- DL manuals

- IBC

- Boiler

- SL 26-260 G3

- Installation and operating instructions manual

IBC SL 26-260 G3 Installation and operating instructions manual - Safety Considerations

INSTALLATION AND OPERATION INSTRUCTIONS

2

SL 26-260 G3, SL 40-399 G3 MODULATING GAS BOILERS

SAFETY CONSIDERATIONS

Installation, start-up and servicing of IBC boilers must be performed by competent,

qualified, licensed and trained heating technicians.

Failure to read and comply with all instructions and applicable National and local codes

may result in hazardous conditions that could result in property damage and injury to

occupants which in extreme cases might result in death.

HAZARDS & PRECAUTIONS

WARNING

If the information in this manual

is not followed exactly, a fire or

explosion may result causing

property damage, personal

injury, or loss of life.

WARNING

Points out a potentially

hazardous situation which must

be avoided to prevent serious

injury or death.

CAUTION

Points out a potentially

hazardous situation which must

be avoided to prevent possible

moderate injury and/or property

damage

NOTE

Points out installation,

maintenance and operation

details that will result in

enhanced efficiency, longevity

and proper operation of your

boiler.

DANGER

Points out an immediately

hazardous situation which must

be avoided in order to prevent

serious injury or death.

• 1 x Wall mounting bracket

• 1 x Condensate trap assembly

• 1 x 30 psig pressure relief valve

• 1 x Outdoor temperature sensor

• 6 x 1/4” x 2 1/2” Lag screws/w flat

washers

• Installation and Operating Instructions

Manual

• User Manual

• V10 Touchscreen Operating Instructions

Manual

Supplied with the boiler

- The IBC boiler is shipped with an accessory parts kit

consisting of the following items:

Summary of SL 26-260 G3

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not store or use gasoline or other flammable vapors and liquids or other comb...

Page 2: Safety Considerations

Installation and operation instructions 2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers safety considerations installation, start-up and servicing of ibc boilers must be performed by competent, qualified, licensed and trained heating technicians. Failure to read and comply with all instructions ...

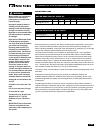

Page 3: Specifications

Installation and operation instructions 3 sl 26-260 g3, sl 40-399 g3 modulating gas boilers specifications specification sl 26-260 g3 sl 40-399 g3 csa input (natural gas or propane) - mbh csa input (natural gas or propane) - kw csa output - mbh csa output - kw 26 - 260 7.6 - 76.2 24.9 - 239 7.30 - 7...

Page 4

Installation and operation instructions 4 sl 26-260 g3, sl 40-399 g3 modulating gas boilers this page is intentionally left blank..

Page 5: Contents

Installation and operation instructions 5 sl 26-260 g3, sl 40-399 g3 modulating gas boilers contents 1.0 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

Installation and operation instructions 6 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.0 maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 4.1 boiler maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

Installation and operation instructions sl 80-399 modulating gas boiler 7 sl 26-260 g3, sl 40-399 g3 modulating gas boilers the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel a...

Page 8

Installation and operation instructions 8 sl 26-260 g3, sl 40-399 g3 modulating gas boilers this page is intentionally left blank.

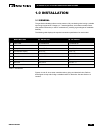

Page 9: 1.0 Installation

1-1 installation sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.0 installation 1.1 general the gas-fired modulating boilers are low pressure, fully condensing units having a variable input range. Approved as “category iv” vented appliances, the boilers use either direct vent (sealed combustion)...

Page 10

Installation and operation instructions 1-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 1a: dimensions / connections for sl 26-260 g3 9.7in [246mm] figure 1b: dimensions / connections for sl 40-399 g3.

Page 11

1-3 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.2 code requirements the boilers are tested and certified under csa 4.9-2014 / ansi z21.13-2014. Installation must conform to local codes, or in the absence of these, with the latest editions of can/c...

Page 12

Installation and operation instructions 1-4 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers • at a new construction site, or during renovations, action must be taken to protect the boiler from drywall dust or other construction related contaminants; combustion air s...

Page 13

1-5 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers all venting must be installed in accordance with the requirements of the jurisdiction having authority: in canada, part 8, venting systems of the b149.1-10 code and any other local building codes are t...

