- DL manuals

- IBM

- Server

- eserver pSeries 690

- Installation Manual

IBM eserver pSeries 690 Installation Manual

Summary of eserver pSeries 690

Page 1

Pseries 690 installation guide installation guide sa38-0587-01 e rserver ibm.

Page 3

Pseries 690 installation guide installation guide sa38-0587-01 erserver ibm.

Page 4

Second edition april 2002 before using this information and the product it supports, read the information in “safety notices” on page vii, appendix b, “environmental notices” on page 47, and appendix c, “notices” on page 49. © copyright international business machines corporation, 2001, 2002. All ri...

Page 5: Contents

Contents safety notices. . . . . . . . . . . . . . . . . . . . . . . . Vii electrical safety . . . . . . . . . . . . . . . . . . . . . . . Vii laser safety information . . . . . . . . . . . . . . . . . . . . . Ix laser compliance . . . . . . . . . . . . . . . . . . . . . . Ix data integrity and veri...

Page 6

Step 12. Turn on the ibf breaker (if present) . . . . . . . . . . . . . 28 step 13. Have the customer activate the designated circuit breakers . . . . . 28 step 14. Set the console’s date and time . . . . . . . . . . . . . . 28 step 15. Ensure that the latest firmware, hmc code and adapter/drive mic...

Page 7

Mounting internal rack components . . . . . . . . . . . . . . . 53 determine your next step . . . . . . . . . . . . . . . . . . . 54 attach the rack to a concrete (non-raised) floor . . . . . . . . . . . . 55 attaching the rack to a short or long raised floor . . . . . . . . . . . 59 appendix e. Ins...

Page 8

Appendix j. Removing and installing the rack top frame. . . . . . . . 105 options for performing this procedure. . . . . . . . . . . . . . . . 105 required tools . . . . . . . . . . . . . . . . . . . . . . . 106 removing the covers . . . . . . . . . . . . . . . . . . . . . 107 side cover removal . ....

Page 9: Safety Notices

Safety notices attention: when moving or relocating certain configurations of the system, the bulk power regulators (bpr’s) must be removed from the top of the rack (front and rear) to ensure product stability. Specifically, removal of the top two bpr’s in the front and rear is required in systems t...

Page 10

Caution: this product is equipped with a four-wire (three-phase and ground) power cable for the user’s safety. Use this power cable with a properly grounded electrical outlet to avoid electrical shock. Danger to prevent electrical shock hazard, disconnect all power cables from the electrical outlet ...

Page 11

Laser safety information caution: this product may contain a cd-rom, dvd-rom, or laser module on a pci card, which are class 1 laser products. Laser compliance all lasers are certified in the u.S. To conform to the requirements of dhhs 21 cfr subchapter j for class 1 laser products. Outside the u.S....

Page 12

X pseries 690 installation guide.

Page 13

Data integrity and verification ibm computer systems contain mechanisms designed to reduce the possibility of undetected data corruption or loss. This risk, however, cannot be eliminated. Users who experience unplanned outages, system failures, power fluctuations or outages, or component failures mu...

Page 14

Xii pseries 690 installation guide.

Page 15: About This Book

About this book this book provides information on how to set up and cable the server, install and remove options, and verify server operation. Iso 9000 iso 9000 registered quality systems were used in the development and manufacturing of this product. Online publications ibm eserver pseries publicat...

Page 16

V the rs/6000 and eserver adapters, devices and cable information for multiple bus systems, order number sa38-0516, contains information about adapters, devices, and cables for your server. This manual is intended to supplement the service information found in the diagnostic information for multiple...

Page 17

Chapter 1. Getting started this chapter helps you get started with installing and configuring the pseries 690 environment. The following information is included in the chapter: v eserver pseries roadmap v documentation overview - brief description of the printed and softcopy documentation shipped in...

Page 18

The eserver pseries roadmap helps you locate marketing, service, and customer task information. The roadmap guides you through the tasks and the publications that document those tasks. 2 pseries 690 installation guide.

Page 19

Documentation overview this section provides descriptions, and target audience information for the eserver pseries and aix 5l documentation libraries. Some of the documentation may only be available in printed form or in softcopy form. Based on the documentation content, the books are divided into t...

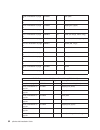

Page 20

Table 2. Installing and configuring (continued) aix 5l documentation cd aix documentation library (system management guides, user guides, application programmer guides, commands and files references, aix man pages, and so on). System administrators softcopy table 3. Using the system documentation ti...

Page 21

Configuring online documentation it is not necessary to install the operating system’s online documentation onto your server. You can access all of the documentation through the internet at the following web address: http://www.Ibm.Com/servers/aix/library however, if you use the documentation librar...

Page 22

6 pseries 690 installation guide.

Page 23

Chapter 2. Installing the pseries 690 use the procedures in this chapter to set up your pseries 690. Minimum system configuration the minimum system configuration consists of the redundant bulk power subsystem, one processor subsystem, a media subsystem, and one i/o subsystem in the same rack, as we...

Page 24

A secondary rack may be required to support additional i/o subsystems and is placed to the left of the primary rack. Multiple system configurations the system configuration may vary. Other configurations include the following: v multiple pseries 690 servers attached to one hmc. For more information ...

