- DL manuals

- IAI

- Controller

- RoboNet

- Operation Manual

IAI RoboNet Operation Manual

Summary of RoboNet

Page 1

Operation manual forth edition robonet.

Page 2

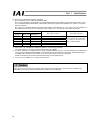

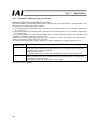

Caution 24-v power supply to be certified for ul standards please see below for the 24-v power supply condition for ul certification. • for ul certification, class2 power supply is required based on nec nfpa 79 (electrical standard for industrial machinery). • if a single class2 power supply unit is...

Page 3

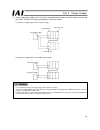

Caution teaching pendant pc, etc. Do not connect the fg. Do not connect the fg of the pc to ground. If the fc may be connected to ground through other com port, disconnect the communication cable from the applicable com port. Pc software rs232 connection type usb connection type * the cable is suppl...

Page 4

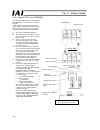

Caution if the positive terminal of the robonet’s 24-v power supply is grounded, a teaching pendant or pc cannot be connected directly to the gatewayr unit. If a teaching pendant or pc is connected directly to the gatewayr unit, the power supply may be short-circuited, causing the pc or teaching pen...

Page 5: Introduction

Introduction introduction thank you for purchasing iai’s robonet. “robonet” is a general term for dedicated single-axis controllers used in a field network environment and characterized by their ultra-compact size, wire-saving features, and easy installation. This manual provides the information you...

Page 6

Safety precautions safety precautions (please read before using the product.) carefully read this operation manual before using the product. In this operation manual, safety instructions are classified into “danger,” “warning,” “caution” and “note” as shown below. Level degree or danger/damage symbo...

Page 7

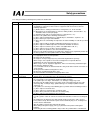

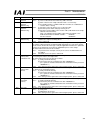

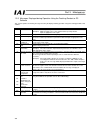

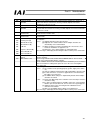

Safety precautions the safety precautions pertaining to this product are listed below. No. Task precautions 1 model selection z this product is not planned or designed for uses requiring high degrees of safety. Accordingly, it cannot be used to sustain or support life and must not be used in the fol...

Page 8

Safety precautions no. Task precautions z securely connect the cable connectors in a manner free from disconnection or looseness. Failure to do so may result in fire, electric shock or product malfunction. Z do not cut and reconnect the cables of the product to extend or shorten the cables. Doing so...

Page 9

Safety precautions no. 7 automatic operation z before commencing automatic operation, make sure no one is inside the safety fences. Z before commencing automatic operation, make sure all related peripherals are ready to operate in the auto mode and no abnormalities are displayed or indicated. Z be s...

Page 10: Ce Mark

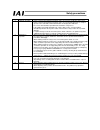

Ce mark ce mark 1. Ec directives the ec directives are a new set of directives issued by the european commission that are intended to protect the health and safety of users and consumers of products distributed within the eu (european union) zone, while ensuring free movements of these products with...

Page 11

Ce mark use environment item standard remarks overvoltage category ii pollution degree ii protection code ip 20 protection class *1 i altitude 2000 m or less *1) protection class i device a device in which additional safety measures are taken against electric shock, without depending solely on the b...

Page 12

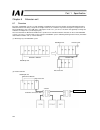

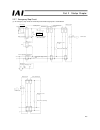

Ce mark 100 or 200-vac power supply bus control panel field network cable plc master clamp filter circuit breaker earth leakage breaker 24-vdc power supply surge protector network connector power- supply terminal fg ground robonet controller encoder cable actuator motor cable actuator encoder cable ...

Page 13

Ce mark (5) clamp filter install clamp filters of the following type on the field network cable, motor cable and encoder cable. Install them immediately near the cable connectors on the controller unit. One clamp filter is required for each gateway unit, and two for each controller unit. On the fiel...

Page 14

Ce mark (6) surge protector install a surge protector on the primary side of the 24-vdc power supply to protect the equipment from surge noise generated by lightning, etc. Manufacturer: okaya electric model: zcat3035-1330 external view of surge protector (7) cables take note that cables are also sub...

Page 15

Warranty warranty the robonet you have purchased passed our strict outgoing inspection. This unit is covered by the following warranty: the details of the warranty are described below. (1) warranty period the warranty period ends upon either of the following, whichever occurs first: • 18 months afte...

Page 16

Warranty related manuals • pc software rcm-101-** operation manual • rcm-* teaching pendant operation manual • robo cylinder series – serial communication [modbus version] operation manual • touch panel display rcm-pm-01 operation manual (not sold in the us market) manual revision history [1] august...

Page 17

Table of contents table of contents introduction safety precautions ce mark warranty related manuals manual revision history part 1 specification ........................................................................................1 chapter 1 overview of robonet .....................................

Page 18

Table of contents 3.8 i/o signals ................................................................................................................................................73 3.8.1 i/o signal timings .................................................................................................

Page 19

Table of contents 6.4 name of each part and external dimensions .........................................................................................230 6.4.1 name of each part......................................................................................................................23...

Page 20

Table of contents chapter 6 setting for external sio link and other .............................................................................. 340 6.1 scon/pcon-cf settings and signal assignments ...............................................................................340 6.2 other ..........

Page 21

1 part 1 specification part 1 specification chapter 1 overview of robonet 1.1 overview “robonet” is a general term for dedicated controllers used to operate robo cylinders (rca/rca2/rcl/rcp2/rcp3) over a field network connected to a host programmable controller (hereinafter referred to as “plc”). A ...

Page 22

2 part 1 specification 1.2 features (1) five types of component units the five types of units specified below can be combined in a desired fashion to build a robonet system. The maximum number of component axes is 16. [1] gatewayr unit four types—devicenet type, cc-link type, profibus type, and rs48...

Page 23

3 part 1 specification (7) six robonet operation modes the robonet can operate robo cylinders in one of the following six modes under the control of the gatewayr unit, regardless of the type of the host fieldbus. The following three modes under [1] to [3] can be combined together. Also, the three mo...

Page 24

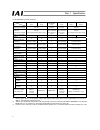

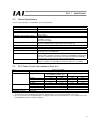

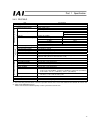

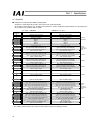

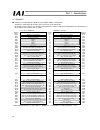

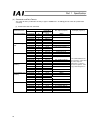

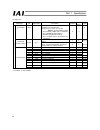

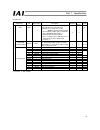

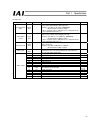

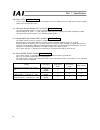

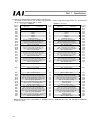

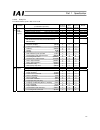

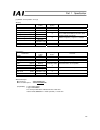

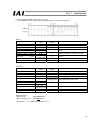

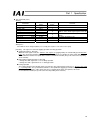

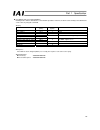

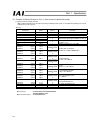

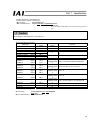

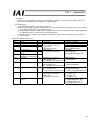

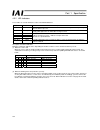

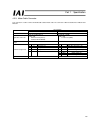

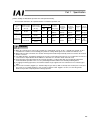

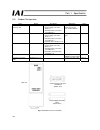

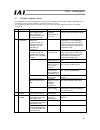

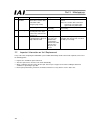

4 part 1 specification list of robonet operation functions operation mode item positioner 1 mode simple direct mode direct numerical specification mode positioner 2 mode solenoid valve mode 1 solenoid valve mode 2 axis area (both input and output) 4 words 8 words 2 words 2 words fixed area (both inp...

Page 25

5 part 1 specification (8) easy setting using the robonet gateway parameter setting tool with this tool, you can set the station number, baud rate, and operation mode of each axis, and also check the occupied areas. Also, reserved axes can be set in consideration of expansion of axis configuration i...

Page 26

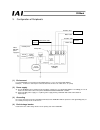

6 part 1 specification chapter 2 system configuration and general specifications 2.1 system configuration a robonet system is comprised of one gatewayr unit and up to 16 axes of controller units. The gatewayr unit is available in four types—devicenet specification, cc-link specification, profibus sp...

