Power systems power supplies for the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc.

Power systems power supplies for the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc.

Note before using this information and the product it supports, read the information in “safety notices” on page v, “notices” on page 91, the ibm systems safety notices manual, g229-9054, and the ibm environmental notices and user guide, z125–5823. This edition applies to ibm power systems servers t...

Contents safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V power supplies for the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc . . . . . . . . 1 removing the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc power supply with the power turned off . . . . 1 removing the 9117-mmb...

Installing a part by using the systems director management console . . . . . . . . . . . . . . . 59 verifying the installed part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 verifying an installed part by using stand-alone diagnostics . . . . . . . . . . . . . . . . . 59 verifying th...

Safety notices safety notices may be printed throughout this guide: v danger notices call attention to a situation that is potentially lethal or extremely hazardous to people. V caution notices call attention to a situation that is potentially hazardous to people because of some existing condition. ...

Danger when working on or around the system, observe the following precautions: electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid a shock hazard: v connect power to this unit only with the ibm provided power cord. Do not use the ibm provided power...

Observe the following precautions when working on or around your it rack system: v heavy equipment–personal injury or equipment damage might result if mishandled. V always lower the leveling pads on the rack cabinet. V always install stabilizer brackets on the rack cabinet. V to avoid hazardous cond...

Caution: removing components from the upper positions in the rack cabinet improves rack stability during relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a room or building: v reduce the weight of the rack cabinet by removing equipment starting at the...

(l003) or all lasers are certified in the u.S. To conform to the requirements of dhhs 21 cfr subchapter j for class 1 laser products. Outside the u.S., they are certified to be in compliance with iec 60825 as a class 1 laser product. Consult the label on each part for laser certification numbers and...

Caution: data processing environments can contain equipment transmitting on system links with laser modules that operate at greater than class 1 power levels. For this reason, never look into the end of an optical fiber cable or open receptacle. (c027) caution: this product contains a class 1m laser...

Power supplies for the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc learn about removing and replacing a power supply in a server. Learn about removing and replacing a power supply, fan, or input power distribution assembly in a 5802 or a 5877 expansion unit. Removing the 9117-mmb, 9117-mmc, 9179-mhb, ...

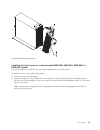

6. Lift the tab (b) toward the power cord retainer (c) to release the power supply. Pull the power supply away from the system, as shown in figure 1. If you want to replace the power supply you removed, see “replacing the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc power supply with the power turned o...

Removing the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc power supply with the power turned on learn how to remove a power supply with the system power turned on if you want to replace a failing power supply, or as a part of another service action. Attention: two power supplies must be present in the ...

Note: when you remove a power supply with the system power turned on, an error is logged. No action is required for this error. If you want to replace the power supply you removed, see “replacing the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc power supply with the power turned on” on page 6. Replacin...

Note: this system is equipped with a second power supply. Before continuing with this procedure, connect all power sources to the system. 4. Start the system, as described in starting the system or logical partition. 5. Note the state of the light-emitting diodes (leds) on the power supply. For more...

6. Close the rack door at the rear of the system. Replacing the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc power supply with the power turned on learn how to replace a power supply with the system power turned on. Attention: two power supplies must be present in the system to power on the system unit...

Attention: v attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic discharge (esd) from damaging your hardware. V when using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It does not increase or decrease your risk ...

7. Close the rack door at the rear of the system. Power supply leds the various states of the power supply light-emitting diodes (leds) can be used to identify or verify a power supply that you are servicing. The power supply has three leds that indicate the power supply status: v an ac power led (g...

Power supplies, fans, and input power distribution assemblies in a 5802 or 5877 expansion unit learn about removing and replacing a power supply, fan, or input power distribution assembly to replace a failing part or as part of another service action in a 5802 or 5877 expansion unit. The power suppl...

5. For the power supply that you want to remove, slide the cable retention bracket to the open position (a), and then disconnect the power cable (b) as shown in figure 8. By moving the bracket to the open position, you turn the power supply off. 6. Attach the wrist strap. Figure 7. Fru fault and ide...

