- DL manuals

- IAI

- Gateway

- RCM-GW-CC

- Operation Manual

IAI RCM-GW-CC Operation Manual

Summary of RCM-GW-CC

Page 1

Iai america inc. Cc-link rcm-gw-cc gateway unit operation manual first edition.

Page 2

Table of contents 1. Outline······················································································································································· 1 1.1 cc-link gateway unit······························································································...

Page 3

8. System build-up ······································································································································ 90 8.1. Communication setting for controller ································································································· 90 ...

Page 4

1 1. Outline 1.1 cc-link gateway unit cc-link gateway unit (hereinafter, referred to as cc-link gateway or gateway unit) is a unit to connect the network of cc-link communication protocol for an upper programmable controller (hereinafter, referred to as plc) and sio communication network (modbus com...

Page 5

2 1.2 what is cc-link (1) system of fa communication for fa communication, communication specifications depend on equipment on the communicating end, content of information and its purpose, however, are roughly divided into information level, controller level and field level as shown in the followin...

Page 6

3 (5) cc-link cc-link has become wide spread mainly for fa as an open network for device level. Communication specifications are open to the public, therefore, equipment in compliance with cc-link can be communicated without a program regardless of manufacturer. Presently, cc-link is spread and oper...

Page 7

4 1.4 features for cc-link gateway, operation modes of the following four patterns can be selected. (1) position data limit designation mode only position data can be directly designated, and the maximum connecting axis number totals 14 axes. Further, various status signals can be input and output, ...

Page 8

5 operation mode and primary functions positioning data designated mode primary functions position data limit designated mode position no. Designated mode normal positioning mode push operation mode simple direct value/position no. Designated mode position data designated operation ○ × ○ ○ ○ speed, ...

Page 9

6 1.5 how to identify model rcm-gw-cc basic model for cc-link gateway unit.

Page 10

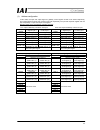

7 2. Specifications and name of each part 2.1 general specifications item specification power supply 24v dc ±10% consuming current 300ma max. Communications standard cc-link ver1.10 (*1) communications speed 10m/5m/2.5m/625k/156kbps (selection with rotary switch) communications system broadcast poll...

Page 11

8 2.2 external dimension drawing (mountin g dim ensio n).

Page 12

9 2.3 name and function of each part [1] gateway status indication led run: normal g.Er: error c.Er: cc-link error t.Er: sio link error [2] sio communication status led txd: data transmission rxd: data reception [3] mode setting switch [sio communication connector] [4] external port switching input ...

Page 13

10 [1] gateway status indication led indicating status description lit in green indicates that the cpu of the gateway is operating. Run unlit indicates cpu operation stop status, and indicates that there is an error in the cpu of the gateway when this is not lit even if power is turned on. Lit in re...

Page 14

11 [3] mode setting switch this switch sets the operation mode of the cc-link gateway. Turn off the power for the cc-link gateway to operate this switch. When selecting no.1, no.3 and no.4, setting of the position table for the controller is disabled. Sw1 input and output byte number no. 4 3 2 1 des...

Page 15

12 [7] cc-link setting switch switch description br [baud rate setting switch] this switch sets the communication rate. Setting of 5 or higher is prohibited. Sa × 10 sa × 1 [station no. Setting switch] this switch sets with decimal two digits, however, effective setting is from 1 to 64. Positions of...

Page 16

13 [9] port switch this is a switch to enable the connector (t.P.) for teaching box and personal computer (port on=communication start). When connecting and disconnecting the teaching box and the communication cable connector for personal computer supporting software, turn off this switch. When usin...

Page 17

14 3. Installation and noise elimination pay sufficient attention to the installation environment. 3.1 installation environment a. Since the gateway unit is not dust-proof or waterproof (oil proof), avoid using the gateway unit in a place subject to significant dust, oil mist or splashes of cutting ...

Page 18

15 b. Precautions regarding wiring method separate the communication lines for the gateway unit and the wiring for the cc-link communication line from high-power lines such as a cable connecting to a power circuit. (do not bundle together wiring for the communication lines with high-power lines or p...

