- DL manuals

- IBC Technologies

- Boiler

- SL 30-175

- Installation And Operating Istructions

IBC Technologies SL 30-175 Installation And Operating Istructions

INST

ALLA

TION AND OPERA

TING INSTR

UCTIONS

www.ibcboiler.com

SL 30-175, SL 45-260

Modulating gas Boilers

(Natural Gas or Propane)

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

this Manual is also available in French - contact iBC or visit our web site www.ibcboiler.com

Summary of SL 30-175

Page 1

Inst alla tion and opera ting instr uctions www.Ibcboiler.Com sl 30-175, sl 45-260 modulating gas boilers (natural gas or propane) warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Do not stor...

Page 2: Safety Considerations

Installation and operation instructions sl 30-175, sl 45-260 modulating gas boilers safety considerations specifications warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. Installation, start-up...

Page 3: Contents

Installation and operation instructions sl 30-175, sl 45-260 modulating gas boilers 1.0 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Installation and operation instructions sl 30-175, sl 45-260 modulating gas boilers the installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensate r...

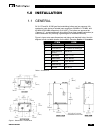

Page 5: Installation

1-1 installation sl 30-175, sl 45-260 modulating gas boilers installation 1.0 general sl30-175andsl45-260gas-firedmodulatingboilersarelowpressure,fully condensing units having a variable input range from 30 mbh to 175 mbh, and 45 mbh to 260 mbh respectively (0 to 8,000’). The boilers are approved as...

Page 6

Installation and operation instructions 1-2 sl 30-175, sl 45-260 modulating gas boilers code requirements thesl30-175andsl45-260boilersweretestedtoandcertifiedundercsa4.9- 2010 / ansi z21.13-2010. Installation must conform to local codes, or in the absence of these, with the latest editions of can/c...

Page 7

1-3 installation sl 30-175, sl 45-260 modulating gas boilers contaminants; combustion air should be drawn from a clean source (e.G. Outdoors) and the boiler should be isolated from interior dust sources. Do not seal boiler case openings directly when firing - allow for air circulation and ventilatio...

Page 8

Installation and operation instructions 1-4 sl 30-175, sl 45-260 modulating gas boilers all venting must be installed in accordance with the requirements of the jurisdiction having authority: in canada, part 8, venting systems of the b149.1- 10 code and any other local building codes are to be follo...

Page 9

1-5 installation sl 30-175, sl 45-260 modulating gas boilers • place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously. • after it has been determined that each appliance remaining connected to the common venting sy...

Page 10

Installation and operation instructions 1-6 sl 30-175, sl 45-260 modulating gas boilers the boiler offers 3" venting connections. Fittings are to be used to adapt to the appropriate diameter – see vent travel below. Exhaust venting is to be inserted directlyintotheleftmost3"femalestainlesssteelfitti...

Page 11

1-7 installation sl 30-175, sl 45-260 modulating gas boilers runs back towards the trap. Support should be provided for intake and vent piping, particularly so for horizontal runs (follow local code). You may have to insulate exhaust piping where it passes through unheated spaces or underground, wit...

Page 12

Installation and operation instructions 1-8 sl 30-175, sl 45-260 modulating gas boilers • optionalbirdscreenmaybeplacedinaterminationfitting.Leaveunglued, and hold in place with a short nipple. This permits easy access for cleaning. • for roof top venting of multiple boiler sets, group all intake te...

Page 13

1-9 installation sl 30-175, sl 45-260 modulating gas boilers • use a 45° elbow on the exhaust termination to launch the plume up and off the sidewall, for protection of wall. • bird screen of 1/4" stainless steel or plastic mesh (ipex system 636 drain grate) is useful to guard against foreign object...

Page 14

Installation and operation instructions 1-10 sl 30-175, sl 45-260 modulating gas boilers or paved driveway that is located between two single family dwellings and serves both dwellings • clearance under veranda, porch, deck or balcony: - 12" (0.3m) ibc strongly recommends a minimum of 48” with the s...

Page 15

1-11 installation sl 30-175, sl 45-260 modulating gas boilers 1.4.7 “direct vent” combustion air intake piping there are two basic methods of supplying combustion air to an ibc boiler. The direct vent option uses piping from the outside to supply combustion air directly to the boiler’s combustion ai...