Page 25

Step 2. Check the inventory use the packing lists for each ship group to verify that you have all the items shipped with the pseries 690. Other tools that might be needed for installation, but not shipped with the system, include: v electronic service multimeter v lift tool v service vacuum v servic...

Page 26

Step 3. Position and level the primaryrack to adjust the leveling feet on the rack, do the following: 1. Ensure the rack is positioned according to the customer plan. 2. Loosen the jam nut on each leveling foot by turning the nut counterclockwise (away from the bottom of the rack). 3. Rotate each le...

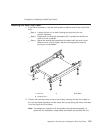

Page 27

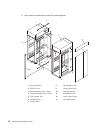

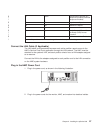

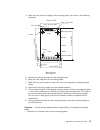

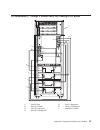

Step 4. Attach and cable secondary rack (if ordered) use the illustration on page 12 for more information on following these procedures. 1. Screw two standoffs to the primaryrack and the other two to the secondary rack. 2. Attach emc bottom trim to the secondary rack, using four screws. 3. Place low...

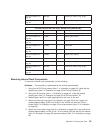

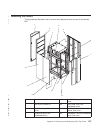

Page 28

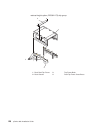

9. Use screws and washers to screw the frames together. 1 2 7 4 6 6 6 4 3 10 13 12 11 3 3 9 8 6 4 5 3 1 secondary rack 8 top hat side cover 2 emc top trim 9 primary side cover 3 bolt and washer (qty. 4 each) 10 rear vertical trim 4 threaded standoff (qty. 4 each) 11 emc bottom trim 5 front vertical ...

Page 29

Connecting internal power cords for the secondary rack if you are installing a secondary rack, route the power cords from the primary rack to the secondary rack and connect them to the drawers in the secondary rack. See appendix h, “cabling information” on page 95 for additional information. To back...

Page 30

Connecting i/o cables for the secondary rack if you are installing a secondary rack, route the i/o cables from the primary rack to the secondary rack and connect them to the drawers in the secondary rack. Secondary rack rear to primary rack primary rack rear ports 0 and 1 ports 0 and 1 note: for mor...

Page 31

Connecting the integrated battery feature power for the secondary rack if you are installing an ibf for the secondary rack, route the cables as shown in the following illustration: ibf-p1 ibf-p1 secondary rack front secondary rack rear chapter 2. Installing the pseries 690 15.

Page 32

Step 6. Observe this safety notice during installation danger an electrical outlet that is not correctly wired could place hazardous voltage on metal parts of the system or the devices that attach to the system. It is the responsibility of the customer to ensure that the outlet is correctly wired an...

Page 33

Step 7. Check the cables and connect i/o devices cables may loosen during shipping. Check for loose cables before completing the installation. For cabling illustrations, see appendix g, “subsystem positioning and cabling” on page 83. For further details on the cable descriptions and labels, see appe...

Page 34

Connection is made. This figure illustrates the back of the machine uepo panel with the room epo cable plugging into the machine. Notice the switch actuator. Once the switch actuator is moved to make the cable connection possible, the room epo cable must be installed for the machine to power on. 1 2...

Page 35

Step 9. Check the outlets and the power source caution: do not touch the receptacle or the receptacle faceplate with anything other than your test probes before you have met the requirements in below. Do the following to ensure that the customer has provided the correct power to the system: __ 1. Th...

Page 36

Note: if your power source does not have a standard receptacle, check for voltage using local procedures. Measure for appropriate voltages between phases. If no voltage is present on the receptacle case or grounded pin, the receptacle is safe to touch. __ 8. With an appropriate meter, verify that th...

Page 37

Step 10. Connect and route the power cords to the pseries 690 before you connect the power cords, loosen or remove the cable retainers and filler plate located along the side and bottom of the frame. The following tables shows a listing of each of the brackets and recommended range of cable sizes fo...

Page 38

2. Secure the power cord from top to bottom in the channel with the brackets. 3. Remove the lower panel of the frame, and route the cord through the channel under the frame. 4. Route the rear line cord underneath the frame to the back floor tile hole. For more information on floor cutouts, refer to ...

Page 39

1. Attach the monitor cable to the monitor connector, and tighten the screws. Chapter 2. Installing the pseries 690 23.

Page 40

2. If a label for the monitor was shipped with your system, attach the label to the bottom-right corner of the monitor. 3. Attach the power cord to the monitor (item 1 in the following illustration). If the hmc has a voltage switch, ensure that it is in the correct position for the supply voltage. A...

Page 41

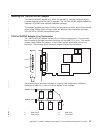

5. Connect the hmc serial cable to serial port hmc1 on the primary i/o book. For two hmcs, connect the redundant hmc into serial port hmc2 on the primary i/o book. The following illustration shows the location of the serial ports on the back of the hmc and the hmc connectors located on the primary i...

Page 42

Part number 11p3956 15m cable 9 position to 9 position part number 31l7196 15m cable 9 position to 25position connect the external modem the external modem is used in conjunction with the hmc’s service agent and call home features. To properly service your machine, it is important that you configure...

