- DL manuals

- IBC

- Racks & Stands

- TopFix 200

- Installation Manual

IBC TopFix 200 Installation Manual

Summary of TopFix 200

Page 1

1 installation manual ibc topfix 200 version 17.01, as of: 27-june-2017.

Page 2

2 version 17.01, as of: 27-jun-2017 dear customer, congratulations, you have chosen an ibc product! Experience for yourself the quality and reliability of the ibc topfix 200 module mounting system. To simplify the installation and commissioning of your ibc topfix 200 mounting system, we have include...

Page 3

3 version 17.01, as of: 27-jun-2017 contents 01. What you will need: tool list .........................................................................................................4 02. General information, standards and regulations ..................................................................

Page 4

4 version 17.01, as of: 27-jun-2017 01. What you will need: tool list cordless screwdriver with a variety of bits (torx, phillips, etc.) drill bits (up to Ø 15 mm) pencil tape measure folding rule plumb line open-ended spanner power drill or cordless screwdriver with wrench socket and torque control...

Page 5

5 version 17.01, as of: 27-jun-2017 02. General information, standards and regulations the ibc topfix 200 mounting system is used for installing your solar modules. The modules are fastened by means of clamps and carrier rails. The number of components varies according to the size of the system. Imp...

Page 6

6 version 17.01, as of: 27-jun-2017 please note in particular (this is not an exhaustive list): din/vde 0100, particularly part 712 (erection of power installations with nominal voltage up to 1000v) din/vde 0298 (electrical wiring) vdi 6012 (distributed energy systems in buildings – photovoltaic) di...

Page 7

7 version 17.01, as of: 27-jun-2017 solar modules solar modules may only be used if they hold the following valid certification: iec 61215/iec 61646 and protection class ii/iec 61730 framed solar modules please note that the guarantee for the solar modules will be rendered void if modifications are ...

Page 8

8 version 17.01, as of: 27-jun-2017 laying the cables starting with the frame installation, several points concerning the direction of power lines and laying of cables should be observed. To avoid overvoltage couplings from lightning strikes, the resulting conductor loop must be kept to a minimum. R...

Page 9

9 version 17.01, as of: 27-jun-2017 03. Mounting diagram there are various possibilities for the arrangement of the mounting system and the modules on the roof. The most common option is to horizontally assemble type e.G. Tf50+ carrier rails and arrange solar modules vertically. For this reason, any...

Page 10

10 version 17.01, as of: 27-jun-2017 we have illustrated the layout of the ibc topfix 200 mounting system to improve transparency: figure 2: fastenings for the ibc topfix 200 pitched roof mounting system figure 3: module fastening of the ibc topfix 200 pitched roof mounting system description a sola...

Page 11

11 version 17.01, as of: 27-jun-2017 figure 4: layout of the ibc topfix 200 pitched roof mounting system description l = (mb + 24 mm) × n + 32 mm carrier rail length = (mb + 24 mm) × number of modules per row + 32 mm mb module width mh module height a type tf50+/tf50m/tf60 carrier rail b roof hooks ...

Page 12

12 version 17.01, as of: 27-jun-2017 04. Fitting the various mounting systems 4.1 general dimensioning information the pv system on your roof is subject to considerable forces caused by snow and, most of all, wind. Improper fastening of the pv system, particularly the modules, may cause significant ...

Page 13

13 version 17.01, as of: 27-jun-2017 4.2 fitting the roof hooks in order to comply with warranty conditions (rain-proofing etc.) we recommend having the roof hooks fitted by a roofing firm. Please also take into account the manufacturer's regulations and specifications for the corresponding roofing,...

Page 14

14 version 17.01, as of: 27-jun-2017 if the roof hook cannot be fitted as shown above due to the form of the tile or the position of the depression, it is imperative that a roofer is engaged. Changes to roof covering materials (roof tiles, clay tiles, roof panels, cast stone, etc.) may only be made ...