Page 16

Installation and operation instructions 1-12 sl 30-175, sl 45-260 modulating gas boilers 1.4.8 “indoor air” combustion air intake an “indoor combustion air installation”, as described herein, is one in which air for combustion is taken from the ambient air around the boiler. To support combustion, a...

Page 17

1-13 installation sl 30-175, sl 45-260 modulating gas boilers condensate removal ibc’sspecifiedventconfigurationpromotesthesafedrainageofmoisturefrom theboilerandexhaustventingwithoutflowingliquidsbackthroughtheheat exchanger (as done by some other condensing boilers). Reliable system operation requ...

Page 18

Installation and operation instructions 1-14 sl 30-175, sl 45-260 modulating gas boilers 1.5.3 condensate trap assembly - cleaning procedure 1. Turn off the power to the boiler and allow it to cool down. 2. Remove the trap from the boiler (reverse the installation procedure above). 3. Remove the tra...

Page 19

1-15 installation sl 30-175, sl 45-260 modulating gas boilers figure 19: condensate neutralization tank figure 18: condensate trap drainage warning if condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization package must be used. Caution w...

Page 20

Installation and operation instructions 1-16 sl 30-175, sl 45-260 modulating gas boilers water piping 1.6.1 general piping issues the sl modulating series boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4" npt) issuppliedf...

Page 21

1-17 installation sl 30-175, sl 45-260 modulating gas boilers do not place any water connections overhead the boiler; leaks can damage the fan & controls. If needed, create a shield over the top of the cover, but allow clearanceforairflowandserviceaccess. For best results, use a primary: secondary p...

Page 22

Installation and operation instructions 1-18 sl 30-175, sl 45-260 modulating gas boilers ensure the pump is rated for the design circulating water temperatures; some pumps have a minimum water temperature rating above the low temperature potentialoftheboiler.Followinginstallation,confirmactualperfor...

Page 23

1-19 installation sl 30-175, sl 45-260 modulating gas boilers primary / secondary piping - benefits and installation rules 1. Goodcirculatingwaterflowthroughtheboilerirrespectiveofloadorradiation system head 2. AllowsflexibleΔt°controlinsecondaryloops 3. Adds to the system’s thermal buffering, to as...

Page 24

Installation and operation instructions 1-20 sl 30-175, sl 45-260 modulating gas boilers zone space heating conditions, a pressure activated bypass or other means of bypassmustbeusedonanyloadwheretheflowratemightdropbelowminimum requirements (6 usgpm). For further information and details, consult ou...

Page 25

1-21 installation sl 30-175, sl 45-260 modulating gas boilers each boiler will control its own pump, turning it off or on when heat is required. This approach saves electricity by reducing the pumping power required as load conditions are reduced. Check valves are to be used in each boilers piping t...

Page 26

Installation and operation instructions 1-22 sl 30-175, sl 45-260 modulating gas boilers gas piping the sl 30-175 and sl 45-260 boilers require an inlet gas pressure of at least 5.0"w.C.Fornaturalgasorpropane,ensuring4”atthegasvalveathighfire. Foreitherfuel,theinletpressureshallbenogreaterthan14.0"w...

Page 27

1-23 installation sl 30-175, sl 45-260 modulating gas boilers removing wiring box covers line voltage power block terminals line voltage pump block terminals electrical connections all electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or national electr...

Page 28

Installation and operation instructions 1-24 sl 30-175, sl 45-260 modulating gas boilers 1.8.3 zone valve hook-up if zone valves rather than pumps are used to manage multiple heating loads, then 24vac for the zone valves should be provided to the power contacts on the pump/ zone valve terminal block...

Page 29

1-25 installation sl 30-175, sl 45-260 modulating gas boilers cb input to processor input to processor electrical ladder diagram sl 20-115, 30-175, 45-260 load 1 contacts outdoor sensor auxiliary interlock (l.W.C.O., air proving, etc.) - jumper if not used load 2 contacts load 3 contacts interlock 1...

Page 30

Installation and operation instructions 1-26 sl 30-175, sl 45-260 modulating gas boilers this page intentionally left blank.

Page 31: Boiler Systems and Operation

2-1 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers boiler systems and operation 2.0 2.1 general the sl 30-175 and sl 45-260 modulating boilers are designed to service larger residential, light-to-medium commercial space and domestic water heating loads. External load contro...

