- DL manuals

- IAME

- Engine

- Parilla MINI SWIFT

- Overhauling Manual

IAME Parilla MINI SWIFT Overhauling Manual

Summary of Parilla MINI SWIFT

Page 1

12/10/05 man-045 ing 1 engine overhauling manual 60cc baby & mini swift - tag.

Page 2: Index

12/10/05 man-045 ing 2 index page 1. - engine disassembly 1 2. - crankshaft assembly / disassembly 7 2.1- crankshaft disassembly 7 2.2- crankshaft assembly 9 3. - engine assembly 12 attachments - fastener torque value - cross pattern locking order on crankcase - main prescriptions - little / big end...

Page 3

Man-045 ing 1 1 – engine disassembly operation tools required 1. Insert two screws m8x60 on the crankcase toposition motor on the bench. Vice on bench (tool as per draw. S725/3) 2. Remove clutch: -remove clutch cover 3 screws m6 (see fig.1). (5mm allen t type) -remove sparkplug and install special p...

Page 4

Man-045 ing 2 - remove piston fitting and using clutch wrench remove the fixing nut. (see fig.4) (clutch wrench: p.N. 10270) (12 point wrench - 24mm) attention: turn clockwise as nut has left thread. -remove safety washer. -remove clutch from the crankshaft using the clutch disassembly tool (see fig...

Page 5

Man-045 ing 3 4. Remove the ignition: -remove stator . 2 screws m5x25 (see fig.8). (5mm allen t type) -install piston fitting and remove nut with washer. (piston fitting : p.N. 10271) (12 point wrench - 17mm) -remove rotor (see fig.9). -remove key from crankshaft seat. 5. Remove starter group 4 scre...

Page 6

Man-045 ing 4 -remove the countershaft support cover . 3 screws m6x20 (see fig.13). -extract the countershaft from the support. (see fig.14). 6. Remove the head : -loosen nuts by ½ turn (cross pattern disassembly) and then remove (see fig.15). 4 nuts m8 4 washers (13mm socket t- type) fig.13 fig.14 ...

Page 7

Man-045 ing 5 7. Remove cylinder (see fig.16). Remove cylinder gasket. 8. Remove circlips from piston (see fig.17) (screwdriver with round edges) attention: do not scratch piston or circlip seats. 9. Remove piston pin, piston and roller cage using the piston pin punch (see fig.18). (piston pin punch...

Page 8

Man-045 ing 6 remove the pump fixing screws (see fig.20). 2 screws m6x45 1 nut m6 (5mm allen t type) (6 point wrench - 10mm) 11. Opening the crankcase: -remove 7 fixing screws (see fig.21). 4 screws m6x40 3 screws m6x50 (5mm allen t type) (plastic mallet) -open the crankcase (using a plastic mallet)...

Page 9

Man-045 ing 7 2 – crankshaft assembly/disassembly attention: the disassembly/assembly operations on the engine crankshaft, must be performed only by an authorized support center using the specially designed tools. Use of unfitted tools or operations performed by unskill personnel may damage the cran...

Page 10

Man-045 ing 8 4. Disassemble the con-rod with washers. Repeat the operations to extract the crankpin from the other half crankshaft (see fig.3). Before reassembling, wash all parts with kerosene a) check status of con-rod (top and bottom) . If ovalization exceeds 0.01mm, replace con-rod. -centesimal...

Page 11

Man-045 ing 9 2.2 – crankshaft assembly operation tools required 1. Place the crankshaft assembly tool (p.N. 10110-c) under the press, vertically - 5 met press - crankshaft assembly kit: p.N. 10110-c 2. Place the crankshaft half into the assembly tool. 3. Oil crankpin and crankpin hole on crankshaft...

Page 12

Man-045 ing 10 7. Extract bush from crankpin and put tool in horizontal position (see fig.4). 8. Insert on crankpin (oil crankpin): -conrod with roller cage and washers (see fig.5). Attention: rollers are free in the cage. Prevent rollers from falling, when inserting on crankpin. 9. Place second cra...

Page 13

Man-045 ing 11 11. Oil crankpin and crankpin hole on crankshaft half . 12. Put tool in vertical position (see fig.8). 13. Progressively press the two crankshaft halves together. 14. Open the tool. Put it in horizontal position and extract the crankshaft. 15. Check axial play of the conrod (see fig.9...

Page 14

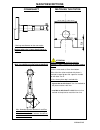

Man-045 ing 12 b. Rotate crankshaft and look at deflection of gauge needles. Deflection must be, after centering max. 0.01mm (see drawing). C. Adjust centering with copper hammer, if necessary (see fig.11). 3 – engine assembling before reassembling, wash all the parts with kerosene operation tools r...