Page 19

16 3.4 installation design the control box size, installing position of the gateway unit and cooling method of the control box in such a way that the temperature around the gateway unit will not exceed 40°c. Install the gateway unit vertically on a wall, as shown below, and provide a minimum clearan...

Page 20

17 4. Wiring 4.1 overall configuration the following diagram shows an example of configuration to build a cc-link by using a gateway unit. Host system (plc master st ation) te rminal resist or slave st atio n gateway unit teachi ng b ox te rminal resistor 4-directi on j unc tion sio communication n ...

Page 21

18 sio communication connection is allowed even by multi-drop method using terminal blocks as follows. Gateway unit terminal block terminal resistor.

Page 22

19 reference outline of cc-link network configuration for details of the cc-link, refer to the operation manual for the master side (plc). This section describes a point for network wiring. The following diagram shows an example of network connection. (1) equipment connected by the cc-link is referr...

Page 23

20 4.2 input and output signal of gateway unit (1) connection diagram gateway unit cc-link cable (blue) (white) (yellow) (not colored) connector for teaching box and personal computer teaching box teaching box emergency stop signal output allowable load voltage: 30v dc allowable load current: 1a por...

Page 24

21 (2) port control and emergency stop signal output the connector port for the teaching box and personal computer can be also turned on/off by an external signal other than the on/off signal from the port switch on the gateway unit main body. Further, since the contact signal from the emergency sto...

Page 25

22 (3) specification of input and output signal and wiring material conn ectin g plu g is st andar d att achment. Mc1.5/6-st 3 ・81 (phoenix cont act) conn ectin g plu g is st andar d att achment. Mc1.5/4-st 3 ・5 (phoenix cont act) t he gatew ay u nit incorp orates a terminal resistor , therefore, co...

Page 26

23 4.3 building of sio communication network (sio communication) 4.3.1 wiring (1) basic item contents number of connecting units 16 axes max. (depends on the operation mode. Refer to “1.4 features”) communication cable length total cable length 100m or shorter communication cable two-paired twisted ...

Page 27

24 a. Detail connection diagram the diagram below shows the details of the sio communication connection. The controller link cables are optionally prepared, but the communication main line must be prepared by the customer. B. Preparation of communication main line [1] strip off approx. 15-20mm of th...

Page 28

25 c. Controller link cable (cb-rcb-ctl002) * controller’s option the following parts are provided together: [1] four-way junction model: 5-1473574-4, manufacturer: mp, quantity: 1 [2] e-con connector model: 4-1473562-4, manufacturer: mp, quantity: 1 compatible wire coating outline: 1.35-1.6mm [3] t...

Page 29

26 (3) link connection for erc2-se gateway unit (incorporating terminal resistor) e-con connector (amp made 4-1473562-4: green) e-con connector (amp made 3-1473562-4: orange) junction (amp made 3-1473574-4:) recommended brand: taiyo electric wire & cable sio communication main line first axis second...

Page 30

27 detail connection diagram connection between the gateway unit and four-way junction is the same as in item (2). Connection between each erc2-se and four-way junction is as shown in the following diagram. For details, refer to the operation manual for the erc2-controller. (4) in the case of a comb...

Page 31

28 (5) wiring of emergency stop (emg) circuit when incorporating an emergency stop switch on the teaching box connected to the gateway unit into an emergency stop circuit, emergency stop signal output outputted from the “s1” and “s2” terminals for the gateway unit can be used. The controller for all...

Page 32

29 [1] example of drive signal shutdown caution: [1] the input current to the emg terminal of pcon-se is 5 ma. When connecting the contact of the emg relay r to the emg terminals of multiple controllers, check the current capacity of the relay contact. Input power supply 24v dc (2a max/one unit) tea...

Page 33

30 [2] example of motor drive power shutdown input power supply 24v dc (2a max/one unit) teaching box emg push button t.P. Connector gateway unit pcon-se controller emg reset switch emg push button gateway power supply sio communication sio connector sio connector connection detecting circuit connec...