Page 14

Installation and operation instructions 1-6 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers • place in operation the appliance being inspected. Follow the lighting instructions. Adjust the thermostat so that the appliance operates continuously. • after it has been d...

Page 15

1-7 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers for pps material, use the transition / adaptor fitting (sch 40 to pps) offered by the respective pps manufacturers centrotherm / innoflue tm (their part # isaa0303 or # isaa0404) or m&g dura vent / pol...

Page 16

Installation and operation instructions 1-8 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers sl 40-399 g3 exhaust pipe size maximum equivalent length sched.40; rigid pps 4" cpvc / rigid pps 200' (each side) 90° vent elbow allow 8' equivalent 90° long sweep elbow allo...

Page 17

1-9 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 5a: 26-260 fan control harness plug figure 5b: 40-399 fan control harness plug best practices to reduce the possibility of expansion noise, allow a 1/4” gap around the exhaust and air intake pip...

Page 18

Installation and operation instructions 1-10 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 8: rooftop vent terminal configurations 1.4.6 sidewall vent termination a) vent terminal clearance minimums are as follows: • the exhaust vent terminal is to be place...

Page 19

1-11 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 10: vent terminal clearances figure 11: vent terminal clearances b) sidewall vent termination for indoor combustion air applications shall be as follows: • the vent shall be terminated with a t...

Page 20

Installation and operation instructions 1-12 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers • figure 12: sidewall vent termination c) sidewall direct vent with separate vent and air pipes shall be terminated as follows: • both the intake air and exhaust vent termin...

Page 21

1-13 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers d) sidewall direct vent with stainless sidewall terminal shall be terminated as follows: • the stainless sidewall terminal (sst) 3 inch ibc part number 180-149 (sold separately included with the ibc k...

Page 22

Installation and operation instructions 1-14 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 14: allowed sst installation orientations figure 15: pipes extend completely through the wall (vertical orientation shown). Figure 17: minimum separations for multipl...

Page 23

1-15 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.4.7 “direct vent” combustion air intake piping the direct vent option uses piping from the outside to supply combustion air directly to the boiler’s combustion air connection. Figure 18: direct vent...

Page 24

Installation and operation instructions 1-16 sl 26-260 g3, sl 40-399 g3 modulating gas boilers sl 40-399 g3 intake pipe size maximum equivalent length sched.40; rigid pps 4" cpvc / rigid pps 200' (each side) 90° vent elbow allow 8' equivalent 90° long sweep elbow allow 5' equivalent 45° elbow allow ...

Page 25

1-17 installation sl 26-260 g3, sl 40-399 g3 modulating gas boilers to support combustion, an ample air supply is required. This may require direct openings in the boiler room to the outside. If the boiler is not in a room adjacent to an outside wall, air may be ducted from outside wall openings. Pr...

Page 26

Installation and operation instructions 1-18 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.5 condensate removal ibc’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust venting without flowing liquids back through the...

Page 27

1-19 installation sl 26-260 g3, sl 40-399 g3 modulating gas boilers note it is the responsibility of the installing and/or service contractor to advise and instruct the end user in how to perform the trap cleaning procedure, and to advise that the trap be checked at least every two months and cleane...

Page 28

Installation and operation instructions 1-20 sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 25: condensate neutralization tank figure 24 condensate trap drainage warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization...

Page 29

1-21 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.6 water piping 1.6.1 general piping issues primary/secondary piping, or the use of a hydraulic separator is recommended for maximum flexibility in multi-load applications, but piping loads in parall...

Page 30

Installation and operation instructions 1-22 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers fluid fill is most often accomplished by using a boiler regulator & fill valve set at 12 psig or more, with the appropriate backflow prevention device as required by local c...

Page 31

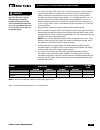

1-23 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers boiler head loss boiler head loss sl 26-260 g3 flow rate (gpm) 6 10 15 20 25 head @ flow (ft wc) 2’ 3.5’ 5.5’ 8’ 13’ table 5a: boiler head loss boiler head loss - sl 40-399 g3 flow rate (gpm) 20 25 30...