Page 15

Man-045 ing 13 d) insert ball-bearings to be on upper side and oil when assembling . Use tool as per drawing s725/3 (see fig.2/3). -special tool as per draw. S725/3 e) insert crankshaft after oiling crankshaft seat in crankcase. Crankshaft must be in same position as in original installation (see fi...

Page 16

Man-045 ing 14 attention: as first step, assemble crankcase with 4 screws and check crankshaft axial play to be 0.20 ±0.05mm. If lower or higher, disassemble the crankcase, extract the bearings and use different shims (0.10/0.15/0.20). To recover the play, shims must be equally positioned (see fig.6...

Page 17

Man-045 ing 15 insert oil seals . Use tool as per drawing s725/3 (see fig.10). (mark on the oil seal must be towards the external). Attention: the oil seal must be replaced after max. Working 6 hrs and always when removed. Install piston : a) check status of the roller cage. It must be replaced afte...

Page 18

Man-045 ing 16 f) place circlip on tool grease tool, to keep circlip in place. (see fig.14). G) insert circlip (see fig.15). Check that circlips are in seat. -special tool: p.N. 10121 4. Install a new cylinder gasket . 5. Install cylinder (see fig.16). Visual check. Oil cylinder and piston. 6. Check...

Page 19

Man-045 ing 17 before assembling the clutch , wash with diluent the shaft taper, the connecting hole on the clutch body, the clutch drum and starter ring . Install the clutch : a) install the starter ring on the clutch body by matching the 3 holes and the dragging pin (3 screws m6) . Torque at 10 nm...

Page 20

Man-045 ing 18 d) install the clutch body fixing nut using the clutch wrench (see fig.21). Torque at 40÷50 nm ( 350÷440 in-lb). Attention: torque counterclockwise as nut has left thread. - clutch wrench: p.N. 10270 - 24m allen wrench e) install the inner washer (see fig.22). Attention: install washe...

Page 21

Man-045 ing 19 g) install the piston fitting so that the shaft does not rotate (see fig.25) and torque the m1o nut on the drum. (m10 nut) (see fig.26). Torque at 30÷40 nm ( 265÷350 lb-in). - piston fitting: p.N. 10271 - 12 point wrench - 17mm h) reinstall clutch cover 3 screws m6 (see fig.27). Torqu...

Page 22

Man-045 ing 20 install the ignition: a) install piston fitting on head. -piston fitting: p.N. 10271 b) insert key on shaft (see fig.28). C) install ignition rotor on shaft (with timing plate towards the external) (see fig.29). Install screw and nut m10. Torque at 20÷26 nm (175 ÷ 230 in-lb). -12 poin...

Page 23

Man-045 ing 21 10. Install the starting assembly: a) install starter countershaft in the starter support (see fig.32). B) install countershaft support cover. 3 screws m6x20 (see fig.33). C) install starter. Oil’ “or” and press starter in seat, make sure that gears engage. 1 screw m6x16 1 screw m6x20...

Page 24

Man-045 ing 22 11. Install fuel pump (see fig.36) 2 screws m6x45 1 nut m6. (5mm allen t type) (12 point wrench - 10mm) connect pump intake pressure to the crankcase fitting (see fig. 37). Install the carb. And secure it to the fitting, by means of the steel clamp (see fig. 38). Connect the carb. Fue...

Page 25

Man-045 ing 23.

Page 26

Man-045 ing 24 cross pattern locking order on crankcase 7 3 1 5 2 6 4.

Page 27: Main Prescriptions

Man-045 ing 25 main prescriptions matching the piston crankshaft - bearing seat diameter on the new engine replace when size is lower than 0.03mm vs. Original. Max. Allowed ovalization on conrod max. Allowed ovalization between a and b on new conrod: 0.002mm. Max. Allowed ovalization between a and b...

Page 28

Man-045 ing 26.

Page 29

Man-045 ing 27 overhaul tool list specific tools available at iame description p.N. • piston fitting 10271 • clutch locking wrench 10270 • clutch disassembly tool b-55614-c • piston pin fitting 10202 • circlip assembly tool 10121 • crankshaft assembly kit it includes: - crankpin bush 10110-c 10150 •...

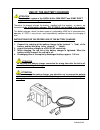

Page 30: Use of The Battery Charger

Man-045 ing 28 use of the battery charger attention the electrical system of the parilla 60cc mini swift and baby swift engines does not charge the battery. Therefore, to properly charge the battery, supplied with the engines, as above, we recommend use of the battery charger, p.N. A-120910 (not inc...

Page 31

Man-045 ing 29 disegno s725/3.