- DL manuals

- IBM

- Desktop

- 7012 G Series

- Service Manual

IBM 7012 G Series Service Manual

Summary of 7012 G Series

Page 1

7012 g series service guide.

Page 2: Third Edition (April 1997)

Third edition (april 1997) this edition notice applies to the 7012 g series service guide. This edition obsoletes all previous editions. The following paragraph does not apply to the united kingdom or any country where such provisions are inconsistent with local law: this publication is printed “as ...

Page 3: Table of Contents

Preface iii table of contents communications statements vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety notices xi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . About this book xi...

Page 4

Iv service guide reset 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power-off 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . System bo...

Page 5

Preface v chapter 6. Expansion installation 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rs-485 cable interconnection 6-...

Page 6

Vi service guide.

Page 7: Communications Statements

Preface vii communications statements the following statement applies to this product. The statement for other products intended for use with this product appears in their accompanying manuals. Federal communications commission (fcc) statement note: this equipment has been tested and found to comply...

Page 8

Viii service guide european union (eu) statement this product is in conformity with the protection requirements of eu council directive 89/336/eec on the approximation of the laws of the member states relating to electromagnetic compatibility. Neither the provider nor the manufacturer can accept res...

Page 9

Preface ix radio protection for germany dieses gerät ist berechtigt in Übereinstimmung mit dem deutschen emvg vom 9.Nov.92 das eg-konformitätszeichen zu führen. Der aussteller der konformitätserklärung ist die ibm germany. Dieses gerät erfüllt die bedingungen der en 55022 klasse a. Für diese klasse ...

Page 10

X service guide.

Page 11: Safety Notices

Preface xi safety notices note: for a translation of these notices, see system unit safety information, order number sa23-2652. Definitions of safety notices a danger notice indicates the presence of a hazard that has the potential of causing death or serious personal injury. A danger notice appears...

Page 12

Xii service guide laser safety information the optical drive in this system unit is a laser product. The optical drive has a label that identifies its classification. The label, located on the drive, is shown below. Class 1 laser product laser klasse 1 luokan 1 laserlaite appareil a laser de classe ...

Page 13: About This Book

Preface xiii about this book this book provides maintenance information that is specific to the 7012 g series system unit, adapters, and attached devices that do not have their own service information. It also contains maintenance analysis procedures (maps) that are not common to other systems. Maps...

Page 14

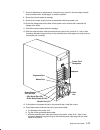

Reference information 1-1 chapter 1. Reference information use the following views of the system unit to locate the feature positions, connectors, and system board slot positions. Base unit system unit locations media bays front door operator panel 3.5-inch diskette drive front cover left side cover...

Page 15

1-2 service guide rear view without cover parallel port (p1) adapters power cord receptacle power control port (rs-485) mouse 9-pin serial port (s3) 25-pin serial port (s1/s2) rear fan keyboard.

Page 16

Reference information 1-3 side view without covers micro channel adapter cards optional second cpu card position 0 or two disk drives positions f and g (g30 only) disk drive positions d and e system planar media drive position a media drive position b diskette drive position c operator panel power s...

Page 17

1-4 service guide memory cards there are four types of memory cards as shown below. Memory cards can house from one to four memory module kits composed of four memory modules each, which comply with the jedec standard for 68 pin, ecc, 60 ns, 5 volt memory modules. The figure below illustrates the ty...

Page 18

Reference information 1-5 • nf256 board, based on 16m bit technology, which gives 256mb memory. It contains two mm128 memory module kits. • nf512 board, based on 16m bit technology, which gives 512mb memory. It contains four mm128 memory module kits. • nf1024 board, based on 16m bit technology, whic...

Page 19

1-6 service guide expansion unit system unit locations description of the disk expansion unit the disk expansion unit is used to increase the number of media devices and/or disk drives. All hardware components inside the disk expansion unit are accessible from the left side after having removed the ...

Page 20

Reference information 1-7 rear side the following figure shows the rear side of the disk expansion unit. Rear fan rs-485 out port rs-485 in port scsi connector to base unit power cord connector disk expansion unit scsi bus the disk expansion unit is equipped with one internal scsi bus. It is driven ...

Page 21

1-8 service guide rs-485 card the rs-485 card is installed in the rear of both the base and the disk expansion units. It is provided with a variety of connectors, whose functions are explained in the following figures. Mouse external fan keyboard rs-485 power/signal connector (coming from the operat...

Page 22

Reference information 1-9 cluster power control the cluster power controller (cpc) provides: • connectivity between the remote support facility and multiple cpus through the modem • connectivity from any attached cpu to any disk drive drawer • central power-on and power-off through the tty. The cpc ...

Page 23

1-10 service guide system planar connector locations power supply power cable connector power supply signal cable connector operator panel connector diskette drive connector battery connector memory card cpu card position 0 adapter slots parallel port serial ports 1 and 2 (with splitter) serial port...

Page 24: Data Flow

Reference information 1-11 data flow cpu card 60x l2 tag l2 cac address bus data bus smc dcb memory bus bump standard io system io mca bus mca bus memory card and dimms system planar cpu array memory array expansion unit i/o controller jtag bus cop bus ssga i2c bus eprom ram s2 service console s3 s1...

Page 25

1-12 service guide power flow operator panel tod eeprom standby voltages +5 +12 –12 pdu power voltages +5 +3,3/3,6 –12 +12 disk disk diskette system ac cable power supply front fan module rear fan module system planar cpu cards media position a media position b 3.5-inch system guard processor local ...

Page 26

Reference information 1-13 scsi cable routing scsi controller 3rd disk 1st disk 2nd disk 4th disk upper dev. Lower dev. Terminator scsi controller 1st disk 2nd disk upper dev. Lower dev. Terminator f (2) d (0) g (3) e (1) (4) (5) d (0) e (1) (4) (5) 6-position scsi cable 4-position scsi cable.

Page 27: Specifications

1-14 service guide specifications dimensions (vertical position) height: 450mm (17.5 inches) depth: 613mm (28.2 inches) width: 173mm (6.9 inches) weight (maximum) 19 kg to 25 kg (43 to 55 pounds) operating environment – class b temperature: 16 ° to 32 ° c (60 ° to 90 ° f) humidity: 8% to 80% maximum...

Page 28: Power Cables

Reference information 1-15 power cables to avoid electrical shock, a power cable with a grounded attachment plug is provided. Use only properly grounded outlets. Power cables used in the u.S.A. And canada are listed by underwriter’s laboratories (ul) and certified by the canadian standards associati...

Page 29: Service Inspection Guide

1-16 service guide service inspection guide perform a service inspection on the system when: • the system is inspected for a maintenance agreement. • service is requested and service has not recently been performed. • an alterations and attachments review is performed. • changes have been made to th...

Page 30

Reference information 1-17 7. Check for alterations or attachments. If there are any, check for obvious safety hazards such as broken wires, sharp edges, or broken insulation. 8. Check the internal cables for damage. 9. Check for dirt, water, and any other contamination within the system unit. 10.Ch...

Page 31: Introduction

Using systemguard 2-1 chapter 2. Using system guard this chapter introduces the systemguard service processor which is included in all symmetric multiprocessor models. Introduction smp servers include a service processor, called systemguard, as a standard feature. Systemguard continually monitors th...

Page 32: Systemguard Power

2-2 service guide systemguard power systemguard has its own dc power boundary. This means that even if the system power is off (power button of the system in the off position), systemguard is still powered on, as long as the unit is still plugged into a power outlet. This allows control of the syste...

Page 33: The Operator Panel

Using systemguard 2-3 the operator panel the operator panel is the first level of user interface to systemguard. The operator panel has the following features: power button it should generally stay pushed in all the time if you want to be able to power on or off the system remotely. Reset button it ...

Page 34: Systemguard Consoles

2-4 service guide systemguard consoles systemguard works with two types of consoles: • the bump console, which is an ascii terminal attached to the s1 serial port. This console provides the normal input to the bump. It can be local or remote. The line speed for the bump console must be set to 9600 b...

Page 35

Using systemguard 2-5 init phase init phase is entered when the power button on the operator panel is pressed on or when the power-on command is entered on the bump console or service console. If the system key is in normal mode, the bump runs the built-in or resident power-on (pon)-tests on the sys...