Page 32

Installation and operation instructions 1-24 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.6.2 installation rules if the installation involves small loads, as in typical zoned baseboard heating applications, use of a buffer tank is recommended. To aid in temperature transition from hot to cool...

Page 33

1-25 installation sl 26-260 g3, sl 40-399 g3 modulating gas boilers compared with the primary/secondary approach, the above design saves one pump. Lost is the simplicity of constant head and flow at the boiler. Check valves or thermal traps should be used to isolate both the supply and return piping...

Page 34

Installation and operation instructions 1-26 sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 30: trim for multiple boiler installations note the piping drawings in this manual are simple schematic guides to a successful installation. There are many necessary components not shown, and detail...

Page 35

1-27 installation sl 26-260 g3, sl 40-399 g3 modulating gas boilers figure 34: multiple boiler inter-wiring note when using the sequential load feature of the ibc boiler, attention must be paid to the operation of system components in order to ensure they are compatible. Many air handlers (fan coils...

Page 36

Installation and operation instructions 1-28 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.7 gas piping the boilers require an inlet gas supply pressure of at least 4.0" w.C. For natural gas or propane during high fire operation. This will ensure that gas pressu...

Page 37

1-29 installation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.8 electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or to the national electrical code, ans/nfpa no. 70 – latest edition, or...

Page 38

Installation and operation instructions 1-30 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers note the ibc touch-screen controller has the ability to connect to most power stealing thermostats. See the v-10 touchscreen boiler controller manual for details. Note the i...

Page 39

1-31 boiler systems and operation sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1.8.6 thermostat heat anticipator ibc “therm.” contacts draw no power, so an anticipator setting for the thermostat is not applicable with the sl modulating series boilers. In the case...

Page 40

Installation and operation instructions 1-32 sl 26-260 g3, sl 40-399 g3 modulating gas boilers this page is intentionally left blank..

Page 41: 2.0 Ibc Boiler Controller

2-1 boiler systems and operation sl 26-260 g3, sl 40-399 g3 modulating gas boilers 2.0 ibc boiler controller 2.1 general this boiler is equipped with the v-10 touchscreen controller. The controller simplifies the programming of the boiler while providing greater flexibility. For more detailed instru...

Page 42

Installation and operation instructions 2-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 2.3 control interface the control interface is provided through a 2-1/4 x 4 inch, color touchscreen display. The touchscreen responds to a light finger touch on the screen. You can also use a stylus or simi...

Page 43: 3.0 Startup & Commissioning

3-1 startup and commissioning sl 26-260 g3, sl 40-399 g3 modulating gas boilers 3.0 startup & commissioning 3.1 boiler shutdown & lighting.

Page 44

Installation and operation instructions 3-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensure venting system is complete and seal tested. Confirm any common venting system at the installation site is isolated and independent of the sl boiler....

Page 45

3-3 startup and commissioning sl 26-260 g3, sl 40-399 g3 modulating gas boilers 1. Turn off the gas supply. With a small (1/8” or 3 mm) flat screwdriver, open the inlet gas supply pressure test port by turning its center-screw one full turn counterclockwise. Attach a manometer to the pressure test p...

Page 46

Installation and operation instructions 3-4 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 3.3.1 gas valve and fan diagrams figure 37b: gas valve and pressure reference system - sl 40-399 g3 figure 37a: gas valve and pressure reference system - sl 26-260 g3.

Page 47

3-5 startup and commissioning sl 26-260 g3, sl 40-399 g3 modulating gas boilers 3.4 fuel conversion the sl boilers are factory fire-tested to operate with natural gas or propane as ordered. The rating plate will be marked to indicate which fuel the particular boiler has been set up with. Firing a bo...

Page 48

Installation and operation instructions 3-6 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers note the safety warning regarding burner refractory on page 4-2 of this manual must be observed. Heat exchanger lid removed refractory removed burner and heat exchanger lid 3...

Page 49

3-7 maintenance sl 26-260 g3, sl 40-399 g3 modulating gas boilers 11. With a permanent marker or equivalent, make an alignment mark on the refractory, lining it up with the same mark made earlier between the lid and heat exchanger. 12. Carefully remove the refractory, and place in a clean dry area. ...