Page 15

15 version 17.01, as of: 27-jun-2017 4.3 roof hook types important! The specifications of the general building approval z-14.4.-661 for steel roof hooks and z-14.4.-515 for aluminum roof hooks have to be considered. 4.3.1 "standard s+" roof hook generally the "standard" s+" roof hook is used. It is ...

Page 16

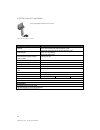

16 version 17.01, as of: 27-jun-2017 4.3.2 "standard s+ 35 mm" roof hooks parameters value material stainless steel 1.4301 s460 yield strength f y,k = 460 n/mm² dimensions base plate (length / width / height) 135/ 70/ 4 mm dimensions hook (width / height) 30/ 6 mm drilling holes baseplate ∅ 9 mm dri...

Page 17

17 version 17.01, as of: 27-jun-2017 4.3.3 "mammut s+" roof hooks "mammut s+" roof hooks are used to ensure the safety of the structure under high snow loads. This roof hook provides improved static characteristics compared with the "standard s+" roof hook. In certain conditions (e.G. Low snow load ...

Page 18

18 version 17.01, as of: 27-jun-2017 4.3.4 “mammut sv+” roof hooks for vertical installation of the carrier profile in the 1st layer. Parameters values material stainless steel 1.4301 s460 yield strength f y,k = 460 n/mm² dimensions base plate (length / width / height) 157/ 65/ 5 mm dimensions hook ...

Page 19

19 version 17.01, as of: 27-jun-2017 4.3.5 “vario s+” roof hooks for horizontal and vertical adjustability at the base plate. Parameters value material stainless steel 1.4301 s460 yield strength f y,k = 460 n/mm² dimensions base plate (length / width / height) 155/ 75/ 5 mm dimensions hook (width / ...

Page 20

20 version 17.01, as of: 27-jun-2017 4.3.6 “schiefer s+” roof hooks special roof hooks designed for the particular roofing tile shape are used for slate tiles. Parameters value material stainless steel 1.4301 s460 yield strength f y,k = 460 n/mm² dimensions base plate (length / width / height) 280/ ...

Page 21

21 version 17.01, as of: 27-jun-2017 4.3.7 “plain tile” roof hook plain tiles have a different shape from normal roofing tiles. For this reason, a different roof hook type is used. Parameters value material stainless steel 1.4301 s460 yield strength f y,k = 460 n/mm² dimensions base plate (length / ...

Page 22

22 version 17.01, as of: 27-jun-2017 4.3.8 “alu-vario s+” roof hooks 4-way adjustable aluminum roof hooks parameters value material hook: alumnium en ac-42100 (din en 1706) base plate: alumnium en ac-43000 (din en 1706) yield strength hook: f y,k = 210 n/mm² base plate: 220 n/mm² dimensions base pla...

Page 23

23 version 17.01, as of: 27-jun-2017 4.3.9 “alu-mammut s+” roof hooks parameters value material alumnium en ac-42100 (din en 1706) yield strength hook: f y,k = 210 n/mm² dimensions base plate (length / width / height) 150/ 63,5/ (12) mm dimensions hook (width / height) 35/ 6-8 mm drilling holes base...

Page 24

24 version 17.01, as of: 27-jun-2017 4.3.10 “alu-mammut sv+” roof hooks for vertical installation of the carrier profile in the 1st layer. Parameters value material alumnium en ac-42100 (nach din en 1706) yield strength hook: f y,k = 210 n/mm² dimensions base plate (length / width / height) 181/ 71/...

Page 25

25 version 17.01, as of: 27-jun-2017 4.4 asd screws- mounting on rafter-mounted insulation systems asd screws are designed to install roof hooks on roofs with rafter-mounted insulation roofing. They are designed so the insulation is fitted on the rafters, between the layer of rafters and the battens...

Page 26

26 version 17.01, as of: 27-jun-2017 two asd flat head screws are required to fasten one roof hook. Each roof hook connection must additionally be secured by a asd countersunk screw to absorb sliding forces at an angle of 60°. Figure 34: inserting flat head screws figure 35: inserted flat head screw...