Page 36

2-6 service guide phase change (stand-by to init stage) the phase change from stand-by to init is called crossing the power boundary. This is achieved by pushing the power button on the operator panel or by typing the keyword power at the stand-by prompt (>). Note that if you type power while the po...

Page 37

Using systemguard 2-7 power-on (pon) tests pon tests are run by systemguard whenever the system power comes on. There are two types of tests: • a comprehensive set of tests are performed on the processors, cache, memory and related hardware when the fast-ipl flag is disabled. • a minimum core set of...

Page 38

2-8 service guide • enabling at least one processor from the stand-by menu there are other resident pon tests to check other system resources. These tests are a subset of the systemguard maintenance offline tests, and reside within the flash eeprom. These tests are divided into the following groups:...

Page 39

Using systemguard 2-9 phase change (init to boot) the maintenance phase is entered from the init phase if the system key is in service mode. If the bump console present flag is set, the maintenance menu is displayed on the bump console, and the system waits for an operator action. The maintenance me...

Page 40

2-10 service guide working with systemguard you can change systemguard parameters and flags from different locations they can be changed from the systemguard stand-by menu, the systemguard maintenance menu, the diagnostics interface, and also from aix. When the key signal is received, systemguard cl...

Page 41

Using systemguard 2-11 when the system is in stand-by mode and the system key (physical or electronic key) is in service mode, the stand-by menu can be accessed and systemguard executed. If you turn the system unit power on from stand-by mode with the system key in the normal position, the system bo...

Page 42

2-12 service guide stand-by menu the stand-by menu can only be entered when the system is in stand-by mode (the word stand-by must be displayed on the lcd display). Perform the following steps to bring up the stand-by menu. 1. With stand-by displayed on the lcd display press the enter key on the bum...

Page 43

Using systemguard 2-13 how to display the system configuration the system configuration can be displayed through the stand-by menu or through the maintenance menu. Displaying configuration through the stand-by menu this option displays the system configuration table. This configuration can be viewed...

Page 44

2-14 service guide display configuration sib14 ps04 sib24 sib15 ps05 sib25 sib16 ps06 sib26 fc8e000000000000 sib17 ps07 sib27 mp d78605 19h0464 mpe d78605 mca 01 c fc8e000000000000 mcae 01 c e1ff000000000000 mca 02 c f48e000000000000 mcae 02 c 708f000000000000 mca 03 c fc8e000000000000 mcae 03 c ec8...

Page 45

Using systemguard 2-15 • cpux ec+s: the agent status information of the cpu cards and the vpd information is given. • mcx ec+s: this field gives the memory card vpd values. • mcax loc. Code+status: this parameter contains the location code and the status information of the micro channel adapters (mc...

Page 46

2-16 service guide and parameters (set during manufacturing), see the table in “default parameter values” on page b–1 of the service guide for your system. The following flags can be managed: • remote authorization: only the local operator can enable this flag to enable remote maintenance to be perf...

Page 47

Using systemguard 2-17 set configuration this menu option enables you to configure or unconfigure units and devices. 1. Enter 3 in the main menu to select this option. 2. You should then see a first-level screen similar to the following. It displays the units and devices that can be configured, alon...

Page 48

2-18 service guide ssbus maintenance this option is used to investigate and check devices on the ssbus and is meant only for trained service personnel. Use this option to investigate and check devices on the ssbus. 1. Enter 4 in the main menu to select this option. Systemguard displays the following...

Page 49

Using systemguard 2-19 i 2 c maintenance use this option to do maintenance operations on the i 2 c buses of a selected unit, in order to investigate and check the connected devices. When exiting this menu, the previous status of the op and sib microcontrollers are restored (except for voltage margin...

Page 50

2-20 service guide set voltage margins note: this option can be only used for error analysis or factory test and must be used only by trained service personnel. Restore nominal voltage values before restarting other operations. Any data written on the disk in marginal mode must be removed before res...

Page 51

Using systemguard 2-21 maintenance menu the maintenance menu also enables you to display the configuration of the system in a non-cryptic, easily understandable way, to perform various tests, to continue ipl either from network, a specific scsi device or from the boot list, and to set flags concerni...

Page 52

2-22 service guide display configuration use this option to view the system hardware configuration. This option provides different screens with the following levels of information: • system-level information • unit-level information • device-level information. Enter 0 in the maintenance menu to sele...

Page 53

Using systemguard 2-23 • voltage margins for cpus, asics, and other components. • device status information. • options to select various types of devices. Display configuration – main unit margins value: +5 volt –> normal cpu (3.65 volt) –> normal asic (3.6 volt) –> normal scsi devices: present –> #...

Page 54

2-24 service guide 1. To see device-level information, enter the corresponding command number for the device. The device-level screen is displayed. 2. Enter x to return to the system-level configuration display screen. Display configuration – device level this screen is shown when you select one of ...

Page 55

Using systemguard 2-25 display bump error log use this option to view the bump firmware error log. 1. Enter 1 in the maintenance menu to select this option. The contents of the logging buffer are displayed as shown in the following screen: display bump error log event # 1: 40140100000000000000000000...

Page 56

2-26 service guide system boot this command enables you to begin boot activity. Enter 6 in the main menu to select this option. The following screen is displayed: system boot 0> boot from list 1> boot from network 2> boot from scsi device select [x:exit]: the menu enables you to boot in three differ...

Page 58

2-28 service guide off-line tests attention: these menus are only to be used when directed by service support personnel. Some of the tests described require test equipment or resources not available on your system. This option under the maintenance menu enables you to run the off-line tests in a con...

Page 59

Using systemguard 2-29 0 displays the build test menu, which enables you to specify the test list (see “build test list” below). 1 displays and enables modification of the tests in the build list (see page 2-31). 2 deletes the tests in the build list, after operator confirmation. Attempting to delet...

Page 60

2-30 service guide 3. Once you have selected the test groups, you can specify individual tests within a group. For example, the following screen enables you to specify individual bump quick io tests: build test list group 01 bump quick io test description test description 01 debug line 02 s1 asl (bu...

Page 61

Using systemguard 2-31 modify/display test list once the test list is built, you can use this option to view or modify it. Each test is identified by a number xxyy, where xx is the group number and yy is the test number. 1. Enter 2 in the off-line tests menu to view or modify the test list. The foll...

Page 62

2-32 service guide execute test list this command enables you to run the test list once it is built (and possibly modified). All the tests in the test list are run one at a time with the selected execution options. • enter 3 in the off-line tests main menu to run the selected tests. The following sc...

Page 63

Using systemguard 2-33 power-on command parameters during the standby idle phase, the system power can be turned on (and the ipl started) by entering a bump console power-on string through line s1 or a service console power-on string through line s2 (see “working with systemguard” on page 2-10 for a...

Page 64

2-34 service guide set configuration this command is used to configure electronic boards like i/o cards or micro channel adapter (mca) devices. 1. Enter 2 in the set parameters menu to display the set configuration menu as shown below: set configuration 0> cpu card 1> memory card 2> basic mca adapte...

Page 65

Using systemguard 2-35 1. Enter 3 in the set parameters menu to display the phone numbers menu shown here: phone numbers 0> service center dial–out (1) –> 1> service center dial–out (2) –> 2> customer hub dial–out (1) –> 3> customer hub dial–out (2) –> 4> system dial–in –> 5> system operator voice –...

Page 66

2-36 service guide • enter 4 in the set parameters menu to display the miscellaneous parameters menu. The value set for all the flags, except fast ipl, is permanent until a new change is made. Miscellaneous parameters 0> bump console –> present 1> autoservice ipl –> disabled 2> dial_out authorizatio...

Page 67

Using systemguard 2-37 2. The new flag status (opposite of the previous state) is displayed. Boot multiuser aix in service flag enables multiuser aix boots to proceed even if the mode switch is in the service position (when booting by selecting option 6 in the maintenance menu). When the flag is ena...

Page 68

2-38 service guide set national language use this option in the main menu to set the national language used for “systemguard”. Once selected, the effect is immediate and all the console messages are presented in the selected language. 1. Enter 9 in the maintenance menu to select this option. The fol...

