- DL manuals

- IBC

- Boiler

- DC 23-84

- Installation And Operating Instructions Manual

IBC DC 23-84 Installation And Operating Instructions Manual

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

DC Series Combi Boilers

DC 23-84, DC 29-106, DC 33-124, DC 33-160

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com

Summary of DC 23-84

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 (natural gas or propane) warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or los...

Page 2: Safety Considerations

Installation and operation instructions 2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 safety considerations installation, start-up and servicing of ibc boilers must be done with due care and attention, and should only be performed by competent, qualified, licensed and trained h...

Page 3: Specifications

3 installation and operating instructions dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 specification dc 23-84 dc 29-106 dc 33-124 dc 33-160 csa input (natural gas or propane) – mbh 23 – 84 28.5 – 106 33 – 124 33 – 160 csa input (natural gas or propane) – kw 6.7 – 24.9 8.4 – 31.0...

Page 4

Installation and operation instructions 4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 hotter water increases the risk of scald injury. Before changing the temperature setting, see instruction manual. Warning caution water heater installation guidelines this boiler must be insta...

Page 5: Contents

5 installation and operating instructions dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Installation and operation instructions 6 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, ...

Page 7: Installation

1-1 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 installation 1.0 general dc series gas-fired modulating combi boilers are low pressure, fully condensing units having variable input ranges (see specification chart - inside, front cover). The boilers are approved as ...

Page 8

Installation and operation instructions 1-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 code requirements the dc 23-84, dc 29-106, dc 33-124, dc 33-160 models were tested to and certified under csa 4.9-2014 / ansi z21.13-2014 and water heater csa 4.3- 2013 / ansi z21.10.3. The ...

Page 9

1-3 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 surface distance from combustible surfaces recommended distance for installation and service front 2" 24" rear 0" 0" left side 1.5" 6" (labels may be difficult to read with reduced clearance) right side 4" 6" (labels ...

Page 10

Installation and operation instructions 1-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 all venting must be installed in accordance with the requirements of the jurisdiction having authority: in canada, part 8, venting systems of the b149.1- 10 code and any other local building...

Page 11

1-5 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 • place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously. • after it has been determined that each appliance remaining connected to...

Page 12

Installation and operation instructions 1-6 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 do not use abs or any cellular core pipe for exhaust venting. Use of cellular core pvc (astm f891), cellular core cpvc, or radel® (polyphenolsulfone) in venting systems shall be prohibited. ...

Page 13

1-7 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 exhaust piping is inserted directly into the 3" female stainless steel fitting on the top, left side of the boiler and run horizontally or vertically to the outdoors. Bird screen of 1/4" stainless steel or plastic mes...

Page 14

Installation and operation instructions 1-8 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.4.5 rooftop vent termination direct vent - two pipe rooftop vents must terminate as follows: • the exhaust pipe can terminate in an open vertical orientation without concern about rain inf...

Page 15

1-9 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 6: vertical concentric termination - two kits figure 7: vertical concentric termination - single kit 1.4.6 sidewall vent termination direct vent - two pipe sidewall direct vent applications shall be vented as f...

Page 16

Installation and operation instructions 1-10 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 • the elevation of both pipes can be raised in “periscope style” after passing through the wall, then configured as in figure 8, to gain required clearance. • use a 45° elbow on the exhaust...

Page 17

1-11 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 9: horizontal concentric termination - two kits figure 10: horizontal concentric termination - single kit for side venting of multiple boiler sets, group all intake terminals together with 4" (minimum) lateral...

Page 18

Installation and operation instructions 1-12 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 concentric side wall termination kits: must be installed on the same horizontal line (not stacked) must be installed with a min separation of 12” center to center do not use concentric side...

Page 19

1-13 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 f= clearance to outside corner * * g= clearance to inside corner * * h= clearance to each side of center line extended above meter/regulator assembly 3 ft (91 cm) within a height 15 ft above the meter/ regulator asse...

