- DL manuals

- IBC Water

- Water Dispenser

- AST1257-940

- Installation & Operating Instructions Manual

IBC Water AST1257-940 Installation & Operating Instructions Manual

AST1257-940

Page

1

WATER SOFTENER

WITH 12 DAY SERIES

TIMER CONTROL

INSTALLATION & OPERATING

INSTRUCTIONS

Model : AST1257-940

Serial No : ………………………..

Telephone: (07) 3219 2233

Facsimile: (07) 3219 2266

Email: sales@ibcwater.com.au Website: www.ibcwater.com.au

FILTRATION & WATER TREATMENT PRODUCTS

for commercial, industrial and residential application

Manufacturer and Supplier of

Summary of AST1257-940

Page 1

Ast1257-940 page 1 water softener with 12 day series timer control installation & operating instructions model : ast1257-940 serial no : ……………………….. Telephone: (07) 3219 2233 facsimile: (07) 3219 2266 email: sales@ibcwater.Com.Au website: www.Ibcwater.Com.Au filtration & water treatment products for...

Page 2: Hardness Test

Ast1257-940 page 2 1. Water to be tested should be taken from a tap after the water softener 2. Measure 10ml of water into plastic bottle supplied (approximately 1/3 full) 3. Add one yes/no tablet to sample water, replace cap and shake until tablet has completely dissolved. (note: do not handle yes/...

Page 3: Model Ast1041-940

Ast1257-940 page 3 to ascertain days between regeneration periods the following data or estimations are required. (let n be the number of days to be calculated) .1. ð water hardness in mg/l call ð h .2. ð water softener hardness removal capacity from table 1 in grams call ð c .3. ð daily water usage...

Page 4: Water Softener

Ast1257-940 page 4 water softener performance data sheet automatic model no. Capacity & salt dosage recommended maximum service flow rate pipe size resin volume approx. Shipping weight (kg) space required minimum maximum contin uous peak inlet outlet drain w x d x h gram/kg gram/kg flow lpm flow lpm...

Page 5

Ast1257-940 page 5 installation of ibc two tank water softener unit fitted with model 255 valve/940 control check the equipment upon arrival for damage or shortages and report same to our office or agent before starting. Position the softener and brine tank on a firm foundation, preferably concrete,...

Page 6

Ast1257-940 page 6 note: on a number of softener models and filters it is necessary to package the valve with the top strainer supplied loose. It is important that this strainer is assembled to the valve during installation. The length of the internal riser pipe is factory adjusted for the tank size...

Page 7

Ast1257-940 page 7 940i low voltage timer control the softener control fitted is powered by a 240 to 12 volt transformer. The transformer plugs into a 10amp 240volt gpo and the transformer lead plugs into a socket located on the back of the timer at the left-hand side. The transformer is only suitab...

Page 8

Ast1257-940 page 8 water conditioning control system installation, operating and maintenance manual series 255 valve / 940 control.

Page 9

Ast1257-940 page 9 table of contents page introduction ……………………………………………………………… 10 superior design superior operation installation ……………………………………………………………….. 10 location selection water line connection drain line connection brine line connection brine tank overflow line connection electrical connect...

Page 10

Ast1257-940 page 10 introduction thank you for purchasing a water conditioner system featuring the series 255 with a model 940 control. The model 940 control provides dependable time clock based operation. The series 255 valve combines simplicity with reinforced noryl * construction to provide an un...

Page 11

Ast1257-940 page 11 figure 1 - control bypass valve (optional) air check brine tube fitting connection 1/4" figure 2 - tank adaptor tank tread 2-1/2" - 8 male npsm drain connection 3/8" or 1/2" npt or bspt outlet connection 3/4" or 1" npt or inlet connection 3/4" or 1" npt or bspt.

Page 12

Ast1257-940 page 12 water line connection a bypass valve system must be installed to provide for occasions when the water conditioner must is by- passed for hard water or for servicing. The most common bypass systems are the autotrol series 156 bypass valve, figure 3, and plumbed-in globe valves, fi...

