- DL manuals

- IAME

- Engine

- EASY-KART 2003

- Assembly Instructions And User's Manual

IAME EASY-KART 2003 Assembly Instructions And User's Manual

Summary of EASY-KART 2003

Page 1

Man-028 easy-kart engines 2003 assembly instructions and user manual.

Page 2

Man-028 1 index general description of the engine characteristics of the tag engines – operational limits 1- contents of the packing 2- motor identification number 3- preparation and installation of the engine on the chassis 3.1 exhaust header assembly 3.2 preparation and installation of the motor-m...

Page 3

1 general description of the engine the “tag” engines have been expressly designed and developed for the powering of karts for hobby racing on closed tracks, destined for this specific purpose. When designing this new line of engines, the technical solutions already adopted for the high performance ...

Page 4

2 man-028 the carburetor is a diaphragm tillotson carburetor with fixed jet on the high speed, integral fuel pump and filter and has an all position mounting. The battery (12 v- 7.2ah) is a sealed type, without maintenance battery and is supplied already preassembled in the battery and power pack su...

Page 5

3 man-028 characteristics of the tag engines - operational limits 1. The characteristics which are in common to all tag engines are the following. Between brackets, the exceptions and possible alternatives are shown : • cycle: otto / 2 stroke • lubrication : fuel-oil mix • induction: piston port on ...

Page 6

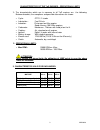

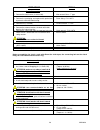

4 man-028 1- content of the packing each engine of the tag series is delivered with the under shown accessories which are preinstalled on the easy-kart chassis. Piston port engine 62 cc. Reed valve engine 100/125 cc. Air air exhaust • flexible 1 1 • spring for flexible 3 3 • exhaust fiber strip 1 1 ...

Page 7

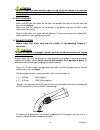

5 man-028 2- motor identification number the official motor identification number can be found stamped in the lower left part of the crankcase, aside of the electric starter (see fig.) the number normally includes 2 letters “ek” followed by 4 digits. Other numbers stamped on the crankcase or other s...

Page 8

6 man-028 3- preparation and installation of the engine on the chassis note: in case the engine is supplied already assembled on the chassis, it is at care of the assembler to follow these instructions. The final customer, in this case, can skip this section and can start reading from section 4. Whe...

Page 9

7 man-028 3.2 preparation and installation of the motor mount 3.2.1 drill 4 holes (diam 8.5mm) in the motor mount in case the supply includes the additional motor mount motor mount horizontal view motor mount horizontal view.

Page 10

8 man-028 3.2.2 before installing the motor mount, position the additional mount plate (if included in the supply) on the crankcase (see fig. 3). 3.2.3 install the motor mount. Make sure to use m8 allen screws with a lenght such as to engage, in the crankcase, a threaded portion lenght of appr. 18mm...

Page 11

9 man-028 3.3.2 remove 2 screws 3.5mm on the carb. Pump (in correspondence of the throttle lever) (see fig. 6). Screwdriver 4.8 mm. 3.3.3 insert the gas bracket and the two screws (see fig. 7). 3.3.4 install the intake support – 2 screws m5 x10 (see fig. 8) 3 mm allen wrench 3.3.5 install the carbur...

Page 12

10 man-028 attention: when replacing the carb gasket always make sure that the gasket is installed so that the hole in the gasket matches with the two pressure holes in the carb. And in the crankcase: otherwise the engine won’t start. Install the carburetor. N.2 nuts m6 and two washers. Torque at 6 ...

Page 13

11 man-028 3.4.2 check thealignment of the engine sprocket and the axle sprocket (see fig. 14). 3.4.3 install the chain (pitch: 7.775) (see fig. 15). 3.4.4 move the engine on the rails and optimize the chain tension . Attention: the play of the chain must be appr. 15mm measured in the shown point (s...

Page 14

12 man-028 install the clutch cover with h.T. Coil 3.5 3.5.1 remove the 3 screws m6 x 30 on the crankcase (see fig. 17) and install the clutch cover with h.T. Coil (see fig.18). Torque the 3 screws at 8 ÷ 10 nm attention: always make sure that the ground cable always connects the coil with the engin...

Page 15

13 man-028 electrical connection (refer to the attached electrical schematic) 3.6 installation and connection of the power pack box. Note: the power pack box is supplied already assembled on the battery support (with battery) . For a correct installation follow the under shown instructions. 3.6.1 ex...

Page 16

14 man-028 3.6.4 insert the battery strap (see fig. 22). 3.6.5 insert the battery with terminals towards the outside (see fig. 23). Connect the battery terminals. Suggestion: never connect the battery until you are ready to start the engine. Seal the battery terminals with plastic tape to avoid that...

Page 17

15 man-028 3.7.3 fix the ground cable, from the power-pack, on the engine crankcase, by means of the proper threaded hole (see fig. 25). Attention: this operation is extremely important as an uncertain grounding could damage the power pack box beyond repair. 3.7.4 connect the terminals (3 and 4 ways...