Page 27

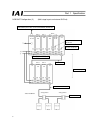

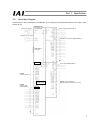

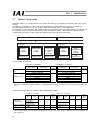

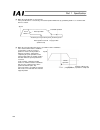

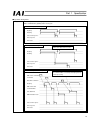

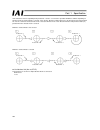

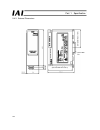

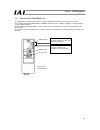

7 pa rt 1 sp ec if ica tio n field network (devicenet, cc-link, profibus) rs485 sio axis 0 axis 1 axis 2 axis 3 axis 14 axis 15 gateway r unit racon unit rpcon unit raon unit simple absolute r unit rpcon unit simple absolute r unit simple absolute connection circuit board terminal resistor circuit b...

Page 28

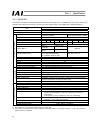

8 part 1 specification gateway r unit racon unit rpcon unit raon unit simple absolute r unit extension unit simple absolute connection circuit board robonet communication connection circuit board power-supply connection plates extension unit racon unit rpcon unit extension unit unit link cable contr...

Page 29

9 part 1 specification 2.3 general specifications the general specifications of a robonet system are listed below. Item specification power-supply voltage 24 vdc ± 10 % power-supply current varies depending on the system configuration. Maximum number of connectable axes 16 axes (controller units can...

Page 30

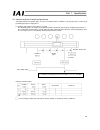

10 part 1 specification gateway r unit robonet racon or rpcon (up to 16 axes) circuit breaker power supply the method to select an appropriate 24-vdc power supply to be used with your robonet system is explained below. (1) current consumption of controller units when the respective axes operate simu...

Page 31

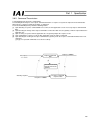

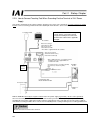

11 part 1 specification 2.5 connection diagram shown below is a connection diagram of a robonet system comprising of a rpcon and a racon connected to a simple absolute r unit. 24-v power supply terminal block emergency stop circuit rpcon encoder cable port racon encoder cable (cb-acs-pa***) gatewayr...

Page 32

12 part 1 specification chapter 3 gatewayr unit 3.1 overview the gatewayr unit is a slave station with gateway function for connecting robo cylinders to a field network of a host plc and operating the connected robo cylinders. The gatewayr unit is available in four types to support field networks of...

Page 33

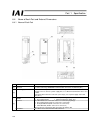

13 part 1 specification 3.2 how to read the model name 3.3 gatewayr unit and accessories the four types of units each come with a different set of accessories appropriate for the applicable field network. Cc-link devicenet rs485 sio communication profibus fig. [1] fig. [2] fig. [3] - emg connector m...

Page 34

14 part 1 specification 3.4 general specifications 3.4.1 cc-link this product is a maximum 4-station remote device station supporting cc-link version 2.00. (its specifications vary depending on the extended cyclic setting.) this product supports the following functions of cc-link version 2.00: • ext...

Page 35

15 part 1 specification item specification power supply 24 vdc ± 10% current consumption 600 ma max. Communication protocol cc-link version 2.00 (version 1.10) baud rate 10m/5m/2.5m/625k/156k [bps] (set by a robonet gateway parameter) communication method broadcast polling method synchronization met...

Page 36

16 part 1 specification 3.4.2 devicenet item specification power supply 24 vdc ± 10% current consumption 600 ma max. (*1) an interface module certified under devicenet 2.0 is used. Group 2 only server communication protocol network-powered insulated node bit strobe polling communication specificatio...

Page 37

17 part 1 specification 3.4.3 profibus item specification power supply 24 vdc ± 10% current consumption 600 ma max. (*1) group 2 only server communication protocol network-powered insulated node bit strobe polling communication specification master-slave connection cyclic baud rate 9.6 kbps to 12 mb...

Page 38

18 part 1 specification 3.4.4 rs485 sio two modes are available: the modbus gateway mode in which the unit operates as a modbus/rtu slave station, and the sio through mode in which the unit operates by means of serial communication per the modbus/rtu and ascii protocols. Specification item modbus ga...

Page 39

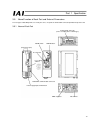

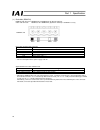

19 part 1 specification 3.5 name/function of each part and external dimensions the four types of gatewayr units are exactly the same, except for the field network connector provided on top of the unit. 3.5.1 name of each part (front cover open) user setting switches robonet communication connector p...

Page 40

20 part 1 specification 3.5.2 led indicators these leds are used to monitor the status of the gateway unit. Symbol indicator color explanation run/alm green/orange steady green: operating normally. Steady orange: an error is present. Emg red this led is lit when an emergency stop is actuated. Error ...

Page 41

21 part 1 specification (3) profibus name indicator color status explanation steady online. Green blinking online (clear command executed). Status 1 orange blinking an error (parameter error or profibus configuration error) is present. Steady initialization has completed. Green blinking initializati...

Page 42

22 part 1 specification 3.5.3 mode switch this switch is used to set the operation mode of the controller. Status explanation manu manual operation: the robonet system can be operated using a teaching pendant or pc. Auto auto operation: the robonet system is controlled via field network communicatio...

Page 43

23 part 1 specification the photographs show the parts supplied with the axis controller unit or simple absolute r unit. 3.5.8 fg terminal (frame ground) this terminal is used to connect the gatewayr unit to ground. The thread size is m3. 3.5.9 emg connector (emergency stop) this connector is used t...

Page 44

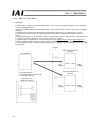

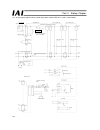

24 part 1 specification recommended emergency stop circuit shown below is an example of an emergency stop circuit of a robonet system. The built-in drive-source cutoff relays of all axis controller units are turned on/off simultaneously using the emergency stop switch of the emergency stop circuit o...

Page 45

25 part 1 specification 3.5.10 field network connector this connector is used to connect the master unit of each field network. The connector varies according to the field network type. (1) cc-link (rgw-cc) rgw-cc-end connector: mstba2.5/5-g-5.08au (by phoenix contact) cable-end connector: mstb2.5/5...

Page 46

26 part 1 specification (1) devicenet (rgw-dv) rgw-dv-end connector: mstba2.5/5-g-5.08abgyau (by phoenix contact) cable-end connector: mstb2.5/5-st-5.08abgyau (by phoenix contact) = standard accessory devicenet communication connector pin color explanation black power-supply cable- * blue communicat...

Page 47

27 part 1 specification (3) profibus (rgw-pr) rgw-pr connector: d-sub, 9-pin connector (female) profibus communication connector pin number signal name explanation 1 nc not connected 2 nc not connected 3 b-line communication line b (rs485) 4 rts send request 5 gnd signal ground (insulated) 6 +5 v +5...

Page 48

28 part 1 specification (4) rs485sio (rgw-sio) rgw-sio connector: mc1.5/4-g-3.5 (by phoenix contact) cable-end connector: mc1.5/4-st-3.5 (by phoenix contact) = standard accessory sio communication connector signal name explanation sa communication line a (+) sb communication line b (-) built-in term...

Page 49

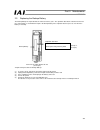

29 part 1 specification 3.5.11 external dimensions * installable on a 35-mm din rail (50 from din rail ce n ter) (69.3 from din rail surface).

Page 50

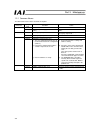

30 part 1 specification 3.6 operation function list racon/rpcon function list positioner 1, 2 mode solenoid valve mode 1 and 2 home return operation o o solenoid valve mode 1 x solenoid valve mode 2 (not required) positioning operation u specify a position table number. U specify a position table nu...

Page 51

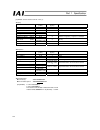

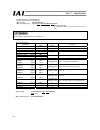

31 part 1 specification {: direct control u: indirect control x: not available simple direct mode numerical specification mode { { { specify position data (32-bit signed integer). { specify position data (32-bit signed integer). U set in the position table. { specify speed data (16-bit integer). U s...

Page 52

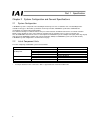

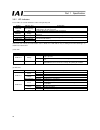

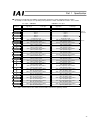

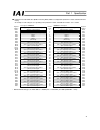

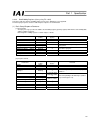

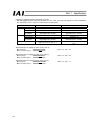

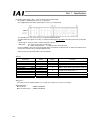

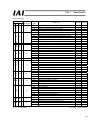

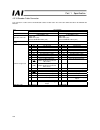

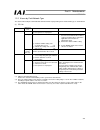

32 part 1 specification 3.7 address configuration robonet addresses are configured in the same manner with all four types of gateway units regardless of the type of field network. The addresses occupied by the network consist of a fixed 8-word area and a data area that changes according to the opera...

Page 53

33 part 1 specification (3) data area configuration in the direct numerical specification mode plc output ⇒ axis input axis output ⇒ plc input upper byte lower byte number of words upper byte lower byte number of words position data specification (l)* current position data (l)* position data specifi...

