- DL manuals

- IBC

- Software

- BoilerNet Interface Controller II

- User Manual

IBC BoilerNet Interface Controller II User Manual

Summary of BoilerNet Interface Controller II

Page 1

Boilernet interface controller ii.

Page 2: Www.Ibcboiler.Com

For the latest version of this and other manuals, as well as information regarding new software releases, new and current products, technical bulletins, etc., please consult the ibc web site: www.Ibcboiler.Com in the interest of improving the internal design, operational function, or reliability of ...

Page 3

Boilernet interface controller ii i v1.00.6 table of contents introduction ........................................................................................................................................................ 1 1 configuration .........................................................

Page 4

Boilernet interface controller ii ii v1.00.6 4.16 run profile ........................................................................................................................................ 34 5 bacnet interface ..................................................................................

Page 5

Boilernet interface controller ii 1 v1.00.6 introduction the ibc boilernet interface controller ("bic") provides both web and bacnet/ip interfaces to ibc’s line of high efficiency condensing boilers, including the vfc 15-150, vfc 45-225, sl 80-399, and others. It can interface from 1 to 24 ibc boile...

Page 6

Boilernet interface controller ii 2 v1.00.6 1.2 bacnet setup a unique bacnet device id is required for every bacnet device on a network, including the bic ii. The bic ii will use the standard bacnet port number of 47809 (0xbac1) by default, though this may be different at your site, particularly if ...

Page 7

Boilernet interface controller ii 3 v1.00.6 the site information must be entered into the "site.Dat" file, and optionally the "alerts.Dat" file before the boilernet interface controller can be used. There are many text editors (wordpad ® , for example) can be used to edit these files (please note th...

Page 8

Boilernet interface controller ii 4 v1.00.6 1.3.1 configuring site data when you open the "site.Dat" file, it should appear similar to that shown in figure 2 below. Figure 2 table 1 - "site.Dat" field description field field name field description max. Size 1 name the site name 40 2 ipaddr the ip ad...

Page 9

Boilernet interface controller ii 5 v1.00.6 (1) if a dynamic ip address is to be obtained from a dhcp server, then "ipaddr", "ipmask", "ipgate", "ipdns1", and "ipdns2" should all be set to "0.0.0.0" (a dynamic ip address is generally not recommended). (2) "ipdns2" is optional. Set to "0.0.0.0" if no...

Page 10

Boilernet interface controller ii 6 v1.00.6 1.3.2 configuring the alert data the "alert data" contains the information for accessing a smtp mail server, allowing e-mail alerts to be sent in the event a problem with a boiler is detected. All site information is stored in the "alert.Dat" file in the "...

Page 11

Boilernet interface controller ii 7 v1.00.6 2 sd-card the boilernet interface controller requires a standard secure digital flash card (sd-card) for operation. Figure 4 the bic ii can support both "standard" and "sdhc" sd-cards. A 2gb sd-card is more than sufficient for the bic's operation. Ibc will...

Page 12

Boilernet interface controller ii 8 v1.00.6 3 installation the boilernet interface controller requires a network (ethernet) cable connection to the network it is to be connected to, a boilernet twisted pair connection to the boilers, and a power source. 3.1 location typically the bic ii will be inst...

Page 13

Boilernet interface controller ii 9 v1.00.6 3.3 boilernet connections the boilernet interface utilizes a 2-wire can-bus communications interface between the boilers and the bic ii. Boilernet wiring needs to be performed in accordance to published standards, such as iso 11898 or sae j2284. A suitable...

Page 14

Boilernet interface controller ii 10 v1.00.6 figure 6 please also refer to ibc document "tech memo 2310081 – multiple boiler systems" for additional information. Important: the boilernet (can-bus) interface on both the bic ii and the boiler's controller can be damaged by static electricity and other...

Page 15

Boilernet interface controller ii 11 v1.00.6 3.5 operation the boilernet interface controller’s operation is fairly straight forward. Insert the configured sd-card into the bic ii's sd slot, ensure the boilernet cables are connected, and if not using poe, that the ethernet cable is connected. Then a...

Page 16

Boilernet interface controller ii 12 v1.00.6 4 web (html) interface once each boiler has been assigned a boiler id through the boiler’s control panel, all other settings for the boiler can configured using the boilernet interface controller’s web interface. Multiple individual boilers can also be mo...

Page 17

Boilernet interface controller ii 13 v1.00.6 figure 7 only basic information regarding the boilernet system will be initially displayed on the opening screen. You must "login" using a valid user name and password to be able to access and alter detailed information regarding the bic ii and the indivi...