Page 18

16 man-028 3.7.6 chek the electric starter cable fixing (see fig. 29) and complete the fixing of the harness (see fig. 30). Attention : never let the harness get in touch with the ground or with a rotating part as it could be damaged beyond repair. 3.7.7 connect the coil cable from the power pack to...

Page 19

17 man-028 3.7.9 puncture the insulating material on the h.T. Cable with the end of the cap spring so that the spring is in sure contact with the internal wire (see fig. 33). 3.7.10 insert the spark plug cap on the spring (see fig. 34). Install the spark plug and the cap over the spark plug. • insta...

Page 20

18 man-028 3.9 install the exhaust note: see section 9 for recommendations on the ideal lenght of the exhaust. 3.9.1 install the flexible (l= 65mm – flexible completely closed) and the exhaust header (see fig. 37) and connect the exhaust. 3.9.2 install the fiber strip around the flexible and fix wit...

Page 21

19 man-028 4- gasoline and oil use leaded or unleaded premium gasoline (96 to 98 octane ron) mixed with oil at 6% -(16:1). Use oils containing castor oil which guarantees an optimized lubrication at high temperatures. As on the other hand, use of castor oils creates gummy residues which give origin ...

Page 22

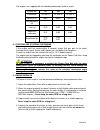

20 man-028 5- carburetor adjustment guide 1 t.O. * rich lean 1 ¼ t.O. ¾ t.O. 1 ½ t.O. * t.O . = turns open the carburetors are originally supplied with a fixed jet on the high speed. The screws l and i are pre-set to start and run the engine. L: 1 ¼ t.O. For the 62cc engine and 1 ½ t.O. For the 100 ...

Page 23

21 man-028 note: (l) may need to be fine tuned again after a jet change. If so proceed as above. Procedure for changing fixed side jet 1. Remove sealing screw and gasket using a flat ended screwdriver turning anti-clockwise (see fig.1) fig. 1 2. Remove fixed jet using a 3mm flat ended screwdriver tu...

Page 24

22 man-028 the engines are supplied with the following carburetors and kits of jets: engine (cc) 62 100 125 carburetor hl 385 a hl 384 a hl 384 b jet kit (p.N.) 10971 10972 10973 a composition of kit lean jet 0.73 0.83 0.87 normal on carburetor 0.74 0.85 0.88 enrichment jet 0.76 0.77 0.86 0.87 // 6-...

Page 25

23 man-028 attention: once the break-in is over and the engine is cold, check the torque of the exhaust header nuts as, during the break-in, the nuts tend to become loose (refer to the attached table). 8- inlet silencer make sure that the inlet holes on the filter are towards the front of the kart a...

Page 26

24 man-028 having fixed a sprocket ratio, it could be necessary to improve the engine performance either at low or at high rpm. This could be achieved by modifying the exhaust lenght. In general, by shortening the total exhaust lenght an improvement at high rpm is achieved and vice versa, by lenghte...

Page 27

25 man-028 attention: in case the friction material has been totally worn out and there has been a metal contact between the clutch body and the clutch drum, it is necessary to replace the clutch drum. See drawing. 11- instructions for the disassembly / assembly of the clutch attention: the followin...

Page 28

26 man-028 operations tools clutch disassembly 1. Remove the clutch cover (3 screws m6). Allen wrench 5mm – t type 2. Remove the spark plug and replace with special tool to prevent crankshaft from turning. Piston fitting : p.N. 10271 3. Remove nut (1 nut m10). 12 point wrench - 17 mm 4. Remove the e...

Page 29

27 man-028 12- battery the battery (12 v–7.2 ah) included in the supply is sealed and without maintenance. In order to lengthen the battery life it is necessary though to follow a few recommendations: when the tension drops below 12.6v it is necessary to recharge the battery. Max. Allowed recharging...

Page 30

28 man-028 13- sparkplug and thermal degree the engine is supplied with a standard ngk br10eg sparkplug which represents a good compromise between the needs of a good break-in and the racing needs in normal conditions. Use of different sparkplugs is possible and, as a general information, we are att...

Page 31

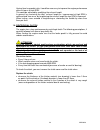

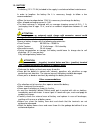

29 man-028 14- scheduled maintenance following some simple maintenance standards will allow the engine to perform more reliably and have a longer life. Schedule components actions and comments before using exhaust flexible check status exhaust springs check status exhaust strap check status exhaust ...

Page 32

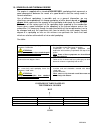

30 man-028 15- troubleshooting below are some common faults, their probable causes and suggested remedy: faults probable cause remedy starter will not crank when pushing the start button. Bad connections on starter cables. Check and tighten bad grounding check connections and tighten damaged cables ...

Page 33

31 man-028 16- engine preservation when engine is to remain unoperative for a long period it must be preserved as follows: disconnect the battery and charge it periodically (see par. 12) disconnect carburetor and clean it seal with tape the engine inlet and exhaust the external of the engine must be...

Page 34

32 man-028.

Page 35

33 man-028.