Page 43

11 down asynchronous terminal (at) responses enabled (extended responses enabled) 12 *down asynchronous operation 13 up 28.8kb line speed 14 up 15 up carrier detect (cd) and data set ready (dsr) normal functions 16 up 2-wire leased line enabled note: * only switches 5 and 12 are changed from the fac...

Page 44

Step 12. Turn on the ibf breaker (if present) turn the integrated battery feature (ibf) breaker on before turning the uepo switch on the pseries 690. Step 13. Have the customer activate the designated circuit breakers have the customer activate the designated circuit breakers by doing the following:...

Page 45

5. Select customize console date / time to open the customize console date / time window. This window is similar to the following: 6. Either type or use the up and down arrows to enter the date and time information as appropriate. 7. From the list, select the time zone closest to your location, and ...

Page 46

V access core or go to the website http://techsupport.Services.Ibm.Com/server/mdownload/download.Html proceed to verifying the hardware operation the installation of the pseries 690 is now complete. Proceed to chapter 3, “verifying the hardware operation” on page 31. 30 pseries 690 installation guid...

Page 47

Chapter 3. Verifying the hardware operation use the system verification procedure discussed in this chapter to check the system for correct hardware operation. Considerations before running this procedure read the following before using this procedure: v the aix operating system must be installed on...

Page 48

10. Select power on. 11. Select the power on diagnostics stored boot list option. 12. Ensure that the media subsystem contains no media devices. 13. Enter any passwords, if requested. Note: if you are unable to load the diagnostics to the point when the diagnostic operating instructions display, go ...

Page 49

Chapter 4. Completing the installation this chapter contains information on the final installation steps. Complete the steps described in this chapter after you verify the hardware operation as described in chapter 3, “verifying the hardware operation” on page 31. For instructions on returning the c...

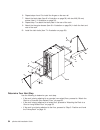

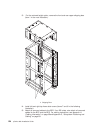

Page 50

1 1 1 1 2 2 2 3 4 2 1 hinge pin (typical front and rear door) 3 front door 2 rack hinge (typical front and rear door) 4 rear door 34 pseries 690 installation guide.

Page 51

Configure the network to configure the network, do the following: v log in to the hardware management console for pseries (hmc) using the user id hscroot and password abc123 . Note: user ids and passwords are case-sensitive. Enter the user id and password exactly as shown. V select the system config...

Page 52

1. In the navigation area, double-click the inventory scout services icon. 2. In the contents area, select inventory scout profile configuration. 3. From the list, select a managed system. 4. Select next. 5. From the list, select the partition you want to configure. 6. Select next. 7. The next windo...

Page 53

Configure the service agent note: you must configure the network before you configure the service agent. To start the service agent, click on the service agent icon on the hmc virtual terminal window. If you are configuring service agent for the first time, select start service agent processes to st...

Page 54

5. Select network. Fill in the appropriate information. Note: some of the fields are prefilled with information taken from the service agent initial configuration panel. 6. Select ok. 7. Expand the contents of the gateway category by clicking the key next to your gateway machine. 8. Select dialer. 9...

Page 55

Running system verification before you run system verification, the diagnostics must have been loaded. For information about how to load diagnostics, see chapter 3, “verifying the hardware operation” on page 31. While the power-on sequence is completing, the following events occur: v the power led o...

Page 56

V the a problem was detected on (time stamp) menu displays, with either a service request number (srn) or an error code. Make a note of any codes displayed on the display or operator panel. To perform additional system verification, go to “performing additional system verification”. To exit diagnost...

Page 57

Date on a partition’s software is set 90 days behind the hmc’s set time, the serviceable events reported from this partition are immediately discarded. Getting started when you are setting up service focal point, keep the following in mind: v if the /var file system is full (either on the hmc or par...

Page 58

Note: disable the enable/disable call home in sfp, as this will generate an event that will transfer to service agent and potentially create a pmh. Enable extended error data collection. V start concurrent diagnostics from the aix partition. V invoke either problem determination or system verificati...

Page 59

Appendix a. Communications statements the following statement applies to this product. The statement for other products intended for use with this product appears in their accompanying documentation. Federal communications commission (fcc) statement note: this equipment has been tested and found to ...

Page 60

International electrotechnical commission (iec) statement this product has been designed and built to comply with iec 60950. United kingdom telecommunications safety requirements this equipment is manufactured to the international safety standard en60950 and as such is approved in the uk under the g...

Page 61

Electromagnetic interference (emi) statement - taiwan the following is a summary of the emi taiwan statement above. Warning: this is a class a product. In a domestic environment this product may cause radio interference in which case the user will be required to take adequate measures. Radio protect...

Page 62

46 pseries 690 installation guide.

Page 63

Appendix b. Environmental notices product recycling and disposal this unit contains materials such as circuit boards, cables, electromagnetic compatibility gaskets and connectors which may contain lead and copper/beryllium alloys that require special handling and disposal at end of life. Before this...

Page 64

Acoustical noise emissions the equivalent continuous a-weighted sound pressure level at workstations (emission sound pressure level at the 1-meter bystander positions) does not exceed 70 db(a). Der geräuschpegel der einheit ist kleiner oder gleich 70 db(a). Declared acoustical noise emissions acoust...