Page 13

Ast1257-940 page 13 2. Insert the overflow fitting (not supplied) into the tank and tighten with the plastic thumbnut and gasket as illustrated in figure 6. 3. Attache a length of 1/2in (1.3cm) tubing (not supplied) to the fitting and run to the drain. Note: don not elevate the overflow line higher ...

Page 14

Ast1257-940 page 14 finally, rotate the indicator knob counter- clockwise until the indicator points to regeneration complete. Run water from a nearby cold-water faucet until the water is clear and soft. Adjustment of timer 1. Set days of regeneration (figure 8). • pull all day pins outward (away fr...

Page 15

Ast1257-940 page 15 gpm flow control. One gallon of water will dissolve 3.0 pounds of salt. To calculate the time for brine refill, it is necessary to determine the needed pounds of salt and divide that number by three (3 pounds per gallon) and also divide by the flow control gpm. The result is the ...

Page 16

Ast1257-940 page 16 4. Slide the camshaft back, disengage it from the timer, figure 12. 5. Lift the timer off the valve, figure 13. 6. To replace the timer, reverse the above procedure. Note: the camshaft and the timer indicator knob need to be positioned correctly before the camshaft can be install...

Page 17

Ast1257-940 page 17 5. Apply downward hand pressure on the valve and remove the locking bar, figure 16. 6. Using the rocking motion, lift the valve from the tank adaptor, figure 16. If the o-ring seals come off with the valve put them back into the tank adaptor sockets. Lubricate the o-rings with si...

Page 18

Ast1257-940 page 18 10. Slowly open the water supply valve or return the bypass valve(s) to the not in bypass" position. 11. Reconnect electric power, and reset the time of day. Hydrostatic test pressure ……………………………………………………………………………. 300 psi (2069kpa) working pressure ………………………………………….. 20 to 127 p...

Page 19

Ast1257-940 page 19 distributor tube length …………………………………………... 1 1/4 in (31.8mm) higher than top of mineral tank standard manifold connection ……………………… 3/4 in npt inlet-outlet, 1/2 in npt drain in noryl manifold, 3/8 in npt drain in brass manifold optional manifold connections …………… 1 in npt inlet-...

Page 20

Ast1257-940 page 20 control valving identification valve disc operation.

Page 21

Ast1257-940 page 21 flow diagrams.

Page 22

Ast1257-940 page 22.

Page 23

Ast1257-940 page 23 replacement parts 940 timer code part no. Description qty 1 1000855 backplate 1 2 1000879 gear support plate, 12 - hour clock 1 3 1000881 timer cover, english standard 1 4 1000887 7 - day calendar cap assembly 1 5 1000888 12 - day calendar cap assembly 1 6 1000877 main drive stac...

Page 24

Ast1257-940 page 24.

Page 25

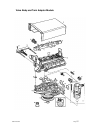

Ast1257-940 page 25 valve body and tank adaptor module.

Page 26

Ast1257-940 page 26 code part no. Description qty 1 1000238 valve assy. W/o flow controls 1 2 1000824 camshaft, std, one-piece 1 3 1000827 valve cover, black 1 4 brine refill flow control assy. : 1 1000221 .14 gpm 1000222 .33 gpm 1000223 .40 gpm 5 1000226 screen/cap assy. With o-ring 1 6 backwash co...

Page 27

Ast1257-940 page 27 code part no. Description qty 1 1040769 bypass body assy 1 2 1040524 installation kit: 3 1001606 3/4 in copper tube adaptor kit 1 1001670 1 in copper tube adaptor kit 1 1001608 22mm copper tube adaptor kit 1 1001609 28mmcopper tube adaptor kit 1 1001613 3/4 in cpvc tube adaptor k...

Page 28

Ast1257-940 page 28 troubleshooting the technology upon which the series 255/940 control is based, is well established and proven in service over many years. However, should a problem or question arise regarding the operation of the system, the control can be very easily serviced. The control module...

Page 29

Ast1257-940 page 29.

Page 30

Ast1257-940 page 30 disinfection of water conditioners the construction materials of the water conditioner system do not support bacterial growth or contaminated the water supply. However, we recommend that the conditioners be disinfected after installation and before the conditioners are used to tr...