- DL manuals

- IBC

- Boiler

- SL 35-199

- Operating Instructions Manual

IBC SL 35-199 Operating Instructions Manual

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

SL 35-199, SL 45-260

MODULATING GAS BOILERS

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

•

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com

Summary of SL 35-199

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com sl 35-199, sl 45-260 modulating gas boilers (natural gas or propane) warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not stor...

Page 2: Safety Considerations

Installation and operation instructions 2 sl 35-199, sl 45-260 modulating gas boilers safety considerations installation, start-up and servicing of ibc boilers must be done with due care and attention, and should only be performed by competent, qualified, licensed and trained heating technicians. Fa...

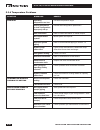

Page 3: Specifications

3 installation and operating instructions sl 35-199, sl 45-260 modulating gas boilers specifications specification sl 35-199 sl 45-260 csa input (natural gas or propane*) - mbh csa input (natural gas or propane*) - kw csa output - mbh csa output - kw 35 - 199 10.3 - 58.3 32.7 - 181.3 7.7 - 43 45 - 2...

Page 4

Installation and operation instructions 4 sl 35-199, sl 45-260 modulating gas boilers this page intentionally left blank.

Page 5: Contents

5 installation and operating instructions sl 35-199, sl 45-260 modulating gas boilers 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Installation and operation instructions 6 sl 35-199, sl 45-260 modulating gas boilers the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensate...

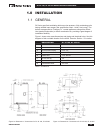

Page 7: Installation

1-1 installation sl 35-199, sl 45-260 modulating gas boilers installation 1.0 general sl series gas-fired modulating boilers are low pressure, fully condensing units having variable input ranges (see specification chart - inside, front cover). The boilers are approved as “category iv” vented applian...

Page 8

Installation and operation instructions 1-2 sl 35-199, sl 45-260 modulating gas boilers code requirements the sl 35-199 and sl 45-260 models were tested to and certified under csa 4.9-2014 / ansi z21.13-2014. Installation must conform to local codes, or in the absence of these, with the latest editi...

Page 9

1-3 installation sl 35-199, sl 45-260 modulating gas boilers surface distance from combustible surfaces recommended distance for installation and service front 2" 24" rear 0" 0" left side 1" 0" (min. For non-combustible surface) right side 1" 2" (min. For electrical connections) top 2" 6" (for vent ...

Page 10

Installation and operation instructions 1-4 sl 35-199, sl 45-260 modulating gas boilers all venting must be installed in accordance with the requirements of the jurisdiction having authority: in canada, part 8, venting systems of the b149.1- 10 code and any other local building codes are to be follo...

Page 11

1-5 installation sl 35-199, sl 45-260 modulating gas boilers • after it has been determined that each appliance remaining connected to the common venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas-burning appliance to...

Page 12

Installation and operation instructions 1-6 sl 35-199, sl 45-260 modulating gas boilers use of cellular core pvc (astm f891), cellular core cpvc, or radel® (polyphenolsulfone) in venting systems shall be prohibited. The boiler offers 3” venting connections. Fittings are to be used to adapt to the ap...

Page 13

1-7 installation sl 35-199, sl 45-260 modulating gas boilers exhaust venting must slope down towards the boiler with a pitch of at least 1/4” per foot (pps vent: follow pps manufacturer requirements) so condensate runs back towards the trap. Support should be provided for intake and vent piping, par...

Page 14

Installation and operation instructions 1-8 sl 35-199, sl 45-260 modulating gas boilers 1.4.5 rooftop vent termination rooftop vents must terminate as follows: • the exhaust pipe can terminate in an open vertical orientation without concern about rain infiltration; rain will drain away through the c...

Page 15

1-9 installation sl 35-199, sl 45-260 modulating gas boilers • the exhaust outlet is to be placed so as to reach 24” minimum above the down-turned intake - to avoid intake re-ingestion of exhaust gases. • the elevation of both pipes can be raised in “periscope style” after passing through the wall, ...

Page 16

Installation and operation instructions 1-10 sl 35-199, sl 45-260 modulating gas boilers vent terminal clearance minimums are as follows: • clearance above grade, veranda, porch, deck or balcony – 12” (0.3m), but check local code also (anticipated snow levels may supersede). • clearance to openable ...

Page 17

1-11 installation sl 35-199, sl 45-260 modulating gas boilers • clearance above paved sidewalk or paved driveway located on public property: - 7’ (2.2m) note: cannot terminate directly above a paved sidewalk or paved driveway that is located between two single family dwellings and serves both dwelli...

Page 18

Installation and operation instructions 1-12 sl 35-199, sl 45-260 modulating gas boilers exhaust pipe size maximum equivalent length sched.40; rigid pps 3” 200’ 4” 200’ 90° long sweep elbow allow 5’ equivalent 90° vent elbow allow 8’ equivalent 45° elbow allow 3’ equivalent pps 87-90° elbows use 8’ ...