Page 65: Appendix C. Notices

Appendix c. Notices this information was developed for products and services offered in the u.S.A. The manufacturer may not offer the products, services, or features discussed in this document in other countries. Consult the manufacturer’s representative for information on the products and services ...

Page 66

50 pseries 690 installation guide.

Page 67

Appendix d. Securing the rack this appendix contains information about installing the rack for the pseries 690. For further information, refer to pn44p0159, installation instructions for rpq’s 8a1183, 8a1185, 8a1186 shown below: v rpq 8a1183 for attaching the rack-mounting plates to the concrete flo...

Page 68

Item 8 in illustration on page 54. 11p3530 2 latch plate item 6 in illustration on page 54. 11p3531 2 eq support item 2 in illustration on page 54. 11p3532 2 shipping bar (upper) item 7 in illustration on page 54. 76x4687 2 latch bolt item 1 in illustration on page 54. 1624804 20 screw (hex flange, ...

Page 69

Item 9 in illustration on page 54. 1621546 8 screw (hex, 25mm, long, hinge) item 10 in illustration on page 54. 1622307 8 washer (m-8, hinge) 11p4758 frame tie-down kit (long - raised floor) (rpq 8a1186) item part number qty description illustration on page 63. 44p0674 4 turnbuckle assembly (long) i...

Page 70

6. Repeat steps 4 and 5 to install the hinges on the rear rail. 7. Attach the latch plate (item 8 in illustration on page 54) with two m-8 (20 mm) screws (item 1 in illustration on page 54). 8. Repeat step 7 to attach the latch plate in the rear of the rack. 9. Attach the triangular braces (item 6 i...

Page 71

Attach the rack to a concrete (non-raised) floor use this procedure to attach the rack to a concrete (non-raised) floor. Attention: it is the customer’s responsibility to ensure the following steps are completed before the service representative performs the tie-down procedure. Note: the customer sh...

Page 72

1. Be sure the rack is in the correct location. Rack tie down (non-raised floor) 1 1 2 2 3 3 4 4 5 5 6 6 2. Place the mounting plates (item 1 in illustration on page 56), front and rear, in the approximate mounting position under the system rack. 3. To align the mounting plates to the system rack, d...

Page 73

4. Mark the floor around the edge of the mounting plates, as shown in the following illustration: mounting plate mounting plate mounting plate bolt locations caster caster caster caster rack rear front 750 mm ref 709.8 mm ref 27.5 mm ref 20.1 mm (2x) 2.9 mm ref 22.5 mm ref (10x) 65.5 mm ref (32x) 21...

Page 74

2. Place the four rack-mounting bolts through the plate assemblies with the d-washer positioned so that the straight side of the washer is facing inward toward the system rack. 3. Place the isolator bushing (item 4 in illustration on page 56) inside the leveling foot with a washer between the isolat...

Page 75

Attaching the rack to a short or long raised floor attention: it is the customer’s responsibility to ensure the following steps are completed before the service representative performs the tie-down procedure. Note: to accommodate a floor with a depth of more than 16 inches, asteel beam or a steel ch...

Page 76

3. Plan for installing four eyebolts positioned to match the dimensions given in the following illustrations. 654.8 mm 654.8 mm (4x) 450 mm ref (8) x 49.3 mm eyebolts (4x) 75 mm ref 610 mm ref (4x) 170 mm ref 2440 mm ref 1019 mm 64.6 mm 64.6 mm 100.5 mm 24 inch floor tile layout (4) opening for cabl...

Page 77

To install the frame, do the following: attention: it is the service representative’s responsibility to complete the following steps. 1. Before starting the installation, check all cable openings in the floor panel and location of the rubber bushing holes so that they match the dimensions given in t...

Page 78

(4x) opening for cables 654.8 mm (8) 49.3 mm eyebolt 654.8 mm 600 mm (23.6 inch floor) tile layout 600 mm ref 23.6 in ref (4) 170 mm ref 1200 mm ref 47.2 in ref 1019 mm 90.5mm (4) 75 mm 2.96 in 64.6 mm 64.6 mm (4x) 450 mm ref 2. Power off the system and make sure all cables and connectors are discon...

Page 79

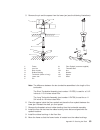

5. Remove the pin and the spacer from the lower jaw (see the following illustrations). 1 2 3 4 5 6 9 10 11 12 13 7 8 1 frame 8 floor eyebolt (customer-supplied) 2 jam nut 9 threaded rod 3 rack leveler 10 nut 4 rubber bushing 11 washer 5 turnbuckle (short or long) 12 spacer 6 lower jaw 13 shaft 7 pin...

Page 80

Attention: to avoid a tipping hazard, make sure that the frame casters do not roll into the cable opening. 11. Turn the leveling foot of the plate assembly down until it contacts the bushing, and then level the rack using the four leveling feet by tightening the lock nuts. 12. Lock the leveling feet...

Page 81: Management Console

Appendix e. Installing multiple pseries 690s to one hardware management console this appendix details how to install multiple pseries 690 servers to one hardware management console (hmc). The hmc might have an 8-port async adapter or a 128-port async adapter installed to allow multiple servers to co...

