- DL manuals

- IAI

- Controller

- X-SEL PX

- Operation Manual

IAI X-SEL PX Operation Manual

Summary of X-SEL PX

Page 1

Operation manual seventh edition x-sel controller px/qx type tenth edition.

Page 3

Please read before use thank you for purchasing our product. This operation manual explains the handling methods, structure and maintenance of this product, among others, providing the information you need to know to use the product safely. Before using the product, be sure to read this manual and f...

Page 4

Caution operator alarm on low battery voltage this controller is equipped with the following backup batteries for retention of data in the event of power failure: [1] system-memory backup battery for retention of position data, global variables/flags, error list, strings, etc. [2] absolute encoder b...

Page 5

Caution 200 to 230 vac power supply auxiliary power circuit top: 0 v bottom: 24 v brake power +24-v power supply example of x-sel-px controller (4-axis scara robot of 250 to 600 mm in arm length, without expansion i/os) power-supply capacity 45 w: arm length 500 to 800 23 w: arm length 250 to 350 14...

Page 6

Caution drive-source cutoff relay error (detection of fused relay: e6d) because of their circuit configuration, xsel-px controllers of single-phase, standard specification are the only class of controllers that may generate a “drive-source cutoff relay error (e6d),” notifying fusion of an internal r...

Page 7

Caution note on controllers with increased cpu unit memory size * controllers with gateway function come with an increased memory size in their cpu unit. If you are using a controller with increased cpu unit memory size, use pc software and teaching pendants of the versions specified below. Teaching...

Page 9: Table Of Contents

Table of contents table of contents safety guide.................................................................................................................................. 1 introduction..............................................................................................................

Page 10

Table of contents chapter 8 how to perform an absolute encoder reset of a direct movement axis (absolute specification)...................................................................................................................... 87 1. Preparation ...............................................

Page 11

Table of contents part 4 commands .................................................................................................................. 132 chapter 1 list of sel language command codes ......................................................................... 132 chapter 2 explanation of...

Page 12

Table of contents 1. How to use .............................................................................................................................. 362 2. Palletizing setting .....................................................................................................................

Page 13

Table of contents battery backup function ......................................................................................................... 422 1. System-memory backup battery ................................................................................ 422 2. Absolute-encoder backup batt...

Page 15

Pre-1 safety guide this “safety guide” is intended to ensure the correct use of this product and prevent dangers and property damage. Be sure to read this section before using your product. Regulations and standards governing industrial robots safety measures on mechanical devices are generally clas...

Page 16

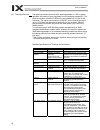

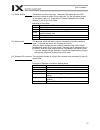

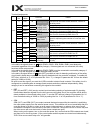

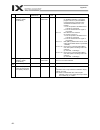

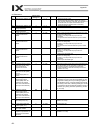

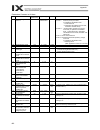

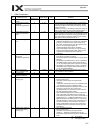

Pre-2 requirements for industrial robots under ordinance on industrial safety and health work area work condition cutoff of drive source measure article signs for starting operation article 104 outside movement range during automatic operation not cut off installation of railings, enclosures, etc. A...

Page 17

Pre-3 applicable modes of iai’s industrial robot machines meeting the following conditions are not classified as industrial robots according to notice of ministry of labor no. 51 and notice of ministry of labor/labor standards office director (ki-hatsu no. 340): (1) single-axis robo with a motor wat...

Page 18

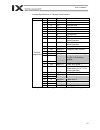

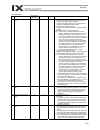

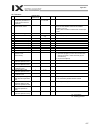

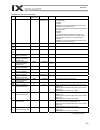

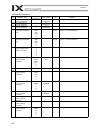

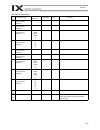

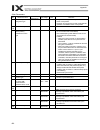

Pre-4 notes on safety of our products common items you should note when performing each task on any iai robot are explained below. No. Task note 1 model selection this product is not planned or designed for uses requiring high degrees of safety. Accordingly, it cannot be used to sustain or support l...

Page 19

Pre-5 no. Task note (2) wiring the cables use iai’s genuine cables to connect the actuator and controller or connect a teaching tool, etc. Do not damage, forcibly bend, pull, loop round an object or pinch the cables or place heavy articles on top. Current leak or poor electrical continuity may occur...

Page 20

Pre-6 no. Task note 5 teaching when releasing the brake of the vertically installed actuator, be careful not to let the actuator drop due to its dead weight, causing pinched hands or damaged load, etc. * safety fences --- indicate the movement range if safety fences are not provided. 6 confirmation ...

Page 21

Pre-7 indication of cautionary information the operation manual for each model denotes safety precautions under “danger,” “warning,” “caution” and “note,” as specified below. Level degree of danger/loss symbol danger failure to observe the instruction will result in an imminent danger leading to dea...

Page 22: Ce Marking

Ce marking if a compliance with the ce marking is required, please follow overseas standards compliance manual (me0287) that is provided separately. Pre-8.

Page 23

Pre-9 steel band (piano wire) bundle loosely. Use a curly cable. Do not use a spiral tube where the cable flexes frequently. Prohibited handling of cables caution when designing an application system using actuators and controllers, incorrect wiring or connection of each cable may cause unexpected p...

Page 24

Pre-10 7. Do not let the cable got tangled or kinked in a cable track or flexible tube. When bundling the cable, keep a certain degree of flexibility (so that the cable will not become too taut when bent). 8. Do not cause the cables to occupy more than 60% of the space in the cable track. 9. Do not ...

Page 25

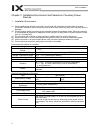

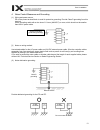

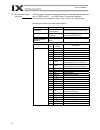

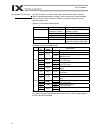

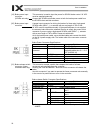

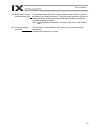

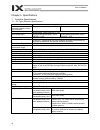

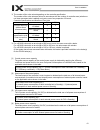

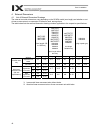

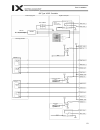

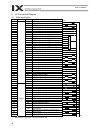

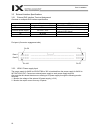

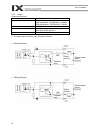

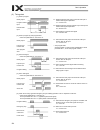

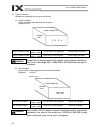

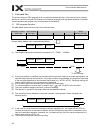

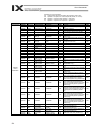

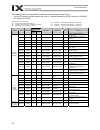

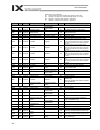

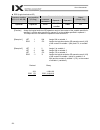

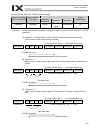

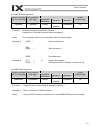

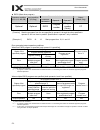

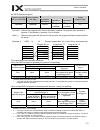

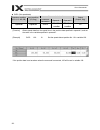

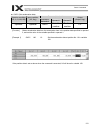

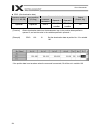

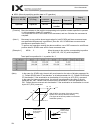

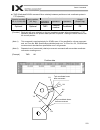

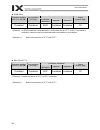

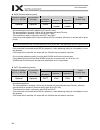

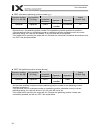

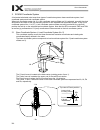

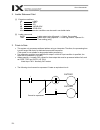

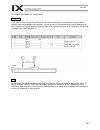

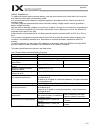

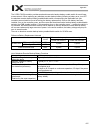

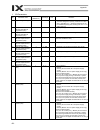

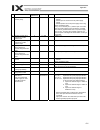

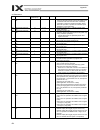

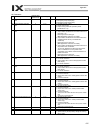

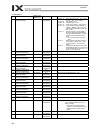

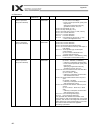

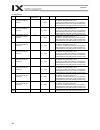

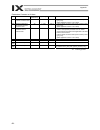

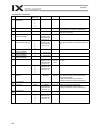

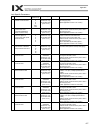

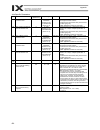

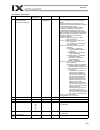

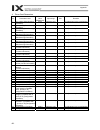

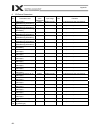

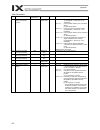

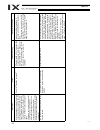

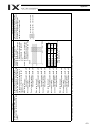

1 introduction [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] slot 1 slot 2 slot 3 slot 4 [1] series [2] controller type [3] ix actuator type [4] axis 5 motor wattage [5] axis 6 motor wattage [6] network (dedicated slot) [7] standard i/o [8] expansion i/o [9] i/o flat cable length [10] power- source volta...

