- DL manuals

- IAME

- Engine

- REEDSTER 125cc

- Assembly Instructions & User Manual

IAME REEDSTER 125cc Assembly Instructions & User Manual

Summary of REEDSTER 125cc

Page 1

Man-051 ing assembly instructions & user manual 09/03/07 reedster 125cc f1 - f2 - f3 - f4 versions.

Page 2

Man-051 ing 0 i n d e x section 1 description of the “parilla reedster 125cc”engine 1.1. Main features 1.2. Engine characteristics / operation limits 1.3. Contents of the packing 1.4. Accessories 1.5. Motor identification number section 2 preparation & installation of the engine on the chassis 2.1. ...

Page 3

Man-051 ing 1 section 1 - description of the “parilla reedster 125cc”engine 1.1 main features the “parilla reedster” engine is the result of the decennial racing experience of iame and it contains many technological and construction innovations which enable the engine to achieve both high performanc...

Page 4

Man-051 ing 2 the battery (12 v - 7.2ah) is a sealed, no maintenance battery and is supplied already pre-assembled in a support box, which can be easily adapted to all existing chassis. Both a throttle carburettor and a float chamber carburettor (on the f4 version), can be fitted on the engine. In t...

Page 5

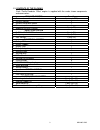

Man-051 ing 3 1.3 contents of the packing each “parilla reedster 125cc” engine is supplied with the under shown components and accessories: exhaust system quantity • power valve on the exhaust duct 1 (excepted f3) • exhaust springs 2 • exhaust fitting with spacer 1 • exhaust system 1 • additional ex...

Page 6

Man-051 ing 4 1.4 accessories exhaust system battery with support complete electric system clutch cover / h.T. Coil inlet silencer carburettor radiator radiator support kit water hoses kit thermostat ngk spark plug fuel pump.

Page 7

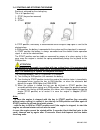

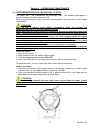

Man-051 ing 5 1.5 motor identification number the official motor identification number can be found stamped on the lower front right part of the crankcase, near the reed group (see fig.). The number normally includes a letter followed by 4 digits (there can be exceptions in some special cases). Othe...

Page 8

Man-051 ing 6 section 2 - preparation and installation of the engine on the chassis note: in case the engine is supplied already assembled on the chassis, it is at care of the assembler to follow these instructions. The final customer, in this case, can skip this section and can start reading from s...

Page 9

Man-051 ing 7 2.2 install the water cooling system (only for f3 - f4) before installing the radiator preassemble the following components 1 install the 4 rubber dampeners in the radiator fixing holes (see fig.1). 2 - place the radiator support bracket between the radiator fixings by tilting one end ...

Page 10

Man-051 ing 8 - complete insertion of the radiator support bracket in the rubber dampeners (see fig.3 and 4). 3 fix the radiator support bracket inserting also the radiator fixing bracket (radiator cap side – n°1 screw m6x90 and n°1 screw m6x85 with nut). Install the "z" shape bracket on the radiato...

Page 11

Man-051 ing 9 5 place the radiator so that the hole on the radiator fixing bracket matches with one of the upper holes on the bearing support box (see fig.7). Once you find the correct position, tighten the m8x45 screw and m8x65 on the lower “z” shape bracket thus fixing the radiator . Tighten at 8÷...

Page 12

Man-051 ing 10 2.3 initial preparation of the engine 2.3.1 on the exhaust power valve there is a warning tag to remind the user that the gear box must be filled with oil before starting the engine (see fig.1). Note: the engine is supplied with the exhaust fitting and spacer already pre-installed. 2....

Page 13

Man-051 ing 11 2.4.2 install the motor-mount: make sure to use m8 allen screws with a length such as to engagÈ, in the crankcase a threaded length of approx. 16÷19mm (the screws must protrude from the plate for approx 16÷19mm - see fig. 3 and drawing page 10) 4 m8 allen screws – torque at 22÷24 nm (...

Page 14

Man-051 ing 12 f4 version (float chamber carb) 2.5.3 installation of the fuel pump (if not already assembled in origin) install the vibration dampeners on the gear box cover i (see fig. 6). Place the fuel pump with the outlet fitting towards the upper side and torque the self-locking nuts m6. Torque...