Page 69

Using systemguard 2-39 some common systemguard tasks the following tasks are done through the stand-by and maintenance menus that are part of systemguard. Note that these tasks can also be carried out from aix diagnostics. How to set the electronic key the key can be set electronically, making it ea...

Page 70

2-40 service guide display configuration machine type/model: 7013j30 45067 firmware release: standby –> 1600 backup eprom –> 0701 flash eprom –> 0704 service contract: last update (yymmdd) –> 950707 validity –> unlimited contract remote service support –> valid quick on call service –> not valid aut...

Page 71

Using systemguard 2-41 setting fast ipl through the maintenance menu 1. Enter the maintenance menu. 2. Enter 8 to select the set parameters menu. 3. Enter 4 from the set parameters menu to select the miscellaneous parameters menu. 4. Option 3 in this menu should show the current status of the fast i...

Page 72

2-42 service guide how to set the service line speed by default, the service line speed is 1200 baud or 2400 baud depending on the level of systemguard. This speed can be changed through the systemguard maintenance menu. In order to use the service console properly, the terminal connected to the s2 ...

Page 73

Using systemguard 2-43 setting line speed through aix 1. With aix up and running, log in as user root. 2. Type the following command to view current settings: mpcfg –dm the following is the output of the command: index name value 1 modem parameters file name 2 service line speed 3 protocol inter dat...

Page 74

2-44 service guide how to set up console mirroring console mirroring concepts console mirroring is a way to provide the customer a view of what the person working remotely from the service console is doing on the system. When mirroring is active, the service console and the bump console are logicall...

Page 75

Using systemguard 2-45 setting up console mirroring in order to setup console mirroring, you need first to authorize the service console, and set up the right line speed. Refer to previous chapters on how to set up the service line speed and how to authorize the service console. Then do the followin...

Page 76

2-46 service guide how to enable surveillance surveillance is implemented by the survd daemon. This daemon, when started, establishes a heartbeat between aix and systemguard. In case of an aix hang, systemguard detects it and reboots the system. To implement the surveillance, do the following: 1. En...

Page 77

Using systemguard 2-47 modem configuration the modem on line s2 must be configured using an ascii modem configuration file which describes various parameters using a specific syntax. Aix uses this file directly. Systemguard uses the same information (in condensed form) stored in non-volatile memory ...

Page 78

2-48 service guide how to reboot aix from the remote service console it is possible for the remote personnel connected via the service console to reboot aix from the remote site. Prerequisites the following procedure must be carried out from the bump console in order to allow aix to boot remotely fr...

Page 79

Using systemguard 2-49 rebooting to single-user and then to multi-user this allows the remote support personnel connected to the system via a modem to the s2 port to shut down and reboot the system in diagnostics mode for hardware diagnostics purposes. After running diagnostics, the remote personnel...

Page 80

2-50 service guide 3. From this menu, enter 4 . To select the miscellaneous parameters menu, which is similar to the following: miscellaneous parameters 0> bump console –> present 1> autoservice ipl –> disabled 2> dial_out authorization –> disabled 3> fast ipl –> enabled 4> set mode to normal when b...

Page 81

Using systemguard 2-51 10.At this point, a boot from scsi device screen appears. This displays the present device location code. If it is not the device you want to boot from, go through each option and change it to the desired bus, slot, scsi id, and lun id. Option 4 allows you to change all these ...

Page 82

2-52 service guide how to boot from the network the system can be booted from the network through the maintenance menu. Network boot allows a system to be reinstalled via the network and also allows various maintenance tasks to be carried out on the local machine. Use the following procedure to boot...

Page 83

Using systemguard 2-53 5. The select boot (startup) device menu appears, which is similar to the following: select boot (startup) device select the device to boot (startup) this machine. Warning: if you are using token–ring, selection of an incorrect data rate can result in total disruption of the t...

Page 84

2-54 service guide 7. Enter the appropriate ip addresses, and enter 99 to return to the main menu. A screen similar to the following appears: main menu 1. Select boot (startup) device 2. Select language for these menus 3. Send test transmission (ping) 4. Exit main menu and start system (boot) type t...

Page 85

Using systemguard 2-55 how to disable and enable processors in the smp servers, it is possible to disable/enable processors. A suspected faulty processor can be disabled so that the system can run without it. The processors can be disabled/enabled through the stand-by menu, maintenance menu, diagnos...

Page 87

Using systemguard 2-57 5. The cpu card screen appears and looks similar to the following: cpu card – (cpu1) present conditions: pr #0 –> valid & enabled pr #1 –> valid & enabled commands: 0> enable 1> disable 2> temporary disable select [x:exit]: 6. From this screen, you can disable or enable a part...

Page 88

2-58 service guide customizing systemguard for your needs systemguard is controlled by several flags. The flags consist of contract flags, operational flags, remote maintenance flags, and test flags. Remote service flag this flag is disabled at the factory and must be enabled for remote service oper...

Page 89

Using systemguard 2-59 phone numbers if remote maintenance is used, systemguard requires several phone numbers to be entered. Additional information is provided in “phone numbers” on page 2-34. Service line speed parameters if remote maintenance is used, systemguard requires that the line speed be c...

Page 90

2-60 service guide reloading the flash eeprom follow this procedure to load a new version of systemguard into the flash eeprom. Only system administrators should perform this procedure. Prerequisites to install a new version of the flash eeprom firmware, you need either a firmware diskette containin...

Page 91

3-1520-1 maintenance analysis procedures (maps) chapter 3. Maintenance analysis procedures (maps) map 1520: 7012 g series system unit - power map note: this is not a start of call map. Use this power map only if you have been directed here from a map step in the diagnostic information for micro chan...

Page 92: Step 1

3-1520-2 service guide power supply status in 7012 g series models, if the system detects a power supply failure on the base unit or mca expansion unit, it turns the power off and displays srn 409-axy , where xy is the hexadecimal value of the power status register and gives some information on the ...

Page 93: Step 3

3-1520-3 maintenance analysis procedures (maps) step 3 (from step 2) is the operator panel display illuminated? No go to step 4 yes go to step 6 step 4 (from step 3) 1. Check that the external power cable to the system unit has continuity. 2. Check that the external power cable is plugged into both ...

Page 94: Step 6

3-1520-4 service guide step 6 (from step 3) note: either the operator panel (99 % failure probability) or the system planar (1 % failure probability) is defective. 1. Unplug the system unit power cable from the wall outlet. 2. Exchange the operator panel. See “operator panel” on page 4-11. 3. Connec...

Page 95: Step 8

3-1520-5 maintenance analysis procedures (maps) step 8 (from step 7) 1. Power on the system unit, with the key mode switch set to service. 2. Find your symptom in the following table; then follow the instructions given in the action column. Symptom action the power-on light does not come on or comes...

Page 96: Step 9

3-1520-6 service guide step 9 (from step 1 and 8) the xy value in srn 409-axy is the hex value for the power status register byte. Line 2 of the operator panel display identifies the unit that contains the error. The bits in the power status register are defined as follows: 8 4 2 1 8 4 2 1 = hex val...

Page 97: Step 10

3-1520-7 maintenance analysis procedures (maps) step 10 (from step 9) an over temperature problem can be caused by an environmental problem (see specifications on page 1-15 in 7012 g series service guide) or blocked air ducts. Check each of these items. Did you find the problem? No go to step 11. Ye...

Page 98

3-1520-8 service guide.

Page 99

3-1540-1 maintenance analysis procedures (maps) map 1540:7012 g series minimum configuration note: this is not a start of call map. You should use this map only if you have been directed here from a map step in the diagnostic information for micro channel bus systems. Purpose of this map this map is...

Page 100: Step 1

3-1540-2 service guide step 1 (from step 3, 6, 7, 9, 10, 17) 1. Ensure that the diagnostics and the operating system are shut down. 2. Turn the key mode switch to the service position. 3. Sometimes an srn or error code will be logged in the bump error log. Before proceeding, check the bump error log...

Page 101

3-1540-3 maintenance analysis procedures (maps) note: before verifying any condition indicated in the following steps of this map (for example, a certain code displayed on the operator panel display), be sure that the system activity has stopped on that condition (same condition for more than 3 minu...

