Summary of Parilla X30

Page 1

28/09/05 man-044 /a 1 overhaul manual.

Page 2: Index

28/09/05 man-044 /a 2 index page 1. - parilla x30 125cc rl – tag engine disassembly 1 2. - crankshaft disassembly/ assembly 10 2.1- crankshaft disassembly 10 2.2- crankshaft assembly 12 3. - parilla x30 125cc rl – tag engine assembly 15 attachments - fastener torque values - cross pattern locking or...

Page 3

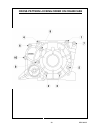

Man-044/a 1 1 – x30 125cc rl – tag engine disassembly operations pictures 1. Discharge oil from the engine - unscrew the oil level plug (see fig.1). (14mm socket wrench) - tilt the engine to discharge oil (see fig.2). 2. Fix the engine on the bench vice - screw on n°2 screws m8x60 on the crankcase b...

Page 4

Man-044/a 2 4. Remove the ignition - remove the stator unscrew n°4 allen screws m5x25 (see fig.4) (4mm allen wrench - t type) - remove sparkplug and install the the piston fitting (p.N. 10271) to prevent the crankshaft from turning (see fig.5). - remove the nut m10 and washer (see fig.6). (17mm sock...

Page 5

Man-044/a 3 5. Remove the gear box cover - unscrew n°7 allen screws m6x16 (see fig.8). (5mm allen wrench - t type) - remove cover and washer (use a plastic mallet if necessary) (see fig.9). 6. Remove gears - remove retaining rings from the crankshaft and balance shaft (see fig.10). (pliers for retai...

Page 6

Man-044/a 4 - remove gear from the balance shaft (see fig.12). (use a screwdriver if necessary) . 7. Remove electric starter - unscrew n°2 allen screws m6x35 (see fig.13). ( 5mm allen wrench – t type ) - remove starter (see fig.14). Note: in the engines mnufactured after september ’05, the starter c...

Page 7

Man-044/a 5 - remove clutch cover unscrew n°3 allen screws m6x25 (see fig. 16). (5mm allen wrench – t type) - remove the locking nut m10 from clutch drum (see fig.17). (17mm socket wrench ) note: make sure that the piston stop tool is installed (p.N. 10271) - remove outer washer, clutch drum, roller...

Page 8

Man-044/a 6 - remove starting ring from clutch body unscrew n°3 screws m6x12 (see fig.20). (10mm socket wrench) 9. Remove starter countershaft - remove starter countershaft cover unscrew n°3 allen screws m6x25 (see fig.21). ( 5mm allen wrench – t type ) - extract starter countershaft (see fig.22). 1...

Page 9

Man-044/a 7 - remove reed group (see fig.24). - remove inner washer from reed group 11. Remove cylinder head - unloose n°4 nuts m8 by half turn (cross pattern disassembly), remove nuts (see fig.25). ( 13mm hexagon ring wrench) - remove washers 12. Remove cylinder (see fig.26). - remove cylinder base...

Page 10

Man-044/a 8 - remove piston pin with special piston punch (p.N. 10200) (see fig.28). - remove piston - remove roller cage 14. Open crankcase - unscrew n°10 allen screws m6x45 (see fig.29). (5mm allen wrench – t type) - open crankcase with a plastic mallet (see fig.30). (prevent the crankshaft from f...

Page 11

Man-044/a 9 16. Remove oil seals (use a screwdriver) (see fig.32). 17. Remove bearings ( if necessary ) check the inner diameter of bearings, on different points. Refer to the attached table to check bearing wear status. - remove bearings from crankshaft with the special tool (p.N. 10291) (see fig.3...

Page 12

Man-044/a 10 - remove internal bearing from balance shaft heat bearing seat externally with a blowpipe (see fig.36). Attention: carefully degrease the surfaces near the bearing before heating once the proper temperature is reached, remove bearing knocking the halfcrankcase on the working bench. 2 – ...

Page 13

Man-044/a 11 3. Insert the crankshaft insert (p.N. 10106) and using the crankpin pusher ( p.N. 10107 ) press the crankpin out (vedi fig.2). 4. Disassemble the complete con-rod with washers. Repeat the operations to extract the crankpin from the other half crankshaft (see fig.3). Before reassembling,...

Page 14

Man-044/a 12 2.2 – crankshaft assembly operations operations pictures 1. Place the crankshaft assembly tool (p.N. 10110b-c) under the press, vertically (press 5 met). 2. Place the crankshaft tool into the assembly tool. 3. Oil crankpin hole on crankshaft half. 4. Place crankpin with crankpin bush (p...

Page 15

Man-044/a 13 7. Extract bush from crankpin and put tool in horizontal position (see.Fig.4). 8. Oil crankpin and install: -silver shim -con-rod with roller cage -silver shim (see fig.5). Attention: rollers are free in the cage. Prevent them from falling, when inserting the cage on the crankpin. 9. Pl...

Page 16

Man-044/a 14 11. Oil crankpin and crankpin hole on crankshaft half. 12. Put tool in vertical position (see fig.8). 13. Progressively press the two crankshaft halves together. 14. Open the tool, put it in horizontal position and extract crankshaft. 15. Check the axial play of the con-rod (see fig. 9)...

Page 17

Man-044/a 15 b. Rotate crankshaft and look at deflection of gauge needles the deflection must be, after centering, max. 0.01mm (see drawing). C. Adjust alignment with a copper hammer, if necessary (see fig.11). 3 –x30 125cc rl – tag engine assembly before reassembling, wash all parts with kerosene o...