Attention: v attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic discharge (esd) from damaging your hardware. V when using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It does not increase or decrease your risk ...

A. To identify the failing fan. Press the fan identify button (a), as shown in figure 10. An amber left or right fan-fault led (c) on solid, as shown in figure 11, indicates the faulty fan. B. Loosen the thumbscrew (a) that holds the fan in the power-supply assembly, as shown in figure 11. Figure 10...

C. Use the recessed fan handle (b) to lift the fan from the power-supply assembly, as shown in figure 11 on page 12. If you removed the power supply or fan as part of another service action, or if you want to replace the power supply or fan that you removed from an expansion unit, see replacing a po...

7. Attach the wrist strap. Attention: v attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic discharge (esd) from damaging your hardware. V when using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It does not incr...

9. Optional: if you want to remove a failing power-supply fan, complete the following steps: note: if a fan fails, the amber fan fault led on the front of the offline converter assembly (oca) (b), shown in figure 15, is on solid. Figure 14. Removing a power supply figure 15. Fan fault led and fan id...

A. Identify the failing fan by pressing the fan identify button (a) shown in figure 15 on page 15. An amber left or right fan-fault led (c) on solid, as shown in figure 16, indicates the faulty fan. B. Loosen the thumbscrew (a) that holds the fan in the power-supply assembly, as shown in figure 16. ...

Attention: two power supplies must be present in the expansion unit. If one power supply fails, the expansion unit continues to operate. If you are performing this procedure concurrently (with the power turned on), there is a time limit. From the moment the power supply is removed, the exchange of t...

6. To replace the power supply, with the locking handle (a) in the open position, push the power supply into the expansion unit as shown in figure 18. 7. Close the locking handle (a) until the power supply locks into position. Figure 17. Replacing a fan figure 18. Replacing a power supply 18 power s...

8. Reconnect the power cable (a) to the front of the power supply, and then slide the cable retention bracket (b) to the closed position to secure the cable as shown in figure 19. By moving the bracket to the closed position, you turn on the power supply. 9. Note the state of the green ac power in (...

Note: if you replaced a power-supply fan as part of this procedure, note the state of the fan fault led (b) shown in figure 21. If the led is off, indicating that both fans are operating normally, continue to the next step. If not, remove the power-supply assembly from the expansion unit and repeat ...

Replacing a power supply or fan in a 5802 or 5877 expansion unit with the power turned off learn how to replace a power supply or power-supply fan in a 5802 or 5877 expansion unit if you removed a failing part and want to replace the power supply assembly with the power turned off. If your system is...

C. Tighten the thumbscrew (d) as shown in figure 22. 6. To replace the power supply, with the locking handle (a) in the open position, push the power supply into the expansion unit as shown in figure 23 on page 23. 7. Close the locking handle (a) until the power supply locks into position. Figure 22...

8. Connect the power cable (a) to the front of the power supply, and then slide the cable retention bracket (b) to the closed position to secure the cable as shown in figure 24. 9. Start the system, as described in starting the system or logical partition. Figure 23. Replacing a power supply figure ...

10. Note the state of the green ac power in (a) and offline converter assembly (oca) power (b) light-emitting diodes (leds) shown in figure 25, and do one of the following actions, as applicable: v if the leds indicate that the power supply is operating normally, that is, that the ac power in led (a...

11. Verify the installed part, as described in verifying the installed part. 12. Close the front rack door. Continue with any other service actions you need to perform. Removing an input power distribution assembly from a 5802 or 5877 expansion unit with the power turned off learn how to remove an i...

6. Attach the wrist strap. Attention: v attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic discharge (esd) from damaging your hardware. V when using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It does not incr...

8. Loosen the thumbscrew (b) on the input power distribution assembly. Pull out the assembly from the expansion unit, as shown in figure 29. Figure 28. Removing an input power distribution assembly cover figure 29. Removing an input power distribution assembly power supplies 27.