Page 102: Step 2

3-1540-4 service guide step 2 (from step 1) 1. Power off the system. 2. Unplug the system unit power cord from the wall outlet. 3. Record the slot numbers of the adapters. Label and record the location of any cables attached to the adapters. Remove all the adapters from the mca area. 4. Record the s...

Page 103: Step 3

3-1540-5 maintenance analysis procedures (maps) step 3 (from step 2) one of the parts installed into the system unit is defective. To test each part, exchange them in the following order: 1. System planar 2. Cpu card 3. Memory card 4. Power supply 5. Operator panel the system is working correctly if...

Page 104: Step 4

3-1540-6 service guide step 4 (from step 2) no failure was detected with this configuration. 1. Power off the system unit. 2. Unplug the system unit power cord from the wall outlet. 3. If any cpu cards were removed, install a cpu card and continue with substep 4. If there are no additional cpu cards...

Page 105: Step 5

3-1540-7 maintenance analysis procedures (maps) step 5 (from step 4) the failure may be caused by the last cpu card (cpu) or memory card (mc) installed. To isolate the failing card, do the following: 1. Power off the system unit. 2. Unplug the system unit power cord from the wall outlet. 3. Exchange...

Page 106: Step 6

3-1540-8 service guide step 6 (from step 5) one of the installed parts is defective. To test each part, exchange them in the following order: • system planar • cpu card • memory card • power supply the system is working correctly if it stops with 269 displayed in the operator panel display or if the...

Page 107: Step 7

3-1540-9 maintenance analysis procedures (maps) step 7 (from steps 1, 2, and 4) 1. Power off the system unit. 2. Unplug the system unit power cord from the wall outlet. 3. Record the slot numbers of the adapters. Label and record the location of any cables attached to the adapters. 4. Remove all the...

Page 108: Step 8

3-1540-10 service guide step 8 (from steps 7 and 17) the system is working correctly with this configuration. One of the adapters or devices that you removed is probably defective. 1. Power off the system unit. 2. Unplug the system unit power cord from the wall outlet. 3. Install one adapter, and co...

Page 109: Step 9

3-1540-11 maintenance analysis procedures (maps) step 9 (from step 8) 1. Power off the system unit. 2. Unplug the system unit power cord from the wall outlet. 3. Starting with the last installed adapter, disconnect one attached device and cable. 4. Insert the diagnostic cd-rom disc into the cd-rom d...

Page 110: Step 10

3-1540-12 service guide step 10 (from step 1) 1. Set the power button on the system unit to off. 2. Unplug the system from the electrical outlet. 3. Record the slot numbers of the adapters. Label and record the location of any cables attached to the adapters. Remove all the mca adapters except the o...

Page 111: Step 11

3-1540-13 maintenance analysis procedures (maps) step 11 (from step 10) 1. Follow the instructions on the display to select your console. 2. When the diagnostics operating instructions display, press the enter key. 3. If the terminal type has not been defined or you are ipling from cd-rom, you must ...

Page 112: Step 13

3-1540-14 service guide step 13 (from step 19, 20, 21, 22) 1. Set the power button on the system unit to off. 2. Unplug the system from the electrical outlet. 3. Record the location of all the internal scsi devices attached to the scsi bus you are attempting to ipl from. 4. If there are any external...

Page 113: Step 14

3-1540-15 maintenance analysis procedures (maps) step 14 (from step 13) this problem can be caused by: – the cd-rom pulling the bus down or opening the positive temperature coefficient (ptc) on the scsi adapter – a defective scsi adapter – a defective terminator – a defective system board (elm) – a ...

Page 114: Step 16

3-1540-16 service guide step 16 (from steps 14 and 15) in the following order, exchange the frus that have not been exchanged: 1. Scsi adapter 2. Cd-rom drive (if still in the system). 3. System board (elm) 4. Scsi cable test each fru by trying to load diagnostics from cd-rom if installed or disk. W...

Page 115: Step 17

3-1540-17 maintenance analysis procedures (maps) step 17 (from step 16) 1. Set the power button on the system unit to off. 2. Unplug the system from the electrical outlet. 3. Record the slot numbers of the adapters. Label and record the location of any cables attached to the adapters. Remove all the...

Page 116: Step 18

3-1540-18 service guide step 18 (from step 13) the system is working correctly with this configuration. One of the devices that you removed is probably defective. 1. Set the power button on the system unit to off. 2. Unplug the system from the electrical outlet. 3. Install a device. 4. Plug the syst...

Page 117: Step 19

3-1540-19 maintenance analysis procedures (maps) step 19 (from step 1) this problem can be caused by: – a scsi device pulling the bus down or opening the ptc on the scsi adapter. – a defective scsi adapter – a defective terminator – a defective system board (elm) – a defective cable the most likely ...

Page 118: Step 20

3-1540-20 service guide step 20 (from step 1) a message should be displayed with the flashing 269. Find the message in the table and do the listed action. Message displayed perform the listed action(s) 269 - no bootable go to step 21. 269 - no device go to step 13. 269 - no dev type go to step 22. S...

Page 119

Removal and replacement procedures 4-1 chapter 4. Removal and replacement procedures this chapter describes the removal and replacement procedures for all replaceable units installable into the system, and for other hardware components, such as the system unit covers. Note: unless otherwise noted, t...

Page 120

Service guide 4-2 handling static-sensitive devices attention: adapters, planars, diskette drives, and disk drives are sensitive to static electricity discharge. These devices are wrapped in antistatic bags, as shown in this illustration, to prevent this damage. Take the following precautions: • do ...

Page 121: Front Cover

Removal and replacement procedures 4-3 front cover attention: do no operate the system unit with the covers removed. Operating with the covers on ensures adequate cooling of the components. Removal 1. Set the power switches of the attached devices to off. 2. Set the power switch of the system unit t...

Page 122

Service guide 4-4 note: pull tools, for ease in removing cpu and memory cards, are located on the inside of the front cover. Pull tools.

Page 123

Removal and replacement procedures 4-5 replacement 1. Hook the top of the front cover into the top of the unit frame and insert the positioning pins located on the inside of the cover in the corresponding holes on the unit frame. P 2. Ush the middle of the cover toward the frame and then push the bo...

Page 124: Side Cover

Service guide 4-6 side cover removal 1. Remove the front cover following the procedure on page 4-3. 2. Remove the three retaining screws located on the front of the side cover. Screws 3. With a firm grip on the panel, rotate it slightly to the left while pulling it forward. Retaining clips.

Page 125

Removal and replacement procedures 4-7 replacement 1. Center the holes on the left of the side cover with the corresponding retaining clips on the unit. Retaining clips 2. Push the cover against the unit. 3. Install and tighten the retaining screws. Screws 4. Replace the front cover following the pr...

Page 126: Rear Cover

Service guide 4-8 rear cover removal 1. Remove the front cover following the procedure on page 4-3. 2. Remove the side cover following the procedure on page 4-6. 3. There may be a retaining screw securing the rear cover, if so, loosen the retaining screw of the rear cover. This screw is located insi...

Page 127

Removal and replacement procedures 4-9 4. Firmly grip the rear cover and remove it from the unit. Note: be careful when removing the rear cover from the unit. Removing it too roughly can cause accidental disconnection of the cables coming from the rear of the unit. Replacement note: before replacing...

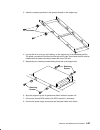

Page 128: System Unit Base

Service guide 4-10 system unit base removal 1. Set the power switches on the attached devices to off. 2. Set the power switch on the system unit to off. 3. Unplug the power cable from the wall outlet. 4. Put the system unit in horizontal position. 5. Loosen the retaining screws used to lock the base...

Page 129: Operator Panel

Removal and replacement procedures 4-11 operator panel attention: after the operator panel is installed and the system is powered–up, the system id is down-loaded to the operator panel from a backup source within the system. This id becomes permanent on the operator panel and cannot be altered witho...

Page 130

Service guide 4-12 3. Move the operator panel from left to right to help remove it from its slot. Be careful in handling the operator panel. The cables are still connected and these could be damaged. Keep the operator panel near the unit. 4. For the base unit, disconnect the cables connected to the ...

Page 131

Removal and replacement procedures 4-13 5. For the expansion unit, disconnect the cables in the following order: a. The cable coming from the rs-485 card, which is connected to the operator panel. B. The cable going to the ecb card, which is connected to the ecb card itself. Operator panel cable (go...

