- DL manuals

- IBC Water

- Water Dispenser

- AS0922TC-CL

- Installation & Operating Instructions Manual

IBC Water AS0922TC-CL Installation & Operating Instructions Manual

AS0922TC-CL

Page

1

WATER SOFTENER

WITH TIME CLOCK CONTROL

INSTALLATION & OPERATING

INSTRUCTIONS

Model : AS0922TC-CL

Serial No : ………………………..

Telephone: (07) 3219 2233

Facsimile: (07) 3219 2266

Email: sales@ibcwater.com.au Website: www.ibcwater.com.au

FILTRATION & WATER TREATMENT PRODUCTS

for commercial, industrial and residential application

Manufacturer and Supplier of

Summary of AS0922TC-CL

Page 1

As0922tc-cl page 1 water softener with time clock control installation & operating instructions model : as0922tc-cl serial no : ……………………….. Telephone: (07) 3219 2233 facsimile: (07) 3219 2266 email: sales@ibcwater.Com.Au website: www.Ibcwater.Com.Au filtration & water treatment products for commerci...

Page 2: Warning

As0922tc-cl page 2 time clock model no. Capacity & salt dosage recommended maximum service flow rate pipe size resin volume approx. Shipping weight (kg) space required minimum maximum inlet outlet drain w x d x h gram/kg gram/kg flow lpm mm mm litres per kg metres as0922tc-cl 770/1.4 1540/5.3 22 25b...

Page 3

As0922tc-cl page 3.

Page 4: Basic Installation

As0922tc-cl page 4 fitted with model ws1 valve and tc control check the equipment upon arrival for damage or shortages and report same to our office or agent before starting. Position the softener on a firm foundation, preferably concrete, with sufficient space for operation and maintenance. The sof...

Page 5

As0922tc-cl page 5 1. Water to be tested should be taken from a tap after the water softener 2. Measure 10ml of water into plastic bottle supplied (approximately 1/3 full) 3. Add one yes/no tablet to sample water, replace cap and shake until tablet has completely dissolved. (note: do not handle yes/...

Page 6: Model As0922Tc-Cl

As0922tc-cl page 6 hardness ppm = (number tablets x 2) – 1 contact ibc water if further details are required. Water softener calculations model as0922tc-cl it is necessary to input into the control a number of basic parameters based on the expected water usage of the system and the water hardness le...

Page 7

As0922tc-cl page 7 = 9.3 days = 9 days (nearest lower number) note: maximum number of days that can be selected is 99.

Page 8: Customer/ Installer

As0922tc-cl page 8 the ws1-tc has been factory programmed with the majority of the commands and parameters installed. It is necessary on commissioning of the softener to program in the “days between regenerations as calculated on page 5 and if desired another time of day when regeneration is to proc...

Page 9

As0922tc-cl page 9 power outage when electric power is interrupted the microprocessor will hold all relevant information in memory except for the current time of day. Current time of day when power is restored the display will flash and go to the time-hour setting. Press set hour and input the curre...

Page 10

As0922tc-cl page 10 model as0922 water softener with control valve series model ws1-tc.

Page 11: Specificatons

As0922tc-cl page 11 inlet/outlet fittings 25mm bspf pvc elbows cycles 6 valve material noryl (1) or equivalent regeneration down flow flow rates service @15psi/1 bar drop (includes bypass & meter) 102 lpm backwash @25psi/1.7 bar drop (includes bypass) 102 lpm operating pressure minimum/maximum 330-6...

Page 12

As0922tc-cl page 12 table of contents specifications …………………………………………………………… 9 introduction ……………………………………………………………… 11 special features general conditioner information …………………………………….. 11 how your conditioner works model tc control front panel installation – important installation details….……………………...

Page 13

As0922tc-cl page 13 introduction the model tc control provides sophisticated electronic time clock-based water conditioning. The control is factory default programmed for the majority of the required settings and only requires simple minimal on site programming for the remaining settings to suit the...

Page 14

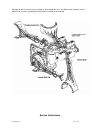

As0922tc-cl page 14 • bypass untreated water is automatically available during regeneration unless a prevention solenoid valve fitted. Installation all plumbing and electrical connections must conform to local codes. Inspect the unit carefully for carrier shortage or shipping damage. Location select...