Page 32

Installation and operation instructions 2-2 sl 30-175, sl 45-260 modulating gas boilers 2.3.2 lcd display uponpower-up,thelcdscreeninitiallyflashesasoftwarereleasenumber then switches to a standby- display mode, showing real time data plus key temperature target settings. Whenthereisacallforheatfrom...

Page 33

2-3 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers 2.4.1 user setup the occupant has access to a number of practical settings. The most meaningful include adjustment of the indoor temperature target plus the temperature setback and occupied / unoccupied modes. The user menu...

Page 34

Installation and operation instructions 2-4 sl 30-175, sl 45-260 modulating gas boilers sequence of operation the control module has 5 cycles during normal operation, as well as an error mode for problem detection: 1. Standby cycle 2. Purging 3. Ignition cycle 4. Heating cycle 5. Circulating cycle 6...

Page 35

2-5 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers the pump remains on for 5 minutes (adjustable) after the heating cycle ends. If the heating cycle ends as a result of water temperature exceeding the load specificbandlimit,the postpurge will continue as normal, but the boi...

Page 36

Installation and operation instructions 2-6 sl 30-175, sl 45-260 modulating gas boilers the pump remains on until the loop drops ½ the differential below the new load target temperature. Note: if there is no place to sink heat during such circ. Mode, thisphasewillcontinueindefinitely,affectingheatde...

Page 37

2-7 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers initial cycle, the clashing loads will switch back and forth after further 10 min. Intervals pending satisfaction of one or both loads. To cause repeated unequal run times (for example, constant 35 vs 5 min. Runs) it is nec...

Page 38

Installation and operation instructions 2-8 sl 30-175, sl 45-260 modulating gas boilers theboilertofireusingonwardleadstotheboiler’sdrycontacts(useoneofthe pairs marked “therm 1, 2 or 3” on the sensor block terminal strip. Gang such leads in parallel from multiple zone valves for single connection t...

Page 39

2-9 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers 2.6.6 unoccupied mode users can further reduce energy consumption by switching the boiler to the unoccupied mode during holidays or other away periods. While in the unoccupied mode, the dhw load is turned off, while space h...

Page 40

Installation and operation instructions 2-10 sl 30-175, sl 45-260 modulating gas boilers set up & load definition after the boiler is powered up, the installer can use the keypad and display to characterize the application, as follows: 1. In the standby mode, start by pressing any key to call up the...

Page 41

2-11 boiler systems and operation sl 30-175, sl 45-260 modulating gas boilers use the summer shutdownfieldtoenterathresholdtemperatureforthe avoidance of heating during warmer times. This is typically set at 60° to 65°f so as to eliminate excessive boiler cycling in marginal heating conditions. Use ...

Page 42

Installation and operation instructions 2-12 sl 30-175, sl 45-260 modulating gas boilers 17. If desired, use load pairing option to allow two loads of compatible temperature demands to run at the same time. Consult ibc technical note: load pairing. 18. Upon completion of the input of load parameters...

Page 43: Startup and Commissioning

3-1 startup and commissioning sl 30-175, sl 45-260 modulating gas boilers startup and commissioning 3.0 3.1 lighting and shutting down the boiler for your safety read before operating operating instructions to turn off gas appliance a. This appliance does not have a pilot. It is equipped with an ign...

Page 44

Installation and operation instructions 3-2 sl 30-175, sl 45-260 modulating gas boilers 3.2 prior to start-up 3.2.1 pre-ignition checks 1. Ensureventingsystemiscompleteandsealtested.Confirmanycommon venting system at the installation site is isolated and independent of the sl boiler, that any holes ...

Page 45

3-3 startup and commissioning sl 30-175, sl 45-260 modulating gas boilers 2. Allowtheboilertoignite.Runagainstalargeload,tomaintainhighfire. 3. Withacombustionanalyzerprobeinthefluegastestport,turnthegas:air ratio adjustment screw (see figure 32, “b”) to achieve 25% excess air (see table 8 below for...

Page 46

Installation and operation instructions 3-4 sl 30-175, sl 45-260 modulating gas boilers fuel conversion thesl30-175andsl45-260modulatingboilersarefactoryfire-testedto operate with natural gas, or propane as ordered. The rating plate will be marked to indicate which fuel the particular boiler has bee...