Page 132: Base Unit Adapters

Service guide 4-14 base unit adapters note: refer to “handling static-sensitive devices” on page 4-2 before removing or installing adapters in this system. Removal 1. Remove the front cover following the procedures on page 4-3. 2. Remove the side cover following the procedures on page 4-6. 3. Remove...

Page 133

Removal and replacement procedures 4-15 8. On the front fan cage, loosen the retainer screw which locks the adapters. Retaining screw.

Page 134

Service guide 4-16 9. Slide the retainer down until the adapters are unlocked. Retainer 10.Slide the adapter out of the slot. If you are removing a type 3 adapter, move the tongue of the plastic frame. Using the tabs on the adapter card, firmly grip the adapter, pull it up and slide it out of the sl...

Page 135

Removal and replacement procedures 4-17 replacement note: if the adapter removed will not be replaced with another one, you must install a dummy blank in the free slot to protect the unit from dust or any debris, and to guide cooling air. • position the dummy plate in the free slot, inserting it fro...

Page 136

Service guide 4-18 5. Slide the retainer to lock the adapters and tighten the retaining screws. Retainer 6. Connect any attached devices and internal cables to the adapter. Attention: before re-starting the system, make sure of any free slot has been protected by inserting an appropriate dummy plate...

Page 137: Rear Fan

Removal and replacement procedures 4-19 rear fan note: before removing the rear fan, make a note of the air flow direction of the fan. Removal 1. Remove the rear cover of the unit following the procedure described on page 4-8. 2. Put the system unit in a horizontal position. Note: be careful when la...

Page 138: Base Unit Front Fan

Service guide 4-20 base unit front fan notes: before removing the front fan, record the following: • the routing of all cables involved in the replacement procedure of this fan. • the air flow direction of the fan. Removal 1. Remove the front cover using the procedure on page 4-3. 2. Remove the side...

Page 139

Removal and replacement procedures 4-21 12.Remove the four rubber shock mounts from the fan mounting holes. Shock mounts shock mounts bracket 13.Lift up and remove the fan module from the bracket. Replacement 1. Replace the four rubber shock mounts in the fan mounting holes. 2. Place the fan back in...

Page 140

Service guide 4-22 base unit cpu/memory card retainers note: there are two types of card retainers. One is used when only one cpu card is installed into the system; the other one must be used when two cpu cards are installed. Model g40 uses the card retainers for two cpu boards only. Note the differ...

Page 141

Removal and replacement procedures 4-23 removal 1. Remove the screws used to secure the cpu/memory cards retainers to the lower support tray for the hard disks (at the front and rear of the system). Retainer screw retainer screw 2. Slide the upper tongue of the cpu/memory cards retainer out of the s...

Page 142: Disk Drive

Service guide 4-24 disk drive references to the small computer systems interface (scsi) input/output controller is abbreviated as scsi controller in this publication. Note: refer to “handling static-sensitive devices” on page 4-2. Removal 1. Keep the system unit in vertical position. 2. Remove the f...

Page 143

Removal and replacement procedures 4-25 9. To remove the drives from the support tray, remove the four retaining screws holding the drives to the support tray. Retaining screws retaining screws 10.Lift the disk drive out of the support tray. 11. Record the settings of any jumpers and/or switches tha...

Page 144

Service guide 4-26 replacement notes: it is important to remember the following facts when installing or replacing optional disk drives in positions f and g (g30, and g02 only): • the third and fourth disk drives, positions f and g, must be installed on the upper support tray. • the third disk drive...

Page 145

Removal and replacement procedures 4-27 3. Install the required grommets in the grooves located on the support tray. Grommets 4. Lay the disk drive, that you are installing, on the support tray in the dedicated position. The power connectors of the disk must be kept on the right, that means the disk...

Page 146

Service guide 4-28 9. Replace the retaining screws that anchor the disk drive support tray to the system unit frame. Mounting screws lower support tray upper support tray 10.Replace the cpu/memory board retainers. 11. Replace the side cover following the procedure on page 4-6. 12.Replace the front c...

Page 147: Base Unit Diskette Drive

Removal and replacement procedures 4-29 base unit diskette drive removal 1. Remove the front cover following the procedure on page 4-3. 2. Remove the side cover following the procedure on page 4-6. 3. Remove the diskette drive retaining screws located in the left side of the system unit. Retaining s...

Page 148: Media Devices

Service guide 4-30 media devices notes: 1. For a translation of this notice, see system unit safety information. 2. This caution only applies to the cd-rom drive. Caution: a class 3 laser may be contained in the device. Do not attempt to operate the drive while it is disassembled. Do not attempt to ...

Page 149

Removal and replacement procedures 4-31 6. Remove the retaining screws for the guide from the device. Emc band retaining screw guide 7. Remove the emc band, if installed, from the device. (the emc band will be installed on the new device using the same retaining screws as the guide.) 8. Remove the s...

Page 150

Service guide 4-32 replacement 1. If you do not replace the device just removed with any other device; a. Install the emc blank in the area corresponding to the empty slot. Emc blank b. Install the plastic blank in the area corresponding to the empty slot. Access the front panel from its internal si...

Page 151

Removal and replacement procedures 4-33 3. Install the emc band on the device. 4. Install the plastic guide. 5. Adjust the setting of any jumper and/or switches to match the device you are replacing. 6. Gently push the device into the appropriate slot and secure it in place with the retaining screws...

Page 152: Base Unit Cpu Card

Service guide 4-34 base unit cpu card note: refer to “handling static-sensitive devices” on page 4-2 before removing or installing the cpu card in this system. Removal 1. Remove the front cover following the procedure on page 4-3. 2. Remove the side cover following the procedure on page 4-6. 3. Put ...

Page 153

Removal and replacement procedures 4-35 note the use of the card extractor tools being inserted into the holes located on each end of the adapter. Card extractor tool card support bracket cpu card retainer card extractor tool 8. Slide the board out of the slot by pressing the extractors toward the s...

Page 154: Base Unit Memory Card

Service guide 4-36 base unit memory card note: refer to “handling static-sensitive devices” on page 4-2 before removing or installing the cpu card in this system. Removal 1. Remove the front cover following the procedure on page 4-3. 2. Remove the side cover following the procedure on page 4-6. 3. P...

Page 155

Removal and replacement procedures 4-37 note the use of the card extractor tools being inserted into the holes located on each end of the adapter. Card support bracket memory card card extractor tool card extractor tool 6. Slide the board out of the slot by pressing the extractors toward the system ...

Page 156: Memory Modules

Service guide 4-38 memory modules note: there are four types of memory cards; an mre card, a two bank (8 slots) rlx card, a four bank (16 slots) nfx card, and an sf5 memory card. Removal 1. Remove the front cover using the procedure on page 4-3. 2. Remove the side cover using the procedure on page 4...

Page 157

Removal and replacement procedures 4-39 replacement 1. Place the memory module on the appropriate connector on the memory card; then firmly press the memory module into the connector. White release lever 2. In reverse order, do the steps listed in “removal” on page 4-38..

Page 158: Rs-485 Card

Service guide 4-40 rs-485 card note: before attempting to handle the rs-485 card, read “handling static sensitive devices ”, on page 4-1. Removal 1. Remove the front cover using the procedure on page4-3. 2. Remove the side cover using the procedure on page 4-6. 3. Remove the rear cover using the pro...

Page 159

Removal and replacement procedures 4-41 replacement 1. Position the rs-485 card and slide it into the system unit. 2. Secure the card, tightening the retaining screw. 3. Replace the three rs-485 card back connector retaining screws. 4. Connect any external and internal rs-485 card connections. 5. Pu...

Page 160: Base Unit Battery

Service guide 4-42 base unit battery note: for a translation of this safety notice, refer to the system unit safety information, order number sa23-2652. Caution: a lithium battery can cause fire, explosion, or a severe burn. Do not recharge, disassemble, heat above 100 ° c (212 ° f), solder directly...

Page 161

Removal and replacement procedures 4-43 replacement 1. Attach a piece of loop and hook strip to the new battery. (the loop and hook strip is furnished with the battery.) 2. Position the new battery in the same position as the previous one. 3. Connect the battery cable to the connector on the system ...