Page 82

Connect the serial cables from the pseries 690 to the 8-port async adapters up to two optional 8-port async adapters can be installed. The d-shell connector on the back of the adapter attaches to the 8-port expansion cable. The cable is about 3 feet long, and on the other end, has a slim box (8 1/2 ...

Page 83

Installing the 128-port async adapter the 128-port async adapter is an option for the hmc. It must be configured by the customer engineer when the hmc is installed. The 128-port async adapter software is installed in the hmc base software installation package. This adapter provides the control funct...

Page 84

V up to eight rans may be attached to one adapter total. If 4 are attached to line one, then only 4 more can be attached to line 2. V rans must be numbered in ascending order. The ran closest to the adapter is assigned as node 1. No gaps in the numbering should occur. Example, numbering rans as 1, 3...

Page 85

Ports on the 8-port expansion cable or a ran if used. Configuring the 128-port async adapter when a 128-port async adapter is installed in the hmc and the hmc is first used, the adapter must be configured. To configure the 128-port async adapter in the hmc, two configuration utilities must be run (/...

Page 86

11) 88 12) 96 13) 104 14) 112 15) 120 16) 128 board #1 how many ports? (1–16) answer: count the total number of enhanced rans you are attaching to the 128-port async adapter and multiply by two. For example: 2 (rans) multiplied by 2 equals 4. Enter the selection number 4), for 32 in this example, at...

Page 87

Updating the device driver to update the device driver for the 128-port async adapter, perform the following: 1. Move the .Rpm device package to the hmc. 2. At the command prompt, enter rpm -i -force epca-1.51-2.I386.Rpm the device driver is installed as /lib/modules/2.4.9–12/misc/epca.O if lib/modu...

Page 88

Verify installation is complete by using the hmc interface the hmc provides a predefined user called hscroot. The hscroot password is abc123. This hscroot user id is a member of the system administrator role. When the console is powered on for the first time, use this user id to log in. After you ar...

Page 89

Host system applications that are managed by the console. Each system application contains its own set of applications that contain managed objects, tasks, and actions for a related set of system entities or resources. The panel on the right (the contents area) displays results based on the item you...

Page 90

74 pseries 690 installation guide.

Page 91

Appendix f. System records use this appendix to keep a record of your server configuration. Record the identification numbers the basic server consists of the redundant bulk power subsystem, one processor subsystem, a media subsystem, and one i/o subsystem in the same rack, as well as access to one ...

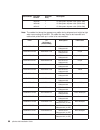

Page 92

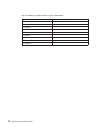

Use the following to keep a record of your components. Component serial number pseries 690 i/o drawer 1 i/o drawer 2 i/o drawer 3 i/o drawer 4 (or drawer 7 if installed) i/o drawer 5 i/o drawer 6 i/o drawer 7 i/o drawer 8 76 pseries 690 installation guide.

Page 93

Record system - cpu, memory, and i/o configuration the following illustration shows the location codes for the primary rack. These codes are used to identify the major functional units in the pseries 690. Rear front u1.35-p1-x2 u1.35-p2-x2 u1.35-p1-x4 u1.35-p2-x4 u1.17 u1.17 u1.9 u1.9 u1.1 u1.1 u1.5...

Page 94

The following illustration shows the location codes for the secondary rack. These codes are used to identify the major functional units in the pseries 690 systems. Rear front u2.17-p1-v5 u2.13 u2.13 u2.17-p2-v6 u2.9 u2.1 u2.1 u2.5 u2.5 u2.9 u2.19 u2.19 78 pseries 690 installation guide.

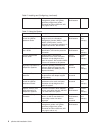

Page 95

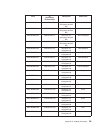

Physical memory card location available other description information mcm 0 installed u1.18-p1-c1 mcm 0 vpd card u1.18-p1-h2.3 memory u1.18-p1-m2 memory book v 4 gb v 8 gb v 16 gb v 32 gb memory u1.18-p1-m3 memory book v 4 gb v 8 gb v 16 gb v 32 gb l3 modules v u1.18-p1-c6 v u1.18-p1-c7 v u1.18-p1-c...

Page 96

Physical memory card location available other description information memory u1.18-p1-m4 memory book v 4 gb v 8 gb v 16 gb v 32 gb memory u1.18-p1-m8 memory book v 4 gb v 8 gb v 16 gb v 32 gb l3 modules v u1.18-p1-c8 v u1.18-p1-c12 v u1.18-p1-c16 v u1.18-p1-c20 l3 vpd card u1.18-p1-h2.1 mcm 3 instal...

Page 97

Physical memory card location available other description information secondary i/o book v u1.18-p1-h3 - i/o slot 2 - drawer 5 v drawer 6 v outside rio connector a0 and a1 v outside rio connector b0 and b1 secondary i/o book v u1.18-p1-h4 - i/o slot 3 - drawer 7 v drawer 8 v outside rio connector c0...

Page 98

82 pseries 690 installation guide.

Page 99

Appendix g. Subsystem positioning and cabling this section shows subsystem positioning and cabling for the pseries 690. Operator panel cable and diskette drive cable to the media subsystem (rear view) 1 primary i/o book 3 diskette drive data cable 2 cable connecting the operator panel to the media s...