Page 27

27 version 17.01, as of: 27-jun-2017 4.5 "mammut form s+" roof hook the same conditions and prerequisites as described in section 4.1 apply. "mammut form s+" roof hooks are suitable for 30×50mm and 40×60 mm battens. For available types and colours of tiles, please refer to the ibc premium partner po...

Page 28

28 version 17.01, as of: 27-jun-2017 step 2: figure 38: fastening the batten rail remove roof tile from the specified area horizontally move the reinforcing runner (2) horizontally until the slot on the support member (3) covers the hole of the reinforcing rail. Secure the reinforcing runner using o...

Page 29

29 version 17.01, as of: 27-jun-2017 4.5.2 fitting "mammut form s+" roof hooks on bitumen roofs figure 40: "mammut form s+ bitumen" specify the roof hook position so that the roof hook (1) can be attached to the rafter using screws (3). Secure roof hooks to the roofing substructure using screws (2+3...

Page 30

30 version 17.01, as of: 27-jun-2017 4.5.3 fitting "mammut form s+" roof hooks on plain tile roofing figure 41: "mammut form s+" plain tile dual roofing figure 42: mammut form s+" plain tile crown roofing.

Page 31

31 version 17.01, as of: 27-jun-2017 4.5.4 fitting „mammut form s+“ roof hook for slate and metal shingle roofs step 1: fix the position of the roof hook in such a way, that this can be fastened with the screws in the rafter. Observe the edge distances according figure 121 replace the slate plate wi...

Page 32

32 version 17.01, as of: 27-jun-2017 step 3 step 4 fix the cover cap (4) and the roof hook (5) at the mountig plate with the m6 nuts (6). (torque 10 nm) figure 45 cover cap and roof hook figure 46 roof hook fixing.

Page 33

33 version 17.01, as of: 27-jun-2017 4.6 installation using m12×300 hanger bolts and m10x200 hanger bolts on the timber substructure. Hanger bolts are used on corrugated eternit and trapezoidal sheet metal roofs as well as bitumen roofs to attach the carrier rails. The load bearing roof construction...

Page 34

34 version 17.01, as of: 27-jun-2017 l =100 mm cut hanger bolts using an angle grinder if they protrude too far (comply with accident prevention regulations). For stress reasons, the universal connector must always be mounted in the direction of the roof ridge. Important! The stress values for the m...

Page 35

35 version 17.01, as of: 27-jun-2017 4.7 assembly with solar fasteners on a steel substructure solar fasteners are intended for attachment to metal purlin or rafter structures with roofing made of trapezoidal profiles and sandwich profiles. In this process, the outer shell is made either of steel or...

Page 36

36 version 17.01, as of: 27-jun-2017 please note: comply with the following requirements regarding the roof profile type: the nominal sheet metal profile panel thickness around the fasteners is ≥ 0.4 mm for steel and ≥ 0.5 mm for aluminium. The nominal width of the outer layer of the sandwich elemen...

Page 37

37 version 17.01, as of: 27-jun-2017 4.8 mounting plate duo the mounting plate duo is used for fixing with two hanger bolts or two solar fasteners. The two screws are connected through the mounting plate duo. The rooftop connector profile is then fixed on the mounting plate duo. There are two differ...

Page 38

38 version 17.01, as of: 27-jun-2017 4.9 mounting with trapezoidal sheet metal clamps 4.9.1 introduction ibc solar ag trapezoidal sheet metal mounting in combination with the ibc topfix 200 mounting system is a fast, universal and structurally tested solution for attaching solar modules onto trapezo...

Page 39

39 version 17.01, as of: 27-jun-2017 * the listed tools and auxiliary agents are required exclusively for installation and processing of the trapezoidal sheet metal panels. Information about tools for module and carrier rail mounting is provided in section 1 in these installation instructions. 4.9.3...

Page 40

40 version 17.01, as of: 27-jun-2017 step 4: affix the trapezoidal clamp note: the heavy-duty adhesive tape can be used from an object and working temperature of 0° c; final adhesion occurs after approx. 72 h at an ambient temperature of 20° c. The higher the temperatures, the faster this process is...