Page 19

1-13 installation sl 35-199, sl 45-260 modulating gas boilers 1.4.8 “indoor air” combustion air intake an “indoor combustion air installation”, as described herein, is one in which air for combustion is taken from the ambient air around the boiler. To support combustion, an ample air supply is requi...

Page 20

Installation and operation instructions 1-14 sl 35-199, sl 45-260 modulating gas boilers condensate removal ibc’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust venting without flowing liquids back through the heat exchanger (as done by some other con...

Page 21

1-15 installation sl 35-199, sl 45-260 modulating gas boilers 1.5.3 condensate trap assembly - cleaning procedure 1. Turn off the power to the boiler and allow it to cool down. 2. Remove the trap from the boiler (reverse the installation procedure above). 3. Remove the trap cleanout assembly (h), fr...

Page 22

Installation and operation instructions 1-16 sl 35-199, sl 45-260 modulating gas boilers figure 17: condensate trap drainage warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization package must be used. Caution when a condensat...

Page 23

1-17 installation sl 35-199, sl 45-260 modulating gas boilers water piping 1.6.1 general piping issues the sl 35-199 and sl 45-260 boilers were designed to be easy to install in almost any application. Primary/secondary piping, or the use of a hydraulic separator is recommended for maximum flexibili...

Page 24

Installation and operation instructions 1-18 sl 35-199, sl 45-260 modulating gas boilers system piping is connected to the boiler using the 1-1/2” npt male threaded fittings on the bottom connection ports. Unions and gate or ball valves at the boilers supply and return water connections are recommen...

Page 25

1-19 installation sl 35-199, sl 45-260 modulating gas boilers the minimum flow rate required through the heat exchanger is 6 usgpm with a maximum of 25 usgpm allowed. Primary/secondary piping ensures adequate flow and de-couples Δ°t issues (boiler vs. Distribution). Aim for a 20° to 30° f Δ°t across...

Page 26

Installation and operation instructions 1-20 sl 35-199, sl 45-260 modulating gas boilers figure 23: basic primary/secondary piping with closely-spaced tees concept figure 24: important primary/secondary piping details with closely-spaced tees note the piping drawings in this manual are simple schema...

Page 27

1-21 installation sl 35-199, sl 45-260 modulating gas boilers figure 25: basic primary/secondary piping with hydraulic separator concept figure 26: primary/secondary with indirect domestic hot water.

Page 28

Installation and operation instructions 1-22 sl 35-199, sl 45-260 modulating gas boilers warning do not use automotive-type ethylene or other types of automotive glycol antifreeze, or undiluted antifreeze of any kind. This may result in severe boiler damage. It is the responsibility of the installer...

Page 29

1-23 installation sl 35-199, sl 45-260 modulating gas boilers the use of the multi-temperature modulating system is optimized when the need to shutdown the boiler is reduced or eliminated during the transitional period. System design enhancements: (a) keep a relatively low thermal mass in the primar...

Page 30

Installation and operation instructions 1-24 sl 35-199, sl 45-260 modulating gas boilers check valves or thermal traps should be used to isolate both the supply and return piping for each load - to avoid thermal siphoning and reverse flow. To ensure adequate water flow through the boiler under high-...

Page 31

1-25 boiler systems and operation sl 35-199, sl 45-260 modulating gas boilers 1.7 gas piping the boiler should have an inlet gas pressure of at least 5.0" w.C. For natural gas or propane. For either fuel, the inlet pressure shall be no greater than 14.0" w.C. Confirm this pressure range is available...

Page 32

Installation and operation instructions 1-26 sl 35-199, sl 45-260 modulating gas boilers electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or national electrical code, ans/nfpa no. 70 – latest edition, or the canadian electric...

Page 33

1-27 installation sl 35-199, sl 45-260 modulating gas boilers note the ibc touch-screen controller has the ability to connect to most power stealing thermostats. See the wiring diagram for details. Note the ibc boiler (like any modern appliance that contains electronic equipment), must have a “clean...

Page 34

Installation and operation instructions 1-28 sl 35-199, sl 45-260 modulating gas boilers 1.8.6 thermostat heat anticipator ibc “therm.” contacts draw no power, so an anticipator setting for the thermostat is not applicable with the sl modulating series boilers. In the case of a single temperature / ...

Page 35: 2.0 Ibc Boiler Controller

2-1 boiler systems and operation sl 35-199, sl 45-260 modulating gas boilers 2.0 ibc boiler controller general this boiler is equipped with the v-10 touch screen controller. The controller simplifies the programing of the boiler while providing greater flexibility. For more detailed instructions, re...