Page 54

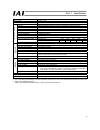

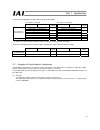

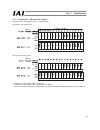

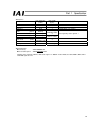

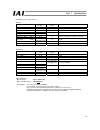

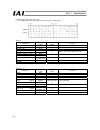

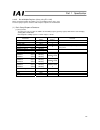

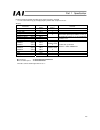

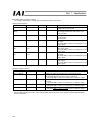

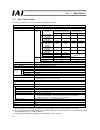

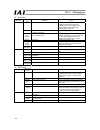

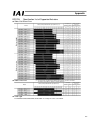

34 part 1 specification example of overall cc-link address configuration (positioner 1 mode/simple direct mode + direct numerical specification mode) an example of connecting 12 axes operating in the positioner 1 mode or simple direct mode and two axes operating in the direct numerical specificati...

Page 55

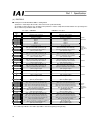

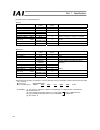

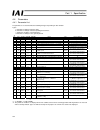

35 part 1 specification example of overall cc-link address configuration (positioner 2 mode and solenoid valve mode) an example of connecting 16 axes operating in the positioner 2 mode, solenoid valve mode 1 or 2 is shown. Plc output ⇒ robonet robonet ⇒ plc input output register upper byte lower b...

Page 56

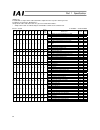

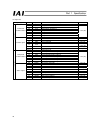

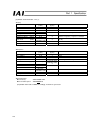

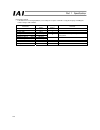

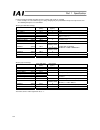

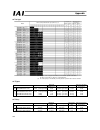

36 part 1 specification (2) devicenet example of overall devicenet address configuration (positioner 1 mode/simple direct mode + direct numerical specification mode) an example of connecting 12 axes operating in the positioner 1 mode or simple direct mode and two axes operating in the direct numer...

Page 57

37 part 1 specification example of overall devicenet address configuration (positioner 2 mode and solenoid valve mode)) an example of connecting 16 axes operating in the positioner 2 mode, solenoid valve mode 1 or 2 is shown. Plc output ⇒ robonet robonet ⇒ plc input relative channel* upper byte lo...

Page 58

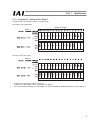

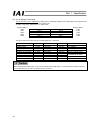

38 part 1 specification (3) profibus example of overall profibus address configuration (positioner 1 mode/simple direct mode + direct numerical specification mode) an example of connecting 12 axes operating in the positioner 1 mode or simple direct mode and two axes operating in the direct numeric...

Page 59

39 part 1 specification example of overall profibus address configuration (positioner 2 mode and solenoid valve mode)) an example of connecting 16 axes operating in the positioner 2 mode, solenoid valve mode 1 or 2 is shown. Plc output ⇒ robonet robonet ⇒ plc input relative channel* upper byte low...

Page 60

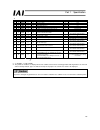

40 part 1 specification (4) rs485sio example of overall rs485 sio (modbus gateway mode) address configuration (positioner 1 mode/simple direct mode + direct numerical specification mode) an example of connecting 12 axes operating in the positioner 1 mode or simple direct mode and two axes operatin...

Page 61

41 part 1 specification example of overall rs485 sio (modbus gateway mode) address configuration (positioner 2 mode and solenoid valve mode)) an example of connecting 16 axes operating in the positioner 2 mode, solenoid valve mode 1 or 2 is shown. Plc output ⇒ robonet robonet ⇒ plc input register ...

Page 62

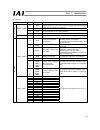

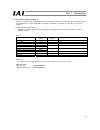

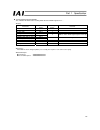

42 part 1 specification 3.7.2 gateway control/status signals in the address configuration of the gatewayr unit, the first two input words and output words are used to control the gatewayr unit. These signals can be used to perform on/off control of robonet communication (sio control) and monitor the...

Page 63

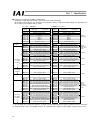

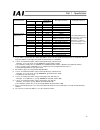

43 part 1 specification i/o signal list signal type bit signal name description 15 mon when this signal is on (“1”), control outputs from the plc are effective (outputs from the plc are reflected in the controller unit). When the signal is off (“0”), the outputs are ineffective. 14 - cannot be used....

Page 64

44 part 1 specification 3.7.3 command area the eight input words and eight output words from the initial address of the gateway unit are fixed areas. With both output and input, six words in this fixed area are assigned as a command area where various commands can be used to read/write the position ...

Page 65

45 part 1 specification (2) command list the available command and command codes are listed below. Function classification code explanation positioner 1 mode simple direct mode direct numerical specification mode positioner 2 mode solenoid valve mode 1 and 2 handshake 0000h clear request command { {...

Page 66

46 part 1 specification (3) commands and data formats the rewrite life of the position table memory is approx. 100,000 times. Accordingly, do not rewrite the position table constantly. [1] position table data write commands relative address from beginning command name cc-link*8 devicenet profibus rs...

Page 67

47 part 1 specification relative address from beginning command name cc-link devicenet profibus rs485sio *1 plc output (request) plc input (response) ry 2*/rx 2* +2 +4/+5 1006h ry 3*/rx 3* +3 +6/+7 position number ry 4*/rx 4* +4 +8/+9 deceleration data *6 ry 5*/rx 5* +5 +10/+11 0 ry 6*/rx 6* +6 +12/...

Page 68

48 part 1 specification [2] position table data read commands relative address from beginning command name cc-link*6 devicenet profibus rs485sio *1 plc output (request) plc input (response) ry 2*/rx 2* +2 +4/+5 1040h ry 3*/rx 3* +3 +6/+7 position number if the command has been successful, the value ...

Page 69

49 part 1 specification relative address from beginning command name cc-link*6 devicenet profibus rs485sio *1 plc output (request) plc input (response) ry 2*/rx 2* +2 +4/+5 1046h ry 3*/rx 3* +3 +6/+7 deceleration read pos number if the command has been successful, the value returned in the response ...

Page 70

50 part 1 specification [3] group-specific broadcast operation commands these operations can be used in the positioner mode. The axes specified by the group number are started simultaneously to the position specified by the pos number. Since these commands implement broadcast communication between t...

Page 71

51 part 1 specification (4) error responses if a command error occurs, the most significant bit (b15) of the response command will turn on and an error code will be set in response data 1. Code explanation 0101h invalid axis number *1 0102h invalid position number *1 0103h invalid request command *1...

Page 72

52 part 1 specification 3.7.4 position table racon and rpcon controllers can be operated in one of six modes—positioner mode 1and 2, simple direct mode, direct numerical specification mode and solenoid valve mode 1 and 2—using one of four types of gatewayr units. To perform positioning operation in ...

Page 73

53 part 1 specification position the position table is explained using the screen of the pc software as an example. (the display is different on the teaching pendant.) (1) no. • a position data number is indicated. (2) position • input the target position to which to move the actuator [mm]. Absolute...

Page 74

54 part 1 specification (4) acceleration/deceleration • input the acceleration/deceleration at which to move the actuator (unit: [g]). Input a value within the rated range. (refer to appendix, “specification list of supported actuators.”) exercise caution when setting the acceleration/deceleration, ...

Page 75

55 part 1 specification “push operation” this field defines the maximum distance traveled from the target position in push operation. Consider the mechanical variation of the load and set an appropriate positioning band so that the positioning will not complete before the actuator contacts the load....

Page 76

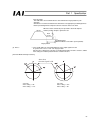

56 part 1 specification [for straight slide actuators] caution zone functions differ depending on the application version. • for application version v0015 or earlier, zone output is not performed for the setting below; zone setting + ≤ zone setting – • for application version v0016 or earlier, zone ...

Page 77

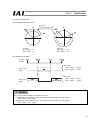

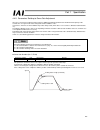

57 part 1 specification (9) acceleration/deceleration mode • this field defines the acceleration/deceleration pattern characteristics. The factory setting is “0.” 0: trapezoid pattern 1: s-motion 2: primary delay filter the acceleration and deceleration are set in the “acceleration” and “deceleratio...

Page 78

58 part 1 specification the actuator accelerates/decelerates over a curve that is more gradual than in linear acceleration/deceleration (trapezoid pattern). Use this pattern if you don’t want the load to receive micro-vibration during acceleration/deceleration. The primary delay level is set in para...