Page 34

31 4.3.2 setting of axis no. For pcon-se, acon-se and erc2-se set axis no. For slave station no. On the sio link. Set the axis no. In a hexadecimal of 0 to f so that the first axis no. Is 0, and 16 th axis no. Is f. Axis no. Is set by the teaching box or personal computer supporting software. ◎ oper...

Page 35

32 5. Outline of cc-link 5.1 data communication a scheme for basic data communication of the cc-link is as shown in the following diagram. For slave to master station of the plc, there are remote i/o stations which handle bit information only and remote device stations which handle bit information a...

Page 36

33 * cpu internal user device for plc input: x bit device output: y internal relay: m data register: d link register: w 5.2 address assignment of master plc number of maximum link points per one system is respectively 2048 points for remote input and output (rx, ry) and 256 points for remote registe...

Page 37

34 cc-link memory map (mitsubishi q series) plc-cpu master station buffer memory remote station internal device remote input (rx) automatic refresh automatic refresh automatic refresh automatic refresh (2 words) for one station (2 words) for one station (2 words) for one station (2 words) for one st...

Page 38

35 6. Address configuration of gateway as described in 1.4 features of gateway unit, actuators can be roughly operated by five modes. Address configuration as a slave depends on each mode. 6.1 gateway control signal this is a signal to control the gateway, and consists of respective two words of wor...

Page 39

36 details of input and output signal signal type bit signal name contents 15 mon link communication starts at on, and stops at off. When all of cfg15 to 0 (link connection axis selection) are off, do not turn on mon signal. Further, while mon signal is on, do not turn off all of cfg15 to 0. When al...

Page 40

37 signal type bit signal name contents 15 run gateway unit now normally operating output this is turned on while gateway unit is normally operating. This is synchronized with light up of the led (run) on the front of the unit. 14 g.Er gateway unit error detection output this is turned on when major...

Page 41

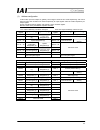

38 6.2 position data limit designation mode this is an operation mode in which function of the controller is limited only to positioning, and allows for control of a maximum 14 axes. Position data for positioning is directly written in the data register of the plc, and operation is performed. Commun...

Page 42

39 (1) address configuration in this mode, gateway control signal/status signal consists of two words respectively for input and output word register (rwr, rww), and control signal/status signal for each axis consists of one byte respectively for input and output bit register (rx, ry) and one word f...

Page 43

40 (2) assignment for each axis input and output signal for each signal consists of one byte respectively for input and output bit register (rx, ry) and one word for input and output word register (rwr, rww). Control signal and status signal are on/off signals in bit units. Position data designation...

Page 44

41 details of input and output signal signal type bit signal name contents detail f/7 - cannot be used. - e/6 - cannot be used. - d/5 - cannot be used. - c/4 son servo on command b/3 stp pause command a/2 home home return command 9/1 cstr start command control signal 8/0 res reset command plc outp u...

Page 45

42 6.3 position no. Designation mode this is an operation mode to operate by designating position no. Of the position table, and allows for control of a maximum 14 axes. It is necessary to set the position table for each axis by personal computer supporting software or teaching box. Operation is per...

Page 46

43 (1) address configuration in this mode, the input and output signal for gateway control signals consist of two words respectively, and control signals for each axis consist of one byte respectively for input and output bit register and one byte respectively in input and output word register. Nume...

Page 47

44 (2) assignment for each axis input and output signal for each axis consists of one byte respectively for input and output bit register and one byte respectively for input and output word register. Control signal and status signal are on/off signals in bit units. Command position no. And completed...

Page 48

45 details of input and output signal signal type application signal name contents detail f/7 - cannot be used. - e/6 - cannot be used. - d/5 - cannot be used. - c/4 son servo on command b/3 stp pause command a/2 home home return command 9/1 cstr start command position data designation 8/0 res reset...

Page 49

46 [list of alarm content] this list shows alarm content to be outputted (binary code) in pm8 to pm1 while an alarm occurring. For details of alarm content, refer to the operation manual for the controller. ○ : on ×: off alm pm8 pm4 pm2 pm1 output code contents remarks × - - - - - normal ○ × × × ○ 1...