Page 41

41 version 17.01, as of: 27-jun-2017 step 6: insert and align the tf27-t carrier rail figure 60: insert the carrier rail figure 61: align the carrier rail figure 62: close the clamp step 7a: affix the trapezoidal clamp to the outer roofing with blind rivets important: a drill with a diameter of 5.0 ...

Page 42

42 version 17.01, as of: 27-jun-2017 step 7b: affix the trapezoidal clamp to the outer roofing with self drilling screws when using the self drilling screws, two screws are placed per trapezoidal clamp. In this process, make sure you screw carefully to maintain static properties. The enclosed self d...

Page 43

43 version 17.01, as of: 27-jun-2017 now insert the 4.8x15mm blind rivets into the bores and rivet. Figure 71: rivet transverse securing clamps step 8b: insert and affix the transverse securing clamp with self drilling screws the transverse securing clamps are affixed next to the trapezoidal clamp o...

Page 44

44 version 17.01, as of: 27-jun-2017 step 9: if required: insert butt connector butt connectors are inserted via the tf27 carrier rail and fixed. Figure 73: insert butt connectors figure 74: joining together the carrier rails the butt connector is either attached using two 4.8x15 mm blind rivets (pr...

Page 45

45 version 17.01, as of: 27-jun-2017 4.9.5 eco trapezoidal system the eco trapezoidal system is a pre-assembled, short-rail system to which trapezoidal profiles are riveted or scrwed together. Important: thermal expansion dictates a thermal separation after 15 modules in one row. Step 1: dimensionin...

Page 46

46 version 17.01, as of: 27-jun-2017 step 4: affixing the "eco trapezoidal system" step 5: distributing the "eco trapezoidal system" as specified step 6a: affix "eco trapezoidal system" to the outer roofing with blind rivets important: a drill with a diameter of 5.0 mm is mandatory to maintain stati...

Page 47

47 version 17.01, as of: 27-jun-2017 figure 80: inserting blind rivets figure 81: riveting using a standard rivet head step 6a: affix "eco trapezoidal system" to the outer roofing with blind rivets when using the self drilling screws, two screws are placed per “clamp base”. In this process, make sur...

Page 48

48 version 17.01, as of: 27-jun-2017 step 7: alignment of pv modules figure 84: aligning pv modules.

Page 49

49 version 17.01, as of: 27-jun-2017 4.10 installation of sheet seam clamps special fastening elements are used to fasten pv modules on standing seam roofs, which are then attached to the carrier rails. The roofing must not be damaged by the load on the installed clamps. For this reason, we recommen...

Page 50

50 version 17.01, as of: 27-jun-2017 05. Fitting carrier rails insert the pre-assembled securing screw (m10 connection piece for roof hook profile) through the roof hook slot. Rotate by 90° and insert into the mounting groove of the e.G. Tf50+ carrier rail. Connect tf50+ carrier rail to the roof hoo...

Page 51

51 version 17.01, as of: 27-jun-2017 important! Do not use fitted carrier rails as step ladders! Figure 90: butt connectors for type tf50 carrier rails important! Ensure that all t-head screws and hammer nuts have engaged with the rail so they are completely inserted. Note: interlocking has been pro...

Page 52

52 version 17.01, as of: 27-jun-2017 figure 91 assembled clamps (sectional view) 06. Fitting pv modules the middle and outer clamp are delivered pre- assembled. The middle clamp g3 covers a clamping area of 30-50 mm. However the outer clamp g3 must be ordered for each module height. G3 middle and ou...

Page 53

53 version 17.01, as of: 27-jun-2017 the middle and outside clamps can be inserted into the carrier rail directly from the top, into the position where they are required. The middle clamp g4 is swiveled into the carrier rail, where it is needed important! The slot nut of the g4 clamp must be aligned...

Page 54

54 version 17.01, as of: 27-jun-2017 the adaptor ec is clamped by the given frame height with the middle clamp g4 and substitutes thus the outer clamp. Subsequently place the first module onto both carrier rails, loosely tighten it to the outside clamps respectively the middle clamp including ec ada...