To replace an input power distribution assembly, see “replacing an input power distribution assembly in a 5802 or 5877 expansion unit with the power turned off.” replacing an input power distribution assembly in a 5802 or 5877 expansion unit with the power turned off learn how to replace an input po...

6. Replace the input power distribution assembly cover, and then tighten the thumbscrew (a) as shown in figure 31. Figure 30. Replacing an input power distribution assembly figure 31. Replacing an input power distribution assembly cover power supplies 29.

7. At the rear of the expansion unit, connect both of the power cables, as shown in figure 32. 8. Close the rear rack door. 9. Start the system, as described in starting the system or logical partition. 10. Verify the installed part, as described in verifying the installed part. Continue with any ot...

3. Open the rear rack door. 4. Attach the wrist strap. Attention: v attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic discharge (esd) from damaging your hardware. V when using a wrist strap, follow all electrical safety procedures. A wrist strap is for stat...

7. At the rear of the expansion unit, connect both of the power cables, as shown in figure 32 on page 30. Figure 34. Replacing an input power distribution assembly cover figure 35. Connecting the power cables at the rear of an expansion unit 32 power systems: power supplies for the 9117-mmb, 9117-mm...

8. Close the rear rack door. 9. Start the system, as described in starting the system or logical partition. 10. Verify the installed part, as described in verifying the installed part. Continue with any other service actions you want to perform. Common procedures for installable features this sectio...

Danger observe the following precautions when working on or around your it rack system: v heavy equipment–personal injury or equipment damage might result if mishandled. V always lower the leveling pads on the rack cabinet. V always install stabilizer brackets on the rack cabinet. V to avoid hazardo...

Blue or terra-cotta on a part of the hardware indicates a touch point where you can grip the hardware to remove it from or install it in the system, open or close a latch, and so on. Terra-cotta might also indicate that the part can be removed and replaced with the system or logical partition power ...

V a : power-on button v b : power led – a constant light indicates full system power to the unit. – a blinking light indicates standby power to the unit. Note: there is approximately a 30-second transition period from the time the power-on button is pressed to when the power led goes from blinking t...

Related concepts identifying a failing part use these instructions to learn how to locate and identify a failing part on your system or expansion unit using the appropriate method for your system. Identifying a failing part in an aix system or logical partition use these instructions to learn how to...

Identifying a failing part in an ibm i system or logical partition you can activate or deactivate the indicator light by using ibm i to assist in locating a failing part. Identifying a failing part in a linux system or logical partition if the service aids have been installed on a system or logical ...

After you complete a removal and replacement procedure, you must deactivate the failing-part indicator light. To deactivate the indicator light, follow these steps: 1. Log in as root user. 2. At the command line, type /usr/sbin/usysident -s normal -l and press enter. Note: ibm provides hardware diag...

2. Before you press the power button on the control panel, ensure that power is connected to the system unit as follows: v all system power cables are connected to a power source. V the power led, as shown in the following figure, is slowly blinking. V the top of the display, as shown in the followi...

V h : decrement button v i : enter button v j : increment button v k : pinhole reset button 4. Observe the following after pressing the power button: v the power-on light begins to blink faster. V the system cooling fans are activated after approximately 30 seconds and begin to accelerate to operati...

Stopping a system that is not managed by an hmc or an sdmc you might need to stop the system to perform another task. Use these instructions to stop the system using the power button or advanced system management interface. Before you stop the system, follow these steps: 1. If an integrated xseries ...

Stopping a system by using the hardware management console you can use the hardware management console (hmc) user interface to stop the system or a logical partition. By default, the managed system is set to power off automatically when you shut down the last running logical partition on the managed...

By default, the managed system is set to power off automatically when you shut down the last running virtual server on the managed system. If you set the managed system properties on the sdmc so that the managed system does not power off automatically, you must use this procedure to power off your m...

4. While holding the system unit release latches (a) down on both the left and right sides, pull the system unit (b) out from the rack until the rails are fully extended and locked. Placing the rack-mounted 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system into the operating position use this procedu...