Page 15

As0922tc-cl page 15 important installation details the control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments but are not designed to support the weight of the system or the plumbing. Do no use vaseline, oils, other hydrocarbon lubricants or spray silicone any...

Page 16

As0922tc-cl page 16 water is supplied to the plumbing system. (figure 2) 3. Diagnostic position: the inlet handle points in the direction of flow and the outlet handle points to the centre of bypass valve, system water pressure is allowed to the control valve and the plumbing system while not allowi...

Page 17

As0922tc-cl page 17 water conditioner regeneration your water conditioner regenerates for one of two reasons: • the control determines that the conditioner has reached the days to regen. Setting. • the regen button was manually pressed. Automatic regeneration the control makes regeneration decisions...

Page 18

As0922tc-cl page 18 brine line connection the brine line comprises a pick up air check assembly installed in the brine wall in the cabinet and connected by tubing to the brine elbow on top of the valve. Note: make sure that all fittings and connections are tight so that premature checking does not t...

Page 19

As0922tc-cl page 19 placing softener into operation initial start-up 1. Mains water turned off to unit or bypass valve in shut off mode. 2. Connect transformer to power point and turn on. 3. Program controller as per “customer/install programming instructions”. 4. Press the “ ▲▼” buttons in once sim...

Page 20

As0922tc-cl page 20 ws1-tc manual control valve function and cycles of operation this glass filled noryl 1 (or equivalent) fully automatic time clock control valve is designed as the primary control center to direct and regulate all cycles of a water softener. The control valve is set to regenerate ...

Page 21

As0922tc-cl page 21 the pc board powers the motor. The pc board’s two- prong jack connects wires to the direct current (dc) motor. The motor is held in place on the drive bracket by a spring-loaded clip and a small bulge in the plastic, which fits in one of the slots on the motor housing. The motor ...

Page 22

As0922tc-cl page 22 the refill flow control assembly is installed in an easy to access refill elbow located on top of the control valve.. The refill flow control assembly is attached to the control valve with a locking clip. The locking clip allows the elbow to rotate 270 degrees so the outlet can b...

Page 23: Spare Parts

As0922tc-cl page 23 spare parts and servicing instructions.

Page 24

As0922tc-cl page 24 ws1-tc front cover and drive assembly drawing no. Order no. Description quantity 1 v3175tc-01 ws1tc front cover assembly 1 2 v3107-01 ws1 motor 1 3 v3106-01 ws1 drive bracket & spring clip 1 4 v3108tc ws1 pc board 1 5 v3110 ws1 drive gear 12x36 3 6 v3109 ws1 drive gear cover 1 v3...

Page 25

As0922tc-cl page 25 ws1tc drive cap assembly, downflow piston, regenerant piston and spacer stack assembly drawing no. Order no. Description quantity 1 v3005 ws1spacer stack assembly 1 2 v3004 drive cap asy 1 3 v3178 ws1 drive back plate 1 4 v3011 ws1 piston downflow asy 1 5 v3174 ws1 regenerant pis...

Page 26

As0922tc-cl page 26 injector cap, injector screen, injector, plug and o-ring drawing no. Order no. Description quantity 1 v3176 injector cap 1 2 v3152 o-ring 135 1 3 v3177 injector screen 1 v3010-1a ws1 injector assy - black v3010-1b ws1 injector assy - brown v3010-1c ws1 injector assy - violet v301...

Page 27

As0922tc-cl page 27 refill flow control assembly drawing no. Order no. Description quantity 2 h4615 elbow locking clip 1 3 jcp-p-6 polytube insert 3/8” 1 4 jcpg-6pblk nut 3/8” 1 5 h4613 elbow cap 3/8” 1 6 v3163 o-ring 019 1 7 v3165-01* ws1 rfc retainer asy 1 8 v3182 wsc rfc 1 not shown h4650 elbow ½...

Page 28

As0922tc-cl page 28 drain line – ¾” drawing no. Order no. Description quantity 1 h4615 elbow locking clip 1 2 pkp10ts8- bulk polytube insert 5/8 option 3 v3192 ws1 nut ¾ drain elbow option 4 v3158-01 ws1 drain elbow ¾ male 1 5 v3163 o-ring 019 1 6 v3159-01 ws1 dlfc retainer asy 1 v3162-007 ws1 dlfc ...