Page 20

Installation and operation instructions 1-14 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.4.7 “direct vent” combustion air intake piping the boiler must always be installed as a direct vent venting system with the combustion air piped directly from the outdoors to the boilers ...

Page 21

1-15 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 for the inlet air – schedule 40 pvc, cpvc, abs or pps piping of any type is permitted. Use same diameter as vent pipe. Combustion air piping is inserted directly into the 3" female stainless steel fitting on the top,...

Page 22

Installation and operation instructions 1-16 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 condensate removal ibc’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust venting without flowing liquids back through the heat exchanger. Rel...

Page 23

1-17 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.5.3 condensate trap assembly - cleaning procedure 1. Turn off the power to the boiler and allow it to cool down. 2. Remove the trap from the boiler (reverse the installation procedure above). 3. Remove the trap cle...

Page 24

Installation and operation instructions 1-18 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 20: condensate trap drainage figure 21: condensate neutralization tank warning if condensates are to be discharged into building drain piping materials that are subject to corrosion,...

Page 25

1-19 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 water piping - space heating 1.6.1 general piping considerations the dc series boilers include a factory installed, integral grundfos ups 15/58 heating pump. The pump is designed to provide adequate flow through the ...

Page 26

Installation and operation instructions 1-20 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 the dc series modulating boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4" npt) is supplied for field installa...

Page 27

1-21 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 do not place any water connections overhead the boiler; leaks can damage the fan and controls. If needed, create a shield over the top of the cover, but allow clearance for airflow and service access. For best result...

Page 28

Installation and operation instructions 1-22 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 we recommend water flow after burner shutdown to utilize legacy heat – this is significant due to the mass of the heat exchanger. The boiler pump is under the control of the boiler to allow...

Page 29

1-23 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.6.2 basic heating piping arrangements primary / secondary piping - benefits and installation rules 1. Good circulating water flow through the boiler irrespective of load or radiation system head 2. Allows flexible ...

Page 30

Installation and operation instructions 1-24 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 multiple boiler piping - benefits and installation rules multiple ibc dc series boilers can be installed in a single heating system to provide redundancy, increased output, and greater heat...

Page 31

1-25 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 27: typical two temperature space heating piping concept with direct domestic hot water – concept drawing. This drawing is only a simple schematic guide. Figure 28: typical two temperature space heating piping...

Page 32

Installation and operation instructions 1-26 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 domestic hot water system figure 29: air handler and direct domestic hot water – concept drawing. This drawing is only a simple schematic guide. 1.7 hotter water increases the risk of scald...

Page 33

1-27 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.7.1 domestic hot water system the dc series boilers have an independent piping circuit for efficiently generating domestic hot water. When a faucet is opened to draw hot water, water flow is detected with a flow se...

Page 34

Installation and operation instructions 1-28 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.7.2 – domestic hot water piping the domestic water piping connections are located at the bottom of the boiler, see figure 30, page 1-29. The connections are 3/4" male npt threads. The col...

Page 35

1-29 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 30: tankless dhw piping options – concept drawing. This drawing is only a simple schematic guide. Thermostatic mixing valve domestic hot water delivery @ 70°f / 39°c temperature rise dc 23-84 2.0 gpm dc 29-106...

Page 36

Installation and operation instructions 1-30 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 gas piping the boiler should normally have an inlet gas pressure of at least 7.0" w.C. For natural gas and 11" w.C. For propane gas. For either fuel, the inlet pressure shall be no greater ...

Page 37

1-31 boiler systems and operation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or national electrical code, ans/nfpa no. 70 – latest edition, or the canadi...

Page 38

Installation and operation instructions 1-32 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 external low water cut off device dc series boiler only - an external low water cut-off device is not required if the boiler is only being used as a direct domestic hot water unit. If an ex...