Page 162: Power Supply

Service guide 4-44 power supply note: for a translation of this safety notice, refer to the system unit safety information, order number sa23-2652. Danger do not attempt to open the covers of the power supply. The power supply is not serviceable and is to be replaced as a unit. Removal 1. Remove the...

Page 163

Removal and replacement procedures 4-45 replacement 1. Position the power supply in the system unit. (the side with the power cables for the designated components in the unit must be kept toward the front of the system unit.) 2. Replace the retaining screw used to anchor the tongue located at the ba...

Page 164: Base Unit System Planar

Service guide 4-46 base unit system planar the system planar and operator panel eeproms contain the sysid of the system. When one of the two components is to be replaced (for example the system planar), the sysid information will be copied from operator panel eeprom into the system planar eeprom whe...

Page 165

Removal and replacement procedures 4-47 14.Remove the standoff screws used to secure the planar serial/parallel connectors to the rear of the unit. S1/s2 p1 s3 planar board 15.Gently lift the system planar right side (the side towards the front of the system) (a). 16.Once the planar is lifted, take ...

Page 166

Service guide 4-48 replacement note: before installing the new planar in the system unit, test the memory card by placing it in position on the memory connectors of the system board (do not plug the memory board completely at this time). If you find that guide pins on the memory connectors of the sy...

Page 167: Key Lock

Removal and replacement procedures 4-49 key lock removal 1. Remove the front cover, the side cover, and the rear cover of the unit following the procedures described in “front cover” on page 4-3, “side cover” on page 4-6, and “rear cover” on page 4-8. 2. Disconnect any cable connected to the micro c...

Page 168: Expansion Unit Ecb Card

Service guide 4-50 expansion unit ecb card note: before attempting to handle the ecb card, please read the “how to use the antistatic envelope” section at the beginning of this chapter. Removal 1. Remove the front cover, the side cover, and the rear cover of the unit following the procedures describ...

Page 169: Expansion Unit Scsi Cable

Removal and replacement procedures 4-51 expansion unit scsi cable removal note: before removing the scsi cable from the expansion unit, note how it is routed. 1. Remove the front cover, the side cover, and the rear cover of the unit following the procedures described in “front cover” on page 4-3, “s...

Page 170

Service guide 4-52 installation 1. Position the scsi cable in the unit, making it follow the correct routing. Then connect any scsi cable connector to the designated disk drives and/or media devices in the unit, and to the ecb card. See the following scsi cable routing scheme. Scsi cable routing scs...

Page 171: Step 1. Inventory

System installation 5-1 chapter 5. System installation step 1. Inventory diagnostic removable media the about your machine document (in the plastic bag on the outside of the box) cable labeling kit microcode diskettes (quantity shipped may vary) wrap plugs and container (quantity shipped may vary) s...

Page 172

Service guide 5-2 step 2. Observe this safety notice during installation note: for a translation of the following notices, see system unit safety information, order number sa23-2652. Danger an electrical outlet that is not correctly wired could place hazardous voltage on metal parts of the system or...

Page 173

System installation 5-3 step 3. Checking customer outlets note: for a translation of the following notices, see system unit safety information, order number sa23-2652. Caution: do not touch the receptacle or the receptacle faceplate with anything other than your test probes before you have met the r...

Page 174

Service guide 5-4 step 4. Setting up the system unit 1. Be sure the power cable on the system unit is unplugged and the power switch is set to the off position. 2. Remove the packing material from all of the media devices installed in the front panel. 3. Remove the rear cover and top cover. 4. Look ...

Page 175

System installation 5-5 step 7. Connecting devices to the adapters refer to the “about your machine” document to determine which adapters are installed. 1. Using the customer planning information, or other information supplied by the customer, connect the cables to the adapter connectors. 2. Record ...

Page 176: Installation Checkout

Service guide 5-6 installation checkout installation checkout procedure the installation checkout procedure is used to check out the system after initial installation or after a system upgrading kit is installed. Notes: 1. The following procedure can be followed only if the autoserviceipl flag (this...

Page 177

System installation 5-7 step 3. Loading the diagnostics the diagnostics can be run from a cd rom disk, from a locally attached disk, or from a server if version 4.1 (or higher) of the aix operating system is installed on the system. If you are not sure whether version 4.1 (or higher) of the aix oper...

Page 178

Service guide 5-8 step 4. Checking for the correct resources use the “display or change configuration or vpd” service aid to check the resources that are present (memory cards, scsi devices, adapters, diskette drives, disk drives, and input devices). Note: if the terminal type has not been defined, ...

Page 179

System installation 5-9 step 6. Completing the installation some of the following steps only apply to an initial installation. These steps are provided as reminders in completing the installation or finishing a system upgrading activity. 1. If present, remove the cd rom diagnostic disk from the appr...

Page 180: Installation

Expansion installation 6-1 chapter 6. Expansion installation this chapter describes how to connect one or more additional expansion units to the existing system configuration. In addition it illustrates briefly the general rules to disconnect a unit from the system configuration. For details about s...

Page 181

Service guide 6-2 disconnecting expansion units before disconnecting any units, perform the following steps: 1. If the machine is running, perform a system shutdown first. For further information about the shutdown procedure, refer to the shutdown command in your operating system documentation. 2. T...

Page 182: Chapter 7. Parts

Parts list 7-1 chapter 7. Parts all parts shown pertain to both the base and the expansion units, unless otherwise noted. Acronyms for fru parts occasionally, an acronym is displayed with an srn or error code on the lcd display to identify a failing fru. The listing below defines the frus associated...

Page 183: Covers and Chassis

7-2 service guide covers and chassis 4 8 9 2 3 1 18 7 14 15 12 13 10 11 16 17 5 6.

Page 184

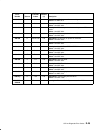

Parts list 7-3 index number part number units per asm description 1 40h2841 1 chassis assembly 2 40h2873 1 hinge 3 40h2690 1 front cover, base unit 40h2691 1 front cover, expansion unit 4 52g0284 1 bezel blank 5 52g0231 1 fan bracket 6 78x8993 1 mounting screw 7 52g0249 1 base stand 8 52g0241 1 side...

Page 185

7-4 service guide electronics, drives, and power (1 of 2) 22 23 4 5 6 7 8 9 11 12 19 18 14 15 1 2 3 21 17 16 13 20 10

Page 186

Parts list 7-5 index number part number units per asm description 1 11h7687 1 mode switch and cable 2 52g0254 1 non lock mode keylock 2 52g0252 1 locking mode keylock 3 78x8993 1 mounting screw 4 52g0292 1 bracket 5 78x8993 1 mounting screw 6 see note 1 cd-rom drive 7 78x8993 4 mounting screw 8 see ...

Page 187

7-6 service guide electronics, drives, and power (2 of 2) 32 33 34 28 29 30 26 27 31 36 35 24 25 23.

Page 188

Parts list 7-7 index number part number units per asm description 23 19h0287 1 memory module, 8mb (mre, nfx, rtx, or sf5) 19h0288 1 memory module 16mb (mre, nfx, rtx, or sf5) 19h0289 1 memory module 32mb (mre, nfx, rtx, or sf5) 35h8751 memory module, 64mb (nfx or sf5) 24 35h8694 1 mre memory card, b...

Page 189

7-8 service guide 7012 g series expansion unit unique parts 1 2 4 5 6 9 3 2a 7 8 10 index number part number units per asm description 1 52g9501 1 external scsi cable 2 40h2691 1 front cover assembly 2a 52g0284 1 bezel blank 3 11h3904 1 operator panel 4 11h3629 1 internal rs485 cable 5 11h7538 1 ecb...

Page 190

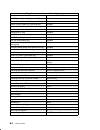

Systemguard test groups a-1 appendix a. Systemguard test groups systemguard test groups table the following diagram shows the various test groups and their associated tests. To modify the test list, the tests have to be selected in the xxyy format, where xx is the group number and yy is the test num...

Page 191

Service guide a-2 group no test test no group 05 dcb and memory test group 01 02 03 04 05 06 07 08 09 50 mm data lines test mm address lines test mm board dec. Test mm basic acc. Test mm components test ecc component test ecc mechanism test refresh mech. Test ecc data lines access. Test mm full test...