Page 18

Boilernet interface controller ii 14 v1.00.6 the web interface and the boiler's screen and keypad should not be used simultaneously for entering or altering settings. If a key on the boiler's keypad is pressed, then the web interface will be "locked out" for a period of 2 minutes from the last key p...

Page 19

Boilernet interface controller ii 15 v1.00.6 4.1 user passwords the web interface employs a password system to control access. Up to 10 user accounts can be configured. Figure 8 note that both the "user id" and "passwords" are case sensitive, both on this screen and when logging in using the web int...

Page 20

Boilernet interface controller ii 16 v1.00.6 table 3 – security levels level description view view access only; access to certain screens is restricted operator equivalent to the "user" access level on the boiler's controller supervisor view access to all screens, write access to all but "advanced" ...

Page 21

Boilernet interface controller ii 17 v1.00.6 4.2 site data the "site data" screen allows all the information in the "site.Dat" file to be configured. Note that this screen is not accessible until after an ip address has been initially assigned through editing the "site.Dat" file, and the boilernet i...

Page 22

Boilernet interface controller ii 18 v1.00.6 note that for all fields except "site name", "display units", "e-mail alerts", "system logs", and "boiler logs", the boilernet interface controller will need to be rebooted before the changes will take effect. setting the "reboot boilernet controller"...

Page 23

Boilernet interface controller ii 19 v1.00.6 4.3 alert data the bic ii can be configured to send an e-mail alert when a problem is detected with a boiler. This screen allows the information in the "alert.Dat" file to be configured, which contains the information for the smtp server to be used for se...

Page 24

Boilernet interface controller ii 20 v1.00.6 4.4 site log this is the event log for the boilernet interface controller. This displays events for the bic ii itself. For the logs for the individual boilers, please refer to sections "4.14 - boiler logs" and "4.15 - boiler error logs". Figure 11.

Page 25

Boilernet interface controller ii 21 v1.00.6 4.5 system status display an example of the system status display is shown below: figure 12 note that in this example there is a * after boiler 01; this indicates that this boiler is the "master" boiler in the system..

Page 26

Boilernet interface controller ii 22 v1.00.6 if there is no master boiler in the system, then "boilers responding" and "boilers firing" are not applicable, and "target", "actual", "outdoor" and "indoors" temperatures will be displayed from the first online boiler in the list. if a boiler is show...

Page 27

Boilernet interface controller ii 23 v1.00.6 4.6 boiler status display this is the main status of an individual boiler on the network. All settings and information regarding the boiler is subsequently accessed from this screen. Figure 13.

Page 28

Boilernet interface controller ii 24 v1.00.6 4.7 user settings figure 14.

Page 29

Boilernet interface controller ii 25 v1.00.6 4.8 setbacks figure 15 note that the boiler's use of the setbacks is controlled on the "4.7 - user settings" screen..

Page 30

Boilernet interface controller ii 26 v1.00.6 4.9 installer settings figure 16 to alter the "load type" for a load, select the desired load type from the pull-down box, then select "save". Once the "load type" is set to the desired type, you can then edit the settings for the load. do not alter t...

Page 31

Boilernet interface controller ii 27 v1.00.6 whenever the "load type" is altered, always verify that the settings for the load are indeed correct for your system. As previously mentioned, if the "load type" is altered, some of the load settings may be reset to the system default values..

Page 32

Boilernet interface controller ii 28 v1.00.6 4.10 load settings an example of the screen for a "reset heating" load is shown below. The actual fields displayed will vary by the load type selected. If the load type is altered through "4.9 - installer settings", always verify that the load settings ar...

Page 33

Boilernet interface controller ii 29 v1.00.6 4.11 multi-boiler settings figure 18.

Page 34

Boilernet interface controller ii 30 v1.00.6 4.12 cleaning information figure 19 when the boiler has been cleaned, select "yes" from the "boiler cleaned" pull-down, and then click "save". The "cleaning counter" will then be reset, and the "last cleaned" date updated. the cleaning intervals are f...

Page 35

Boilernet interface controller ii 31 v1.00.6 4.13 diagnostics this screen is intended for use by, or on the advice of, ibc or other qualified service personnel only. "supervisor" or higher security rights are required to access this screen. Do not alter any value on this screen unless directed to do...

Page 36

Boilernet interface controller ii 32 v1.00.6 4.14 boiler logs figure 21 note that in this particular example, the boiler was not configured for a remote load; therefore the "remote on-time" is zero..

Page 37

Boilernet interface controller ii 33 v1.00.6 4.15 boiler error logs each boiler maintains a log of the last 8 "event" and "watchdog" errors that have occurred on it. The information in the logs is mainly intended for use by ibc service personnel. If you notice errors are frequently occurring, you sh...