Page 50

47 6.4 position/speed/acceleration and deceleration designation this is an operation mode to perform operation by directly writing position data, acceleration and deceleration and speed in the register of the plc, and allows for control of a maximum seven axes. Further, it is always possible to read...

Page 51

48 (1) address configuration in this mode, input and output for gateway control signal consist of two words respectively, and control signal for each signal consists of one word respectively for input and output bit register and two words respectively for input and output word register. Numeric valu...

Page 52

49 (2) assignment for every axis control signal and status signal are set by on/off signal in bit units, and acceleration and deceleration are set by binary data of one byte (8 bits). Further, speed, position data designation and present position data can be handled in binary data of one word (16 bi...

Page 53

50 details of input and output signal signal type bit signal name contents detail acceleration and deceleration designation 8 bit data set acceleration and deceleration in hexadecimal number. (unit: 0.01g) example) when setting to 0.2g, designate 14h (rync and ryna are on). C8 h (decimal 200) at max...

Page 54

51 signal type bit signal name contents detail 7 emgs on emergency stop 6 - cannot be used. - 5 pwr controller preparation completion 4 sv operation preparation completion (servo on status) 3 move on moving 2 hend home return completion 1 pend positioning completion status signal 0 alm alarm occurri...

Page 55

52 6.5 push operation enable mode this is an operation mode to perform operation by directly writing current limit value (%) and positioning width for push in addition to direct designation of position data, acceleration and deceleration and speed into the register of the plc, and allows for control...

Page 56

53 (1) address configuration in this mode, input and output for gateway control signal consist of two words respectively, and control signal for each axis consists of six words respectively for input register and three words respectively for output register. Further, axis no.0 uses bit register, and...

Page 57

54 (2) assignment for each axis control signal and status signal are set by on/off signal in bit units, and acceleration and deceleration are set by binary data of one byte (8 bits). Designations of speed, position and positioning width and present position data handle numeric values in binary data ...

Page 58

55 caution 1. 24 bit binary data with a sign of plc output and input is handled as a negative number when the uppermost bit is “1.” however, note that the data is handled as normal numeric data on the plc. Plc input 1 word = 16 bits position data designation present position data cannot be used pres...

Page 59

56 details of input and output signal signal type application signal name contents detail position data designation 24bit data - 24 bit integer with sign (unit: 0.01mm) set position data in hexadecimal number of 24 bits. Example) in the case of +25.4mm, designate 0009ec h (decimal 2540). (note) ● wh...

Page 60

57 signal type application signal name contents detail positioning width designation 24 bit data - 24 bit integer (unit: 0.01mm) set it in hexadecimal number. Example) in the case of +25.4mm, designate it as 0009ec h (decimal 2540). ● set position data in a range of soft stroke. ● designate push ope...

Page 61

58 6.6 simple direct value/position no. Designation mode this is an operation mode for operation by mixing a mode to operate by designating position no. And a simple direct value mode in which target position data is designated by numeric value and the other movement parameters are designated by pos...

Page 62

59 6.6.1 overall address configuration input and output for gateway control signal are two words respectively, and only in this mode, patterns of position no. Designated axes and number of axes are set by pps0 to pps2 and nps0 to nps4 of control word 0. Subsequently, command input and output regions...

Page 63

60 plc output⇒gateway unit⇒each axis input each axis output⇒gateway unit⇒plc input output register input register higher byte lower byte higher byte lower byte gateway control signal 0 gateway control signal 1 request command data 0 data 1 data 2 data 3 data 4 (reserve) data 5 (reserve) gateway cont...

Page 64

61 6.6.2 assignment for each axis input and output signals for each axis position no. Designated mode and those in simple direct value mode are different from each other in size of region and its content. Further, in the position no. Designated mode, meaning of each bit depends on the pattern set by...

Page 65

62 detail of input and output signal signal type bit signal name pattern no. Contents detail b15 son 0 – 4 servo on command b14 res 0 – 4 reset command cstr 0, 2, 3 start command b13 pwrt 1 position data capturing command teac b12 stp 0 – 4 pause command b11 home 0 – 4 home return command b10 bkrl 0...