When placing the system into operating position, ensure that the cables at the back of the system do not catch or bind as you push the system unit back into the rack. 1. Unlock the blue rail safety latches (a) by lifting them upwards. The rail safety latches are located near the middle of the system...

Removing and replacing covers for the 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c use these instructions to remove, replace, or install covers to access components or perform service. Removing the front cover on a rack-mounted 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to remo...

Removing the front cover on a stand-alone 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to remove the cover to access components or perform service. To remove the front cover, follow these steps: 1. Open the front door (a) by swinging it towards the left as shown in the followi...

Installing the front cover on a rack-mounted 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to install the cover to access components or perform service. To install the front cover, follow these steps: 1. Push the cover onto the system. 2. Gently push the cover in until the four...

Installing the front cover and front door on a stand-alone 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to install the cover to access components or perform service. To install the front cover and front door, complete the following steps. 1. Align the cover (a) until the two c...

3. Hold the front door at an approximate 120 degree angle to the system as show in the following figure. Engage the latches. Removing the service access cover on a rack-mounted 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to remove the service access cover. 1. Loosen the two t...

Attention: when the service access cover is removed, the system powers down. Removing the service access cover on a stand-alone 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to remove the service access cover. 1. Loosen the thumbscrew (a) located at the back of the outside cove...

3. Loosen the two thumbscrews (a) located at the back of the inside cover. 4. Slide the cover (b) toward the back of the system unit. When the front of the service access cover has cleared the upper frame ledge, lift the cover up and off the system unit. Attention: when the service access cover is r...

Installing the service access cover on a rack-mounted 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to install the service access cover. 1. Place the service access cover on top of the system, about 25 mm (1 in.) from the upper chassis ledge. 2. Hold the service access cover ag...

5. Place the outside service access cover (a) on top of the system. 6. Hold the service access cover against the system unit and slide it toward the front of the system. The tabs of the service access cover slide beneath the upper chassis ledge. 7. Align the thumbscrew (b) located on the back of the...

Disconnecting the power cords from the 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use these procedures to disconnect the power cords from the 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system. 1. For a rack-mounted system, open the back rack door on the unit you are servicing and identify the s...

Figure 52. Removing the power cords for a rack-mounted system figure 53. Removing the power cords for a stand-alone system power supplies 57.

Connecting the power cords to the 8202-e4b, 8202-e4c, 8205-e6b, or 8205-e6c system use this procedure to connect the power cords. 1. Identify the system unit you are servicing in the rack. 2. Connect all power cords to the unit you are servicing. Ensure that the cords are threaded through the handle...

Note: the hmc might open external instructions for installing the feature. If so, follow those instructions to install the feature. Installing a part by using the systems director management console you can use the ibm systems director management console (sdmc) to perform many service actions, inclu...

E. Click save settings and power on. As soon as the optical drive has power, insert the standalone diagnostic cd-rom. F. Go to step 5. 4. Turn on the system unit power and immediately insert the diagnostics cd-rom into the optical drive. 5. After the keyboard post indicator displays on the system co...

Yes : continue with the next step. 3. Record the list of open service action events. 4. Examine the details of the open service action event. Is the error code associated with this service action event the same as you gathered earlier. V no : select one of the following options: – review the other s...

V a verification that the logical partition led was deactivated. V an indication that there still might be open problems within the logical partition. V an indication that you cannot activate the logical partition led. Activating or deactivating identify led: the system provides several leds that he...

The upper table shows information, such as problem number and reference code. The lower table shows the field replaceable units (frus) associated with this event. 5. Select the error for which you want to view comments and history, and follow these steps: a. Select actions → view comments. B. When y...

You can deactivate a system attention led or a logical partition led. For example, you might determine that a problem is not a high priority and decide to repair the problem at a later time. However, you want to be alerted if another problem occurs, so you must deactivate the system attention led so...