Page 18

Man-044/a 16 - insert crankshaft bearings; balls to be on upper side visible during the assembly (see fig. 2). Oil bearings and bearing seats outside. Use tool to insert the bearings (p.N. 10290) (see fig.3). - install inner balance shaft bearing; bearing balls to be on upper side. (oil bearing ball...

Page 19

Man-044/a 17 - install the bearing retaining. Screw m5x10 (see fig.6). Allen. Torque at a 6 ÷ 8 nm (50 ÷ 70 in-lb). (4mm allen wrench – t type) 2. Crankcase assembly - insert crankshaft after oiling the crankshaft seat in the crankcase and the bearing balls. The crankshaft must be in same position a...

Page 20

Man-044/a 18 before final assembling of crankcase halves apply fluid gasket (motorseal or equivalent) on crankcase halves. Clean eventual excess of product (see fig.10). - oil crankshaft and bearing balls seats before assembling. (see fig.11). - insert the crankshaft and balance shaft. Close the cra...

Page 21

Man-044/a 19 - install seal (gear side) with special tool with bush to be inserted on the crankshaft (p.N. 10295a) (see fig.14). (mark on seal to be outside). - install seal (clutch side) using the special tool (p.N. 10295a) (see fig.15). (mark on seal to be outside). - insert seal in gear cover usi...

Page 22

Man-044/a 20 - install gear on the crankshaft (letter “a” to be visible ) aligning the reference notches on the internal teeth with reference notches on the external teeth of the 2 gears (check both gears to be on the same level). (see fig.18) note: if gears have not been replaced, reinstall them in...

Page 23

Man-044/a 21 - position cover by inserting starter end in the proper seat. (check that the “o’ring” for vibration damping is in place and oil it before inserting the starter). N°7 allen screws m6x16 (see fig.22). Torque at 8÷10 nm (70 ÷ 90 in-lb) (5mm allen wrench – t type). 7. Filling with oil - pu...

Page 24

Man-044/a 22 attention: check play between ring gaps to be within 0.25 and 0.30mm. Play must be controlled with a thickness gauge and inserting the piston ring in the cylinder (see fig.26). Replace piston ring when play exceeds 0.4mm. Attention: play between piston and liner must be between 0.11÷0.1...

Page 25

Man-044/a 23 9. Installing the cylinder - install a new gasket on the cylinder base. Oil cylinder liner and piston. Install cylinder (see fig.30). - install the o’rings: (see fig.31) - on internal of cyilinder - on external of cylinder - on tie-rods 10. Assembling the cylinder head - clean combustio...

Page 26

Man-044/a 24 - install rotor on shaft. (see fig.34). - install piston fitting (p.N. 10271) on head and insert washer and m10 nut on shaft. Torque at 20÷26 nm (175÷230 in-lb) (see fig.35). (17mm socket wrench) - install stator n°4 allen screws m5x25 (see fig.36). Torque at 5÷6 nm (45 ÷ 50 in-lb). (4m...

Page 27

Man-044/a 25 - install countershaft cover n°3 allen screws m6x25 (see fig.38). Torque at 6÷8 nm ( 50 ÷ 70 in-lb). (5mm allen wrench – t type) before assembling the clutch, wash with diluent the shaft taper, the starter ring hole, the clutch body and the clutch drum. 13. Assembling the clutch - insta...

Page 28

Man-044/a 26 - apply “loctite 641” on the taper shaft for coaxial lockings. (see fig.41). - install starter ring with clutch body on crankshaft. (see fig.42). - install starter ring fixing nut use clutch wrench (p.N. 10270). Torque at 100÷110 nm (885 ÷ 970 in- lb) (see fig.43). (30mm socket type - t...

Page 29

Man-044/a 27 - install roller cage, clean and grease it before installing on the shaft. (see fig.45). - install clutch drum and external washer. (see fig.46). Attention: install washer with bevel towards shaft. - install piston fitting (p.N. 10271) to prevent shaft from turning and tighten the m10 n...

Page 30

Man-044/a 28 - fix the ground cable on the crankcase allen screw m6x12 (see fig.49). Torque at 8÷10 nm (70÷ 90 in-lb) (5mm allen wrench – t type) 14. Installing the reed group - install internal gasket - install the reed group (so that “iame” is towards upper side) (see fig.50). Attention: check bef...

Page 31

Man-044/a 29.

Page 32

Man-044/a 30 cross pattern locking order on crankcase.

Page 33: Main Prescriptions

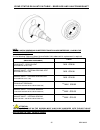

Man-044/a 31 main prescriptions matching the piston crankshaft - bearing seat diameter on new engine refer to the attached table to determine wear status of the crankshaft halves. Max allowed ovalization of con-rod big-end max. Allowed ovalization between a and b on new conrod: 0.002mm max. Allowed ...

Page 34

Man-044/a 32.

Page 35: Yes

Man-044/a 33 recommendations to be followed when installing the gears no 2- install gear on balance shaft so that the “c” letter can be read on the surface and align the marked gear tooth space (1) with the marked tooth on balance shaft (2). 1 2 3- install gear on crankshaft so that the “a” letter c...

Page 36

Man-044/a 34 overhaul tool list specific tools available at iame description p.N. • piston fitting 10271 • clutch locking wrench 10270 • clutch disassembly tool 10272-c • piston pin fitting 10200 • piston circlip assembly tool 10120 • crankshaft assembly kit it includes: - crankpin bush 10110b-c 101...

Page 37

Man-044/a 35 wear status evaluation table - bearings and halfcrankshaft note: always check dimensions in different points on circumference, looking for eventual ovalizations on the following table are shown the ovalization limits above which replacement is required measured part (measuring instrumen...

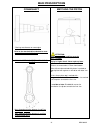

Page 38: Fixing Tool On Vice Bench

Man-044/a 36 fixing tool on vice bench.