Page 66

63 (2) simple direct value designated axis each axis consists of four words for output and three words for input as shown below. Position data designation and present data are hexadecimal numbers of 32 bit integer with the sign in units of 0.01mm. Plc output = control signal m is a head address assi...

Page 67

64 details of input and output signal signal type bit signal name contents detail target position data 32 bit data - this is a 32 bit integer with sign (unit: 0.01mm), and is set in hexadecimal number. Example) in the case of +25.4mm, set it to 0009ec h (decimal 2540). ● when the integer is negative...

Page 68

65 caution setting of the “parameter initial value” is not applied to the movement data which must be directly designated in numeric value from the plc. Therefore, note that if it is not designated in numeric value, operation is not performed or alarm occurs. The following summarizes how to designat...

Page 69

66 6.6.3 command region when request command ry (2f-20) and data ry (8f-30) related to the request command are outputted from the plc, response command (2f-20) and data related to the response command are inputted to the plc input. The request command and response command respectively consist of one...

Page 70

67 (2) each command and data format [1] position table data write command command name *1 plc output (request) plc input (response) +2 1000 h 3 position no. 4 5 position data (24 bit integer with sign) 6 axis no. 0 to f h (0-15) 7 0 target position write 8 0 same value as request at normal +2 1001 h...

Page 71

68 command name *1 plc output (request) plc input (response) +2 1006 h 3 position no. 4 deceleration data (8 bit integer) 5 0 6 axis no. 0 to f h (0-15) 7 0 deceleration write 8 0 same value as request at normal +2 1007 h 3 position no. 4 0000 to 00ff h (00ff h : maximum current) 5 0 6 axis no. 0 to...

Page 72

69 [2] position table data read command command name *1 plc output (request) plc input (response) +2 1040 h 3 position no. Same value as request at normal 4 0 5 0 target position data *2 6 axis no. 0 to f h (0-15) 7 0 target position read 8 0 same value as request at normal +2 1041 h 3 position no. ...

Page 73

70 command name *1 plc output (request) plc input (response) +2 1046 h 3 deceleration reading pos no. Same value as request at normal 4 0 deceleration data *4 5 0 6 axis no. 0 to f h 7 0 deceleration read 8 0 same value as request at normal +2 1047 h 3 position no. Same value as request at normal 4 ...

Page 74

71 [3] position table data rom writing command command name *1 plc output (request) plc input (response) +2 0da0 h 3 0 4 coil on/off 00ff h = on 0000 h = off 5 0 6 axis no. 0 to f h 7 0 position table data rom writing coil write 8 0 same value as request at normal +2 02e0 h 3 0 same value as request...

Page 75

72 [5] group designated broadcast pos movement start this command simultaneously starts an axis designated by group no. To a position designated by pos no. This command performs communication between gateway and controller by broadcast, therefore, response from the controller does not return. The re...

Page 76

73 (3) error response when command error occurs, the uppermost bit (b15) is turned on. Further, the following error codes are set to the response data 1. Code description 0101 h invalid axis no. *1 0102 h invalid position no. *1 0103 h invalid request command *1 0201 h communication fault 0202 h con...

Page 77

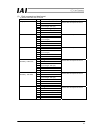

75 7. Contents of communication signal 7.1 outline of timing for communication signal in order to operate robo-cylinder by the sequence program for the plc, any of the control signals is turned on, and maximum response time until the response (status) returns to the plc is expressed by the following...

Page 78

76 7.2 communication signal and operation timing (1) controller preparation completion (pwr) this is turned on when the controller becomes controllable after power is turned on. ■ function this is turned on when the controller has been normally initialized and becomes controllable after power is tur...

Page 79

77 (5) direct numeric value designated operation (position data, present position data, cstr, pend, move, acceleration and deceleration data, speed data) this is a function to operate the robo-cylinder by directly writing position data, acceleration and deceleration data, speed data onto the link re...

