- DL manuals

- IAME

- Engine

- Parilla Norswift 60cc

- Assembly Instructions & User Manual

IAME Parilla Norswift 60cc Assembly Instructions & User Manual

Summary of Parilla Norswift 60cc

Page 1

Norswift 60cc man-033 01/11/04 man-071 assembly instructions & user manual.

Page 2

1 man-071 indice general description of engine engine characteristics – operational limits 1-contents of packaging 2-engine identification number 3-preparation and installation of the engine on the chassis 3.1 exhaust header assembly 3.2 preparation and installation of the motor-mount 3.3 assembling...

Page 3

General description of engine this engine is for propaedeutic series and for young drivers and has been specifically designed and developed for powering of kart, either for racing purposes and hobby, but always on closed tracks. During the design phase has been inspired to the technical solutions al...

Page 4

2 man-071 engine characteristics the characteristic of the engine are the following: cycle: original cubic capacity original bore: max. Theorical bore: stroke: lubrification : inductiion: carburettor: cooling: ignition: clutch: starting: otto / 2 stroke single cylinder 59.42 cm³ (60.00 cm³ max) 41.8...

Page 5

3 man-071 illustration of accessories exhaust group spark plug ngk clutch cover tillotson hl series carburettor intake silencer + fixing clamp intake group coil-switch cable coil with spark plug cap.

Page 6

4 man-071 2-engine identification number the official identification number can be found stamped on the left lower part of the crankcase (pull start side), next to the coil (see picture). The number normally includes a letter followed by 4 digits. Other numbers stamped on the crankcase or other surf...

Page 7

5 man-071 3-preparation and installation of the engine on the chassis note: in case the engine is supplied already assembled on to the chassis, it is at care of the assembler to follow these instructions. The final customer, in this case, can skip this section and can start reading from section 4. W...

Page 8

6 man-071 -install the 2 nuts (see fig. 4) torque at 9 ÷ 11 nm (80 ÷ 100 in-lb) “t” wrench 10 mm 3.2 preparation and installation of the motor-mount note: all the dimensions are in millimeters -drill 4 holes (diam. 8.5mm) into the motor-mount. - install the motor-mount. Make sure to use m8 allen scr...

Page 9

7 man-071 3.3 assembling the carburettor -install the gas cable clamp on the support (see fig. 6) 12 point wrench 10mm -remove the 2 screws 3.5mm on the carb pump (in correspondence of the gas cable bracket) (see fig. 7) screwdriver 4.8 mm / torx tool t20 -insert the gas cable bracket, the 2 screws ...

Page 10

8 man-071 --install the intake support n°2 screws m5x10 (see fig. 10) allen wrench 3mm 3.4 install the carburettor remove the n°2 m6 nuts remove the plastic cap keeping 1 carburettor gaskets on the engine , install: (see fig.11-12) - n.2 thermical spacer - n.2 carburettor gasket - carburettor - n.2 ...

Page 11

9 man-071 3.5install engine on the chassis -position the engine on the 2 main rails and fix the motor-mount with the two clamps (see fig.14) suggestion: never torque completely the clamps until the chain is installed and properly aligned. -check the alignment of the engine sprocket and the axle spro...

Page 12

10 man-071 3.6 install the clutch cover -remove the 3 screws m6x30 on the crankcase (see fig. 18) and install the clutch cover (see fig.19). Torque the 3 screws at 8 ÷ 10 nm (70 ÷ 90 in-lb) 5 mm allen wrench 3.7 electrical connection -connect the coil cable (small one) to the terminal on the coil. (...

Page 13

11 man-071 3.8install the intake silencer -make sure that the intake silencer has the inlet hole towards the upperside and that they are not plugged. (see fig. 23) -tighten the fixing clamp on the carb. And support the intake silencer properly. (see fig.24) 3.9 install the exhaust system -install th...

Page 14

12 man-071 4- gasoline and oil use leaded or unleaded gasoline with minimum 95 rom, mixed with oil at 3% (33:1). Use oils containing ricinoleate which ensures optimum lubrication at high temperatures as on the other hand use oils containing ricinoleate creates gummy residues which give origin to car...

Page 15

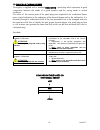

13 man-071 5- carburettor adjustment guide 1 t.O. * rich lean 1 ¼ t.O. ¾ t.O. 1 ½ t.O. * t.O. = turns open normally the correct setting of the mixture screws is the following: l (close the screw completely and then open): 1.00 t.O. For hl 334b and 1.00 t.O. For hl 394a. H (adjust t.O from closed to ...

Page 16

14 man-071 6- starting and stopping the engine the engine is started by pulling the handle that uncoils the rope. The rope rotates the pulley that engages the ignition flywheel connected to the crankshaft. This action, made with the appropriate energy and eventually repeated if needed, starts the en...

Page 17

15 man-071 9-recommendations on the exhaust system always make sure that the springs are well hooked to the manifold and in place. In case of breakage, replace the broken spring. Never race the kart without the 2 springs in place, as otherwise the exhaust pipe could vibrate beyond control. Every 10 ...

Page 18

16 man-071 11-instructions for the disassembly / assembly of the clutch attention: the following operations must be performed by a skilled mechanic under the condition to have available the dedicated tools shown on the text, otherwise it is necessary to apply to an authorized service center. Refer t...

Page 19

17 man-071 before assembling the clutch, degrease with diluent the shaft taper, the conical hole on the clutch body, the clutch drum. Clutch reassembly tools 1. Insert key on shaft. 2. Install clutch body and cone safety washer on shaft. 3. Install the m16x1 nut using the clutch wrench. Attention: t...

Page 20

18 man-071 12- spark-plug thermal degree the engine is supplied with a standard ngk br9eg spark plug which represents a good compromise between the needs of a good break-in and the racing needs in normal conditions. The colour of the various parts of the spark plug more exposed to the combustion fla...

Page 21

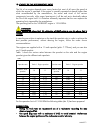

19 man-071 13- choice of the best sprocket ratio the life of an engine depends upon many factors but most of all upon the speed at which the engine is operated. If an engine is normally operated at speeds higher than what recommended by the manufacturer, the wears and stress of the various component...

Page 22

20 man-071 the following example should clarify the procedure for the optimization of the sprocket. Assume to use the engine with z=10 teeth engine sprocket and that during the preliminary track tests a z=72 teeth axle sprocket has been used. From table 1 with z=10 as engine sprocket and z=72 on the...

Page 23

21 man-071 14- scheduled maintenance following some simple maintenance standards will allow to perform more reliably and guarantee a longer engine life. Schedule components actions and comments before using exhaust check status and fixing engine sprocket check wear check alignment with axle sprocket...

Page 24

22 man-071 15-troubleshooting below are some common faults, their probable causes and suggested remedy. Faults probable cause remedy when pulling the handle don’t start the engine not turned on the “on” position the switch turned on the “on” position the switch bad connections cables check and resto...

Page 25

23 man-071 16-engine preservation when engine has to remain unoperative for a long period it must be preserved as follows : disconnect carburettor and clean it. Seal with tape the engine inlet and exhaust. The external of the engine must be cleaned. Spray with protective oil the steel parts subject ...