Page 26

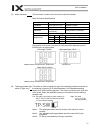

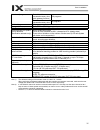

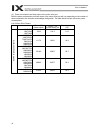

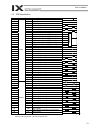

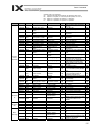

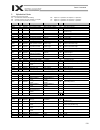

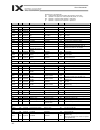

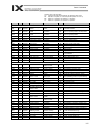

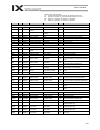

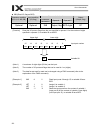

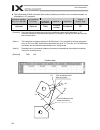

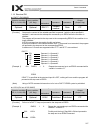

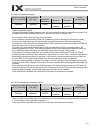

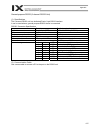

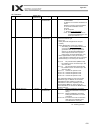

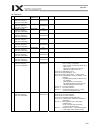

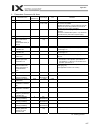

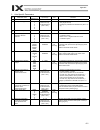

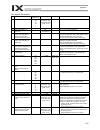

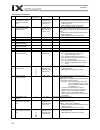

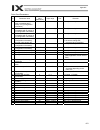

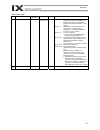

2 [1] series [2] controller type [3] ix actuator type [4] axis 5 motor wattage [5] axis 6 motor wattage [6] network (dedicated slot) [7] standard i/o slot 1 slot 2 slot 3 slot 4 [8] expansion i/o [9] i/o flat cable length [10] power- source voltage (large-capacity 4-axis type) (large-capacity 5-axis...

Page 27

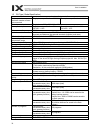

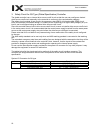

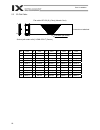

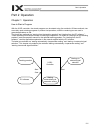

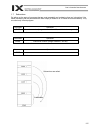

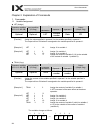

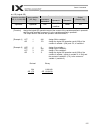

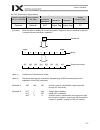

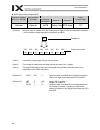

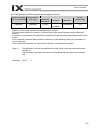

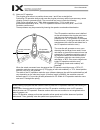

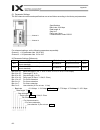

3 introduction this controller receives power in order to drive the actuator motor(s) (three-phase/single-phase, 200 to 220 v) and to operate the controller itself (200 to 220 v). (*the single-phase power specification is applicable only to single-phase controllers.) the actuator motor drive power s...

Page 28

4 part 1 installation part 1 installation caution chapter 1 safety precautions the x-sel px/qx controller can support a combination of a scara robot and linear movement axes to perform integrated control of all axes including peripheral equipment. In other words, the controller has the ability to co...

Page 29

5 part 1 installation chapter 2 warranty period and scope of warranty the x-sel controller you have purchased passed our strict outgoing inspection. This unit is covered by the following warranty: 1. Warranty period the warranty period shall be either of the following periods, whichever ends first: ...

Page 30

6 part 1 installation chapter 3 installation environment and selection of auxiliary power devices 1. Installation environment (1) when installing and wiring the controller, do not block the ventilation holes provided for cooling (insufficient ventilation will not only prevent the product from functi...

Page 31

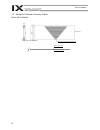

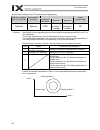

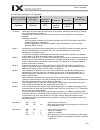

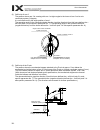

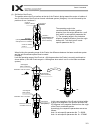

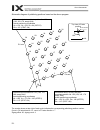

7 part 1 installation 2. Heat radiation and installation design the control panel size, controller layout and cooling method so that the surrounding air temperature around the controller will be kept at or below 40c. Install the controller vertically on a wall, as illustrated below. The controller ...

Page 32

8 part 1 installation 3. Selection of auxiliary power devices this section provides selection guidelines for breakers, earth leakage breakers, contactors, surge absorbers and noise filters that can be used with the ac power supply line of the x-sel controller. These devices must be selected by takin...

Page 33

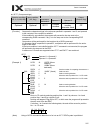

9 part 1 installation (4) auxiliary power devices [1] circuit breaker install a circuit breaker or earth leakage breaker in the ac power-supply line (primary side) of the controller in order to prevent damage due to power switching and short current. One circuit breaker or earth leakage breaker can ...

Page 34

10 part 1 installation [4] noise filter, ring core and clamp filters the global specification has no built-in noise filters in the motor power supply. If your controller is of the global specification, therefore, be sure to install noise filters and ring cores for the motor drive power supply extern...

Page 35

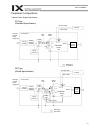

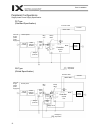

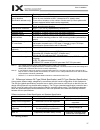

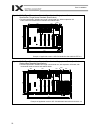

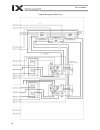

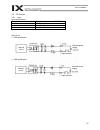

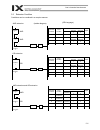

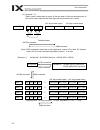

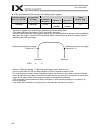

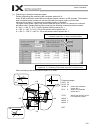

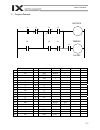

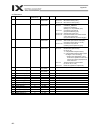

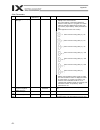

11 part 1 installation peripheral configurations 3-phase power supply specification px type (standard specification) qx type (global specification) control panel circuit breaker earth leakage breaker single- phase noise filter ring core clamp filters encoder cable motor cable actuator controller sys...

Page 36

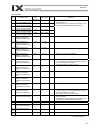

12 part 1 installation peripheral configurations single-phase power supply specification px type (standard specification) qx type (global specification) control panel circuit breaker earth leakage breaker ring core clamp filters encoder cable motor cable actuator controller system i/os brake 24-vdc ...

Page 37

13 part 1 installation 4. Noise control measures and grounding (1) wiring and power source pe on the power terminal block is used for protective grounding. Provide class d grounding from this terminal. Use a grounding cable with a wire size of 1.0 mm 2 (#awg17) or more, which should not be smaller t...

Page 38

14 part 1 installation (3) noise sources and noise elimination there are many noise sources, but solenoid valves, magnet switches and relays are of particular concern when building a system. Noise from these parts can be eliminated using the measures specified below: [1] ac solenoid valve, magnet sw...

Page 39

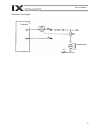

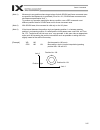

15 part 1 installation reference circuit diagram surge absorber solenoid valve controller 0 v 15.

Page 40

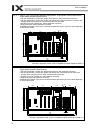

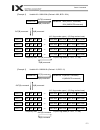

16 part 1 installation chapter 4 name and function of each part 1. Front view of controller px type (standard specification), 4 axes (scara axes only) px type (standard specification), expanded by 2 additional linear movement axes, with i/o brake unit 16.