Page 80

78 position data measurement value present position [1] [2] [3] [4] [4] [5] [6] [7].

Page 81

79 b. Acceleration and deceleration, speed data designation this is an effective function when the positioning data designated mode is selected. [1] set the acceleration and deceleration, and speed data designation to each designated register at the same time when setting the target position data in...

Page 82

80 speed, acceleration and deceleration set value actuator speed speed n2 speed n3 [1] [2] [3].

Page 83

81 (6) positioning data designated mode push operation (position data, acceleration and deceleration data, speed data, current limit value, positioning width, present position data, dir, push, cstr, pend, move) this is a function to operate to push the actuator by directly writing position data, acc...

Page 84

82 position data set value speed, acceleration and deceleration set value positioning width value set value current limit value set value present position [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13].

Page 85

83 (7) position no. Designated operation (command position no., completion position no., cstr, pend, move) this is an effective function when the position no. Designated operation mode is selected. ■ function enter position data into the position table of the controller in advance, and designate a p...

Page 86

84 command position no. Completion position no. [1] [2] [3] [4] [5] [6].

Page 87

85 (8) pause (stp, move) this is a function to perform pause during movement of axis. ■ function axis movement can be stopped and restarted by the stp (pause) signal. Axis movement stops while the stp signal is on. A relationship between the stp signal and move (on-moving) signal is as follows. (9) ...

Page 88

86 (10) home return (home, hend) home return is executed at on edge (at startup of signal) of home (home return). When home return is completed, the hend (home return) signal is turned on. Turn off the home signal when the hend signal is turned on. Home return by the home signal is also effective af...

Page 89

88 7.3 command transmission and reception the diagram below shows a timing chart for command transmission and reception. The gateway analyzes the request command and responds at every time when control and status data exchange for all axes which are always performed are ended. The plc and gateway un...

Page 90

90 8. System build-up it is necessary to set as follows in order to make the controller communicate with the cc-link master (plc) and controller through the gateway unit. [1] controller setting for sio communication (modbus communication) between the gateway unit and controller [2] setting of plc si...

Page 91

91 8.2. Cc-link communication setting it is necessary to set as follows in order to make the gateway communicate with master station. As for this setting, a gateway unit must accord with the master station. ○ : on ×: off item setting of gateway unit setting of plc master communication speed baud rat...

Page 92

92 for an example of the cc-link setting in gx developer v8, refer to the 9.5.2 (2). Number of exclusive stations, expanded cyclic setting and size of data area are as shown in the table below. Cc-link version ver. 1 ver. 2 direct value designation ○ × × × pos designation ○ × × × direct value/speed/...

Page 93

93 8.3. Master plc address assignment the basic concept of address assignment (memory map) for the cc-link master plc has been explained in 5.2. This section explains a case when the gateway unit is a remote station. If the gateway unit is a remote device station (remote station which handles bit in...

Page 94

94 the following shows an example that a remote i/o exclusive one station is set to the station no.1 and gateway unit is set to the station no.2. (1) remote i/o [1] master station ← gateway unit master station remote i/o station (station no. 1: exclusive one station) gateway unit rcm-gw-cc (station ...

Page 95

95 (2) remote register [1] master station ← gateway unit master station remote i/o station (station no. 1: exclusive one station) gateway unit rcm-gw-cc (station no. 2: exclusive four stations) buffer address remote register (rwr) for station no. 1 for station no. 2 for station no. 3 for station no....

Page 96

96 [2] master station ← gateway unit master station remote i/o station (station no. 1: exclusive one station) gateway unit rcm-gw-cc (station no. 2: exclusive four stations) buffer address remote register (rww) for station no. 1 for station no. 2 for station no. 3 for station no. 4 for station no. 5...

Page 97

97 8.4. Csp file when using gx configurator –cc (mitsubishi electric), download the following csp file from our website. Please using gx-developer for the network parameter setting. Website http://www.Iai-robot.Co.Jp to download it, open the “file for field network setting” from the “download & supp...