Page 55

55 version 17.01, as of: 27-jun-2017 07. Fitting cable clips the cable clips are used to fix the module connector cables and prevent sagging of the cable. The clips can be clamped to the carrier rails of the mounting system topfix 200 or to the photovoltaic module frames without any tools. Figure 96...

Page 56

56 version 17.01, as of: 27-jun-2017 08. Fitting the two-layer carrier system 8.1 general information in contrast to single-layer carrier rails, this method additionally employs carrier rails as so-called roof hook connecting rails before the actual carrier rail is fitted. 8.2 type e.G. Tf50+ roof h...

Page 57

57 version 17.01, as of: 27-jun-2017 dimensioning: two-layer systems are dimensioned in the same way as single-layer systems. However, the following special features must be taken into account: plan for one roof hook per area where carrier rail and roof hook connecting rail meet. Please also take in...

Page 58

58 version 17.01, as of: 27-jun-2017 09. Delta support figure 100: delta support 9.1 general information delta supports enable to use the ibc topfix 200 mounting system as an elevated mounting system and achieve optimum module inclination. Delta supports are available with single as well as continuo...

Page 59

59 version 17.01, as of: 27-jun-2017 9.2 assembly assembling single delta supports figure 103: assembling delta supports using single base rails delta supports with single base rails are supplied as complete, folded and pre-assembled units, including three m8×50 hex screws with self-locking nut and ...

Page 60

60 version 17.01, as of: 27-jun-2017 9.3 connection to the roof we offer the following connection types to connect delta supports, depending on the available roof seal and roof substructure: fixation by hanger bolt fixation by universal connector fixation by additional weight (e.G. Positioning walkw...

Page 61

61 version 17.01, as of: 27-jun-2017 figure 108: two--layer fixation (two-layer connector).

Page 62

62 version 17.01, as of: 27-jun-2017 9.4 mounting modules modules can be mounted either horizontally or vertically using delta supports. Modules up to a module size of 1.7 m can are suitable for vertical mounting. Vertical module – clamps on the long sides in this case, delta supports are connected ...

Page 63

63 version 17.01, as of: 27-jun-2017 10. Ibc framefix module frame reinforcements general information we recommend retrofitting ibc framefix frame reinforcements in regions with a high degree of snow loads. A high degree of snow loads on vertically mounted modules may deform the frame and hence rend...

Page 64

64 version 17.01, as of: 27-jun-2017 assembling adapter figure 113: corner bracket figure 114: tensioning piece figure 115 tensioning piece an adapter figure 116 disconnect the cable from the tensioning piece figure 117 insert the adapter under the cable figure 118 adapter mounted.

Page 65

65 version 17.01, as of: 27-jun-2017 11. Bill of materials illustration item no.: item 6800100022 support rail tf50+ (uncut length l = 5200 mm) 6800100023 support rail tf50+ aluminium (uncut length l = 3100 mm) 6800100027 support rail tf50+ (uncut length l = 2100 mm) 6800100033 support rail tf50+ bl...

Page 66

66 version 17.01, as of: 27-jun-2017 illustration item no.: item ibc topfix 200 middle clamp g3 6700400125 middle clamp g3 30-50mm 6700400126 middle clamp g3 30-50mm, black ibc topfix 200 outside clamp g3 6700400127 end clamp g3 31 mm 6700400128 end clamp g3 31 mm black 6700400165 end clamp g3 32mm ...

Page 67

67 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700500005 laminate middle clamp g2 (for module thickness from 6.8 to 8 mm) 6700500006 laminate end clamp g2 (for module thickness from 6.8 to 8 mm) 6700400144 middle clamp g4 33-46mm 6700400145 middle clamp g4 33-46mm black 6700400161...

Page 68

68 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700100027 "mammut s+" roof hook 6700100028 "mammut sv+" roof hook 6700100029 "vario s+" roof hook 6700100030 "biber s+" plain tile roof hook 6700100031 "schiefer s+" slate tile roof hook.