Page 38

Boilernet interface controller ii 34 v1.00.6 4.16 run profile this screen provides a graphical summary of the time the boiler used servicing each of the loads, as well as the modulation (or throttle) percentage being used while servicing each of the individual loads. Figure 23 in the above example...

Page 39

Boilernet interface controller ii 35 v1.00.6 5 bacnet interface the boilernet interface controller provides bacnet "server" functionality over a bacnet/ip interface. To make use of the bic ii's bacnet capabilities, a properly configured bacnet operator's workstation or bacnet web server software pac...

Page 40

Boilernet interface controller ii 36 v1.00.6 an example of a bacnet object list obtained from a boilernet interface controller is shown below: figure 24.

Page 41

Boilernet interface controller ii 37 v1.00.6 an example of the sort of customized display that can be setup for use with your b-ows software package is shown below: figure 25 of course, much more elaborate system and status displays can be developed. The actual configuration and use of the bacnet op...

Page 42

Boilernet interface controller ii 38 v1.00.6 5.2 bacnet objects the boilernet interface controller will provide a set of bacnet objects for each boiler on the network. There is also set of "master" objects, which are associated with the boiler designated as the "master" boiler. Any bacnet object com...

Page 43

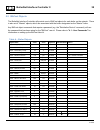

Boilernet interface controller ii 39 v1.00.6 object name value units object id commandable notes boiler 1 supply setpoint 60 °c av1018 1 boiler 1 remote input 50 % av1019 boiler 1 inlet/outlet sensor ok bv1001 boiler 1 remote loop sensor ok bv1002 boiler 1 cleaning required no bv1003 boiler 1 anti-c...

Page 44

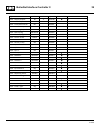

Boilernet interface controller ii 40 v1.00.6 table 5 – master objects object name value units object id commandable notes master target temp. 22 °c ai1101 master actual temp. 22 °c ai1102 master boilers responding 4 av1101 master boilers firing 1 av1102 master outdoor temp. 10 °c av1103 1 master ind...

Page 45

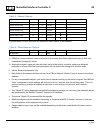

Boilernet interface controller ii 41 v1.00.6 5.3 multi-value objects table 7 – mv1001 – operating status 1 standby 2 purging 3 igniting 4 heating 5 circulating 6 error 7 initialize 8 service 9 restart 10 unknown table 8 – mv1002 – error message 1 none 2 water high limit exceeded 3 vent high limit ex...

Page 46

Boilernet interface controller ii 42 v1.00.6 table 10 – mv1004 – boiler model 1 unknown 2 15-150 3 45-225 4 80-399 5 20-115 table 11 – mv1005, mv1006, mv1007 – load type 1 off 2 dhw 3 reset heating 4 set point 5 external control 6 manual control 7 dhw loop 2.

Page 47

Boilernet interface controller ii 43 v1.00.6 6 enclosure installation notes please note that it is the responsibility of the installer to adhere to any electrical code requirements which may be applicable to the installation of this equipment. The installation must be performed only by qualified s...

Page 48

Boilernet interface controller ii 44 v1.00.6 7 troubleshooting notes as mentioned in section "3.3 boilernet connections", boilernet uses a can-bus interface for communicating between the boilers and the bic ii. The wire type and installation must comply with can-bus standards such as iso 11898 and...

Page 49

Boilernet interface controller ii 45 v1.00.6 8 bootloader configuration this is an optional step that will shorten the start-up time of the bic ii controller board in some specific situations. A bootloader comes pre-installed in the controller's flash memory, which is a customized version of u-boot....

Page 50

Boilernet interface controller ii 46 v1.00.6 press any key within 3 seconds to enter the bootloader configuration menu. You then see the prompt: am3517_crane # type, or preferably copy and paste, the following line (all one line): setenv mmcargs setenv bootargs console=${console} root=/dev/mmcbl...

Page 51

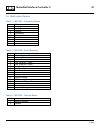

Boilernet interface controller ii 47 v1.00.6 enter the following command, followed by the "enter" key: printenv you should see something similar to the following: the line starting with "mmcargs" is the one to check. The numbers after "eth=" will be different, and most importantly, the line should...

Page 52

Boilernet interface controller ii 48 v1.00.6 9 technical specifications processor 600mhz arm cortex a8 memory 256mb ram 256mb flash file system via sd flash card for data collection and future applications; 2gb minimum with sdhc support. Power requirements controller board: 5vdc @ 7.5w 1...