Page 39

1-33 installation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 1.9.4 thermostat / sensor wiring a thermostat from a single zone heating system can be connected directly to the controller’s terminals x4.6 and x4.7. Do not apply power to the x4 terminal strip. The outdoor sensor i...

Page 40

Installation and operation instructions 1-34 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 35: electrical wiring connections (full page ladder diagram at back of this manual).

Page 41

2-1 boiler systems and operation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 2.0 boiler systems and operation general the dc series modulating condensing boilers are designed to heat both your indoor space and your domestic hot water. The boiler’s unique heat exchanger design i...

Page 42

Installation and operation instructions 2-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 2.3 control 1 power indicator a power - on / off 2 space heating b space heating / dhw toggle 3 domestic hot water c minus 4 main display d plus 5 fahrenheit and psi e fahrenheit/celsius 6 c...

Page 43

2-3 boiler systems and operation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 2.3.2 psi and fahrenheit / bar and celsius psi and fahrenheit are the default setting as shipped from the factory. To change to bar and celsius simply press the to toggle fahrenheit and celsius. 2.3.3 ...

Page 44

Installation and operation instructions 2-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 2.3.4 table of programmable parameters para-meter description default range / options user set up boiler supply temperature 180°f (82°c) 86°f (30°c) to 194°f (90°c) tankless domestic hot wat...

Page 45

2-5 boiler systems and operation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 f. Fan rpm at burner start for tankless dhw model dependent 50-100% of high fire dc 23-84 = 70 dc 29-106 = 60 dc 33-124 = 50 dc 33-160 = 40 (range = 40-75) h max fan speed adjustment model dependent dc...

Page 46

Installation and operation instructions 2-6 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 parameter 1 settings load priority: 0 = highest parameter number 1: detailed description 0 0 = tankless dhw 1 = space heating dc models – both space heating and tankless dhw • internal boile...

Page 47

2-7 boiler systems and operation dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 tankless domestic hot water modes 2.4.1 tankless domestic hot water - standard, comfort and eco comfort modes standard mode (both leds are off): the boiler’s heat exchanger will not maintain its domest...

Page 48

Installation and operation instructions 2-8 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 2.5.2 domestic hot water with an ibc indirect water heater the dc series boiler can be connected to an ibc indirect water heater. Connect the ibc indirect water heater’s boiler supply and bo...

Page 49

2-9 startup and commissioning dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 sequence of operation the boiler will operate in a similar way for both a space heating and a domestic hot water call for heat. When the boiler is powered up the controller enters a self diagnostic mode a...

Page 50

Installation and operation instructions 2-10 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 page intentionally left blank.

Page 51: Startup and Commissioning

3-1 startup and commissioning dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 startup and commissioning 3.0 3.1 lighting and shutting down the boiler.

Page 52

Installation and operation instructions 3-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Fill condensation trap. Ensure venting system is complete and seal tested. Confirm any common venting system at the installation site is is...

Page 53

3-3 startup and commissioning dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 the gas valve will automatically de-rate the maximum input in accordance with the density altitude, by approximately 2% per 1,000' above sea level. The gas valve’s zero governor will ensure that the gas:a...

Page 54

Installation and operation instructions 3-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 fuel conversion the dc series modulating boiler is factory fire-tested to operate with natural gas. The rating plate will be marked to indicate which fuel the particular boiler has been set ...

Page 55

3-5 startup and commissioning dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 figure 36: blower and gas valve assembly figure 37: orifice and o-ring warning fan outlet orifice (25mm) must be installed in the dc 23-84 model. If the fan is being replaced the orifice must be reinstall...

Page 56

Installation and operation instructions 3-6 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 note the safety warning regarding burner refractory on page 4-2 of this manual must be observed. 3. There is no need to drain the boiler’s water unless the boiler will be subject to freezing...

Page 57: Maintenance

4-1 maintenance dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 maintenance 4.0 boiler maintenance 4.1.1 general care • keep combustible materials and flammable liquids and vapours away from the boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspectio...