Page 192

Systemguard test groups a-3 systemguard test group descriptions the following is a description of the different test groups and the tests available under them. All of these tests are performed automatically at power on with default parameters. They can also be performed selectively (selection of tes...

Page 193

Service guide a-4 bump, remote, and special asynchronous lines test these tests are meant to check the asynchronous lines of the standard i/o and the asynchronous lines controller in the super i/o. These tests contain sub-tests, which are described as follows. Each sub-test saves and restores the li...

Page 194

Systemguard test groups a-5 nvram test this test checks the accessibility of nvram bytes. It contains the following sub-tests: nvram data lines access test this test saves the first nvram byte. Then a read / write operation is done word by word. It restores the first nvram byte. Nvram address lines ...

Page 195

Service guide a-6 dtr register test this test writes, reads and compares a 1 among 0 bits in dtr registers. Ctr register test this test writes, reads and compares a 1 among 0 bits in ctr registers. It saves and restores the ctr register value. Miscellaneous registers test this test checks accessibil...

Page 196

Systemguard test groups a-7 entry parameters parameters name definition possible values default value parameter 1 sub test # subtest number 0 or 1 0 = all tests linked parameter 2 proc # processor number 8 8 = bump check–sum test it checks the crc value for all present vpds; it checks the crc value ...

Page 197

Service guide a-8 bpp external loopback test (bpp ext l–b test ) note: this test can only be performed by field or manufacturing people. This test checks the accessibility of the super–io chip. It saves and restores used registers. This test is not performed at power on. Entry parameters parameters ...

Page 198

Systemguard test groups a-9 ionian-ssga registers test this test is performed by all the processors and it checks the accessibility from the processor to the ionian and ssga chips. Following hardware parts are checked. 1. Dcb asic 2. Ionian asic 3. Ssga asic the following sub-tests are included unde...

Page 199

Service guide a-10 super i/o and uart access test this test checks the accessibility of the super i/o chip from the processors. They don’t check the functional aspects of the super i/o chip (this is done by the bump directly). The following sub-tests are available under this test: super i/o uart 1 a...

Page 200

Systemguard test groups a-11 ssga interrupt registers test this test writes and reads specific values from each of the interrupt registers. The values are then compared. Values are saved and restored in all the operations. Floppy disk access test this test needs a formatted diskette in the diskette ...

Page 201

Service guide a-12 level 2 cache. It calculates the memory address available and then validates the level 2 cache before writing 1 mb. Then a read operation is done in word mode and values are compared. Then a read is done in burst mode and comparison is done. Tag data test this test checks the avai...

Page 202

Systemguard test groups a-13 walking 0 data test this test isolates the open lines among the data lines. It writes “0s among 1s” pattern on the cache line. Then it is read and compared. Transfer modes on dcb test this sub-test is used to check the transfer of 1 to 8 bytes to the memory. Initially th...

Page 203

Service guide a-14 this test consists of two sub-tests. Words manipulated / used are not restored at the end of the test. This test is applied to all the memory cards which are present. In case of errors, suitable error messages are displayed on the console. The following is a description of the sub...

Page 204

Systemguard test groups a-15 basic main memory test this test is performed by all the processors and it checks the capability to access the main memory in all kinds of data formats. This test applies to one main memory location and the words used during the test are not restored. This test partially...

Page 205

Service guide a-16 main memory components test this test is performed by all the processors to check all the main memory locations. From the hardware point of view, this test checks the memory chips mounted on the main memory cards. This test can be launched in two modes, as follows: 1. Bit map elab...

Page 206

Systemguard test groups a-17 ecc data lines accessibility test this test checks the accessibility for all the data lines to the ecc memory banks, through smc asics. The following hardware parts are checked by running this test: • dcb asics • smc asics • connection of data lines between cpu daughter ...

Page 207

Service guide a-18 ecc memory component test this test is identical to the main memory components test but it is applied to the ecc memory components. Error correction mechanism test this test checks the hardware mechanisms enabling the detection of and the correction of single bit errors when worki...

Page 208

Systemguard test groups a-19 interrupt tests group these tests are performed by the bump as well as the processors. They are launched at power on and under control of off line test monitor. They collectively check the interrupt system. The following tests are available under this group. Bump to cpu ...

Page 209

Service guide a-20 cpu multiprocessor test group these tests are launched at power-on and are also available under the control of the off line tests monitor. These tests check the multi-processor mechanisms, atomic instructions, cache coherency, main memory sharing, and multi-resources sharing. The ...

Page 210

Systemguard test groups a-21 instruction. This is issued by processor 0 which is set to global copy back mode. Caching is inhibited for processor 1. Paradox detection: dcbst not from line owner here, processor 1 is set to local copy back mode. Memory coherency is enabled for processor 0. This test v...

Page 211

Service guide a-22 main memory sharing test this test is launched by the bump and performed by all configured processors. It has a sub-test to check the capability of all the processors to access the main memory. The following hardware parts are checked during the process: 1. Dcb asics 2. Ionian asi...

Page 212: Default Parameter Values

Modifying systemguard parameters b-1 appendix b. Modifying systemguard parameters many systemguard parameters can be modified in several ways. Some can be modified using the systemguard stand-by menu, others using the systemguard maintenance menu, and others using the aix diag or mpcfg commands or d...

Page 213

B-2 service guide flag, parameter and keyword default values name default value bump console power-on command string power service console power-on command string blank (not set) bump console power-on command flag enabled service console power-on command flag disabled remote authorization flag disab...

Page 214

Modifying systemguard parameters b-3 changing flags and parameters under aix service aids the service aids are recommended to change the flags. The service aids can be entered using the diag command or by booting diagnostics in service mode. They display or change flag values using 0 (zero) for disa...

Page 215

B-4 service guide systemguard maintenance menu starting from the main maintenance menu: • enter 2 to enable the flag. Or • enter 3 to disable the flag. Aix diag command starting from the service aids selection menu: 1. Select the bump service aids option. 2. Select the display or change flags and co...

Page 216

Modifying systemguard parameters b-5 modifying dial-in phone numbers these parameters can be changed under systemguard using the maintenance menu, or under aix using the diag command. Systemguard maintenance menu starting from the main maintenance menu: 1. Enter 8 to set parameters. 2. Enter 3 for p...

Page 217

B-6 service guide modifying the electronic mode switch from service line flag this flag can be changed under systemguard using the maintenance menu, or under aix using the diag command. Systemguard maintenance menu starting from the main maintenance menu: 1. Enter 8 to set parameters. 2. Enter 4 for...

Page 218: Reloading The Flash Eeprom

Modifying systemguard parameters b-7 reloading the flash eeprom follow this procedure to load a new version of systemguard into the flash eeprom. Only system administrators should perform this procedure. Prerequisites to install a new version of the eeprom firmware, you need either a firmware disket...

Page 219: Configuration

Systemguard remote operation configuration c-1 appendix c. Systemguard remote operation configuration in order to utilize the remote operation capabilities of systemguard and also allow console mirroring, you need to have flags, parameters and tty configurations properly enabled. Below, are tty0 and...

Page 220

Service guide c-2 the configuration of the tty1 for the s2 port looks similar to the following: [top] [entry fields] tty tty1 tty type tty tty interface rs232 description asynchronous terminal status available location 00–00–s2–00 parent adapter sa1 port number [s2] enable login disable baud rate [9...

Page 221

Systemguard remote operation configuration c-3 the modem parameters file name value should be set to the file name of your modem configuration file. The service line speed should be set to your modem and tty capabilities (9600 is recommended). • service flags: mpcfg –ds index name value 1 remote ser...

Page 222: Modem Configuration Files

Service guide c-4 modem configuration files if you want to attach a modem to the s2 port to allow automatic problem reporting from systemguard or dial-in access from a remote location, you have to provide a configuration file for the modem you are using. This file is also necessary to utilize the mi...

Page 223

Systemguard remote operation configuration c-5 this is a sample /usr/share/modems/mir_modem file for console mirroring using an ibm 7851 modem. # tested at 9600bps. Icdelay 5 defaultto 10 calldelay 120 # at attention code q0 enable result codes to screen # &f1 set factory profile 1 q1 disable result...