Page 47

3-5 maintenance sl 30-175, sl 45-260 modulating gas boilers part number description qty 180-042 gas valve 1 grommet - equipped with gas valve 1 180-044 or 180-046 brass orifice - for porpane only 1 151-003 screws - equipped with gas valve 3 180-043 or 180-045 venturi 1 figure 33: gas valve dissassem...

Page 48

Installation and operation instructions 3-6 sl 30-175, sl 45-260 modulating gas boilers 3.5.1 gaining access to combustion chamber, burner removal instructions 1. Remove fan and gas valve assembly. See “fan and gas valve removal instructions” on page 4-6 of this manual. 2. Disconnect the igniter cab...

Page 49: Maintenance

4-1 maintenance sl 30-175, sl 45-260 modulating gas boilers maintenance 4.0 boiler maintenance 4.1.1 general care • keepcombustiblematerialsandflammableliquidsandvapoursawayfromthe boiler. • keep vent terminals clear of obstructions (snow, dirt, etc.). 4.1.2 inspection inspection of the boiler is to...

Page 50

Installation and operation instructions 4-2 sl 30-175, sl 45-260 modulating gas boilers 4.1.6 heat exchanger during annual inspection (with the burner removed), examine the heat exchanger for signs of contamination and clean if neccessary. In areas of poor gas quality, there may be a buildup of blac...

Page 51

4-3 maintenance sl 30-175, sl 45-260 modulating gas boilers 4.1.12 boiler treatment • check consistency of any boiler treatment used, for appropriate mixture. Chemical inhibitors are consumed over time, lowering their density. • verify proper operation after servicing. 4.1.13 relief valve - maintena...

Page 52

Installation and operation instructions 4-4 sl 30-175, sl 45-260 modulating gas boilers geography & components 4.2 turn cover button counter clock wise to loosen cover tilts back, then lift up and off clear access to front components clear access to top components lift top cover up at front top cove...

Page 53

4-5 maintenance sl 30-175, sl 45-260 modulating gas boilers sight glass (flame inspection port) fan air pressure reference tube combustion chamber lid bolts (8 bolts) fan flange bolts removal of vent stack to facilitate service of components located behind it air intake snorkel inlet from cabinet (b...

Page 54

Installation and operation instructions 4-6 sl 30-175, sl 45-260 modulating gas boilers 4.2.1 fan and gas valve removal instructions 1. Turn off electric power at the disconnect switch, and gas supply at the gas control valve to the boiler. 2. Ensure boiler cools down to ambient temperature. Do not ...

Page 55: 5.0 Troubleshooting

5-1 troubleshooting sl 30-175, sl 45-260 modulating gas boilers 5.0 troubleshooting the troubleshooting section is divided into 3 sections: 5.1 preliminary checks 5.2 electronic components 5.3 troubleshooting guide often,aproblemcanbeidentifiedandsolvedthroughsimplechecksofthe basics:confirmingtheel...

Page 56

Installation and operation instructions 5-2 sl 30-175, sl 45-260 modulating gas boilers electronic components this section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature sensors...

Page 57

5-3 troubleshooting sl 30-175, sl 45-260 modulating gas boilers 5.2.2 fan/blower operating power is provided by means of a separate 120 vac connector at the bottom of the fan (white/black/green). Control of the fan is provided via a four lead connector at the top of the fan. This connector feeds a p...

Page 58

Installation and operation instructions 5-4 sl 30-175, sl 45-260 modulating gas boilers next,confirmthatthecircuitisproperlypowered.Thesupplyvoltagetothesensor should be 13.8 vdc; to check, the simplest technique is to measure the circuit on the face of the controller circuit board (vs. An attempt t...

Page 59

5-5 troubleshooting sl 30-175, sl 45-260 modulating gas boilers 5.2.8 optional low water cut off kit aul353certifiedprobe-typelowwatercutoffdevicecanbeorderedfactory installed,oralwcoretrofitkit(ibcpart#p-156a)canbeorderedforaretrofit. The lwco has test and reset buttons, located inside the case nea...

Page 60

Installation and operation instructions 5-6 sl 30-175, sl 45-260 modulating gas boilers 5.3 troubleshooting guide symptom diagnosis remedy airflow error lcd screen message: error – insufficient air flow insufficient combustion airflow; soft error; will retry in 5 minutes check fan operation • checkl...