Page 58

Installation and operation instructions 4-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 4.1.6 heat exchanger during annual inspection (with the heat exchanger cover removed), examine the heat exchanger for signs of contamination and clean if necessary. In areas of poor gas qual...

Page 59

4-3 maintenance dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 4.1.12 boiler treatment • check consistency of any boiler treatment used, for appropriate mixture. Chemical inhibitors are consumed over time, lowering their density. • verify proper operation after servicing. 4.1.13 r...

Page 60

Installation and operation instructions 4-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 4.1.15 fan and gas valve removal instructions 1. Turn off the power and the gas supply to the boiler 2. Remove the front cover and allow the boiler to cool down 3. Disconnect the 2 electrica...

Page 61: 5.0 Troubleshooting

5-1 troubleshooting dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.0 troubleshooting the troubleshooting section is divided into 4 sections: 5.1 preliminary checks 5.2 electronic components 5.3 warnings and faults 5.4 other faults often, a problem can be identified and solved th...

Page 62

Installation and operation instructions 5-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic water pressure sensor and the temperat...

Page 63

5-3 troubleshooting dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the upper right side of the fan (white/black/green). Control of the fan is provided via a four lead connector at the bottom o...

Page 64

Installation and operation instructions 5-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.2.5 vent high-limit this sensor has been installed to ensure the boiler is shut down safely if the heat exchanger or the venting system becomes blocked. The vent hi-limit is located at the...

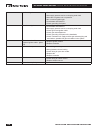

Page 65

5-5 troubleshooting dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.3 warnings and faults 5.3.1 warning codes during operation the controller can detect unusual situations and can take action to avoid damage to the heat exchanger or other unsafe operations. During these situation...

Page 66

Installation and operation instructions 5-6 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 4 no flame signal • gas valve closed • gas supply pressure too low or drooping under load • gas valve or ignition unit not powered • no or incorrect ignition gap • condensate drain blocked •...

Page 67

5-7 troubleshooting dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.4.1 burner does not ignite possible causes solution gas valve is closed. Open gas valve. Air in gas line. Remove air form gas line. Gas supply pressure too low. Contact the gas supply company. No ignition. Replac...

Page 68

Installation and operation instructions 5-8 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.4.5 no space heating possible causes solution room thermostat (end switches or zone controller) / outdoor sensor faulty. • room thermostat must be a dry contact style thermostat • check th...

Page 69

5-9 troubleshooting dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 5.4.8 hot water does not reach temperature possible causes solution dhw flow to high. Adjust the inlet assembly, insert a flow restriction. Temperature setting for water circuit too low. Adjust the hot water circui...

Page 70

Installation and operation instructions 5-10 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 page intentionally left blank.

Page 71: 6.0 Diagrams

6-1 diagrams dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 6.0 diagrams 6.1 - parts diagrams 6.2 - wiring diagrams.

Page 72

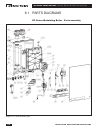

Installation and operation instructions 6-2 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 6.1 parts diagrams diagram 6.1-1: boiler assembly parts dc series modulating boiler - parts assembly.

Page 73

6-3 diagrams dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 diagram 6.1-2: boiler assembly parts list (refer to diagram 6.1-1 on opposite page) some parts are available in kits. Please visit www.Ibcboiler.Com for more information..

Page 74

Installation and operation instructions 6-4 dc series combi boilers dc 23-84, dc 29-106, dc 33-124, dc 33-160 6.2 wiring diagrams diagram 6.2-1: pictorial wiring diagram.

Page 75

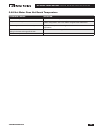

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 76

Service record date licensed contractor description of work done.

Page 77

Notes.

Page 78: Important

Revision history r1 (july 2014) initial release r2 (september 2014) minor updates important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit...

Page 80

Ibc technologies inc. 1445 charles street, vancouver, bc canada v5l 2s7 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-183-a-r2 883967 september 2014 © ibc technologies inc. 2014.