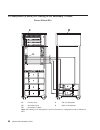

Page 100

I/o subsystem positions, fully populated primary and secondary rack (rear view without ibf) c1 c2 5 3 4 2 eia 1 eia 9 eia 13 eia 19 eia 17 eia 5 1 6 7 c3 c4 8 c1 primary rack 3 third i/o subsystem c2 secondary rack 4 fourth i/o subsystem c3 blank space 5 fifth i/o subsystem c4 blank space 6 sixth i/...

Page 101

I/o subsystem positions, fully populated primary and secondary rack (rear view with ibfs) c1 c2 c3 5 3 2 1 4b 2b 4b 6 4 7 1 1 8 1 c1 primary rack 4b four ibfs (primary rack), position 4 c2 primary i/o book (book 0) 5 fifth i/o subsystem c3 secondary rack 6 sixth i/o subsystem 1 first i/o subsystem 7...

Page 102

Placement of subsystem 4 in a two-rack configuration (rear view with ibf) c1 c2 3 2 1 4b 4b 4 eia 1 eia 5 eia 9 c1 primary rack 3 third i/o subsystem c2 secondary rack 4 fourth i/o subsystem 1 first i/o subsystem 4b four ibfs 2 second i/o subsystem note: the physical location shown for i/o subsystem...

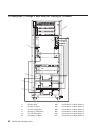

Page 103

I/o subsystems (1 through 4 without ibfs) rio cabling to i/o books a0 c0 a1 c1 b0 0 0 0 0 0 0 0 0 1 1 1 4 3 5 6 7 1 1 1 1 1 b1 d1 d0 1 2 1 primary rack 5 first i/o subsystem 2 primary i/o book 6 fourth i/o subsystem 3 third i/o subsystem 7 secondary i/o book 4 second i/o subsystem appendix g. Subsys...

Page 104

I/o subsystems (5 and 6) rio cabling to the secondary i/o book shown without ibfs c1 primary rack 5 fifth i/o subsystem c2 secondary rack 6 sixth i/o subsystem c3 secondary i/o book note: rio cabling to i/o subsystems 5 and 6 is the same for configurations with or without the ibfs. 88 pseries 690 in...

Page 105

I/o subsystems (7 and 8) rio cabling to the third i/o book 0 c1 c2 c3 5 3 2 1 4b 4b 6 4 7 0 8 c0 c1 d0 d1 shown with ibfs c1 primary rack 4 fourth i/o subsystem c2 secondary rack 4b two ibfs (maximum), position 4 c3 third i/o book (book 3) 5 fifth i/o subsystem 1 first i/o subsystem 6 sixth i/o subs...

Page 106

I/o subsystem (1 through 3 with ibfs) rio cabling to i/o books a0 c0 a1 c1 b0 0 0 0 0 0 0 1 1 4 3 5 6 1 1 1 1 b1 1 2 1 primary rack a0 connection to i/o book (book 0) 2 primary i/o book a1 connection to i/o book (book 0) 3 third i/o subsystem b0 connection to i/o book (book 0) 4 second i/o subsystem...

Page 107

Rio cable to i/o subsystem (4 through 6) with ibfs installed c1 c2 c3 5 3 2 1 4b 4b 6 4 7 8 b0 a0 a1 d1 d0 b1 c1 secondary rack 6 sixth i/o subsystem c2 primary rack 7 seventh i/o subsystem c3 secondary i/o book in i/o slot 3 8 eighth i/o subsystem c4 secondary i/o book in slot 2 a0 connection to i/...

Page 108

I/o subsystems (7 and 8) rio cabling to the third i/o book 0 c1 c2 c3 5 3 2 1 4b 4b 6 4 7 0 8 c0 c1 d0 d1 shown with ibfs c1 primary rack 5 fifth i/o subsystem c2 secondary rack 6 sixth i/o subsystem c3 third i/o book (book 3) 7 seventh i/o subsystem 1 first /o subsystem 8 eighth i/o subsystem 2 sec...

Page 109

Power and scsi cables to the media subsystem 1 2 3 5 4 7 6 1 primary rack 5 scsi cable for media subsystem rear drives 2 primary i/o book 6 scsi cable for media subsystem front drives 3 power cable for media subsystem front drives 7 power cable for media subsystem rear drives 4 rear of media subsyst...

Page 110

Hardware management console for pseries (hmc) to the primary i/o book to connect your hmc to the pseries 690, connect the serial cable into serial port 1 located on the back of the hmc. Connect the other end of the serial cable into the hmc1 connector located on the primary i/o book on the managed s...

Page 111

Appendix h. Cabling information this appendix provides information on the location, and label colors of the pseries 690 cables. Power cabling 1 front rear 3 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 2 6 10 8 12 11 13 9 14 7 15 5 16 4 95.

Page 112

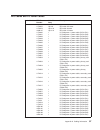

Index part number units per assy description 1 na bulk power distribution on the a side of the system (bpd a side) 2 na bulk power distribution on the b side of the system (bpd b side) 3 na 1 a35-bpc-p03 to bulk power fan p1-f1, cable attached to fan (bpf-a) 4 na 1 b35-bpc-p03 to bulk power fan p2-f...