Page 41

17 part 1 installation qx type (global specification), 4 axes (scara axes only) qx type (global specification), expanded by 2 additional linear movement axes, with i/o brake unit 17.

Page 42

18 part 1 installation [1] fg terminal this terminal is used to ground fg on the enclosure. The enclosure is connected to pe in the ac input part inside the controller. Fg terminal specifications item description m4 3-point sems screw, 5 mm name fg cable size 2.0 ~ 5.5 mm 2 min. Grounding method cla...

Page 43

19 part 1 installation [3] ac-power input connector a 200-vac, single-phase/three-phase input connector consisting of six terminals including motor power terminals, control power terminals and a pe terminal. Note) select the single-phase input specification or three-phase input specification, whiche...

Page 44

20 part 1 installation [6] encoder/axis-sensor connector this connector is used to connect the actuator encoder and axis sensors such as ls, creep and ot. * ls, creep and ot sensors are optional. The connectors are assigned to axis 1, axis 2, and so on, from the right. Encoder/axis-sensor connector ...

Page 45

21 part 1 installation left: pc cable ( conforming to safety category 4) sel-t, sel-td, sel-tg teaching pendant ia-t-xa teaching pendant right: pc cable ia-t-x, ia-t-xd teaching pendant [7] motor connector this connector is used to drive the motor inside the actuator. Motor connector specifications ...

Page 46

22 part 1 installation [9] teaching connector the teaching interface connects iai’s teaching pendant or a pc to enable operation and setting of your equipment from the teaching pendant/pc. The physical interface consists of a rs232c system based on a 25 pin d-sub connector. The signal level conforms...

Page 47

23 part 1 installation interface specifications of teaching serial interface item no. Direction signal name details 1 fg frame ground 2 out txd transmitted data 3 in rxd received data 4 out rts request to send 5 in cts clear to send 6 out dsr equipment ready 7 sg signal ground 8 nc not connected 9 i...

Page 48

24 part 1 installation [10] system i/o connector this i/o connector is used to control the safety actions of the controller. With the global specification, a safety circuit conforming to a desired safety category of up to level 4 can be configured using this connector and an external safety circuit....

Page 49

25 part 1 installation [11] panel window this window consists of a 4-digit, 7 segment led display and five led lamps that indicate the status of the equipment. For the information shown on the display, refer to 2, “explanation of codes displayed on the panel window” or the “error code table.” meanin...

Page 50

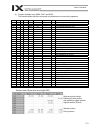

26 part 1 installation i/o interface list pin no. Category port no. Function cable color 1 - +24 v input brown-1 2 000 program start red-1 3 001 general purpose input orange-1 4 002 general purpose input yellow-1 5 003 general purpose input green-1 6 004 general purpose input blue-1 7 005 general pu...

Page 51

27 part 1 installation [14] general rs232c port connector 1 channel 1 of the two-channel rs232c port provided for connection of general rs232c equipment. (refer to i/o parameter nos. 201 to 203.) [15] general rs232c port connector 2 channel 2 of the two-channel rs232c port provided for connection of...

Page 52

28 part 1 installation [19] brake power input connector (scara axis only) this connector is used to input the power for scara brake control. 24 vdc must be supplied externally. Connect the scara-axis brake power to both the brake power cable from the scara robot and this connector. [20] brake power ...

Page 53

29 part 1 installation [22] brake switch (linear movement axis only) this alternate switch with lock is used to release the axis brake. To operate the switch, pull it toward you and tilt. Tilting the switch upward (rls side) will release the brake forcibly, while tilting it downward (nom) will enabl...

Page 54

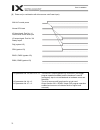

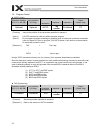

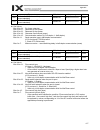

30 part 1 installation 2. Explanation of codes displayed on the panel window 2.1 application display priority (*1) description 1 ac power is cut off (including momentary power failure or drop in power source voltage). 1 system down level error 2 writing data to the flash rom. 3 emergency stop is bei...

Page 55

31 part 1 installation 2.2 core display priority (*1) description 1 ac power is cut off (including momentary power failure or drop in power source voltage) 1 coldstart level error 1 coldstart level error 1 operationcancellation level error 1 operationcancellation level error 2 message level error 2 ...

Page 56

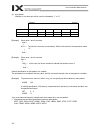

32 part 1 installation 2.3 current monitor and variable monitor other parameter nos. 49 and 50 can be set up to monitor currents or variables on the panel window. (1) current monitor currents of up to four axes having continuous axis numbers can be monitored. Parameter settings other parameter no. 4...

Page 57

33 part 1 installation (2) variable monitor the contents of global integer variables can be displayed on the panel window. Positive integers of 1 to 999 can be displayed. Parameter settings other parameter no. 49 = 2 other parameter no. 50 = variable number of the global integer variable to be monit...

Page 58

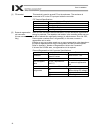

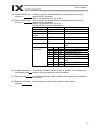

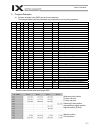

34 part 1 installation chapter 5 specifications 1. Controller specifications 1.1. Px type (standard specification) 1-axis to 6-axis controller total output when maximum number of axes are connected single-phase specification: 1600 w three-phase specification: 2400 w control power input single phase,...

Page 59

35 part 1 installation controller with increased memory size (with gateway function) 128 programs number of programs controller without increased memory size 64 programs multi-tasking 16 programs storage device flash rom + sram battery backup data input methods teaching pendant or pc software absolu...

Page 60

36 part 1 installation 1.2 qx type (global specification) 1-axis to 6-axis controller total output when maximum number of axes are connected single-phase specification: 1600 w three-phase specification: 2400 w control power input single phase, 200 to 230 vac 10% motor power input single-phase spec...

Page 61

37 part 1 installation data input methods teaching pendant or pc software absolute brake unit (brake type or absolute specification actuator only) built-in brake drive circuit driven by over-excitation at 90 v, released at 45 v (steady state) there are no limitation on the number of brake axes (a 6-...

Page 62

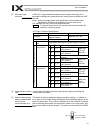

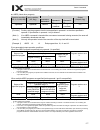

38 part 1 installation 2. External i/o specifications 2.1. Npn specification (1) input part external input specifications (npn specification) item specification input voltage 24 vdc 10% input current 7 ma per circuit on/off voltage on voltage --- 16.0 vdc min. Off voltage --- 5.0 vdc max. Insulatio...

Page 63

39 part 1 installation (2) output part external output specifications (npn specification) item specification load voltage 24 vdc maximum load current 100 ma per point, 400 ma per 8 ports note) leakage current 0.1 ma max. Per point td62084 (or equivalent) insulation method photocoupler insulation ext...

Page 64

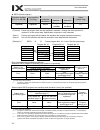

40 part 1 installation 2.2. Pnp specification (1) input part external input specifications (pnp specification) item specification input voltage 24 vdc 10% input current 7 ma per circuit on/off voltage on voltage --- 8 vdc max. Off voltage --- 19 vdc min. Insulation method photocoupler insulation ex...

Page 65

41 part 1 installation (2) output part external output specifications item specification load voltage 24 vdc maximum load current 100 ma per point, 400 ma per 8 ports note) leakage current 0.1 ma max. Per point td62784 (or equivalent) insulation method photocoupler insulation external devices [1] mi...

Page 66

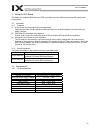

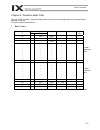

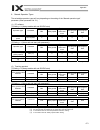

42 part 1 installation 3. Power source capacity and heat output the power consumption and heat output of the x-sel controller will vary depending on the number of connected axes and i/o configuration. This section explains how to estimate the power source capacity and heat output of your x-sel contr...