Page 79

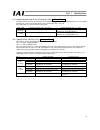

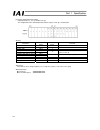

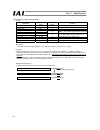

59 part 1 specification profibus position data specification(signed integer) plc output = axis control signal position data specification(signed integer) command position number control signal bkrl mode pwr t jog + jog - pc512 pc256 pc128 pc64 pc32 pc16 pc8 pc4 pc2 pc1 jvel jisl son res stp home cst...

Page 80

60 part 1 specification i/o signal list signal type bit signal name description positioner simple direct details position data specification 32-bit data - set as a hexadecimal number using a 32-bit signed integer (unit: 0.01 mm) example) to set +25.4 mm, specify “0009ec” (decimal number: 2540). Z th...

Page 81

61 part 1 specification i/o signal list signal type bit signal name description positioner simple direct details current position data 32-bit data - output as a hexadecimal number using a 32-bit signed integer (unit: 0.01 mm). Example) to set +25.4 mm, specify “0009ec” (decimal number: 2540). Z the ...

Page 82

62 part 1 specification [alarm list] listed below are simple alarm codes that will be output when the respective alarms generate. For details, refer to part 3, “maintenance.” simple alarm codes and alarm codes are given as hexadecimal numbers. * simple alarm codes are indicated by the status0 to 3 l...

Page 83

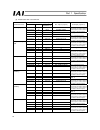

63 part 1 specification 3.7.6 assignments in the direct numerical specification mode assignments in the direct numerical specification mode are shown below. Set the push-current limiting value, acceleration/deceleration and speed within the ranges specified for the applicable actuator, and set the t...

Page 84

64 part 1 specification * m indicates the initial register address of each axis. N indicates the relative address at the beginning of each address. The cc-link and devicenet types use word addresses, while the profibus and rs485 sio types use byte addresses. Plc input = axis status signal address* 1...

Page 85

65 part 1 specification i/o signal list signal type bit signal name description details position data specification 32-bit data - set as a hexadecimal number using a 32-bit signed integer (unit: 0.01 mm) example) to set +25.4 mm, specify “0009ech” (decimal number: 2540). Z the maximum settable value...

Page 86

66 part 1 specification i/o signal list signal type bit signal name description details push-current limiting value 8-bit data - set the push-current limiting value as a hexadecimal number (unit: %) to set the push force. Settable range is 00h to 1ffh, ffh = 100% and 1ffh = 200% example) to set 50%,...

Page 87

67 part 1 specification i/o signal list signal type bit signal name description details current position data 32-bit data - the current position data is output as a hexadecimal number using a 32-bit signed integer (unit: 0.01 mm). Example) if the data is +25.4 mm, “000009ech” (decimal number: 2540) ...

Page 88

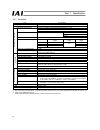

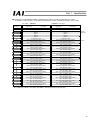

68 part 1 specification 3.7.7 assignment in positioner 2 mode assignment in the positioner 2 mode is explained below. Plc output = axis control signal plc input = axis status signal * m indicates the initial register address of each axis. N indicates the relative address at the beginning of each add...

Page 89

69 part 1 specification 3.7.8 assignment in solenoid valve mode 1 assignment in the solenoid valve mode 1 is explained below. Plc output = axis control signal plc input = axis status signal * m indicates the initial register address of each axis. N indicates the relative address at the beginning of ...

Page 90

70 part 1 specification i/o signal list signal type bit symbol description details b15-b7 - cannot be used. - b6 st6 start position command 6 b5 st5 start position command 5 b4 st4 start position command 4 b3 st3 start position command 3 b2 st2 start position command 2 b1 st1 start position command ...

Page 91

71 part 1 specification 3.7.9 assignment in solenoid valve mode 2 assignment in the solenoid valve mode 2 is explained below. Plc output = axis control signal plc input = axis status signal * m indicates the initial register address of each axis. N indicates the relative address at the beginning of ...

Page 92

72 part 1 specification i/o signal list signal type bit symbol description details b15-b3 - cannot be used. - b2 st2 intermediate point move command b1 st1 front end move command command position number b0 st0 rear end move command 3.8.2 (21) b15 bkrl forced brake release 3.8.2 (19) b14-b5 - cannot ...

Page 93

73 part 1 specification 3.8 i/o signals 3.8.1 i/o signal timings to operate the robo cylinder using the plc’s sequence program, a given control signal is turned on. The maximum response time after the signal turns on until the response (status) signal is returned to the plc is calculated by the form...

Page 94

74 part 1 specification 3.8.2 i/o signal functions (1) controller ready (crdy) plc input signal this signal turns “1” (on) when the controller has become ready to perform control after the power is turned on. function this signal turns “1” (on) when the controller has been successfully initialized...

Page 95

75 part 1 specification (5) servo on command (son) plc output signal ready (sv) plc input signal turn the son signal “1” (on), and the servo will turn on. When the servo is turned on, the sv led (green) on the front panel of the controller will illuminate. The sv signal is synchronized with this led...

Page 96

76 part 1 specification (6) home return command (home) plc output signal home return complete (hend) plc input signal home return operation will start at the “0” (off) Æ “1” (on) leading edge of the home signal. When home return is complete, the hend (home return complete) signal will turn “1” (on)....

Page 97

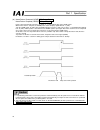

77 part 1 specification (7) positioning start (cstr) plc output signal upon detection of the “0” (off) → “1” (on) leading edge of this signal, the controller will read the target position number consisting of a 10-bit binary code from pc1 to pc512, and perform positioning to the target position spec...

Page 98

78 part 1 specification (10) pause (stp) plc output signal turn this signal “1” (on), and the axis movement will pause (the axis will decelerate to a stop). Turn the signal “0” (off), and the axis movement will resume. (11) command position number (pc1 to pc512) plc output signal the command positio...

Page 99

79 part 1 specification an example is shown below. [for index mode of rotary actuators] [for straight slide actuators] caution zone functions differ depending on the application version. • for application version v0015 or earlier, zone output is not performed for the setting below; zone setting + ≤ ...

Page 100

80 part 1 specification (14) jog+ command/jog- command (jog+/jog-) plc output signal these signals function as start commands for jogging operation or inching operation. The + command starts operation in the direction opposite home, while the – command starts operation in the home direction. Jogging...

Page 101

81 part 1 specification (15) jogging speed/inching distance switching (jvel) plc output signal this signal switches between the parameter for specifying the jogging speed when jogging operation is selected and the parameter for specifying the inching distance when inching operation is selected. The ...

Page 102

82 part 1 specification (17) teaching mode command (mode) plc output signal (effective only in the positioner mode) teaching mode status (modes) plc input signal when this signal is turned “1,” the controller will switch from the normal operation mode to the teaching mode. After switching to the tea...

Page 103

83 part 1 specification (20) start position command (st0 to st6) [solenoid valve mode 1] plc output signal upon detection of an off → on rise edge of this signal or detection of the on level of the signal, the actuator will move to the target position set in the corresponding position data. Before e...

Page 104

84 part 1 specification (22) current position number signal (pe0 to pe6) [solenoid valve mode 1] plc input signal position numbers (0 to 6) that received move command is output individually when positioning is completed. Table for output signal and completed position output signal completed position...

Page 105

85 part 1 specification 3.8.3 basic operation timings (1) ready follow the steps below to start the system after confirming that the slider or rod is not contacting a mechanical end and the load is not contacting any peripherals, either: [1] cancel the emergency stop or enable the motor drive power....

Page 106

86 part 1 specification warning the racon controller performs magnetic-pole phase detection operation during the first servo on processing after the power has been turned on. During this detection operation, the actuator will generally move by approx. 0.5 to 2 mm, although the specific dimension var...

Page 107

87 part 1 specification (2) home return operation this controller unit uses an incremental position detector (encoder) and therefore its mechanical coordinates will be lost once the power is cut off. After the power is turned on, therefore, home return must be performed to establish mechanical coord...

Page 108

88 part 1 specification (3) operation in the positioner 1 mode and positioner 2 mode input position data in the controller’s position table beforehand, and specify a desired position number using a link register of the plc. ■ operation [1] set the position number in the command position number regis...

Page 109

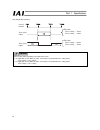

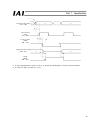

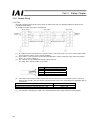

89 part 1 specification *1 t1: set an appropriate time so that “t1 ≥ 0 ms” is satisfied, by considering the scan time of the host controller. *2 yt + 2mt + xt ≤ tdpf ≤ yt + 2mt + xt + 7 (ms) [1] [2] [4] * [3] [5] [6] ≤ 1mt ≤ 1mt command position number (plc → gw) start command cstr (plc → gw) positi...