Page 113

Rio cables and i/o power cables index number fru part number units per assy description 11p2355 up to 8 rio cable 0.5-meter 11p0272 up to 16 rio cable 2-meter 44h9137 up to 16 rio cable 15-meter 11p4490 1 i/o subsystem 1 power cable (dca1-p01) 11p4491 1 i/o subsystem 1 power cable (dca1-p00) 11p4492...

Page 114

Index number fru part number units per assy description 44p0195 1 i/o subsystem 8 power cable (dca1-p00) 44p0196 1 i/o subsystem 8 power cable (dca2-p01) 44p0197 1 i/o subsystem 8 power cable (dca2-p00) note: the cables tied along the raceway may settle during shipment and might be tight when reconn...

Page 115

From to (a=primary) (z=secondary) description label color a35b-bpd2a-p04 z09b-dca1-p01 bpd1a to i/o subsystem #4 (with ibf) yellow w/stripes a35p-bpd2b-p04 z09b-dca1-p00 bpd1b to i/o subsystem #4 (with ibf) yellow a35b-bpd2a-p05 z09b-dca2-p01 bpd1a to i/o subsystem #4 (with ibf) yellow w/stripes a35...

Page 116

From to (a=primary) (z=secondary) description label color a35p-bpd2b-p09 z19b-dca2-p00 bpd2b to i/o subsystem #8 blue 100 pseries 690 installation guide.

Page 117

Appendix i. Service processor setup and test attention: this procedure applies to modems attached to the serial ports (s1 and s2) on the primary i/o book (location u1.18-p1-h2). It does not affect the operation of the modem attached to the hardware management console for pseries (hmc). The call-out ...

Page 118

Testing the setup this section contains sample testing procedures to help ensure your setup is working. These tests include communicating with the server operating system. Before you start, ensure that the necessary serial port(s) is configured. If you need assistance, refer to “serial port configur...

Page 119

Testing call-out during the setup, you entered your phone numbers for the pager and customer voice. These numbers are used for this test. 1. Your remote terminal is disconnected as a result of the call-in test. 2. Call your server again. 3. At the service processor main menu, select call-in/call-out...

Page 120

104 pseries 690 installation guide.

Page 121

Appendix j. Removing and installing the rack top frame options for performing this procedure two scenarios exist for performing this procedure: v removing and installing the rack top frame for clearance through doorways v installing the rack top frame that was shipped unattached from the rest of the...

Page 122

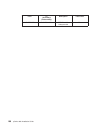

Required tools the following tools are necessary to remove and/or install the rack top frame: v ladder v step ladder table 4. Hand tools tool description ratchet 3/8 inches square drive ratchet accessories 3/8 inches drive, 6 inches extension x2 (8 inch reach required) drive socket 3/8 inches (10mm)...

Page 123

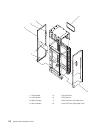

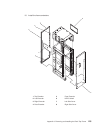

Removing the covers this procedures describes how to remove and replace the side covers of the pseries 690 1 2 3 4 5 6 7 9 10 11 12 13 14 15 1 rear cover pn44p0127 9 pn11p3535 hinge pn2665525 screw 2 rear cover pn44p0107 10 pn11p1096 front latch pn54g2882 screw 3 pn11p4106 hinge pn2665525 screw 11 p...

Page 124

5 pn44p0126 right cover pn54g2882 screw 13 pn05n6585 j bracket pn 2665528 screw 6 pn11p3600 left cover pn44p0125 screw 14 pn44p0126 right cover pn 54g2882 screw 7 pn44p0105 front cover 15 pn44p0125 left cover pn 54g2882 screw side cover removal 1. Always remove the right side cover first. 2. Remove ...

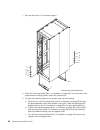

Page 125

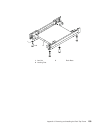

1 2 3 1 jam nut 3 rack base 2 leveling foot appendix j. Removing and installing the rack top frame 109.

Page 126

2. Disconnect cables from the bpds. 3. Remove the front and rear bprs, bpds, bpcs, and the fan assemblies. Attention: make note of location identification of the bprs and bpes for later reinstallation. The pseries 690 will not power on if these components are not reinstalled in their original locati...

Page 127

4) pull the bpf straight out of the bpe. 5) repeat for the other bpf. There are two bpfs, one in front and one in back. E. Remove any front and rear bulk power fillers. 4. Remove the top frame side covers (items 7 and 8 in illustration on 112) as follows: __ step a. Remove the two screws at the top ...

Page 128

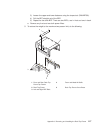

1 8 7 2 3 4 5 1 top extender 5 front extender 2 left extender 6 uepo switch 3 right extender 7 rack top frame left side cover 4 rear extender 8 rack top frame right side cover 112 pseries 690 installation guide.

Page 129

6. Remove the bpes (item 1 in the illustration on page 113). Note: two people are required to remove the bpes. 1 bulk power enclosure 2 hex head screw locations __ step a. Remove the five hex head screws from the front bpe. __ step b. Remove the five hex head screws from the rear bpe. Install (2) sh...

Page 130

7. To reduce the weight to the maximum two-person limit, do the following: 1 front and rear rack top frame top panels 4 foam and metal air baffle 2 rack top frame 5 rack top frame cross brace 3 left and right bpe rails __ step a. Remove the eight screws around the perimeter of the top panels at the ...