Page 67

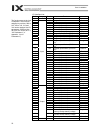

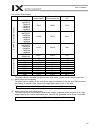

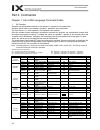

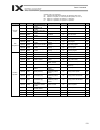

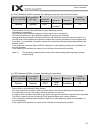

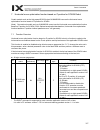

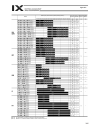

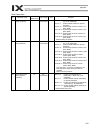

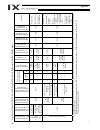

43 part 1 installation *2 the number of fan units varies depending on the controller specification. The number of fan units varies as follows in accordance with the number of controller axes (whether or not linear movement axis is added) and use/no-use of any expansion i/o board. Controller specific...

Page 68

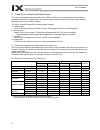

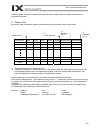

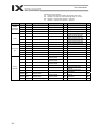

44 part 1 installation (2) power consumption and heat output of the motor drive part both the power consumption and heat output of the motor drive part will vary depending on the number of axes connected to the controller and wattage configuration. The table below lists per axis motor power consumpt...

Page 69

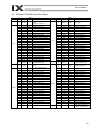

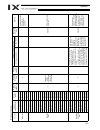

45 part 1 installation list of motor drive powers power [w] (rated output) power 0.6 [power factor] [va output stage loss [w] nn2515 nn3515 tnn3015 tnn3515 unn3015 unn3515 615.8 1026.3 24.75 nn50 nn60 hnn5020 hnn6020 inn5020 inn6020 1122.8 1871.3 44.12 nn70 nn80 hnn7020 hnn8020 inn70...

Page 70

46 part 1 installation (3) calculation example obtain the power source capacities and heat outputs when a controller of the following specifications is used. Scara: ix-nnn5020 linear movement axis: axis 5 --- isa-mxm-200-* (200 w), axis 6 --- isa-mzm-100-*-b (100 w, with brake) standard dio options:...

Page 71

47 part 1 installation (4) reference example the power supply capacity and heat output of a scara-axis controller (4-axis specification without additional linear movement axis) are shown below. All figures assume use of a standard dio board, with devicenet support and a teaching pendant (iai’s stand...

Page 72

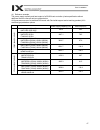

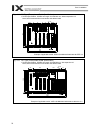

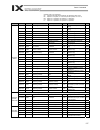

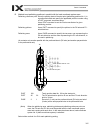

48 part 1 installation 4. External dimensions 4.1 list of external dimension drawings the external controller dimensions vary depending on the scara model (arm length) and whether or not a linear movement axis or expansion i/o board is used, among others. The table below lists the external dimension...

Page 73

49 part 1 installation example of applicable model: x-sel-px-nnn1205-n1-eee-2-3 fig. 4-2 px/qx type (three-phase standard specification, single-phase global specification, single-phase standard specification) 4-axis specification, scara arm length 120/150/180 mm, with expansion i/o board example of ...

Page 74

50 part 1 installation 22 120 120 3-5 284 300 195 186 180 22 5 357 373 5 195 186 180 58.5 120 120 3-5 58.5 fig. 4-3 px/qx type (three-phase standard specification, single-phase global specification, single-phase standard specification) 5/6-axis specification, scara arm length 120/150/180 mm, witho...

Page 75

51 part 1 installation 342 358 5 195 186 180 51 120 120 3-5 51 269 285 5 195 186 180 59.5 75 3-5 75 59.5 fig. 4-5 px/qx type (three-phase standard specification, single-phase global specification, single-phase standard specification) 4-axis specification, scara arm length 250 to 600 mm, without ex...

Page 76

52 part 1 installation 397 413 5 195 186 180 78.5 120 120 3-5 78.5 324 340 5 195 186 180 42 120 120 3-5 42 fig. 4-7 px/qx type (three-phase standard specification, single-phase global specification, single-phase standard specification) 5/6-axis specification, scara arm length 250 to 600 mm, withou...

Page 77

53 part 1 installation 206 222 5 195 186 180 28 75 3-5 28 75 (80) 3 125.3 279 295 5 195 186 180 64.5 75 3-5 64.5 75 4.3 qx type (three-phase global specification) controller example of applicable model: x-sel-qx-nnn1205-n1-eee-2-3 example of applicable model: x-sel-qx-nnn1205-n1-n1n1n1-2-3 fig. 4-...

Page 78

54 part 1 installation 241 257 5 195 186 180 45.5 75 3-5 45.5 75 314 330 5 195 186 180 37 120 3-5 37 120 example of applicable model: x-sel-qx-nnn1205-200i-200i-n1-eee-2-3 example of applicable model: x-sel-qx-nnn1205-200i-200i-n1-n1n1n1-2-3 fig. 4-11 qx type (three-phase global specification) 5/6...

Page 79

55 part 1 installation 226 242 5 195 186 180 38 75 3-5 38 75 299 315 5 195 186 180 29.5 120 3-5 29.5 120 example of applicable model: x-sel-qx-nnn2521-n1-eee-2-3 example of applicable model: x-sel-qx-nnn2515-200i-200i-n1-n1n1n1-2-3 fig. 4-13 qx type (three-phase global specification) 4-axis specif...

Page 80

56 part 1 installation 354 370 5 195 186 180 57 120 3-5 57 120 281 297 5 195 186 180 20.5 120 3-5 20.5 120 example of applicable model: x-sel-qx-nnn5020-400ab-200ab-n1-eee-2-3 example of applicable model: x-sel-qx- nnn5020-400ab-200ab-n1-n1n1n1-2-3 fig. 4-15 qx type (three-phase global specificati...

Page 81

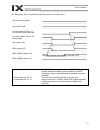

57 part 1 installation chapter 6 safety circuit the circuit configuration for embodying safety actions such as emergency stop is different between the standard specification and global specification of the x-sel controller. The standard controller has a built-in drive source cutoff circuit conformin...

Page 82

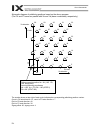

58 part 1 installation 2. Safety circuit for px type (standard specification) controller the px type controller has a built-in drive source cutoff circuit just like iai’s other controllers. The drive source cutoff circuit consists of a relay and conforms to safety category b. If your equipment must ...

Page 83

59 part 1 installation with the px type, use only the signals shown in the shaded fields of the table for connection with the safety switches. Ensure that the specified pins are wired correctly, as incorrect wiring will compromise the safety mechanisms of the controller. The rdyout contacts will clo...

Page 84

60 part 1 installation 3. Safety circuit for qx type (global specification) controller the global controller has no internal drive source cutoff circuit so that the user can configure a desired drive source cutoff circuit externally to the controller to conform to the required safety category. The s...

Page 85

61 part 1 installation terminal assignments pin no. Signal name overview details 9 det in to fused-contact detection circuit external contact error input (paired with no. 18) connected to the fused contact detection contacts of the safety circuit. 8 in emergency stop detection input 7 emgin +24 v to...

Page 86

62 part 1 installation emg1/emg2, enb1/enb2 emg1 (line+)/(line-) and emg2 (line+)/(line-) are redundant emergency stop control lines. Enb1 (line+)/(line-) and enb2 (line+)/(line-) are redundant enabling control lines. Use these lines to cut off the external drive source. Since they are completely dr...

Page 87

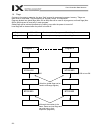

63 part 1 installation qx type x-sel controller power supply part not installed ac cutoff relay rectifier dc bus to power stage external emergency-stop reset contact output teaching pendant power-on reset mpsdwn bit power error mushroom emergency- stop switch emg sw contact 1 emg sw contact 2 double...

Page 88

64 part 1 installation external emergency stop circuit contactor (neo sc) relay contactor (neo sc) 200-vac, three- phase reset switch external emergency-stop switch external emg switch contact 1 external emg switch contact 2 safety relay unit (g9sa-301 by omron) safety gate switch external sgate con...

Page 89

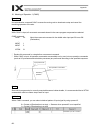

65 part 1 installation 4. Timing chart of safety circuit for qx-type sel controller a timing chart of the safety circuit for qx-type sel controller is shown below. The points in time shown in this timing chart are: “[1] power on,” “[2] emergency stop,” “[3] power on without cancelling emergency stop...