Page 225

Off line diagnostic error codes d-1 appendix d. Off line diagnostic error codes note: the failure percent value is calculated on a system model base. As some failing function codes are system model specific but are associated the the same error number, it may happen that the sum of the failure perce...

Page 226

Service guide d-2 error number source failing function codes failure percent (%) description 401-023 k c59 100 description: s2 asynchronous line junction signal error (dtr to dsr link). Action: use map 0210. 401-024 k c59 100 description: s2 asynchronous line junction signal error (rts to cts link)....

Page 227

Off line diagnostic error codes d-3 error number source failing function codes failure percent (%) description 401-049 k c59 100 description: s3 asynchronous line junction signal error (dtr to dsr link). External loop-back mode. Action: use map 0210. 401-050 k c59 100 description: s3 asynchronous li...

Page 228

Service guide d-4 error number source failing function codes failure percent (%) description 401-140 k all boards description: bad vpd board. 401-141 k all boards description: no board present. 401-142 k all boards description: no coherent configuration on board. 401-150 k c59 c61 c63 c88 40 20 20 2...

Page 229

Off line diagnostic error codes d-5 error number description failure percent (%) failing function codes source 401-182 k c59 modem 20 80 description: dial-out test. No customer hub or service center phone dial-out. 401-183 k c59 modem 20 80 description: dial-out test. Modem parameters failed. 401-18...

Page 230

Service guide d-6 error number source failing function codes failure percent (%) description 401-514 k c59 c63 c61 50 25 25 description: direct io: ionian-ssga. Apr register error. Action: use map 0210. 401-515 k c59 c63 c61 50 25 25 description: direct io: ionian-ssga. Bsr init value. Action: use m...

Page 231

Off line diagnostic error codes d-7 error number description failure percent (%) failing function codes source 401-550 k c59 c61 80 20 description: direct io. Flash eprom access error. Action: use map 0210. 401-560 k c59 c61 80 20 description: direct io. Eprom access error. Action: use map 0210. 401...

Page 232

Service guide d-8 error number source failing function codes failure percent (%) description 401-591 k c59 c63 c61 50 25 25 description: diskette drive access. Error on sense interrupt command. Action: use map 0210. 401-592 k c59 c63 c61 50 25 25 description: diskette drive access. Error on write co...

Page 233

Off line diagnostic error codes d-9 error number description failure percent (%) failing function codes source 401-807 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset and pos. Missing dma interrupt error during transfer. Action: use map 0210. 401-808 k lsa c59 c90 c61 c63 40 20 20 10...

Page 234

Service guide d-10 error number description failure percent (%) failing function codes source 401-824 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset and pos. Scsi bus control lines error. Action: use map 0210. 401-825 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset a...

Page 235

Off line diagnostic error codes d-11 error number description failure percent (%) failing function codes source 401-841 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset and pos. Pos4 register error. Action: use map 0210. 401-842 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channe...

Page 236

Service guide d-12 error number description failure percent (%) failing function codes source 401-851 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset and pos. Buffer exchange error. Action: use map 0210. 401-852 k lsa c59 c90 c61 c63 40 20 20 10 10 description: channel reset and pos....

Page 237

Off line diagnostic error codes d-13 error number source failing function codes failure percent (%) description 402-110 k c63 c61 50 50 description: caches coherencies. Concurrent coherent write accesses error. Action: use map 0210. 402-111 k c63 c61 50 50 description: caches coherencies. Concurrent...

Page 238

Service guide d-14 error number source failing function codes failure percent (%) description 402-132 k c63 c61 50 50 description: dcb ports arbitration error. Memory coherency error. Action: use map 0210. 402-133 k c63 c61 50 50 description: dcb ports arbitration error. Odd processor dcbf or even p...

Page 239

Off line diagnostic error codes d-15 error number source failing function codes failure percent (%) description 402-530 k c59 c61 ??? 50 25 25 description: cpus to cpus interrupt error. Even processors auto interrupt. Action: use map 0210. 402-531 k c59 c61 ??? 50 25 25 description: cpus to cpus int...

Page 240

Service guide d-16 error number source failing function codes failure percent (%) description 403-013 k b94 c61 c63 40 30 30 description: main memory address lines accessibility error. Unexpected interrupt. Action: use map 0210. 403-020 k b94 c61 c63 40 30 30 description: main memory board address a...

Page 241

Off line diagnostic error codes d-17 error number source failing function codes failure percent (%) description 403-038 k b94 c61 c63 40 30 30 description: main memory basic tests error. Work mode main memory addressing error. Action: use map 0210. 403-039 k b94 c61 c63 40 30 30 description: main me...

Page 242

Service guide d-18 error number source failing function codes failure percent (%) description 403-074 k b94 b96 or b97 50 50 description: error correction code mechanism. Multiple error generation error. Action: use map 0210. 403–075 k b94 c64 d28 b96 b97 d33 50 50 50 50 50 50 description: dcb or sm...

Page 243

Off line diagnostic error codes d-19 error number description failure percent (%) failing function codes source 403-506 k c59 c61 c63 50 25 25 description: bump to cpu interrupt error. Iod-hw-sts register error. Action: use map 0210. 403-507 k c59 c61 c63 50 25 25 description: bump to cpu interrupt ...

Page 244

Service guide d-20 error number description failure percent (%) failing function codes source 403-527 k c59 c61 c63 50 25 25 description: cpu to bump interrupt. Xirr4 register error. Action: use map 0210. 403-528 k c59 c61 c63 50 25 25 description: cpu to bump interrupt. Iod-hw-sts register error. A...

Page 245

Off line diagnostic error codes d-21 error number description failure percent (%) failing function codes source 403-555 k c59 c61 c63 50 25 25 description: cpu to cpu interrupt. Xirr register error. Action: use map 0210. 403-560 k c59 c61 c63 50 25 25 description: tod to bump interrupt. Unexpected i...

Page 246

Service guide d-22 error number description failure percent (%) failing function codes source 404-018 k c63 c61 80 20 description: caches coherencies. Dcbi not from line owner error. Action: use map 0210. 404-019 k c63 c61 80 20 description: caches coherencies. Dcbt not from line owner error. Action...

Page 247

Off line diagnostic error codes d-23 error number description failure percent (%) failing function codes source 407-015 k c59 c61 c63 40 30 30 description: cpu interrupt test manager stopping t-o. Action: use map 0210. 407-016 k c59 c61 c63 40 30 30 description: cpu multi-processor test manager laun...

Page 248

Service guide d-24 error number description failure percent (%) failing function codes source 408-060 k b94 b96 or b97 50 50 description: main memory knaizuk-hartmann test error. Action: use map 0210. 408-080 k c63 c61 90 10 description: multi resources full test error. Action: use map 0210. 409-000...

Page 249

Off line diagnostic error codes d-25 error number description failure percent (%) failing function codes source 409-083 b c60 100 description: op microcontroller not working. Action: use map 0210. 409-087 k c63 100 description: mvr not compatible with the cpu boards. Action: use map 0210. 409-088 k ...

Page 250: Error Logging

Service guide d-26 error logging when a failure occurs on a fan or on a power supply, the system produces a logging report for this event. The logging report can be viewed using errpt. An errpt report about power and fan is the following: label: epow_sus description: loss of electrical power probabl...

Page 251

Off line diagnostic error codes d-27 1010 fan 2 fault 1011 fan 3 fault 1100 fan 4 fault 1100 fan 5 fault 1100 fan 6 fault 1111 reserved power up bits 4–6 values description 000 manual on button pushed 001 remote on signal from external 010 timed power on from tod clock 011 remote on signal from powe...

Page 252

Service guide d-28 power system operating in backup mode bit 14 values description 0 no power warning 1 power system operating in backup mode warning cooling system operating in backup mode bit 15 values description 0 no cooling warning 1 cooling system operating in backup mode warning power fault a...

Page 253

Off line diagnostic error codes d-29 understanding pksr the pksr status is logged in hexadecimal value: 8 digits are logged. Each hexadecimal digit must be converted in 4 binary digits: 32 bits are obtained. Divide the bits as indicated in the pksr layout and check the bit values to understand the m...