4. Select a line in the events window, and select actions → properties the properties window opens, showing detailed information about the serviceable event. The table shows information, such as problem number, reference code, and the field replaceable units (frus) associated with this event. Verify...

Correctly. If you cannot correct the problem, collect all srns or any other reference code information that you see. If the system does not start or you have no login prompt, see: problems with loading and starting the operating system. If the system is partitioned, note the logical partition in whi...

Yes: go to step 8. 8. Select the parent or child of the resource for the replaced part from the resource repair action menu if necessary. When a test is run on a resource in system verification mode, and that resource has an entry in the error log, if the test on the resource was successful, the res...

V if the original problem was that an enclosure would not power on and you have another fru to replace, locate and replace the next field-replaceable unit (fru). V if the next fru in the fru list is an isolation procedure, perform the isolation procedure. V if the original problem was that an enclos...

Did you encounter any problems? No reinstall the operating system and continue with step 5. Yes if the original problem still exists, replace the field-replaceable unit (fru) or perform the isolation procedure that is next in the fru list. If you have reached the end of the fru list, contact your ne...

1. Enter diag at the command prompt. 2. Press enter. 3. Select the diagnostics routines option. 4. When the diagnostic mode selection menu displays, select system verification. 5. When the diagnostic selection menu displays, select the all resources option or test the frus you exchanged, and any dev...

When a test is run on a resource in system verification mode, that resource has an entry in the aix error log. If the test on the resource was successful, the resource repair action menu displays. After replacing that fru, you must select the resource for that fru from the resource repair action men...

Yes: continue with the next step. No: continue with step 3. 2. Perform the following tasks: a. Verify that the power cable is plugged into the power outlet. B. Verify that power is available at the customer's power outlet. 3. Was the partition powered off during the repair? Yes: continue with the ne...

No: a new symptom might have occurred. Go to the start of call procedure to determine the cause of the problem. This ends the procedure. 13. Are there any other failing items that need to be replaced? Yes: replace the next failing item listed for the reference code. This ends the procedure.. No: con...

Attention: before returning the system to the customer, remove the system from service mode. If the system is left in service mode, it automatically places a call for service every two hours. V while you were performing the problem analysis on the original serviceable event, other serviceable-event ...

Closing a service call perform these procedures to close problem numbers, clear hardware messages, and prepare the server to return to the customer. Follow this checklist before performing the procedures: v return the server to the state that the customer normally uses such as ipl type, ipl mode, an...

V yes: go to step 11. V no: continue with the next step. 8. Examine the fru list of the service action event. Are any frus listed for the service action event? V yes: continue with the next step. V no: go to step 11. 9. Is the fru list identical (same frus, same number of frus, and same order of fru...

18. Click close event. 19. Add comments for the serviceable event. Include any unique additional information. Click ok. The following steps will add or update fru information. 20. Did you replace, add, or modify a fru of the open service action event? V yes: continue with the next step. V no: go to ...

1. Press enter. 2. Select the task selection option. 3. Select the log repair option. 4. Select the resource associated with the repair action. If the repair action was reseating a cable or adapter, select the resource associated with that repair action. If the resource associated with your repair a...

1. Press enter. 2. Select the task selection option. Note: if the terminal type is not defined, you are prompted to define it before you can proceed. 3. Select the log repair option. 4. Select the resource associated with the repair action. If the repair action was reseating a cable or adapter, sele...

2. Do you have any field-replaceable units (frus) (for example cards, adapters, cables, or devices) that were removed during problem analysis that you want to put back into the system? Note: if the system planar or battery has been replaced and you are loading diagnostics from a server over a networ...

1. If the system supports slow boot (see performing a slow boot), do a slow boot on the system. If the system does not support slow boot, do a normal boot. 2. Power on the system. 3. Wait until the aix operating system login prompt displays or until system activity on the operator panel or display a...

If the resource associated with your action is not displayed on the resource list, select sysplanar0. Note: if the system attention indicator is on, this will set it back to the normal state. Go to step 14. 12. When a test is run on a resource in system verification mode, and that resource has an en...