Page 110

90 part 1 specification (4) operation in the simple direct mode in this mode, position data is written to a link register of the plc and other data such as speed, acceleration/deceleration, positioning band and push current-limiting value are specified by a position table. preparation set in the p...

Page 111

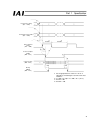

91 part 1 specification *1 set an appropriate time so that “t1 ≥ 0 ms” is satisfied, by considering the scan time of the host controller. *2 yt + 2mt + xt ≤ tdpf ≤ yt + 2mt + xt + 7 (msec) *3 twcson ≥ 1mt *4 twcsoff ≥ 1mt [1] [2] [3] [4] [5] [6] [7] [8] *3 twcson *4 twcsoff *2 tdpf ≤ 1mt ≤ 1mt comma...

Page 112

92 part 1 specification (5) operation in the direct numerical specification mode in this mode, the actuator is operated by writing the target position data, acceleration/deceleration data, speed data, push-current limiting value data and positioning band data to link registers in the plc, without us...

Page 113

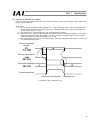

93 part 1 specification *1 set an appropriate time so that “t1 ≥ 0 ms” is satisfied, by considering the scan time of the host controller. *2 yt + 2mt + xt ≤ tdpf ≤ yt + 2mt + xt + 7 (msec) [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [13] [12] ≤ 1mt ≤ 1mt target position data setting (plc Æ gw) spe...

Page 114

94 part 1 specification the target position data, acceleration/deceleration data, speed data, positioning band data and push-current limiting value data can be changed while the actuator is moving. To do so, turn the cstr “1” (on) and keep it “1” (on) for tdpf or more after the data has been changed...

Page 115

95 part 1 specification (6) operation by solenoid valve mode 1 enter the position data into the position table in the controller in advance, and specify the position number with the link register on plc and operate. operation [1] be sure that the positioning complete (pend) is on “1” (on), and cha...

Page 116

96 part 1 specification (7) operation by solenoid valve mode 2 enter the position data into the position table in the controller in advance, and specify the position number with the link register on plc and operate. operation [1] turn to “0” (off) for all the movement commands. [2] turn a movement...

Page 117

97 part 1 specification 3.8.4 other basic operations (1) push operation [1] basic operation as shown below, the actuator moves to the specified target position, and then moves at the specified push speed by up to the specified positioning band while pushing the load. The moment the push force reache...

Page 118

98 part 1 specification push mode specification • in the positioner 1, 2 mode, simple direct mode, solenoid valve mode 1 or 2, set a value other than “0” (push-current limiting value) in the “push” field of the position table. • i in the direct numerical specification mode, set a value in the push...

Page 119

99 part 1 specification [2] when the load was missed in push operation if the load is not contacted (the motor current does not reach the push-current limiting value) after the actuator has moved the distance corresponding to the specified positioning band, the position complete signal is not output...

Page 120

100 part 1 specification [4] when the push direction is set incorrectly if the push direction is set incorrectly, the actuator position will deviate by “positioning band x 2,” as shown below. Exercise caution. [5] when the return operation after push is specified in relative coordinates take note th...

Page 121

101 part 1 specification (2) pause when the pause command signal (stp) is turned “1” (on) while the actuator is moving, the actuator will decelerate to a stop. Since the remaining travel distance is retained, the remaining travel can be resumed by turning the stp “0” (off) again. The remaining trave...

Page 122

102 part 1 specification (3) speed change during movement the actuator can be controlled at multiple speeds in a single operation. In other words, the speed can be decreased or increased at a given point. However, a position data must be set for every point at which the speed is changed. This functi...

Page 123

103 part 1 specification caution [1] when the start signal (cstr) is turned “1” (on), the position complete signal (pend) will turn “0” (off) and the moving signal (move) will turn “1” (on). Turn the start signal (cstr) “0” (off) after confirming that the position complete signal (pend) has turned “...

Page 124

104 part 1 specification (4) operation at different acceleration and deceleration [1] when the controller is used in the positioner 1, 2 mode or simple direct mode, separate values can be set for acceleration and deceleration using the position table. [2] direct numerical specification mode in this ...

Page 125

105 part 1 specification (5) operation by relative coordinate specification the target position in the position table can also be specified in relative coordinates. This function can be used to repeat positioning operations at equal pitches. [1] example of operation in the positioner 1, 2 mode the f...

Page 126

106 part 1 specification * set an appropriate time so that “t1 ≥ 0 ms” is satisfied, by considering the scan time of the host controller. [explanation of operation] [1] positioning operation to position 1 (100.00 mm) is performed. [2] upon completion of positioning to position 1, the position comple...

Page 127

107 part 1 specification [2] notes on positioning operation if a position number specified in relative coordinates is selected/entered and a start signal is input during positioning operation, the actuator will move to the initial target position plus the relative travel distance. (if the relative t...

Page 128

108 part 1 specification [3] notes on push operation if a position number specified in relative coordinates (for which the push mode is specified) is selected/input and a start signal is input while the actuator is moving in the push mode, the actuator will move to the position at which the start si...

Page 129

109 part 1 specification 3.8.5 command transmission a command transmission chart is shown below. The gatewayr unit analyzes each request command and returns a response every time the replacement of control/status data of all axes, which is performed constantly, is completed. The plc and gatewayr uni...

Page 130

110 part 1 specification 3.9 modbus gateway mode of rs485 sio 3.9.1 overview with the rs485 sio gatewayr unit, the modbus gateway mode in which the unit operates as a modbus/rtu slave station, and the sio through mode in which the unit operates by means of serial communication per the modbus/rtu and...

Page 131

111 part 1 specification 3.9.2 modbus/rtu protocol specification the rs485 sio gatewayr unit has an asynchronous serial bus interface conforming to eia rs485 for interfacing with the host. The modbus protocol is used for communication to receive commands from the host or reference internal informati...

Page 132

112 part 1 specification (2) communication method the modbus protocol uses the single-master/multiple-slave communication method. Only the master can issue a query (to start communication). The slave receives a query, performs the specified function, and returns a response message. The master can is...

Page 133

113 part 1 specification (4) message frame query and response messages use the following message frame. Header address function data error check trailer t1-t2-t3-t4 8 bits 8 bits n x 8 bits 16 bits t1-t2-t3-t4 * “t1-t2-t3-t4” represents a silent interval. [1] header field the frame starts with a sil...

Page 134

114 part 1 specification (5) error check crc check each message contains an error check field based on the crc method. The crc field is used to check the content of the entire message. This check is independent of the parity check of individual characters comprising the message. The crc field consis...

Page 135

115 part 1 specification 3.9.9 protocol format 3.9.3.1 gateway address map the slave address is fixed to “63 (3fh)” for the rs485 sio gateway. As for gateway registers, inputs (plc ⇒ robonet) are assigned to word addresses f600 h onward in the plc, while outputs (robonet ⇒ plc) are assigned to word ...

Page 136

116 part 1 specification example of overall rs485sio gateway address configuration an example of connecting 12 axes operating in the positioner 1 mode or simple direct mode and two axes operating in the direct numerical specification mode is shown. Plc output ⇒ robonet robonet ⇒ plc input register a...

Page 137

117 part 1 specification 3.9.3.2 query list the table below lists queries that can be used. Fc function remarks (performable operation) positioner mode axis simple direct mode axis direct numerical mode axis details [1] read gateway status signal 0, 1 1 each 1 each 1 each 3.9.3.3 (2) [1] [2] read re...

Page 138

118 part 1 specification fc function remarks (performable operation) positioner mode axis simple direct mode axis direct numerical mode axis details • forced brake release (bkrl) { { { 3.9.3.4 (2) [3] • push operation mode specification x x { 06h write register • push direction specification x x { 3...

Page 139

119 part 1 specification 3.9.3.3 read holding registers (query using fc = 03h) this query reads the contents of holding registers in the slave. Broadcast is not supported. The basic query/response structures and examples of queries are shown below. (1) basic query/response structures [1] query forma...

Page 140

120 part 1 specification (2) examples of queries/responses queries are implemented by reading a 1-word register and thus the basic pattern is the same with all queries. The only differences are the starting address and data. [1] read gateway status signal 0, 1 the configuration of the completed posi...

Page 141

121 part 1 specification z response field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 data bytes 04 h 1 1-word register x 2 = 4 bytes data 1 (upper) arbitrary data 1 (lower) arbitrary 1 each for upper and lower words 2 data 2...