Page 98

98 9. Cc-link operation case 9.1 outline of configuration (mitsubishi) station no. 0 power switch operation pause emergency stop release emergency stop positioning completed operation preparation completed servo on operation alarm pause emergency stop release indication lamp remote i/o input 8 point...

Page 99

99 9.2 actuator operating pattern prepare position tables for all of the three axes, and designate position no. From the plc to operate. 9.3 various settings on sio link side (1) setting of sio link [1] connect personal computer (supporting software) or teaching box to the gateway unit and turn on t...

Page 100

100 (3) creation of position table start from the personal computer software initial screen subsequently from (2). [1] click the [position (t)] → [edit/teach (e)]. [2] select the axis 0 → click the > → click the ok . [3] position data edit screen for the axis 0 appears, then enter the data. [4] tran...

Page 101

101 9.4 setting of gateway unit (1) mode setting for gateway unit as operation is performed in the position no. Designated mode, set the mode setting switch (sw1) as follows. 1: off 2: on 3: off 4: off (2) setting of node address and communication speed for gateway unit station no. =1 communication ...

Page 102

102 9.5.2 parameter setting in order to make the cc-link operate, it is necessary to set network parameters and automatic refresh parameters. Set them by gx-developer, and write into the parameter area for the plc-cpu. ・ network parameters these parameters are set to the master station, and there is...

Page 103

103 (2) parameter setting [1] double-click the [network param] from the project data list, and network parameter select dialog box appears, then click the cc-link button. [2] network parameter setting screen for cc-link appears, then set the unit sheet number to one. (master station is one sheet in ...

Page 104

104 [3] set parameters as shown below from now. Mode setting should be “remote net [ver. 1 mode].” parameters different from initial setting are as follows. ・ “start i/o no”····················i/o address of master unit, 0080 ・ “all connect account” ·······number of remote stations, 2 ・ “remote inpu...

Page 105

105 [4] click the station information button to display the station information unit 1 edit screen, and set the remote station as follows, then click the end button at the lower part of the screen. ・ the station no. 1 is the gateway unit and is used in the position no. Designated mode, therefore, it...

Page 106

106 (3) writing parameters write parameters set in (2) into the plc. [1] transfer setup click the [online (o)]→[transfer setup (c)] menu, then the following transfer setup designated screen appears. I/f pc side: serial usb i/f plc side: plc module other station: no specification check the above sett...

Page 107

107 [2] writing click write to plc tab to display the following plc write screen. Click param+prog button on the plc write screen, and select the “main” for program and the “pc/network” for parameter. Click execute button, then write is performed, and when it is completed, dialog box for confirmatio...

Page 108

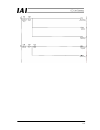

108 9.6 address correlation diagram 9.6 addres s correlation diagram m aster st at ion bu ffe r m em ory (s ta tion no. 0) cc-link gateway unit (s ta tion no. 1) autom atic re fre sh autom atic re fre sh each axi s ou tp ut ⇒ g a teway unit ⇒ p l c inp u t input r egis ter upper by te lower by te s ...

Page 109

109 autom atic r e fr esh outp ut ( w rite) r egi ste r= w or d r e gi ster com m and po si tion canno t be us ed com m and po si tion com m and po si tion com m and po si tion com m and po si tion com m and po si tion com m and po si tion com m and po si tion com m and po si tion com m and po si ti...

Page 110

110 9.7 ladder sequence flowchart operation flowchart for the second axis (axis 0) and third axis (axis 1) which are devicenet slave axes is as follows. Insides of parentheses are sio link axis nos. Gateway unit normal sio link axis designation sio link start axes (0)(1) pwr check turn on servo for ...

Page 111

111 command p.No=1 to axes (0)(1) set cstr to “1” set cstr to “0” positioning completed one second timer [2] [1].

Page 112

112 9.8 ladder sequence emergency stop emergency stop release emergency stop master unit abnormality master unit ready master data link station no. Normal station no. Normal remote i/o input 1 remote i/o input 2 remote i/o output 1 remote i/o output 2 gateway gateway gateway gw control signal 1 gw c...