Did you perform service on a raid subsystem involving changing of the pci raid adapter cache card or changing the configuration? Note: this does not refer to the pci-x raid adapter or cache. V yes: continue with the next step. V no: go to step 16. 15. Use the recover options selection to resolve the...

3. Are there any service action events that are open? V yes: continue with the next step. V no: if the system attention led is still on, turn off the led as described in “activating and deactivating leds” on page 87. Return the system to the customer. This completes the repair. 4. Record the list of...

V yes: continue with the next step. V no: go to step 17. 13. Have you begun a list of axx partitions from prior service action events that you processed in this maintenance analysis procedure (map)? V yes: go to step 15. V no: continue with the next step. 14. Begin a new list of axx partitions by co...

V yes: continue with the next step. V no: go to step 30. 24. Is the error class recorded in step 23 on page 85? V yes: continue with the next step. V no: go to step 30. 25. Perform the following steps for each entry in the list of all partitions you recorded in step 11 on page 84, except the partiti...

32. Perform the following steps for each entry in the list of axx partitions you began recording in step 14 on page 85, except the partition you were using to debug the original problem. 33. From the ivm virtual terminal window of a partition in the list of axx partitions, type diag at the aix comma...

V “activating or deactivating an identify led using the advanced system management interface” on page 90 deactivating a system attention led or partition led using the management console you can deactivate a system attention led or a logical partition led if you decide that a problem is not a high p...

V identify led for a fru associated with a specified enclosure if you want to hook up a cable to a specific i/o adapter, you can activate the led for the adapter, which is a field replaceable unit (fru), and then physically check to see where you should hook up the cable. This is especially useful w...

Activating or deactivating an identify led using the advanced system management interface you can activate or deactivate an identify led using the advanced system management interface (asmi). You can specify the location code of any indicator to view or modify its current state. If you provide the w...

Notices this information was developed for products and services offered in the u.S.A. The manufacturer may not offer the products, services, or features discussed in this document in other countries. Consult the manufacturer's representative for information on the products and services currently av...

This information is for planning purposes only. The information herein is subject to change before the products described become available. This information contains examples of data and reports used in daily business operations. To illustrate them as completely as possible, the examples include the...

Generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user ...

This is a class a product based on the standard of the vcci council. If this equipment is used in a domestic environment, radio interference may occur, in which case, the user may be required to take corrective actions. Japanese electronics and information technology industries association (jeita) c...

Electromagnetic interference (emi) statement - korea germany compliance statement deutschsprachiger eu hinweis: hinweis für geräte der klasse a eu-richtlinie zur elektromagnetischen verträglichkeit dieses produkt entspricht den schutzanforderungen der eu-richtlinie 2004/108/eg zur angleichung der re...

Verantwortlich für die einhaltung der emv vorschriften ist der hersteller: international business machines corp. New orchard road armonk, new york 10504 tel: 914-499-1900 der verantwortliche ansprechpartner des herstellers in der eu ist: ibm deutschland gmbh technical regulations, abteilung m456 ibm...

Any radio or television interference caused by unauthorized changes or modifications to this equipment. Unauthorized changes or modifications could void the user's authority to operate this equipment. This device complies with part 15 of the fcc rules. Operation is subject to the following two condi...

Japanese electronics and information technology industries association (jeita) confirmed harmonics guideline with modifications (products greater than 20 a per phase) ibm taiwan contact information electromagnetic interference (emi) statement - korea germany compliance statement deutschsprachiger eu...

Dieses gerät ist berechtigt, in Übereinstimmung mit dem deutschen emvg das eg-konformitätszeichen - ce - zu führen. Verantwortlich für die einhaltung der emv vorschriften ist der hersteller: international business machines corp. New orchard road armonk, new york 10504 tel: 914-499-1900 der verantwor...

100 power systems: power supplies for the 9117-mmb, 9117-mmc, 9179-mhb, or 9179-mhc.

Printed in usa.