Page 61

5-7 troubleshooting sl 30-175, sl 45-260 modulating gas boilers symptom diagnosis remedy maximum ignition trials error lcd screen message: error – ignition failure after 3 tries boiler has failed to ignite on 3 successive attempts. Boiler in lockout for 1 hour, then repeats 3-try seq. Consult servic...

Page 62

Installation and operation instructions 5-8 sl 30-175, sl 45-260 modulating gas boilers symptom diagnosis remedy hi limit error lcd screen message: error – water high-limit/lwco water temperature exceeds hi- limit or water level is low. Boiler in hard lockout. Will reset in 1 hour. Consult service t...

Page 63

5-9 troubleshooting sl 30-175, sl 45-260 modulating gas boilers symptom diagnosis remedy noisy spark when igniting ignition lead is not firmly connected. Reconnect ignition lead. Contaminants/ moisture on igniter probe/flame sensor. Ensure probe is dry by re-running post-purge; otherwise, clean or r...

Page 64

Installation and operation instructions 5-10 sl 30-175, sl 45-260 modulating gas boilers 5.3.3 cycling problems symptom diagnosis remedy rapid cycling improper values entered via keypad. Check load maximum temps are above target temps, by 1/2 of the selected boiler differential. Ensure boiler differ...

Page 65

5-11 troubleshooting sl 30-175, sl 45-260 modulating gas boilers symptom diagnosis remedy insufficient heat operating temperature too low. Increase temperature target. See section 2.7 priority parameters or load configuration improperly set up. Reviewloadconfigurationparameters.See section 2.7 unit ...

Page 66

Installation and operation instructions 5-12 sl 30-175, sl 45-260 modulating gas boilers 5.3.5 miscellaneous symptom diagnosis remedy fumes and high humidity improperly installed condensate trap refer to installation/operation instructions leak in vent piping inspect using soap solution flue gas lea...

Page 67: 6.0 Diagrams

6-1 diagrams sl 30-175, sl 45-260 modulating gas boilers 6.0 diagrams 6.1 - parts diagrams 6.2 - wiring diagrams 6.3 - sequence of operation.

Page 68

Installation and operation instructions 6-2 sl 30-175, sl 45-260 modulating gas boilers 6.1 parts diagrams diagram 6.1-1: boiler assembly parts sl 30-175 & sl 45-260 modulating boilers - parts assembly.

Page 69

6-3 diagrams sl 30-175, sl 45-260 modulating gas boilers diagram 6.1-2: boiler assembly parts list (refer to diagram 6.1-1 on opposite page).

Page 70

Installation and operation instructions 6-4 sl 30-175, sl 45-260 modulating gas boilers 6.2 wiring diagrams diagram 6.2-1: ladder wiring diagram cb input to processor input to processor electrical ladder diagram sl 20-115, 30-175, 45-260 load 1 contacts outdoor sensor auxiliary interlock (l.W.C.O., ...

Page 71

6-5 diagrams sl 30-175, sl 45-260 modulating gas boilers diagram 6.2-2: multi-boiler “boiler net” wiring diagram electrical ladder diagram sl 20-115, 30-175, 45-260 sensor terminal blocks, multiple boiler inter-wiring detail sl 20-115, 30-175, 45-260 multi-boiler wiring cb input to processor input t...

Page 72

Installation and operation instructions 6-6 sl 30-175, sl 45-260 modulating gas boilers diagram 6.2-3: internal wiring diagram t sl 30-175, 45-260 internal wiring diagram ibc control boar d vs out 4-20 ma red blue orange yellow black red yellow black red white white white p 102 1 2 4 3 5 6 yellow bl...

Page 73

6-7 diagrams sl 30-175, sl 45-260 modulating gas boilers 6.3 sequence of operation diagram 6.3: sequence of operation diagram.

Page 74

Installation & commissioning report boiler details: model number _____________________ serial number ______________________________________________ date of installation ______________ address of installation __________________________________________ _________________________________________________...

Page 75

Service record date licensed contractor description of work done installer set-up load definition - load #1 _______________________________________________________________________ load configuration - load #1 ___________________________________________________________________________________________...

Page 76

Notes.

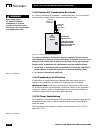

Page 77: Important

Important this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit the use of an external energy management system that serves the same function. Th...

Page 78

Ibc technologies inc. 1445 charles street, vancouver, bc canada v5l 2s7 tel: 604.877.0277 fax: 604.877.0295 www.Ibcboiler.Com 120-156a-r2 september 2012.