Page 113

113 no.2 (axis 0) operation lamp (axis 0) pwr no.2 (axis 0) servo on lamp axis (0) servo on (axis 0) sv (axis 0) hen axis (0) servo on no.2 (axis 0) srdy lamp no.2 (axis 0) home return completed axis (0) operation flag.

Page 114

114 flag axis (0) operation flag axis (0) move axis command position no axis command position no axis command position no axis command position no axis command position no axis command position no axis (0) move axis (0) pend axis (0) po start flag flag flag axis (0) cstr axis (0) pend completion p.N...

Page 115

115 axis (0) po completion 1 second 1 second axis (0) operation flag axis (0) move axis (0) p1 setting flag axis command position no. Axis (0) p1 setting flag axis (0) p1 setting flag axis command position no. Axis command position no. Axis command position no. Axis command position no. Axis command...

Page 116

116 axis (0) pend completion p.No completion p.No completion p.No completion p.No completion p.No completion p.No axis (0) p1 completion 1 second axis (0) cstr axis (0) p1 completion axis (0) p0 start flag axis (0) p1 start flag axis (0) p0 completion axis (0) p1 completion no.2 (axis 0) positioning...

Page 117

117 axis (0) pause no.3 (axis 1) start no.2 (axis 0) pause lamp axis (0) stp no.3 (axis 1) operation lamp axis (1) alm emergency stop no.3 (axis 1) operation lamp axis (1) pwr no.3 (axis 1) servo on lamp axis (1) servo on no.3 (axis 1) srdy lamp no.3 (axis 1) home return completed axis (1) operation...

Page 118

118 flag axis (1) operation flag axis (1) move axis command position no axis command position no axis command position no axis command position no axis command position no axis command position no 1 second axis (1) move axis (1) pend axis (1) p0 start flag flag axis (1) cstr flag axis (1) pend compl...

Page 119

119 axis (1) po completion 1 second 1 second axis (1) operation flag axis (1) move axis (1) p1 setting flag axis (1) p1 setting flag axis (1) p1 setting flag axis command position no axis command position no axis command position no axis command position no axis command position no axis command posi...

Page 120

120 axis (1) pend completion p.No completion p.No completion p.No completion p.No completion p.No completion p.No axis (1) cstr axis (1) po start flag axis (1) p1 completion axis (1) p1 completion 1 second axis (1) p1 start flag axis (1) p0 completion axis (1) p1 completion flag no.3 (axis 1) positi...

Page 121

121 no.3 (axis 1) pause no.3 (axis 1) pause lamp no.3 (axis 1) stp.

Page 122

122 10. Troubleshooting 10.1 action to be taken upon occurrence of trouble upon occurrence of a problem, take an appropriate action according to the procedure below in order to ensure speedy recovery and prevent recurrence of the problem. A. Check the status of various led indications for gateway un...

Page 123

123 10.2 troubleshooting statuses of failures are classified into the following three types. A. Abnormality of gateway unit b. Abnormality of sio communication c. Abnormality of cc-link 10.2.1 abnormality of gateway unit there occurs a control abnormality of the gateway unit if the run (green) on th...

Page 124

124 10.2.3 abnormality of cc-link communication when the cc-link communication is abnormal, c.Er (red) on the gateway status indication led is lit. Further, details of communication status can be checked by run (green), err (red), sd (green) and rd (green) on the cc-link communication status led. Wh...

Page 125

125 cc-link communication status indication list ○ : lit ●: unlit ◎: flashing run (green) err (red) sd (green) rd (green) operation ○ ◎ ◎ ○ communication is normally performed, however, crc(*) error frequently occurs due to noise. ○ 0.4s◎ ◎ ○ baud rate or station no. Has changed from baud rate for r...

Page 126: Iai America Inc.

Catalog no.: mj0169-1a (august 2006) iai america inc. Head office: 2690w 237th street torrance, ca 90505 tel (310) 891-6015 fax (310) 891-0815 chicago office: 1261 hamilton parkway itasca, il 60143 tel (630) 467-9900 fax (630) 467-9912 new jersey office: 7 south main st., suite-f, marlboro, nj 07746...