Page 29

As0922tc-cl page 29 installation fitting assembly order no: v3007-01 description: ws1 fitting ¾” & 1” pvc solvent 90 ۫ asy drawing no. Order no. Description quantity 1 v3151 ws1 nut 1” quick connect 2 2 v3150 ws1 split ring 2 3 v3105 o-ring 215 2 4 v3189 ws1 fitting ¾ & 1 pvc solvent 90 2.

Page 30

As0922tc-cl page 30 bypass valve drawing no. Order no. Description quantity 1 v3151 ws1 nut 1” quick connect 2 2 v3150 ws1 split ring 2 3 v3105 o-ring 215 2 4 v3145 ws1 bypass 1” rotor 2 5 v3146 ws1 bypass cap 2 6 v3147 ws1 bypass handle 2 7 v3148 ws1 bypass rotor seal retainer 2 8 v3152 o-ring 135 ...

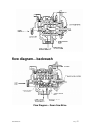

Page 31: Flow Diagram…service

As0922tc-cl page 31 10 v3156 o-ring 214 2 flow diagrams – service and backwash flow diagram…service.

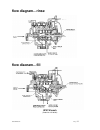

Page 32: Flow Diagram…backwash

As0922tc-cl page 32 flow diagram…backwash flow diagram – down flow brine.

Page 33

As0922tc-cl page 33 flow diagram…downflow brine flow diagrams – rinse and fill.

Page 34: Flow Diagram…rinse

As0922tc-cl page 34 flow diagram…rinse flow diagram…fill ws1 wrench (order no. V3193-01).

Page 35

As0922tc-cl page 35 although no tools are necessary to assemble or disassemble the valve, the ws1 wrench (shown in various positions on the valve) may be purchased to aid in assembly or disassembly. Service instructions.

Page 36

As0922tc-cl page 36 drive assembly remove the valve cover to access the drive assembly. Disconnect the power source plug (black wire) from the pc board prior to disconnecting the motor from the pc board. The power source plug connects to the four-pin jack. The motor plug connects to the two-pin jack...

Page 37

As0922tc-cl page 37 board. If the motor will not easily engage with the drive gears when reinstalling, lift and slightly rotate the motor before reinserting. Reconnect the power plug. Replace the valve cover. After completing any valve maintenance, press set hour and down ▼buttons for 3 seconds or u...

Page 38

As0922tc-cl page 38 reattach the main piston to the drive cap assembly. Reattach the regenerant piston to the main piston. Do not lubricate the piston rod, main piston or regenerant piston. Lubricant will adversely affect the clear lip seals. Reinsert the drive cap assembly and piston into the space...

Page 39

As0922tc-cl page 39 application injector and/or plug(s) main piston regenerant piston stack body ws1tc downflow softener or regenerating filter injector in “dn” hole. V3011 v3174 v3005 v3001 refill flow control assembly or refill port plug to clean or replace the refill flow control, pull out the el...

Page 40

As0922tc-cl page 40 order no.: v3009 description: ws1 auxiliary micro switch assembly iliary micro switch assembly order no.: v3009 description: ws1 auxiliary microswitch assembly drawing no. Order no. Description quantity 1 v3301 ws1 microswitch 1 2 v3302 ws1 molex connector 1 not shown v3303 ws1 m...

Page 41

As0922tc-cl page 41.

Page 42

As0922tc-cl page 42 troubleshooting.

Page 43

As0922tc-cl page 43 your water conditioning system is designed and manufactured for efficient, low maintenance service. However, if problems do occur, this section provides a list of possible causes and solutions. Alarms the control continuously monitors itself and sends an error to the display if i...

Page 44

As0922tc-cl page 44 table 3 – troubleshooting procedures - cont… 6. Control does not draw brine. A. Low water pressure b. Restricted drain line. C. Injector or injector screen plugged. ! D. Injector defective. ! E. Valve general malfunction f. Air check prematurely closed in brine tank a. Increase w...

Page 45

As0922tc-cl page 45 microprocessor troubleshooting procedures problem possible cause solution a. Ac adapter unplugged a. Connect power b. No electric power at outlet b. Repair outlet or use working outlet c. Defective ac adapter c. Replace ac adapter 1. Timer does not display time of day. D. Defecti...

Page 46

As0922tc-cl page 46 glossary of terms alarms display errors alert you to operating conditions requiring attention. The display shows the type of error. Refer to the alarms section in this manual for additional information. Backwash an upward flow of water, which expands the resin bed to remove forei...