Page 142

122 part 1 specification [2] read response command data 0 to 3 z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) f7 h starting address (lower) 02 h 2 initial address of the response command nu...

Page 143

123 part 1 specification [3] monitor current position – axis (0) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) f7 h starting address (lower) 08 h 2 the addresses of current position data o...

Page 144

124 part 1 specification [4] monitor current electrical current – axis (1) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) f7 h starting address (lower) 0e h 2 address of the current electri...

Page 145

125 part 1 specification [5] monitor current speed – axis (1) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) f7 h starting address (lower) 10 h 2 address of the current speed data of axis (...

Page 146

126 part 1 specification [6] monitor alarm information – axis (1) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) f7 h starting address (lower) 12 h 2 alarm address of axis (1) number of reg...

Page 147

127 part 1 specification [7] read completed position number status – axis (0) the configuration of the completed position number register of axis (0) is shown below. Z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 s...

Page 148

128 part 1 specification [8] read status signal status – axis (0) the configuration of the status signal register of axis (0) is shown below. Z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 03 h 1 starting address (upper) ...

Page 149

129 part 1 specification z actual example after axis (0) servo on sent query: 3f03f70b0001c362 received response: 3f03024011604d (explanation) the crdy, sv and pend signals are on. Z actual example after axis (0) home return sent query: 3f03f70b0001c362 received response: 3f03027013f58c (exp...

Page 150

130 part 1 specification 3.9.3.4 preset single register (query using fc = 06h) data is written to (changed in) a holding register in the slave. The basic query/response structures and examples of queries are shown below. (1) basic query/response structures [1] query format the query message specifie...

Page 151

131 part 1 specification (2) examples of queries/responses queries are implemented by changing (writing) a 1-word register and thus the basic pattern is the same with all queries. The only differences are the starting address and data. The following explanations use axis (0) or axis (12) in the exam...

Page 152

132 part 1 specification [2] output command position number a position number (= 1) is specified for axis (0). The configuration of the command position number register of axis (0) is shown below. Z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h ...

Page 153

133 part 1 specification [3] output control signals (axis 0 = positioner mode or simple direct mode) an example of control signals of axis (0) is explained. The configuration of the control signal register of axis (0) is shown below. servo on command (son) z query field name rtu mode data (8 bits)...

Page 154

134 part 1 specification home return command (home) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) ...

Page 155

135 part 1 specification start command (cstr) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) new da...

Page 156

136 part 1 specification pause command (stp) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) new dat...

Page 157

137 part 1 specification reset command (res) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) new dat...

Page 158

138 part 1 specification jogging/inching switching command (jisl) this signal is used to switch jogging operation and inching operation. Jisl = “0”: jogging operation jisl = “1”: inching operation z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f ...

Page 159

139 part 1 specification jogging speed/inching distance switching command (jvel) in jogging operation and inching operation, the jogging speed and inching distance are determined by referencing the applicable control parameters. This signal is used to switch these parameters. Jvel jogging speed of...

Page 160

140 part 1 specification jog+ command (jog+) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) new dat...

Page 161

141 part 1 specification jog- command (jog-) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of axis (0) new dat...

Page 162

142 part 1 specification [summary of jogging operation and inching operation] with both jogging operation and inching operation, the jisl, jvel, jog+ and jog- signals are used in combination. The relationships of these signals are summarized in the table below. Jogging operation inching operation ji...

Page 163

143 part 1 specification teaching mode command (mode) the controller will switch to the teaching mode when the mode signal turns “1.” z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h s...

Page 164

144 part 1 specification position data load command (pwrt) z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 06 h 1 starting address (upper) f6 h starting address (lower) 0b h 2 address of the control signal register of ax...

Page 165

145 part 1 specification forced brake release command (bkrl) normally brake control is linked to the servo on/off operations. However, the brake can be forcibly released while the servo is off, by using this command. Z query field name rtu mode data (8 bits) data length (bytes) remarks header none...

Page 166

146 part 1 specification [4] output control signals (axis 1 = direct numerical specification mode) an example of control signals of axis (1) is explained. The configuration of the control signal register of axis (1) is shown below. The method of use is the same as in [3], except for the dir and push...

Page 167

147 part 1 specification 3.9.3.5 preset multiple registers (query using fc = 10h) data is changed in (written to) multiple successive holding registers in the slave. The basic query/response structures and examples of queries are shown below. (1) basic query/response structures [1] query format the ...

Page 168

148 part 1 specification [2] response format if the data has been changed (written) successfully, the response returned is a copy of the query excluding the number of bytes and new data. Field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function ...

Page 169

149 part 1 specification (2) basic axis operations [1] axis area in the direct numerical specification mode assignments of axis control signals for axis (1) (direct numerical specification mode) are shown below. Refer to the section on gateway specifications for the detailed explanation of signals. ...

Page 170

150 part 1 specification speed • 16-bit integer • register size: 1 (2 bytes) • unit: 1.0 mm/sec or 0.1 mm/sec. Establish the setting in robonet gateway parameter setting tool. • settable range: 0 to 9999 mm/sec if a value exceeding the maximum actuator speed is set, an alarm will generate when a m...

Page 171

151 part 1 specification [1] procedure in the direct numerical specification mode, the actuator is operated by writing data to the axis control signal registers (position data, positioning band, speed, acceleration/deceleration, push-current limiting value, control signals). Operation is started whe...

Page 172

152 part 1 specification (3) examples of queries/responses (axis 1, direct numerical specification mode) [1] query format for normal operation write all data required for axis operation (position, positioning band, speed, acceleration/deceleration, push-current limiting value) to the registers. Z qu...

Page 173

153 part 1 specification [2] query format for normal operation where only the position is changed use the same format in [1] by changing only the position data, to operate the axis. Z query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Functi...

Page 174

154 part 1 specification [3] query format for normal operation where the position and speed are changed. In this example, the same format in [2] is used by changing only the position data and speed, to operate the axis. The following two queries are transmitted. Z query (position data change) field ...

Page 175

155 part 1 specification [4] query format for push operation write all data required for axis operation (position, positioning band, speed, acceleration/deceleration, push-current limiting value) to the registers. Z query (position data change) field name rtu mode data (8 bits) data length (bytes) r...

Page 176

156 part 1 specification (4) use of gateway commands the position table can be read/written by writing request commands and data in the command area of the gateway unit. For details, refer to the specifications of the gateway unit. An address map of the command area is shown below. Register address ...

Page 177

157 part 1 specification [1] write position table data an example of writing the target position, positioning band and speed data one by one to the position table under no. 10 corresponding to positioner mode axis (0) is explained. • target position 100 mm → 10000 = 2710h • positioning band 0.3 mm →...

Page 178

158 part 1 specification z positioning band write query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 10 h 1 starting address (upper) f6 h starting address (lower) 02 h 2 initial request command register address of axis (0) numb...

Page 179

159 part 1 specification z speed write query field name rtu mode data (8 bits) data length (bytes) remarks header none - slave address 3f h 1 fixed. Function code 10 h 1 starting address (upper) f6 h starting address (lower) 02 h 2 initial request command register address of axis (0) number of regis...

Page 180

160 part 1 specification [2] read position table data in [1], the target position, positioning band and speed were written one by one to the position table under no. 10 corresponding to positioner mode axis (0). Next, an example of reading data from this position table is explained. Query send proce...

Page 181

161 part 1 specification send a register read (fc = 03h) query. sent query: 3f03f702000512a3 received response: 3f030a 1040 000a 27100000 0000 2e8a position data the position data (2710h) written to the position table in [1] has been read. Caution each gateway command must be cleared after use. ...

Page 182

162 part 1 specification send a register read (fc = 03h) query. sent query: 3f03f702000512a3 received response: 3f030a 1041 000a 001e0000 0000 4c0c positioning band data the data (001eh) written to the position table in [1] has been read. Caution each gateway command must be cleared after use. Z...

Page 183

163 part 1 specification send a register read (fc = 03h) query. sent query: 3f03f702000512a3 received response: 3f030a 1042 000a 00c80000 0000 4c0c speed data the data (00c8h) written to the position table in [1] has been read. Caution each gateway command must be cleared after use..

Page 184

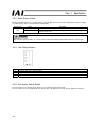

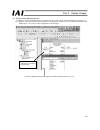

164 part 1 specification in [1] and [2], the target position, positioning band and speed data were written to the position table and the write results were checked. The applicable position table in the rc pc software is shown as follows. before sending the write query after sending the write que...

Page 185

165 part 1 specification 3.9.4 function block 3.9.4.1 dedicated robonet function block (1) overview iai provides a dedicated function block for robonet systems. It is called “robonet gateway modbus cyclic communication fbl” (robonet gw). This function block performs the following operations between ...