Page 131

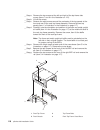

2 3 4 1 rack top frame 3 top frame bolts 2 rack chassis 4 rack top frame cross brace 8. Remove the (16) m8 x 20mm bolts (p/n 1624804) 9. Lift the rack top frame off the locating pins and remove it. Note: two people are required to lift and position the rack top-frame assembly. Preparing for rack top...

Page 132

4. Remove the front and rear bprs, bpds, bpcs, and the fan assemblies. Attention: make note of location identification of the bprs and bpes for later reinstallation. The pseries 690 will not power on if these components are not reinstalled in their original location. 1 2 3 4 5 6 1 bpe 4 bpr 2 bpd 5 ...

Page 133

3) loosen the upper and lower fasteners using the torque tool (pn6422789). 4) pull the bpf straight out of the bpe. 5) repeat for the other bpf. There are two bpfs, one in front and one in back. E. Remove any front and rear bulk power fillers. 5. To reduce the weight to the maximum two-person limit,...

Page 134

__ step a. Remove the two screws at the left and right of the top frame side covers (items 7 and 8 in the illustration on 112). __ step b. Lift off the covers. __ step c. Remove the eight screws around the perimeter of the top panels at the front and rear of the rack top frame assembly. Remove the t...

Page 135

Proceed to “installing the rack top frame”. Installing the rack top frame 1. If you have not done so, use the jack screws to stabilize and lift the rack off the floor. __ step a. Loosen the jam nut on each leveling foot by turning the nut counter-clockwise. __ step b. Rotate each leveling foot downw...

Page 136

Reduced height option (rpq8a1173) ship group. 2 3 4 1 rack rack top frame 3 top frame bolts 2 rack chassis 4 rack top frame cross brace 120 pseries 690 installation guide.

Page 137

__ step a. Align the rack top frame with the four alignment guides on top of the rack. __ step b. Fasten the rack top frame to the rack, using (16) m8 x 20mm bolts (p/n 1624803). Tighten the bolts securely to ensure solid contact along the mating surfaces of the rack and the rack top frame. Appendix...

Page 138

3. Install the front and rear top panels (item 1 in illustration on page 122) for the rack top frame. 4. Install the left and right bpe rails, (item 3 in the illustration on page 122). 1 front and rear rack top frame top panels 4 foam and metal air baffle 2 rack top frame 5 rack top frame cross brac...

Page 139

__ step a. Push the bpc straight into the bulk power enclosure (bpe). __ step b. Tighten the thumbscrew on each side of the bpc using the torque tool (pn6422789). __ step c. Repeat for the other bpcs. There are two bpcs, with one in front and one in back. 10. Install the bpds as follows: __ step a. ...

Page 140

13. For the reduced height option, remove the front and rear upper shipping bars (item 1 in the next illustration). 1 1 shipping bars 14. Install left and right top frame side covers (items 7 and 8 in the following illustration). 15. Attach all removed cables to the bpd. If an ibf exists, also attac...

Page 141

16. Install the frame extenders. 1 8 7 2 3 4 5 1 top extender 5 front extender 2 left extender 6 uepo switch 3 right extender 7 left side cover 4 rear extender 8 right side cover appendix j. Removing and installing the rack top frame 125.

Page 142

17. Install the uepo switch: v install the top and bottom screws. Screws should be bottomed against the end of the slot prior to tightening. V plug in the cables. Cover replacement refer to 107 while performing this task. 1. Examine the bottom of the frame side. There will be (2) ″ u ″ brackets inst...

Page 143: Index

Index numerics 128-port adapter cables connecting 71 8-port adapter cables connecting 66 a about this book xiii acoustical noise emissions 48 adapter 128-port 71 8-port 66 b battery disposal, recycling 47 bolting rack 51 c cabling descriptions 98 hmc 22 lan 27 locations 98 power connection 21 hmc 27...

Page 144

Hmc (continued) monitor connection 22 mouse connection 22 power cords 27 power-on 28 hmc cabling 94 i i/o cpu 77 identification numbers recording 75 install prerequisites 8 installation completing 33 doors 33 frame raised floor 61 hmc 22 power cords 21 rack 51 raised floor 61 installation, system 7 ...

Page 145

Removal top frame 108 replacement top frame 119 routing power cords 21 s safety electrical vii notice 16 safety notices vii laser compliance statement ix saving service processor settings 101 second rack attach 11 cable 11 securing rack 51 service agent configuring 37 service processor backup settin...

Page 146

130 pseries 690 installation guide.

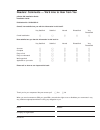

Page 147

Readers’ comments — we’d like to hear from you pseries 690 installation guide installation guide publication no. Sa38-0587-01 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall satisfaction h h h h h how satisfied...

Page 148: Business Reply Mail

Readers’ comments — we’d like to hear from you sa38-0587-01 sa38-0587-01 ibmr cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape no postage necessary if mailed in the united states business reply mail first-...

Page 150

Ibmr part number: 09p6530 printed in u.S.A. April 2002 sa38-0587-01 (1p) p/n: 09p6530