Page 15

Man-051 ing 13 charging the oil in the gear box 2.6 2.6.1 remove the oil breather plug (rear part of the engine) (see fig.10). 12 point wrench - 11mm remove the oil level plug (front part of the engine) (see fig.11). Hexagonal wrench - 4mm 2.6.2 fill with 33cc “iame ep100”oil the gear box (see fig.1...

Page 16

Man-051 ing 14 2.7 installation of the engine on the chassis 2.7.1 place the engine on the two side rails and secure the motor-mount with the two clamps (see fig.13) suggestion: do not tighten thoroughly the clamps until the chain is not installed and properly aligned . 2.7.2 check the alignment of ...

Page 17

Man-051 ing 15 installation of the clutch cover with h.T. Coil 2.8 2.8.1 connect the h.T. Coil ground cable to the crankcase by means of the m6 screw on the front foot (see fig.17). Torque at 8 ÷ 10 nm (70 ÷ 90 in. Lb) hexagonal wrench - 5 mm attention: make sure that the copper ground cable always ...

Page 18

Man-051 ing 16 2.9 electrical connections (refer to the attached electrical schematic) note : for a correct installation follow the under shown instructions. 2.9.1 insert the battery strap in the battery support box (see fig.19). 2.9.2 place the battery support box in the front of the chassis (under...

Page 19

Man-051 ing 17 2.9.5 –connect the terminal from the ignition with the 8 poles terminal on the harness (see fig.23). -connect the one way terminal from the electric starter with the one way terminal on the harness. (see fig.24). Attention: make sure that the fixing tongues are properly inserted to gu...

Page 20

Man-051 ing 18 2.9.8 connect the h.T coil cable to the harness terminal (see fig.27). Attention: fasten the h.T. Coil cable with a plastic clamp to avoid that eventual vibrations might disconnect the terminals (see fig.28). 2.9.9 cut the dual-lock fixing strap and attach it to the rear of the electr...

Page 21

Man-051 ing 19 2.9.11 connect the starter relay to the 4 poles connector on the harness (see fig.31). 2.9.12 drill a Ø 22mm hole in the side edge of the front panel fairing (engine side); and install the starter assembly (see fig.32). Secure the starter assembly with the threaded locking nut. 2.9.13...

Page 22

Man-051 ing 20 2.9.15 drill the fairing and fasten the harness with plastic clamps (see fig.35). 2.9.16 drill the fairing (close to the battery) and place the fuse-holder by means of the 2 hooks of the junction block (see fig.36). 2.9.17 place the battery terminals of the harness under the strap (se...

Page 23

Man-051 ing 21 2.9.19 fix the cap to the h.T. Cable with a plastic clamp (see fig.39). • install the spark plug. Torque at 20 ÷ 26 nm (175 ÷ 230 in-lb) • install the cap on the spark plug. Note: for a correct digital ignition operation, the cap and / or the spark plug, must be of the resistive type ...

Page 24

Man-051 ing 22 section 3 - use of the engine 3.1 charging / discharging the oil in the gearbox attention: the engine is supplied without oil in the gearbox. Before starting the engine fill the gearbox with “iame ep100” motor oil. Starting the engine with a dry gearbox will damage the gears beyond re...

Page 25

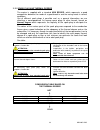

Man-051 ing 23 3.3 carburettor adjustment guide * t.O. = turns open hereinafter are shown some basic carbs. Settings according to the engine version (after engine run-in): f1 engine vers.: “ibea l7” Ø30 carburettor h = 1.10 (1 turn and 10’) l = 1.30 (1 turn and 30’) f2 engine vers.: “ibea l6” Ø24 ca...

Page 26

Man-051 ing 24 f4 engine vers: “dell’orto vhsh30 cs” carburettor the above settings are those prescribed by iame for the carb. Dell'orto vhsh 30 cs, installed on the parilla reedster engine - in the f4 version. The above table shows the reference setting, for the proper engine operation under differ...

Page 27

Man-051 ing 25 we will get a richer carburetion by lifting the needle, that is, by moving down the retainer clip to a lower notch; and on the contrary, a leaner carburetion is achieved lowering the needle, that is by lifting the retainer clip to a higher notch (see fig.3). On the picture is shown th...

Page 28

Man-051 ing 26 on the contrary, by increasing the altitude it is necessary to reduce the max. Jet size by about 2-3 points for every 350m altitude increase. The above data are only indicative, as many factors influence the carburetion and only a few among them are ponderable. With these indications ...