Page 90

66 part 1 installation [2] emergency stop i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are detected). I/o parameter no. 44 = 0: the drive-sourc...

Page 91

67 part 1 installation [3] power on without cancelling emergency stop assume that the same timings will apply when the power is turned on without performing an enable operation. I/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) an...

Page 92

68 part 1 installation [4] enable operation i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are detected). I/o parameter no. 44 = 0: the drive-sou...

Page 93

69 part 1 installation [5] system shutdown level error i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are detected). I/o parameter no. 44 = 0: th...

Page 94

70 part 1 installation [6] cold start level error i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are detected). I/o parameter no. 44 = 0: the dri...

Page 95

71 part 1 installation [7] operation cancellation level error i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are detected). I/o parameter no. 44 ...

Page 96

72 part 1 installation [8] power on (in combination with drive-source cutoff reset input) i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors are dete...

Page 97

73 part 1 installation [9] emergency stop (in combination with drive-source cutoff reset input) i/o parameter no. 24, bits 0 to 3 = 0: the rdyout output (system i/o) is sysrdy (pio trigger program operation enabled) and the hardware is normal (emergency stop is not actuated and no hardware errors ar...

Page 98

74 part 1 installation chapter 7 system setup 1. Connection method of controller and actuator 1.1 connection diagram for px type (standard specification) three-phase specification cp: single-phase 200 to 230 vac power supply mp: three-phase 200 to 230 vac power supply single-phase specification cp: ...

Page 99

75 part 1 installation 1.2 connection diagram for qx type (global specification) three-phase specification cp: single-phase 200 to 230 vac power supply mp: three-phase 200 to 230 vac power supply single-phase specification cp: single-phase 200 to 230 vac power supply mp: three-phase 200 to 230 vac p...

Page 100

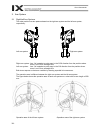

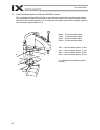

76 part 1 installation the positions of motor connectors and encoder connectors vary depending on the scara type. The figure below shows where the motor connectors and encoder connectors are located for each scara type, as viewed from the front side of the controller. Arm length 700/800 high-speed t...

Page 101

77 part 1 installation 1.3 startup procedure caution: be sure to connect the cables from the respective actuators to the correct connectors. When connecting multiple axes to the controller, be sure the actuator cables are going to the correct connectors. Check the type of the actuator connected. If ...

Page 102

78 part 1 installation 2. I/o connection diagram 2.1 npn specification pin no. Category port no. Function (factory setting) 1 - +24-v input 2 000 program start 3 001 general-purpose input 4 002 general-purpose input 5 003 general-purpose input 6 004 general-purpose input 7 005 general-purpose input ...

Page 103

79 part 1 installation 2.2 pnp specification pin no. Category port no. Function (factory setting) 1 - +24-v input 2 000 program start 3 001 general-purpose input 4 002 general-purpose input 5 003 general-purpose input 6 004 general-purpose input 7 005 general-purpose input 8 006 general-purpose inpu...

Page 104

80 part 1 installation 2.3 i/o flat cable flat cable: kfx-50 (s) (color) (kaneko cord) no. Color no. Color no. Color no. Color no. Color 1 brown-1 11 brown-2 21 brown-3 31 brown-4 41 brown-5 2 red-1 12 red-2 22 red-3 32 red-4 42 red-5 3 orange-1 13 orange-2 23 orange-3 33 orange-4 43 orange-5 4 yell...

Page 105

81 part 1 installation 3. Multipoint dio board this board is a multipoint dio board for xsel controllers on which 48 input points and 48 output points are provided. 3.1 overview 3.1.1 features [1] 96 points can be input/output using a single board. One board provides 48 input points and 48 output po...

Page 106

82 part 1 installation 3.3 external interface specifications 3.3.1 external dio interface terminal assignment overview or multipoint dio interface specifications item overview remarks applicable connector half-pitch flat connector, 100 pins hif6-100pa-1.27ds (hirose) connector name external dio conn...

Page 107

83 part 1 installation 3.4 multipoint i/o board connection cables cable 1 cable 2 category pin no. Color port no. Function category pin no. Color port no. Function - 1 brown-1 - 24-vdc for external power supply pin nos. 2 to 25/51 to 74 51 brown-1 300 alarm output 2 red-1 000 program start 52 red-1 ...

Page 108

84 part 1 installation 3.5 multipoint i/o board connection cables model: cb-x-pioh020 socket: hif6-100d-1.27r (hirose) flat cable (50 cores) ul2651 awg28 x 2 no connector cable 1 (pins 1 to 50) cable 2 (pins 51 to 100) 84.

Page 109

85 part 1 installation internal circuit internal circuit input terminal input terminal external power supply external power supply 3.6 i/o circuits 3.6.1 input input specifications item specification (common to pnp/npn) external power-supply voltage 24 vdc 10% input current max. 7 ma/1 point leak ...

Page 110

86 part 1 installation 3.6.2 output output specifications specification output element transistor array npn specification: td62084af by toshiba pnp specification: td62784af by toshiba external power-supply voltage 24 vdc 10% maximum load current max. 50 ma/1 point (max. 400 ma/24 points): *1 leak ...

Page 111

87 part 1 installation chapter 8 how to perform an absolute encoder reset of a direct movement axis (absolute specification) when the absolute-encoder backup battery voltage of a linear movement axis is abnormal or when the battery or encoder cable of a linear movement axis has been disconnected, an...

Page 112

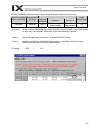

88 part 1 installation (6) the x-sel pc software window will be displayed. Clicking the [ok] button will clear the error message. (7) from the [monitor (m)] menu, select [detailed error information (e)] to check the current error status. In the case of an encoder battery error, the following will be...

Page 113

89 part 1 installation (8) from the [controller (c)] menu, select [absolute reset (linear movement axis) (a)]. (9) when a [warning] dialog box is displayed, click the [ok] button. 89.

Page 114

90 part 1 installation (10) the [abs. Encoder reset] dialog box will be displayed. Click here to select the axis for which you wish to perform an absolute reset. (11) clicking the [encoder rotation data reset 1] button will display a [warning] dialog box. Click the [yes] button. 90

Page 115

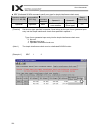

91 part 1 installation (12) another [warning] dialog box will be displayed. Click the [yes] button. (13) when the processing of “encoder rotation data reset 1” is complete, the red arrow will move to the next item. Press the following processing buttons one by one (the red arrow will move to the nex...

Page 116

92 part 1 installation (15) when the [confirmation] dialog box is displayed, click the [yes] button and restart the controller. (note) commencing the operation without first executing a software reset or reconnecting the power may generate an “error no. C70, abs coordinate non-confirmation error.” (...

Page 117

93 part 1 installation chapter 9 maintenance routine maintenance and inspection are necessary so that the system will operate properly at all times. Be sure to turn off the power before performing maintenance or inspection. The standard inspection interval is six months to one year. If the environme...

Page 118

94 part 1 installation 2. Spare consumable parts without spare parts, a failed controller cannot be repaired even when the problem is identified quickly. We recommend that you keep the following consumable parts as spares: consumable parts cables system memory backup battery: cr2032 (note 1) --- mus...

Page 119

95 part 1 installation 3. Replacement procedure for system memory backup battery backing up the system memory if “other parameter no. 20, backup battery installation function type” is set to “2” (installed), the following sram data in the x-sel controller will be backed up by the system memory backu...

Page 120

96 part 1 installation battery replacement procedure [1] remove the 7 segment led panel from the controller. Slide the panel upward and pull it toward you to remove. [2] press the center of the battery using a finger, as shown. The battery will come off from the holder. [3] install a new battery int...

Page 121

97 part 1 installation (8) when the replacement of system memory backup battery is complete, confirm that the battery is installed securely and then turn on the controller power. (9) revert “other parameter no. 20, backup battery installation function type” to the value recorded in step 2, transfer ...