Page 36

Installation and operation instructions 2-2 sl 35-199, sl 45-260 modulating gas boilers operational and historical data may be accessed at any time using the system status and load profiles sections of the control. Error logs are available in the diagnostics section and the controller is capable of ...

Page 37: Startup and Commissioning

3-1 startup and commissioning sl 35-199, sl 45-260 modulating gas boilers startup and commissioning 3.0 3.1 lighting and shutting down the boiler clockwise open close.

Page 38

Installation and operation instructions 3-2 sl 35-199, sl 45-260 modulating gas boilers 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensure venting system is complete and seal tested. Confirm any common venting system at the installation site is isolated and independent of the sl boiler, that ...

Page 39

3-3 startup and commissioning sl 35-199, sl 45-260 modulating gas boilers de-ration. The boiler will automatically de-rate at altitudes above 4,500 feet. Refer to the ibc altitude tables for further information. To verify proper operation of the gas valve in the field, the following procedure can be...

Page 40

Installation and operation instructions 3-4 sl 35-199, sl 45-260 modulating gas boilers figure 31a: sl 35-199 gas valve adjust figure 31b: sl 45-260 gas valve adjust.

Page 41

3-5 startup and commissioning sl 35-199, sl 45-260 modulating gas boilers fuel conversion the sl 35-199 and sl 45-260 modulating boilers are factory fire-tested to operate with natural gas, or propane as ordered. The rating plate will be marked to indicate which fuel the particular boiler has been s...

Page 42

Installation and operation instructions 3-6 sl 35-199, sl 45-260 modulating gas boilers note the safety warning regarding burner refractory on page 4-2 of this manual must be observed. 3.4.1 gaining access to combustion chamber, burner removal instructions 1. Remove fan and gas valve assembly. See “...

Page 43: Maintenance

4-1 maintenance sl 35-199, sl 45-260 modulating gas boilers maintenance 4.0 boiler maintenance 4.1.1 general care • keep combustible materials and flammable liquids and vapours away from the boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection of the bo...

Page 44

Installation and operation instructions 4-2 sl 35-199, sl 45-260 modulating gas boilers 4.1.6 heat exchanger during annual inspection (with the burner removed), examine the heat exchanger for signs of contamination and clean if necessary. In areas of poor gas quality, there may be a buildup of black...

Page 45

4-3 maintenance sl 35-199, sl 45-260 modulating gas boilers 4.1.12 boiler treatment • check consistency of any boiler treatment used, for appropriate mixture. Chemical inhibitors are consumed over time, lowering their density. • verify proper operation after servicing. 4.1.13 relief valve - maintena...

Page 46

Installation and operation instructions 4-4 sl 35-199, sl 45-260 modulating gas boilers removing top service cover removing front cover gas inlet connection on side gas valve gas supply line ignition wire boot fan housing fan pressure sensor fan motor ignition module sight glass (burner observation ...

Page 47

4-5 maintenance sl 35-199, sl 45-260 modulating gas boilers outlet (supply) water temperature sensor upper vessel high limit switch vent temperature sensor bracket inlet (return) water temperature sensor removing vent stack test port plug water pressure sensor water temperature high limit switch com...

Page 48

Installation and operation instructions 4-6 sl 35-199, sl 45-260 modulating gas boilers 4.2.1 fan and gas valve removal instructions 1. Turn off electric power and gas supply to the boiler. 2. Ensure boiler cools down to ambient temperature. Do not drain the boiler unless freezing conditions are exp...

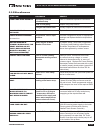

Page 49: 5.0 Troubleshooting

5-1 troubleshooting sl 35-199, sl 45-260 modulating gas boilers 5.0 troubleshooting the troubleshooting section is divided into 3 sections: 5.1 preliminary checks 5.2 electronic components 5.3 troubleshooting guide often, a problem can be identified and solved through simple checks of the basics: co...

Page 50

Installation and operation instructions 5-2 sl 35-199, sl 45-260 modulating gas boilers this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature sensors. 5.2.1 temperature se...

Page 51

5-3 troubleshooting sl 35-199, sl 45-260 modulating gas boilers 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the bottom of the fan (white/black/green). Control of the fan is provided via a four lead connector at the top of the fan. This connector feeds a p...

Page 52

Installation and operation instructions 5-4 sl 35-199, sl 45-260 modulating gas boilers 5.2.5 hi-limit switches (water and uvhl) check resistance between leads. If resistance is very low, temperature should be acceptable. If resistance is very high, temperature should be out of bounds. A simple mean...

Page 53

5-5 troubleshooting sl 35-199, sl 45-260 modulating gas boilers 5.2.7 optional low water cut off the boiler can be ordered with a ul 353 certified probe-type low water cut off (lwco) device factory installed or a field installed retrofit kit (boiler model specific) can be ordered from your local who...