Page 50

Installation and operation instructions 3-8 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 7. Ensure that the lid (orange) gasket is in place and level. 8. Carefully insert the lid-burner assembly straight down. Ensure that there is limited contact between the burner and refractory, and observe t...

Page 51: 4.0 Maintenance

4-1 maintenance sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.0 maintenance 4.1 boiler maintenance 4.1.1 general care • keep combustible materials and flammable liquids and vapors away from the boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection ...

Page 52

Installation and operation instructions 4-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.1.7 pump check that the pump is on in normal operation and that the water Δ°t is reasonable for a given firing rate. 4.1.8 gas piping check for damage or leaks and repair as needed. 4.1.9 touchscreen boil...

Page 53

4-3 maintenance sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.1.13 relief valve - maintenance and testing the relief valve manufacturer requires that under normal operating conditions a “try lever test” must be performed every two months. Under severe service conditions, or if corrosion and/or...

Page 54

Installation and operation instructions 4-4 sl 26-260 g3, sl 40-399 g3 modulating gas boilers components of the sl 26-260 g3 item no. Component item no. Component 1 pressure relief valve 6 low water cutoff probe 2 combustion test port 7 site glass 3 safety ignition module 8 tridicator 4 ignitor 9 su...

Page 55

4-5 maintenance sl 26-260 g3, sl 40-399 g3 modulating gas boilers item no. Component item no. Component 11 venturi mixing device 16 water pressure sensor 12 fan 17 return water temperature sensor 13 supply water temperature sensor 18 return water pipe 14 air intake pipe 19 blocked vent pressure swit...

Page 56

Installation and operation instructions 4-6 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.2.1 fan and gas valve removal instructions sl 26-260 g3 1. Turn off the electric power and gas supply to the boiler. 2. Ensure the boiler cools down to the surrounding temperature. Do not drain the boiler...

Page 57

4-7 troubleshooting sl 26-260 g3, sl 40-399 g3 modulating gas boilers 10. With the venturi mixing device still attached, remove the fan by pulling straight up ensuring that no wires are caught and that the gas line remains in place. Place the removed components in a clean, dry area. 11. Note how the...

Page 58

Installation and operation instructions 4-8 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4.2.3 replacing the gas valve sl 26-260 g3 1. Turn off the electric power and gas supply to the boiler. 2. Remove the electrical connection from the gas valve. 3. Ensure the boiler cools to the surrounding ...

Page 59: 5.0 Troubleshooting

5-1 troubleshooting sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.0 troubleshooting the troubleshooting section is divided into 3 sections: • preliminary checks • electronic components • troubleshooting often, a problem can be identified and solved through simple checks of the basics: confirmi...

Page 60

Installation and operation instructions 5-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.2 electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler. 5.2.1 temperature sensors the resistance of the temperature sensors varies...

Page 61

5-3 troubleshooting sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.2.2 fan operating power is provided by means of a separate 120 vac connector (white/black/ green). Control of the fan is provided via a four lead connector. This connector feeds a pwm control signal (black wire) from the control...

Page 62

Installation and operation instructions 5-4 sl 26-260 g3, sl 40-399 g3 modulating gas boilers the sim’s two status leds indicate the operating status as shown in the table below. Status indicators the sim is continuously communicating with the boiler’s main controller reporting sensor readings and s...

Page 63

5-5 troubleshooting sl 26-260 g3, sl 40-399 g3 modulating gas boilers 4. Tap the lwco test button. 5. Disconnect the yellow wire from the lwco function. A message on the screen indicates that the boiler is in lockout mode. 6. To reset the boiler, reconnect the yellow wire to the lwco function. On th...

Page 64

Installation and operation instructions 5-6 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.3 troubleshooting symptom diagnosis remedy maximum ignition trials error touchscreen message: error – ignition failure after 3 tries boiler has failed to ignite on 3 succes...

Page 65

5-7 troubleshooting sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers symptom diagnosis remedy low water cutoff error touchscreen message: error - low water cutoff the safety and ignition module has detected a low water condition. See section 5.2.4..