Page 29

Man-051 ing 27 3.4 starting and stopping the engine starting is achieved by the starting key. This is a 3 position key: 1- stop (key can be removed) 2- run 3- start in stop position, the battery is disconnected and the engine stop signal is sent to the electronic box. In run position, the battery is...

Page 30

Man-051 ing 28 to stop the engine, proceed as follows: a) turn the key in stop position, both from run position (1 tripping) or from start position (2 trippings). 3.5 engine break-in the break-in of the engine must be performed following a few fundamental recommendations: 1. Adjust the carburetion. ...

Page 31

Man-051 ing 29 3.8 exhaust system before every test, make sure that the springs are well hooked and properly in place. In case of breakage, replace the broken spring. Never race the kart without the 2 springs in place,as otherwise the exhaust pipe could vibrate beyond control. Every 10 ÷15 hrs, open...

Page 32

Man-051 ing 30 Ø0.9mm / l=45mm 2 notches Ø1mm / l=43mm 15 notches note on the pneumatic power- valve operation the power-valve chokes the exhaust port opening at low rpm, and achieves a more limited port timing diagram and a reduced exhaust port. The power valve function is to optimize the engine pe...

Page 33

Man-051 ing 31 3.10 battery the battery (12 v – 7.2 ah) is sealed and without maintenance. In order to lengthen the battery life, it is necessary though to follow a few recommendations: when the tension drops below 12.6v it is necessary to recharge the battery max. Allowed recharging current is ...

Page 34

Man-051 ing 32 3.11 warnings on the electrical system we are listing the main warnings on the electrical system. Please keep this in mind during the whole life of the engine attention: if these prescriptions are not followed the electrical system and the engine could be damaged beyond repair. No obl...

Page 35

Man-051 ing 33 3.12 spark plug and thermal degree the engine is supplied with a standard ngk br10eg, which represents a good compromise between the needs of a good break-in and the racing needs in normal conditions. Use of different spark plugs is possible and, as a general information, we are attac...

Page 36

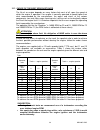

Man-051 ing 34 3.13 choice of the best sprocket ratio the life of an engine depends on many factors but most of all, upon the speed at which the engine is operated. If an engine is normally operated at speed higher than what recommended by the manufacturer, the wears and stress of the various compon...

Page 37

Man-051 ing 35 the following example should clarify the procedure for optimization of sprocket ratio : assume to use an engine, in the f4 version with a z=12 sprocket, and that during the preliminary track tests a z=78 teeth axle sprocket has been used. from the table 1 with z=12 as engine sprocke...

Page 38

Man-051 ing 36 sprocket ratio to achieve max. 14500 rpm (f2) sprocket ratio max. Engine rpm during tests sprocket ratio to achieve max. 15500 rpm (f1) sprocket ratio max. Engine rpm during tests.

Page 39

Man-051 ing 37 section 4 - engine basic maintenance 4.1 recommendations on centrifugal clutch the engine has a low maintenance dry centrifugal clutch. The following prescriptions if carefully followed, will allow a long clutch life. When starting the engine, make sure that the brake pedal is fully p...

Page 40

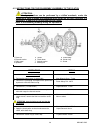

Man-051 ing 38 4.2 instructions for the disassembly/assembly of the clutch attention: the following operations can be performed by a skilled mechanic, under the condition to have available the dedicated tools shown on the text; otherwise it is necessary to apply to an authorized service center. Refe...

Page 41

Man-051 ing 39 before assembling the clutch, wash with diluent the shaft taper, the connecting hole on the clutch body, the clutch drum and the starter ring. Install clutch 1. Install the starter ring on the clutch body by matching the three holes and the dragging pin (3 screws te m6) attention: mak...

Page 42

Man-051 ing 40 4.4 scheduled maintenance following some simple maintenance recommendations will allow the engine to perform more reliably and have a longer life. Schedule components actions and comments before using exhaust fitting springs check status muffler check status and fixing engine sprocket...

Page 43

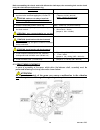

Man-051 ing 41 4.5 troubleshooting below are some common faults, their probable causes and suggested remedy . Faults probable causes remedy starter will not crank when turning the key to run position bad connections on starter cables check and tighten bad grounding check connections and tighten inte...

Page 44

Man-051 ing 42 4.6 engine and accessories preservation when engine is to remain out of operation for a long period it must be preserved as follows: disconnect battery and recharge it periodically (see sect. 3.10) disconnect carburettor and clean it seal with tape the engine, inlet and exhaust ...

Page 45

Man-051 ing 43.