Page 122

98 part 1 installation 4. Replacement procedure for absolute-encoder backup battery for linear movement axis the replacement procedure will vary depending on if errors are present at the time of replacement and if so, which errors are present (nos. A23, 914, ca2). If no error is present, perform ste...

Page 123

99 part 1 installation (5) insert a new battery into the holder and plug in the battery connector. (6) turn on the controller power. (7) set the absolute data backup battery enable/disable switch to the top (enb) position. (note) this operation is not required if no error has occurred or an a23 erro...

Page 124

100 part 1 installation (15) from the [controller (c)] menu on the pc software screen, select [software reset (r)], and restart the controller. Confirmation (note) commencing the operation without first executing a software reset or reconnecting the power may generate the following errors: error no....

Page 125

101 part 2 operation part 2 operation chapter 1 operation how to start a program with the x-sel controller, the stored programs can be started using four methods. Of these methods, two are mainly used to debug programs or perform trial operations, while the remaining two are used in general applicat...

Page 126

102 part 2 operation 1. Starting a program by auto start via parameter setting i/o parameter no. 33 (input function selection 003) = 1 (default factory setting) set the number of the program you wish to start automatically in other parameter no. 1 (auto start program number). Set the controller mode...

Page 127

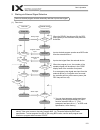

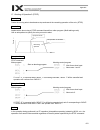

103 part 2 operation 2. Starting via external signal selection (1) flow chart when the ready signal turns on, the rdy lamp (green) on the controller front panel will illuminate. Input a desired program number as a bcd code from the external device.* input a start signal from the external device. Whe...

Page 128

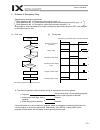

104 part 2 operation (2) timing chart [1] start of program ready output program 1 program 2 program number input external start input t1: duration after the ready output turns on until input of external start signal is permitted t1 = 10 msec min. T2: duration after the program number is input until ...

Page 129

105 part 2 operation 3. Drive source recovery request and operation pause reset request (1) drive source recovery request [1] how to request a drive source recovery a drive source recovery request can be issued using one of the following methods: set i/o parameter no. 44 to “1” (input selection func...

Page 130

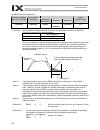

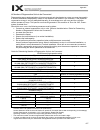

Part 2 operation chapter 2 special function 1. Driver overload warning function setting the motor estimated raised temperature that causes the driver overload error as 100%, the driver overload warning (message level error) will be detected when the load rate (hereafter described as the overload lev...

Page 131

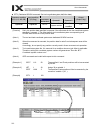

Part 2 operation [reference: check of overload level] the overload level during the motor operation can be checked in the pc interface software for xsel. [1] click “servo addition datamonitor” in “monitor” menu. [2] set the monitor type in “servo addition datamonitor” window to “01: motor load facto...

Page 132

Part 2 operation ● axis-specific parameters no. Parameter name default value (reference) input range unit access right remarks 113 olwl (used be ovld) driver overload warning load level ratio 100 50 ~ 100 % f set in % from the driver overload error load level (invalid when 100) (main application ver...

Page 133

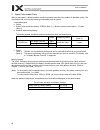

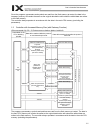

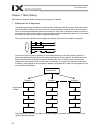

106 part 3 controller data structure part 3 controller data structure the controller data consists of parameters as well as position data and application programs used to implement sel language. X-sel controller data structure the user must create position data and application programs. The paramete...

Page 134

107 part 3 controller data structure chapter 1 how to save data since the x-sel controller uses flash memory, some data are saved by battery backup while others are saved in the flash memory. When data is transferred from the pc software or teaching pendant to the controller, the data is only writte...

Page 135

107 part 3 controller data structure chapter 1 how to save data since the x-sel controller uses flash memory, some data are saved by battery backup while others are saved in the flash memory. When data is transferred from the pc software or teaching pendant to the controller, the data is only writte...

Page 136

109 part 3 controller data structure 2. When the system memory backup battery is not used 2.1 controller without increased memory size other parameter no. 20 = 0 (system memory backup battery not installed) the programs, parameters, symbols and positions are read from the flash memory at restart. Th...

Page 137

109 part 3 controller data structure 2. When the system memory backup battery is not used 2.1 controller without increased memory size other parameter no. 20 = 0 (system memory backup battery not installed) the programs, parameters, symbols and positions are read from the flash memory at restart. Th...

Page 138

111 part 3 controller data structure 3. Points to note point to note when transferring data and writing to the flash memory never turn off the main power while data is being transferred or written to the flash memory. The data will be lost and the controller operation may be disabled. Point to note ...

Page 139

111 part 3 controller data structure 3. Points to note point to note when transferring data and writing to the flash memory never turn off the main power while data is being transferred or written to the flash memory. The data will be lost and the controller operation may be disabled. Point to note ...

Page 140

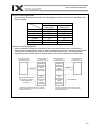

113 part 3 controller data structure chapter 2 x-sel language data 1. Values and symbols used in sel language 1.1 list of values and symbols used the functions required in a program are represented by values and symbols. Function global range local range remarks input port 000 ~ 299 (300) varies dep...

Page 141

113 part 3 controller data structure chapter 2 x-sel language data 1. Values and symbols used in sel language 1.1 list of values and symbols used the functions required in a program are represented by values and symbols. Function global range local range remarks input port 000 ~ 299 (300) varies dep...

Page 142

115 part 3 controller data structure 1.3 virtual i/o ports (1) virtual input ports port no. Function 7000 always off 7001 always on 7002 voltage low warning for system memory backup battery 7003 abnormal voltage of system memory backup battery 7004 (for future expansion = use strictly prohibited) 70...

Page 143

115 part 3 controller data structure 1.3 virtual i/o ports (1) virtual input ports port no. Function 7000 always off 7001 always on 7002 voltage low warning for system memory backup battery 7003 abnormal voltage of system memory backup battery 7004 (for future expansion = use strictly prohibited) 70...

Page 144

117 part 3 controller data structure 1.4 flags contrary to its common meaning, the term “flag” as used in programming means “memory.” flags are used to set or reset data. They correspond to “auxiliary relays” in a sequencer. Flags are divided into global flags (nos. 600 to 899) that can be used in a...

Page 145

117 part 3 controller data structure 1.4 flags contrary to its common meaning, the term “flag” as used in programming means “memory.” flags are used to set or reset data. They correspond to “auxiliary relays” in a sequencer. Flags are divided into global flags (nos. 600 to 899) that can be used in a...

Page 146

119 part 3 controller data structure real variable box variable box 1 (2) types of variables variables are classified into two types, as follows: [1] integer variables these variables cannot handle decimal places. [example] 1234 integer variable number 200 ~ 299 1200 ~ 1299 can be used in all progra...

Page 147

119 part 3 controller data structure real variable box variable box 1 (2) types of variables variables are classified into two types, as follows: [1] integer variables these variables cannot handle decimal places. [example] 1234 integer variable number 200 ~ 299 1200 ~ 1299 can be used in all progra...

Page 148

121 part 3 controller data structure 1.6 tags the term “tag” means “heading.” tags are used in the same way you attach labels to the pages in a book you want to reference frequently. A tag is a destination specified in a jump command “goto.” command operand 1 tag tag number (integer between 1 and 25...

Page 149

121 part 3 controller data structure 1.6 tags the term “tag” means “heading.” tags are used in the same way you attach labels to the pages in a book you want to reference frequently. A tag is a destination specified in a jump command “goto.” command operand 1 tag tag number (integer between 1 and 25...

Page 150

123 part 3 controller data structure 1.8 symbols in the x-sel controller, values such as variable numbers and flag numbers can be handled as symbols. For the method to edit symbols, refer to “editing symbols” in the operation manual for x-sel teaching pendant or “symbol edit window” in the operation...

Page 151

123 part 3 controller data structure 1.8 symbols in the x-sel controller, values such as variable numbers and flag numbers can be handled as symbols. For the method to edit symbols, refer to “editing symbols” in the operation manual for x-sel teaching pendant or “symbol edit window” in the operation...