Page 69

69 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700700022- 6700700040 & 6700700042- 6700700097 "mammut form s+" roof hook includes: 1x roof hook with sheet metal tile 1x reinforcing runner 3x 4.2x32 mm drilling screw (tallow- drop screw, galvanised, aw 20) 1x 5.0x120 mm drilling sc...

Page 70

70 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700100038 “alu-mammut s+” roof hook 6700100039 “alu-mammut sv+” roof hook 6700200036 trapezoidal sheet clamp without accessories 6700200037 eco trapezoidal system, 340 mm without accessories 6700200038 eco trapezoidal system, 420 mm w...

Page 71

71 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700200045 hanger bolt m12x250 a2 sw9 including 1x epdm seal 3x m12 a2 self-locking nuts completely pre-assembled 6700200026 hanger bolt m10x200 a2 sw7 including 1x epdm seal 3x m10 a2 self-locking nuts completely pre-assembled 670...

Page 72

72 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700300050 mounting plate duo topfix 200 including screws + universal connector 6700300051 mounting plate duo topfix 200 including connecting connection piece m10 6700200011 standing seam clamp including universal connector 6700200027 ...

Page 73

73 version 17.01, as of: 27-jun-2017 illustration item no.: item delta support, single pre-assembled 6100300024 delta support, 10°, single 6100300025 delta support, 15°, single 6100300026 delta support, 20°, single 6100300027 delta support, 25°, single 6100300028 delta support, 30°, single 610030002...

Page 74

74 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700300046 butt connector tf50+ / tf50-m including 2x m10x25 a2 t-head screws 2x din 6923 m10 a4 locking nuts -> completely pre-assembled 6700300044 butt connector tf60 including 2x m10x25 a2 t-head screws 2x din 6923 m10 a4 locking nu...

Page 75

75 version 17.01, as of: 27-jun-2017 illustration item no.: item 6700300041 rail end cap for tf50+ and tf50m 6700300061 rail end cap black for tf50+ and tf50m 6700300045 rail end cap for tf60 6900300007 flange head screw 6x100 a2 6900300008 flange head screw 8 x 100 a2 6900300010 flange head screw 8...

Page 76

76 version 17.01, as of: 27-jun-2017 illustration item no.: item 6908300003 blind rivet 4.8x15 pu 100 6900600011 self-drilling-screw 5.5x25 pu 100 6700300032 connection piece m10 for roof hooks 6700300053 connection piece m8 for roof hooks 6700300033 universal connection piece 6700200013 clamp for e...

Page 77

77 version 17.01, as of: 27-jun-2017 12. Appendix 12.1 notes on ibc topfix 200 tightening torques for screw connections the tightening torques for the screw connections used in the ibc topfix200 mounting system must be dimensioned in accordance with din iso 3506, to document and archive for 10 years...

Page 78

78 version 17.01, as of: 27-jun-2017 required rafter and purlin dimensions comply with the following minimum dimensions for rafters and purlins as per en 1995-1-1. The minimum rafter/purlin height must be 100 mm. The minimum distance between fastened flat head screws and the edges of rafters and pur...

Page 79

79 version 17.01, as of: 27-jun-2017 12.2 weights/installation times for pitched roof installations weight per m² of module surface weight per kwp thin-film solar modules 10 … 17 kg/m² 130 … 300 kg/kwp crystalline solar modules 11 … 21 kg/m² 70 … 175 kg/kwp single-layer mounting system *2.4 … 5 kg/m...

Page 80

80 version 17.01, as of: 27-jun-2017 12.3 notes on maintenance the ibc topfix 200 mounting system is largely maintenance-free thanks to the materials used. In addition to the electrical inspections prescribed for the entire pv system, we recommend inspections of the pv generator every two years, con...

Page 81

81 version 17.01, as of: 27-jun-2017 ibc solar ag am hochgericht 10 d-96231 bad staffelstein phone +49 (0) 9573-92 24 0 fax +49 (0) 9573-92 24 111 info@ibc-solar.De www.Ibc-solar.Com.