Page 66

Installation and operation instructions 5-8 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers symptom diagnosis remedy temperature sensor error touchscreen message: error - max. Inlet/outlet sensor temp. Exceeded. -> check water flow water temperature signal not withi...

Page 67

5-9 troubleshooting sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure ...

Page 68

Installation and operation instructions 5-10 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.3.4 temperature problems symptom diagnosis remedy low heat operating temperature too low. Increase temperature target. Priority parameters or load configuration improperly...

Page 69

5-11 troubleshooting sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solutio...

Page 70

Installation and operation instructions 5-12 sl 26-260 g3, sl 40-399 g3 modulating gas boilers this page is intentionally left blank..

Page 71: 6.0 Diagrams

6-1 diagrams sl 26-260 g3, sl 40-399 g3 modulating gas boilers 6.0 diagrams this section includes: • parts diagrams • wiring diagrams • the sequence of operation.

Page 72

Installation and operation instructions 6-2 sl 26-260 g3, sl 40-399 g3 modulating gas boilers 6.1 parts diagrams sl 26-260 g3 boiler - parts assembly diagram 6.1-1: boiler assembly parts - sl 26-260 g3.

Page 73

6-3 diagrams sl 26-260 g3, sl 40-399 g3 modulating gas boilers table : boiler assembly parts list (refer to diagram some parts are available only in kits. Please visit www.Ibcboiler. Com for more information. Item part number description qty 10 240-113 fan 1 20 150-073 mixer o-ring 1 30 180-161 fuel...

Page 74

Installation and operation instructions 6-4 sl 80-399 modulating gas boiler item part number description qty 400 250-867 bracket, blocked vent press. Switch 1 410 240-138 blocked vent pressure switch 1 420 240-008 transformer 1 430 500-105 ignition module 1 440 240-132 flue temperature sensor 1 450 ...

Page 75

6-5 troubleshooting sl 80-399 modulating gas boiler this page is intentionally left blank..

Page 76

Installation and operation instructions 6-6 sl 26-260 g3, sl 40-399 g3 modulating gas boilers sl 40-399 g3 boiler - parts assembly diagram 6.1-2: boiler assembly parts - sl 40-399 g3.

Page 77

6-7 diagrams sl 26-260 g3, sl 40-399 g3 modulating gas boilers table : boiler assembly parts list (refer to diagram 6.1-2 on opposite page) some parts are available only in kits. Please visit www.Ibcboiler. Com for more information. Item part # description qty 10 240-113 fan 1 20 150-073 mixer, ng 1...

Page 78

Installation and operation instructions 6-8 sl 26-260 g3, sl 40-399 g3 modulating gas boilers item part # description qty 170-028 80 psi capacity, 316ti stainless steel 170-029 80 psi capacity, 439 stainless steel 380 250-853 supply water pipe assembly 1 390 180-189 tridicator 1 400 240-010 low wate...

Page 79

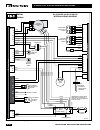

6-9 diagrams sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 6.2 wiring diagrams diagram 6.2-1: ladder wiring diagram.

Page 80

Installation and operation instructions 6-10 sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers diagram 6.2-2: internal wiring diagram better boilers 24 vac 120 vac black white orange white 17 16 green red red yellow white white blue blue white blue green blue tb1 10 9...

Page 81

6-11 diagrams sl 80-399 modulating gas boiler sl 26-260 g3, sl 40-399 g3 modulating gas boilers 6.3 sequence of operation diagram 6.3: sequence of operation diagram.

Page 82

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 83: Installer Set-Up

Installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 _____________________________________________________________________________________________ load definition - load #2 ____________________________________...

Page 84: Service Record

Service record date licensed contractor description of work done.

Page 85: Notes

Notes.

Page 86: Important

As referenced on page 2-7 of this manual, the following message is relevant to users in the usa: important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided prim...

Page 87: Revision History

Revision history r1 (march 2017) initial release r2 (avril 2017) corrections to text (specifications table and part number tables).

Page 88

Ibc technologies inc. 8015 north fraser way burnaby, bc canada v5j 5m8 tel: 604-877-0277 fax: 604-877-0295 toll free: 1-844-432-8422 www.Ibcboiler.Com april 2017 © ibc technologies inc. 2017.