Page 152

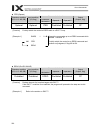

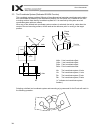

125 part 3 controller data structure (2) axis pattern whether or not each axis will be used is indicated by “1” or “0.” (upper) (lower) axis number axis 6 axis 5 axis 4 axis 3 axis 2 axis 1 used 1 1 1 1 1 1 not used 0 0 0 0 0 0 [example] when axes 1 and 2 are used axis 2 0011 --- the two 0s in front...

Page 153

125 part 3 controller data structure (2) axis pattern whether or not each axis will be used is indicated by “1” or “0.” (upper) (lower) axis number axis 6 axis 5 axis 4 axis 3 axis 2 axis 1 used 1 1 1 1 1 1 not used 0 0 0 0 0 0 [example] when axes 1 and 2 are used axis 2 0011 --- the two 0s in front...

Page 154

127 part 3 controller data structure 3. Command part the primary feature of sel language is its very simple command structure. Since the structure is simple, there is no need for a compiler (to translate into computer language) and high speed operation is possible via an interpreter (the program run...

Page 155

127 part 3 controller data structure 3. Command part the primary feature of sel language is its very simple command structure. Since the structure is simple, there is no need for a compiler (to translate into computer language) and high speed operation is possible via an interpreter (the program run...

Page 156

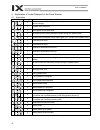

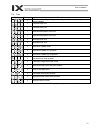

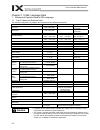

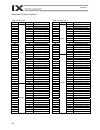

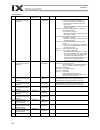

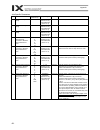

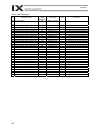

129 part 4 commands part 4 commands chapter 1 list of sel language command codes 1. By function variables can be specified indirectly in the operand 1, operand 2 and output fields. Symbols can be input in the condition, operand 1, operand 2 and output fields. The input items in ( ) under operand 1 a...

Page 157

129 part 4 commands part 4 commands chapter 1 list of sel language command codes 1. By function variables can be specified indirectly in the operand 1, operand 2 and output fields. Symbols can be input in the condition, operand 1, operand 2 and output fields. The input items in ( ) under operand 1 a...

Page 158

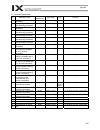

131 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 159

131 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 160

133 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 161

133 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 162

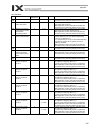

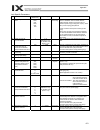

135 part 4 commands rc gateway function commands (controllers with gateway function only) * for the rc gateway function commands, refer to “operation manual for x-sel controller p/q/px/qx rc gateway function.” operation type in the output field cc: command was executed successfully, zr: operation re...

Page 163

135 part 4 commands rc gateway function commands (controllers with gateway function only) * for the rc gateway function commands, refer to “operation manual for x-sel controller p/q/px/qx rc gateway function.” operation type in the output field cc: command was executed successfully, zr: operation re...

Page 164

137 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 165

137 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 166

139 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 167

139 part 4 commands operation type in the output field cc: command was executed successfully, zr: operation result is zero, pe: operation is complete, cp: command part has passed, tu: time up eq: operand 1 = operand 2, ne: operand 1 operand 2, gt: operand 1 > operand 2, ge: operand 1 operand 2, ...

Page 168

141 part 4 commands chapter 2 explanation of commands 1. Commands 1.1 variable assignment let (assign) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional let variable number data zr ...

Page 169

141 part 4 commands chapter 2 explanation of commands 1. Commands 1.1 variable assignment let (assign) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional let variable number data zr ...

Page 170

143 part 4 commands 1.2 arithmetic operation add (add) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional add variable number data zr [function] add the content of the variable speci...

Page 171

143 part 4 commands 1.2 arithmetic operation add (add) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional add variable number data zr [function] add the content of the variable speci...

Page 172

145 part 4 commands mod (remainder of division) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mod variable number data zr [function] assign, to the variable specified in 1, the ...

Page 173

145 part 4 commands mod (remainder of division) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional mod variable number data zr [function] assign, to the variable specified in 1, the ...

Page 174

147 part 4 commands cos (cosine operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional cos variable number data zr [function] assign the cosine of the data specified in operan...

Page 175

147 part 4 commands cos (cosine operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional cos variable number data zr [function] assign the cosine of the data specified in operan...

Page 176

149 part 4 commands atn (inverse-tangent operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional atn variable number data zr [function] assign the inverse tangent of the data s...

Page 177

149 part 4 commands atn (inverse-tangent operation) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional atn variable number data zr [function] assign the inverse tangent of the data s...

Page 178

151 part 4 commands 1.4 logical operation and (logical and) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional and variable number data zr [function] assign the logical and operation...

Page 179

151 part 4 commands 1.4 logical operation and (logical and) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional and variable number data zr [function] assign the logical and operation...

Page 180

153 part 4 commands eor (logical exclusive-or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional eor variable number data zr [function] assign the logical exclusive-or operation res...

Page 181

153 part 4 commands eor (logical exclusive-or) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional eor variable number data zr [function] assign the logical exclusive-or operation res...

Page 182

155 part 4 commands 1.6 timer timw (timer) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional timw time prohibited tu [function] stop the program and wait for the time specified in o...

Page 183

155 part 4 commands 1.6 timer timw (timer) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional timw time prohibited tu [function] stop the program and wait for the time specified in o...

Page 184

157 part 4 commands gttm (get time) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gttm variable number prohibited cp [function] read system time to the variable specified in ope...

Page 185

157 part 4 commands gttm (get time) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gttm variable number prohibited cp [function] read system time to the variable specified in ope...

Page 186

159 part 4 commands btpn (output on pulse) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional btpn output port, flag timer setting cp [function] turn on the specified output port or ...

Page 187

159 part 4 commands btpn (output on pulse) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional btpn output port, flag timer setting cp [function] turn on the specified output port or ...

Page 188

161 part 4 commands wt (wait for i/o port, flag) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wt i/o, flag (time) tu [function] wait for the i/o port or flag specified in ope...

Page 189

161 part 4 commands wt (wait for i/o port, flag) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional wt i/o, flag (time) tu [function] wait for the i/o port or flag specified in ope...

Page 190

163 part 4 commands inb (read i/o, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional inb output, flag bcd digits cc [function] read the i/o ports or flags from the one ...

Page 191

163 part 4 commands inb (read i/o, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional inb output, flag bcd digits cc [function] read the i/o ports or flags from the one ...

Page 192

165 part 4 commands outb (write output, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional outb output, flag bcd digits cc [function] write the value in variable 99 to t...

Page 193

165 part 4 commands outb (write output, flag as bcd) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional outb output, flag bcd digits cc [function] write the value in variable 99 to t...

Page 194

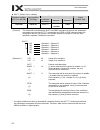

167 part 4 commands [4] operand 1 = 3 data is read or written after its upper 16 bits and lower 16 bits are reversed every 32 bits and its upper eight bits and lower eight bits are reversed every 16 bits. (i/o, flag number upper) (i/o, flag number lower) 01234567h 67h 45h 23h 01h 0110 0111 0100 ...

Page 195

167 part 4 commands [4] operand 1 = 3 data is read or written after its upper 16 bits and lower 16 bits are reversed every 32 bits and its upper eight bits and lower eight bits are reversed every 16 bits. (i/o, flag number upper) (i/o, flag number lower) 01234567h 67h 45h 23h 01h 0110 0111 0100 ...

Page 196

169 part 4 commands 1.8 program control goto (jump) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional goto tag number prohibited cp [function] jump to the position of the tag number...

Page 197

169 part 4 commands 1.8 program control goto (jump) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional goto tag number prohibited cp [function] jump to the position of the tag number...

