failure 6-1 6. B ef or e c ons ider ing f ai lu re 6.1 before considering failure content countermeasures no output voltage • is the specified input voltage connected? • is there a short circuit or ground fault in the output circuit? • has the power supply unit been rebooted i...

Page 57: Power Supply Unit

Maintenance and inspection 7.1 maintenance and inspection····································· 7-1 precautions for inspection ················································ 7-1 power supply unit chapter 7.

Page 58

7.1. Maintenance and inspection 7-1 7. Ma int ena nc e a nd ins pec tion 7.1 maintenance and inspection precautions for inspection ● because there are heat generating parts inside the power supply unit die cast section and interior, perform inspection after allowing sufficient cooling time after tur...

Page 59: Power Supply Unit

External dimensions 8.1 external dimensions ··············································· 8-1 power supply unit chapter 8.

Page 60

8.1. External dimensions 8-1 8. E xter nal d imens ions 8.1 external dimensions item specifications external dimensions psa-24 54(w) x 115(h) x 140(d) psa-24l 54(w) x 131(h) x 140(d) weight psa-24 805g psa-24l 845g psa-fu 40g.

Page 61

8.1. External dimensions 8-2 8. E xter nal d imens ions psa-24 35.2 39.6 142. 8 140 4 16. 4 3.5 54 105 5 5 5 ϕ5 22 22 115.

Page 62

8.1. External dimensions 8-3 8. E xter nal d imens ions psa-24l 35.2 55.6 4 131 140 142. 8 16. 4 3.5 54 5 105 5 (21) 5 ϕ5 22 22.

Page 63: Power Supply Unit

Life 9.1 consumable parts·················································· 9-1 power supply unit chapter 9.

Page 64

9.1 consumable parts 9-1 9. L ife 9.1 consumable parts item life conditions electrolytic capacitor 5 years ambient temperature 40°c continuous rated output fan 3 years.

Page 65: Power Supply Unit

Warranty 10.1 warranty period ··················································· 10-1 10.2 scope of the warranty ··········································· 10-1 10.3 honoring the warranty ·········································· 10-1 10.4 limited liability ·······································...

Page 66

10.1 warranty period 10-1 10. W ar rant y 10.1 warranty period whichever of the following periods is shorter: ● 18 months after shipment from iai ● 12 months after delivery to a specified location ● 2,500 operational hours 10.2 scope of the warranty our products are covered by warranty when all of t...

Page 67

10.4 limited liability 10-2 10. W ar rant y 10.4 limited liability (1) we assume no liability for any special damage, consequential loss or passive loss such as a loss of expected profit arising from or in connection with our product. (2) we assume no liability for any program or control method crea...

Page 68

10-3 10. W ar rant y.

Page 69: Power Supply Unit

Appendix 11.1 relation of actuator and power supply current ·········· 11-1 11.2 connected unit count determination method ············ 11-9 11.3 index ·································································· 11-11 11.4 revision history ··················································· 1...

Page 70

11.1 relation of actuator and power supply current 11-1 11. A pp end ix 11.1 relation of actuator and power supply current table 1-1. Relation of actuator and power supply current ( □con-c/cg/cy/pl/po/se, pcon-cf, □sel, □sep) controller type actuator type motor power capacity power supply current [a...

Page 71

11.1 relation of actuator and power supply current 11-2 11. A pp end ix table 1-2. Relation of actuator and power supply current ( □con-ca/cb/cgb, pcon-cfa/cfb) controller type actuator type motor power capacity power supply current [a] (note 1) acon-ca acon-cb rcl 2w rated 0.8 maximum 4.6 5w rated ...

Page 72

11.1 relation of actuator and power supply current 11-3 11. A pp end ix table 1-3. Relation of actuator and power supply current ( □con-cyb/plb/pob) controller type actuator type motor power capacity power supply current [a] (note 1) acon-cyb acon-plb acon-pob rcl 2w rated 0.8 maximum 4.6 5w rated 1...

Page 73

11.1 relation of actuator and power supply current 11-4 11. A pp end ix table 1-4. Relation of actuator and power supply current (rcon) controller type actuator type motor power capacity power supply current [a] rcon-pc rcp2 rcp3 20p, 28p, 28sp high-output setting disabled maximum 0.8 35p, 42p, 56p ...

Page 74

11.1 relation of actuator and power supply current 11-5 11. A pp end ix table 1-5. Relation of actuator and power supply current (mcon) controller type actuator type motor power capacity power supply current [a] (note 1) mcon (note 2) rcl 2w rated 0.8 maximum 4.6 5w rated 1.0 maximum 6.4 10w rated 1...

Page 75

11.1 relation of actuator and power supply current 11-6 11. A pp end ix table 1-6. Relation of actuator and power supply current (msep) controller type actuator type motor power capacity power supply current [a] (note 1) msep (note 2) rcl 2w rated 0.8 maximum 4.6 5w rated 1.0 maximum 6.4 10w rated 1...

Page 76

11.1 relation of actuator and power supply current 11-7 11. A pp end ix table 1-7. Relation of actuator and power supply current (controller integrated actuator) actuator type motor power capacity power supply current [a] (note 1) elecylinder ec-pr4, ec-gs4, ec-gd4, ec-tc4, ec-tw4 maximum 2.0 other ...

Page 77

11.1 relation of actuator and power supply current 11-8 11. A pp end ix table 1-8. Relation of actuator and power supply current (controller for rcp6s gateway unit) controller type actuator type motor power capacity power supply current [a] (note 1) rcm-p6pc rcp2 rcp3 20p, 20sp, 28p maximum 1.0 28sp...

Page 78

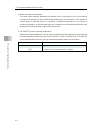

11.2 connected unit count determination method 11-9 11. A pp end ix 11.2 connected unit count determination method refer to the power capacity calculation method below in [method of calculating rated current and peak current] and [required number of power supply units], and determine the number so t...

Page 79

11.2 connected unit count determination method 11-10 11. A pp end ix [required number of power supply units] 1. Calculate the required number based on the total rated current obtained on the previous page and the rated output current of the used power supply. --- (a) 2. Calculate the required number...

Page 80

11.3 index 11-11 11. A pp end ix 11.3 index a actuator and power supply current ········· 11-1 altitude ··············································· 2-1 ambient operating humidity ····················· 2-1 ambient operating temperature ················ 2-1 ambient storage temperature ············...

Page 81

11.3 index 11-12 11. A pp end ix power terminal block ················· intro-12~14 preventive maintenance function ············· 5-1 protective function specifications ············· 1-5 r rated output voltage ····························· 1-4 restrictions in ambient environment ········· 2-4 ripple...

Page 82

11.4 revision history 11-13 11. A pp end ix 11.4 revision history revision date revised content 2018.4 first edition.

Page 84

Ober der röth 4, d-65824 schwalbach am taunus, germany tel 06196-88950 fax 06196-889524 shanghai jiahua business center a8-303, 808, hongqiao rd. Shanghai 200030, china tel 021-6448-4753 fax 021-6448-3992 website: www.Iai-robot.Com head office: 577-1 obane shimizu-ku shizuoka city shizuoka 424-0103,...