Page 54

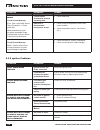

Installation and operation instructions 5-6 sl 35-199, sl 45-260 modulating gas boilers 5.3 troubleshooting guide symptom diagnosis remedy airflow error touch screen message: error – low air flow low combustion airflow; soft error; will retry in 5 minutes check fan operation • check lead is attached...

Page 55

5-7 troubleshooting sl 35-199, sl 45-260 modulating gas boilers symptom diagnosis remedy maximum ignition trials error touch screen message : error – ignition failure after 3 tries boiler has failed to ignite on 3 successive attempts. Boiler in lockout for 1 hour, then repeats 3-try seq. Consult ser...

Page 56

Installation and operation instructions 5-8 sl 35-199, sl 45-260 modulating gas boilers symptom diagnosis remedy temperature sensor error touch screen message: error - max. Inlet/outlet sensor temp. Exceeded. -> check water flow water temperature signal not within acceptable range. Potential flow or...

Page 57

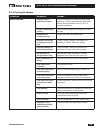

5-9 troubleshooting sl 35-199, sl 45-260 modulating gas boilers 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure boiler differential is ok (16-30°f is ...

Page 58

Installation and operation instructions 5-10 sl 35-199, sl 45-260 modulating gas boilers 5.3.4 temperature problems symptom diagnosis remedy low heat operating temperature too low. Increase temperature target. Priority parameters or load configuration improperly set up. Review load configuration par...

Page 59

5-11 troubleshooting sl 35-199, sl 45-260 modulating gas boilers 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solution flue gas leak within boiler visually...

Page 60

Installation and operation instructions 5-12 sl 35-199, sl 45-260 modulating gas boilers this page intentionally left blank.

Page 61: 6.0 Diagrams

6-1 diagrams sl 35-199, sl 45-260 modulating gas boilers 6.0 diagrams 6.1 - parts diagrams 6.2 - wiring diagrams 6.3 - sequence of operation.

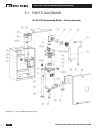

Page 62

Installation and operation instructions 6-2 sl 35-199, sl 45-260 modulating gas boilers 6.1 parts diagrams diagram 6.1-1: sl 35-199 boiler assembly parts sl 35-199 modulating boiler - parts assembly.

Page 63

6-3 diagrams sl 35-199, sl 45-260 modulating gas boilers diagram 6.1-3: p-172 intake air filter item no. Part no. Description qty 10 240-048 fan 1 20 250-401 gasket, fan-adapter plate 1 30 250-640 adapter plate 1 40 240-065 gas valve/fuel mixture assembly 1 50 190-031 3/4” gas line 1 60 500-064 comb...

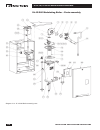

Page 64

Installation and operation instructions 6-4 sl 35-199, sl 45-260 modulating gas boilers diagram 6.1-4: sl 45-260 boiler assembly parts sl 45-260 modulating boiler - parts assembly.

Page 65

6-5 diagrams sl 35-199, sl 45-260 modulating gas boilers diagram 6.1-6: p-172 intake air filter item no. Part no. Description qty 10 240-048 fan 1 20 250-401 gasket, fan-adapter plate 1 30 250-379 adapter plate 1 40 180-042 gas valve 1 45 180-045 fuel mixture venturi 1 50 190-031 3/4” gas line 1 60 ...

Page 66

Installation and operation instructions 6-6 sl 35-199, sl 45-260 modulating gas boilers diagram 6.2-1: ladder wiring diagram 6.2 wiring diagrams.

Page 67

6-7 diagrams sl 35-199, sl 45-260 modulating gas boilers diagram 6.2-2: internal wiring diagram fenwal tb1 9 10 better boilers yellow blue 24 vac 120 vac orange 100-013a 2 x plug mains power supply electrode 5 x plug 3 x plug and flame sensing rod assembly spark yellow black black red black white bl...

Page 68

Installation and operation instructions 6-8 sl 35-199, sl 45-260 modulating gas boilers 6.3 sequence of operation diagram 6.3: sequence of operation diagram.

Page 69

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 70

Installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 _____________________________________________________________________________________________ load definition - load #2 ____________________________________...

Page 71

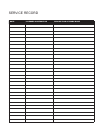

Service record date licensed contractor description of work done.

Page 72

Notes.

Page 73

Notes.

Page 74: Important

Important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit the use of an external energy management system that serves the same function. Th...

Page 75

Revision history r1 (august 2014) initial release - sl 35-199 incorporate the sl 45-260 model r2 (may 2015) address update.

Page 76

Ibc technologies inc. 8015 north fraser way burnaby, bc canada v5j 5m8 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-207e-a-r2 may 2015 © ibc technologies inc. 2015.