Page 198

171 part 4 commands edsr (end subroutine) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited edsr prohibited prohibited cp [function] declare the end of a subroutine. This comman...

Page 199

171 part 4 commands edsr (end subroutine) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) prohibited prohibited edsr prohibited prohibited cp [function] declare the end of a subroutine. This comman...

Page 200

173 part 4 commands expg (start other program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional expg program number (program number (note)) cc [function] start the programs from th...

Page 201

173 part 4 commands expg (start other program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional expg program number (program number (note)) cc [function] start the programs from th...

Page 202

175 part 4 commands sspg (pause program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sspg program number (program number) cc [function] pause the program from the one specifie...

Page 203

175 part 4 commands sspg (pause program) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional sspg program number (program number) cc [function] pause the program from the one specifie...

Page 204

177 part 4 commands 1.10 position operation pget (read position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pget axis number position number cc [function] read to variab...

Page 205

177 part 4 commands 1.10 position operation pget (read position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pget axis number position number cc [function] read to variab...

Page 206

179 part 4 commands pclr (clear position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pclr position number position number cp [function] clear the position data from the ...

Page 207

179 part 4 commands pclr (clear position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pclr position number position number cp [function] clear the position data from the ...

Page 208

181 part 4 commands pred (read current position) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pred axis pattern position number cp [function] read the current position of the a...

Page 209

181 part 4 commands pred (read current position) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pred axis pattern position number cp [function] read the current position of the a...

Page 210

183 part 4 commands ptst (check position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ptst axis pattern position number cc [function] check if valid data is contained in ...

Page 211

183 part 4 commands ptst (check position data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional ptst axis pattern position number cc [function] check if valid data is contained in ...

Page 212

185 part 4 commands pacc (assign acceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pacc acceleration position number cp [function] write the scara cp operation ac...

Page 213

185 part 4 commands pacc (assign acceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional pacc acceleration position number cp [function] write the scara cp operation ac...

Page 214

187 part 4 commands paxs (read axis pattern) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional paxs variable number position number cp [function] store the axis pattern at the posit...

Page 215

187 part 4 commands paxs (read axis pattern) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional paxs variable number position number cp [function] store the axis pattern at the posit...

Page 216

189 part 4 commands gvel (get speed data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gvel variable number position number cp [function] obtain speed data from the speed item ...

Page 217

189 part 4 commands gvel (get speed data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gvel variable number position number cp [function] obtain speed data from the speed item ...

Page 218

191 part 4 commands gdcl (get deceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gdcl variable number position number cp [function] obtain deceleration data from t...

Page 219

191 part 4 commands gdcl (get deceleration data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gdcl variable number position number cp [function] obtain deceleration data from t...

Page 220

193 part 4 commands vels (dedicated scara command: set speed ratio) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vels ratio prohibited cp [function] set the travel speed for pt...

Page 221

193 part 4 commands vels (dedicated scara command: set speed ratio) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vels ratio prohibited cp [function] set the travel speed for pt...

Page 222

195 part 4 commands acc (set acceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional acc acceleration prohibited cp [function] set the scara cp operation acceleration/linear...

Page 223

195 part 4 commands acc (set acceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional acc acceleration prohibited cp [function] set the scara cp operation acceleration/linear...

Page 224

197 part 4 commands dcl (set deceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dcl deceleration prohibited cp [function] set the scara cp operation deceleration/linear...

Page 225

197 part 4 commands dcl (set deceleration) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dcl deceleration prohibited cp [function] set the scara cp operation deceleration/linear...

Page 226

199 part 4 commands vlmx (dedicated linear movement axis command: specify vlmx speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vlmx prohibited prohibited cp [function] set ...

Page 227

199 part 4 commands vlmx (dedicated linear movement axis command: specify vlmx speed) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional vlmx prohibited prohibited cp [function] set ...

Page 228

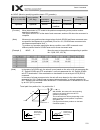

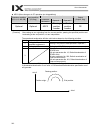

201 part 4 commands s-motion a (operand 2 = blank or 0) s-motion b (operand 2 = 1) if s-motion b is selected, the speed pattern becomes smoother (compared to the s-motion control ratio applicable when s-motion a is selected). (the deviation peak from the trapezoid motion becomes smaller.) [example 1...

Page 229

201 part 4 commands s-motion a (operand 2 = blank or 0) s-motion b (operand 2 = 1) if s-motion b is selected, the speed pattern becomes smoother (compared to the s-motion control ratio applicable when s-motion a is selected). (the deviation peak from the trapezoid motion becomes smaller.) [example 1...

Page 230

203 part 4 commands deg (set arc angle) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional deg angle prohibited cp [function] set a division angle for the interpolation implemented b...

Page 231

203 part 4 commands deg (set arc angle) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional deg angle prohibited cp [function] set a division angle for the interpolation implemented b...

Page 232

205 part 4 commands grp (set group axes) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional grp axis pattern prohibited cp [function] allow only the position data of the axis pattern...

Page 233

205 part 4 commands grp (set group axes) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional grp axis pattern prohibited cp [function] allow only the position data of the axis pattern...

Page 234

207 part 4 commands canc (cancel: declare axis port to abort) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional canc (input port, global flag) (canc type) cp [function] declare an i...

Page 235

207 part 4 commands canc (cancel: declare axis port to abort) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional canc (input port, global flag) (canc type) cp [function] declare an i...

Page 236

209 part 4 commands potp (set path output type) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional potp 0 or 1 prohibited cp [function] set the output type in the output field to be ...

Page 237

209 part 4 commands potp (set path output type) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional potp 0 or 1 prohibited cp [function] set the output type in the output field to be ...

Page 238

211 part 4 commands dftl (dedicated scara command: define tool coordinate system) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dftl tool coordinate system number position numbe...

Page 239

211 part 4 commands dftl (dedicated scara command: define tool coordinate system) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dftl tool coordinate system number position numbe...

Page 240

213 part 4 commands gttl (dedicated scara command: get tool coordinate system definition data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gttl tool coordinate system number p...

Page 241

213 part 4 commands gttl (dedicated scara command: get tool coordinate system definition data) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional gttl tool coordinate system number p...

Page 242

215 part 4 commands slwk (dedicated scara command: select load coordinate system) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional slwk load coordinate system number prohibited cp ...

Page 243

215 part 4 commands slwk (dedicated scara command: select load coordinate system) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional slwk load coordinate system number prohibited cp ...

Page 244

217 part 4 commands righ (dedicated scara command: change current arm system to right arm (arm 2 may operate if the current arm system is the opposite arm)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output...

Page 245

217 part 4 commands righ (dedicated scara command: change current arm system to right arm (arm 2 may operate if the current arm system is the opposite arm)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output...

Page 246

219 part 4 commands ptpr (dedicated scara command: specify right arm as ptp target arm system (movement of the opposite arm system is prohibited when the target value cannot be achieved) (no arm operation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) comma...

Page 247

219 part 4 commands ptpr (dedicated scara command: specify right arm as ptp target arm system (movement of the opposite arm system is prohibited when the target value cannot be achieved) (no arm operation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) comma...

Page 248

221 part 4 commands ptpd (dedicated scara command: specify current arm as ptp target arm system (movement of the opposite arm system is prohibited when the target value cannot be achieved) (no arm operation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) com...

Page 249

221 part 4 commands ptpd (dedicated scara command: specify current arm as ptp target arm system (movement of the opposite arm system is prohibited when the target value cannot be achieved) (no arm operation)) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) com...

Page 250

223 part 4 commands dfif (dedicated scara command: define coordinates of simple interference check zone) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dfif interference check zo...

Page 251

223 part 4 commands dfif (dedicated scara command: define coordinates of simple interference check zone) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional dfif interference check zo...

Page 252

225 part 4 commands seif (dedicated scara command: specify error type for simple interference check zone) command, declaration extension condition (ld, a, o, ab, ob) input condition (i/o, flag) command, declaration operand 1 operand 2 output (output, flag) optional optional seif interference check z...

Page 253