Page 186

166 part 1 specification the function block parameters are used to specify the following addresses of the plc’s i/o memory to be linked with the gateway unit’s memory areas: • initial gateway control signal address • initial request command area address • initial axis data specification area address...

Page 187

167 part 1 specification (2) specifications name robonet gateway modbus cyclic communication fbl function overview • read gateway information, command responses and axis data cyclically from the robonet gateway. • write gateway control information, command requests and axis data to the robonet gatew...

Page 188

168 part 1 specification variable table (parameter settings) the variables and parameter settings of the function block (fb) are described. [inputs] (input variables) name variable name data type default explanation of variable and parameter settings en en bool false 1 (on): start the fb 2 (off): ...

Page 189

169 part 1 specification [ver-in/out] (input/output variables) name variable name data type explanation of variable and parameter settings gateway information table gateway information _table int [2] gateway information data is returned. Set the i/o memory address to be assigned to the initial statu...

Page 190

170 part 1 specification ■ explanation of function [1] when the “start trigger” signal is turned on, gateway information, command responses and axis data will be read cyclically. (constant read mode) [2] when data is set in the gateway control table and the gateway control write signal is turned on,...

Page 191

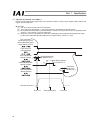

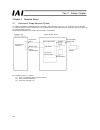

171 part 1 specification ■ operation timing chart timing chart successful pattern of read-only operation data is read from the gateway unit in each cycle. 1. Successful pattern, no request 2. Error pattern, no request 3. Successful pattern, with request fb_busy reading successful response error resp...

Page 192

172 part 1 specification 4. Error pattern, with request caution notes on using the fb • do not issue position data write commands successively, because these commands are written to the flash memory area. The flash memory can be written only so many times. • if communication is cut off while the axi...

Page 193

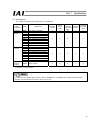

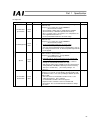

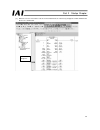

173 part 1 specification (3) address association matrix as explained in (1), “overview,” the plc’s i/o memory is associated with the gateway unit’s memory. Before setting the parameters or creating a ladder sequence, therefore, create an association matrix of sio gateway addresses. An example is sho...

Page 194

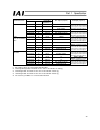

174 pa rt 1 sp ec if ica tio n sio gateway fb address association matrix (plc output) (example) function block variable name set address gateway register address description gw control 0 gw control 1 request command data 0 data 1 data 2 data 3 cannot be used. (axis 0) position data specification (l)...

Page 195

17 5 part 1 speci ficat ion sio gateway fb address association matrix (plc input) (example) function block variable name set address gateway register address description gw control 0 gw control 1 response command data 0 data 1 data 2 data 3 cannot be used. (axis 0) current position data (l) (axis 0)...

Page 196

176 part 1 specification 3.9.4.2 what is a function block? (1) overview a function block is a graphical program language for plcs. It is one of the five program languages for plcs defined by the iec standard (iec 61131-3). Ladder logic (or ladder language) currently adopted by the largest number of ...

Page 197

177 part 1 specification (2) function block configuration a function block consists of a predetermined function block definition and an instance that actually places the function block definition in a program. [1] function block definition a program described in a function block. An algorithm is des...

Page 198

178 part 1 specification [3] parameter every time an instance is created, actual i/o memory addresses (or constants) must be set for data exchange with input/output variables. These set addresses (or constants) are called parameters. Z what is exchanged between the parameters and function block is t...

Page 199

179 part 1 specification [4] variable addresses are not described as actual i/o memory addresses, but they are all described as variable names. The basic items you should know about variables are explained below. variable types [1] internal variable (internals): used only in an instance. [2] input...

Page 200

180 part 1 specification chapter 4 controller unit 4.1 overview the racon and rpcon controllers are dedicated robonet controllers that drive rca* actuators (24-v servo motor type) and rcp* actuators (24-v pulse motor type), respectively. Their basic functions and performance are the same as those of...

Page 201

181 part 1 specification racon controller: 1 unit robonet communication connection circuit board (model jb-1): 1 pc power-supply connection plate (model pp-1): 2 pcs rpcon controller: 1 unit robonet communication connection circuit board (model jb-1): 1 pc power-supply connection plate (model pp-1):...

Page 202

182 part 1 specification 4.2 basic specifications the basic specifications are the same between the racon and rpcon. Item specification number of controllable axes 1 axis power-supply voltage 24 vdc ± 10% standard specification, high acceleration/deceleration type energy-saving type actuator rating ...

Page 203

183 part 1 specification 4.3 name/function of each part and external dimensions. The name/function of each part and external dimensions are exactly the same with both the racon and rpcon. However, the connector is different between the racon and rpcon. 4.3.1 name of each part axis no. Setting switch...

Page 204

184 part 1 specification 4.3.2 led indicators these leds are used to monitor the status of the racon/rpcon. Symbol indicator color explanation sv/alm green/red a steady green light comes on when the servo is on, and changes to a steady read light when an alarm is present. Tx/rx green /yellow a stead...

Page 205

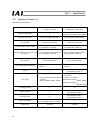

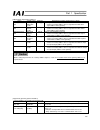

185 part 1 specification alarm indicator list status 3 2 1 0 simple alarm code alarm code alarm name rpcon racon 90 software reset command with servo on { { 91 position number error during teaching { { 92 pwrt signal detection during movement { { { { z { 2 93 pwrt signal detection before home return...

Page 206

186 part 1 specification 4.3.3 brake release switch when an actuator with brake is used, this switch is used to forcibly release the brake when adjusting the actuator assembly, etc. Normally this switch is kept in the bottom (nom) position. Switch name status explanation top (rls) position the brake...

Page 207

187 part 1 specification 4.3.6 robonet communication connector this connector is used to connect racon/rpcon controllers via sio link below the gatewayr unit. It connects to the sio communication (modbus) signal and emergency stop signal. Racon/rpcon controllers are connected using the robonet commu...

Page 208

188 part 1 specification the photographs below show the condition before and after interconnection of units. Gatewayr unit rpcon controller simple absolute r unit racon controller before connection after connection.

Page 209

189 part 1 specification 4.3.9 motor cable connector this connector is used to connect the dedicated actuator motor cable. The connector is different between the racon and rpcon. Specification item racon rpcon connector name mot mot applicable connector df1e-3p-2.5ds (hirose) (cable end) df1e-3s-2.5...

Page 210

190 part 1 specification 4.3.10 encoder cable connector this connector is used to connect the dedicated actuator encoder cable. The connector is different between the racon and rpcon. Specification item racon rpcon connector name pg pg applicable connector s18b-phdrs (jst) (cable end) phdr-18vs (jst...

Page 211

191 part 1 specification 4.3.11 external dimensions the external dimensions are exactly the same between the racon and rpcon. Take note that the motor cable connector and encoder cable connector are different. (50 fr om d in r a il cent er) * installable on a 35-mm din rail (69.3 from din rail surfa...

Page 212

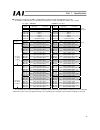

192 part 1 specification 4.4 parameters 4.4.1 parameter list the parameters are classified into the following four types depending on their function. Types: a: parameter relating to actuator stroke b: parameter relating to actuator operating characteristic c: parameter relating to external interface...

Page 213

193 part 1 specification *2 no. Type symbol rpcon racon name unit factory default 43 b hmc { { home check sensor input polarity - (as specified at the time of order) 46 b ovrd { { speed override % 100 47 b iov2 { { pio jogging speed 2 mm/sec 100 48 b ioid { { pio inching distance mm 0.1 49 b iod2 { ...

Page 214

194 part 1 specification 4.4.2 parameters relating to actuator stroke z soft limits (nos. 3/4, limm/liml) set the + soft limit in parameter no. 3 and – soft limit in parameter no. 4. Both parameters have been set to the effective actuator length at the factory. Change the parameter settings if neces...

Page 215

195 part 1 specification z home return offset (no. 22, ofst) parameter no. 22 has been set to an optimal value at the factory so that the distance from the mechanical end to home will remain constant. The minimum setting unit is 0.01 mm. This parameter can be adjusted in the following conditions: [1...

Page 216

196 part 1 specification 4.4.3 parameters relating to actuator operating characteristics z default speed (no. 8, vcmd) the factory setting is the rated speed of the actuator. This value is treated as the speed data corresponding to the applicable position number when a target position has been writt...

Page 217

197 part 1 specification z speed override (no. 46, ovrd) this parameter is used if you want to move the actuator at a slower speed to prevent danger during trial operation or at startup. When issuing a move command from the plc, you can override the travel speed set in the “speed” field of the posit...

Page 218

198 part 1 specification z excited phase signal detection time (no. 29, pdir2) the excited phase is detected when the servo is turned on for the first time after turning on the power. This parameter defines the time of this detection (excitation switching period). Before shipment, this parameter has...

Page 219

199 part 1 specification z push speed (no. 34, pshv) this parameter defines the push speed to become effective after the target position is reached in push operation. Before shipment, this parameter has been set to a value appropriate for the characteristics of the actuator. Set an appropriate speed...

Page 220

200 part 1 specification z home check sensor input polarity (no. 43, hmc) although not equipped on the standard specification, the home check sensor can be added as an option. This parameter need not be changed in normal conditions of use. If the customer wishes to change the mode after shipment, ch...

Page 221

201 part 1 specification z pio inching distance (no. 48, ioid) pio inching distance 2 (no. 49, iod2) these parameters set the inching distances for inching operation. The inching distance parameter is switched according to the jogging speed/inching distance switching signal (jvel), as follows: jvel ...

Page 222

202 part 1 specification z position feed-forward gain (no. 71, plfg) parameter no. Unit input range default 71 - 0 to 100 0 this parameter sets the feed-forward gain of the position control system. When this parameter is set, the servo gain will increase and the response of the position control loop...

Page 223

203 part 1 specification z ball screw lead (no. 77, lead) this parameter defines the ball screw lead. Before shipment, this parameter has been set to a value appropriate for the characteristics of the actuator. * do not change this parameter. Z axis operation type (no. 78, atyp) this parameter sets ...

Page 224

204 part 1 specification if the actuator is moved sequentially from position no. 1 to nos. 2, 3 and 4, the operation will differ as follows depending on whether or not the shortcut mode is selected. To be specific, while the actuator will reverse its direction to move from position no. 4 to no. 1 wh...

Page 225

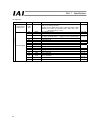

205 part 1 specification [various settings for rotational operation axis and operation details] the list below summarizes the operation details of a rotational operation axis. Encoder system axis operation type (no. 78) rotational axis mode selection (no. 79) rotational axis shortcut selection (no. ...

Page 226

206 part 1 specification 4.4.4 parameters relating to external interface z position complete signal output mode (no. 39, pend) this parameter defines the status of the position complete signal when the servo is turned off or a “position deviation” occurs while the actuator is stopped after position ...

Page 227

207 part 1 specification 4.4.5 parameters relating to servo gain adjustment since the servo has been adjusted at the factory to stabilize positioning operation at the maximum load capacity of the actuator, the servo gain need not be changed in normal conditions of use. In actual use, however, the lo...

Page 228

208 part 1 specification z speed loop proportional gain (no. 31, vlpg) parameter number unit input range default 31 - 1 to 27661 set individually in accordance with the actuator characteristics. This parameter determines the level of response with respect to a speed control loop. Increasing the sett...

Page 229

209 part 1 specification z torque filter time constant (no. 33, trqf) parameter number unit input range default 33 - 1 to 2500 set individually in accordance with the actuator characteristics. This parameter determines the filter time constant applicable to the torque command. If the mechanical reso...

Page 230

210 part 1 specification 4.5 notes on robo rotary (1) home return direction the moving end of the output axis in counterclockwise direction becomes the home position. Actuators of multi-rotational specification can be ordered with their rotating direction reversed. On these reverse rotation models, ...

Page 231

211 part 1 specification (4) home return operation ■ 330 °-rotation specification [1] start of home return → [2] detection of a mechanical stopper → [3] reversing → [4] movement by the offset → [5] home position ■ multi-rotational specification [1] start of home return → [2] detection of a home sens...

Page 232

212 part 1 specification 4.6 notes on robo gripper (1) finger operation [1] definition of position the home of each finger is where the finger is open. The position command specifies the travel distance of each finger from its home position toward the closing side. Accordingly, the maximum command v...

Page 233

213 part 1 specification (2) removing the gripped load this gripper is structured so that the load-gripping force will be maintained by a self-lock function even after the servo is turned off or the controller power is cut off. If the gripped load must be removed while the power is cut off, turn the...

Page 234

214 part 1 specification chapter 5 simple absolute r unit 5.1 overview rpcon and racon controller units can be used as absolute axes by connecting a simple absolute r unit. If the controller unit is used as an absolute axis, home return will not be necessary once an absolute reset is performed, even...

Page 235

215 part 1 specification 5.2 how to read the model name simple absolute r unit: rabu (backup battery included) backup battery: model ab-7, 1 unit (simple absolute connection circuit board), robonet communication connection circuit board: common model jb-1, 2 units power-supply connection plate: mode...

Page 236

216 part 1 specification 5.3 specifications 5.3.1 general specifications model rabu power-supply voltage 24 vdc ± 10% power-supply current max 300 ma environment surrounding air temperature 0 to 40 °c surrounding humidity 95% rh max. (non-condensing) surrounding environment free from corrosive gases...

Page 237

217 part 1 specification 5.3.2 backup battery the absolute specification uses a secondary battery (nickel hydrogen battery) to retain absolute counter data in the fpga and supply power to the encoder drive circuit even when the power is cut off. (1) battery specifications item description classifica...

Page 238

218 part 1 specification 5.4 name/function of each part and external dimensions 5.4.1 name of each part [6]rcp2 and rcp3 actuator connector [7]rca, rca2 and rcl actuator connector front view [4]ni-mh battery [5]power-supply terminal block reference battery replacement timining [1]status indicator le...

Page 239

219 part 1 specification 5.4.2 functions [1] status indicator leds rdy/alm indicator color steady green steady red { - system normal - { system error (alarm) blinking green blinking red { { update mode status 1 steady green steady red operation { - absolute reset completed (rdy: steady green light) ...

Page 240

220 part 1 specification [2] setting switches these switches are used to switch the speed setting and update mode. (the switches are arranged in the order of 1, 2, 3 and 4, from the top.) switch function 1 speed setting switch 1 2 speed setting switch 2 3 update mode selector switch (keep this switc...

Page 241

221 part 1 specification [5] power-supply terminal block use the supplied power-supply connection plate to connect to the power-supply terminal block of the paired controller. [6] rcp2 connector (white) this connector is used to connect the pg cable of the rcp2 actuator. [7] rca connector (red) this...

Page 242

222 part 1 specification 5.4.3 external dimensions (5 0 from din rail center) 35-mm din rail (69.3 from din rail surface).

Page 243

223 part 1 specification 5.5 notes (1) notes on changing parameters if the following parameters are changed, an absolute error will occur. Accordingly, an absolute reset must be performed after changing any of these parameters: [1] parameter no. 5, “home return direction” [2] parameter no. 22, “home...

Page 244

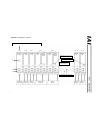

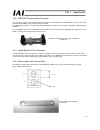

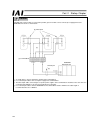

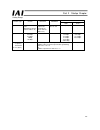

224 part 1 specification [1] [2] [3] [5] [6] [7] [4] [1] [2] [3] [4] [5] [6] [7] [1] [2] [3] rpcon or racon junction gatewayr unit gatewayr unit extension unit unit link cable extension unit gatewayr unit rpcon or racon extension unit controller connection cable terminal resistor chapter 6 extension...

Page 245

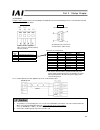

225 part 1 specification 6.2 specifications model rext (main unit) power-supply voltage 24 vdc ± 10% power-supply current max 100 ma surrounding air temperature 0 to 40 °c surrounding humidity 95% rh max. (non-condensing) surrounding environment free from corrosive gases and dust. Surrounding storag...

Page 246

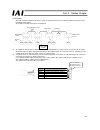

226 part 1 specification 6.3 product configuration name model description application figure robonet extension unit rext • main unit x 1 • power-supply connection plate x 2 • communication connection circuit board x 1 • for robonet multi-stage layout • for external sio link figure 1 unit reversing s...

Page 247

227 part 1 specification fig 3 controller connection set (rext-ctl) communication connection circuit board (model: jb-1) power-supply connection plates (model: pp-1) robonet extension unit unit link cable fig 2 controller connection set (rext-sio) communication connection circuit board (model: jb-1)...

Page 248

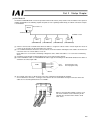

228 part 1 specification harness connection view connection diagram indicates the cable length (l). Example) 010 = 1 m fig. 4 unit link cable (cb-rext-sio ) black2/white red2/white black2/gray red2/gray black2/orange red2/orange black1/pink red1/pink black1/yellow red1/yellow black1/white red...

Page 249