Ibm infoprint color 100 introduction and planning guide g544-5612-00 ibm.

Ibm infoprint color 100 introduction and planning guide g544-5612-00 ibm.

Note: before using this information and the product it supports, be sure to read the general information under “notices” on page v. First edition (august 1998) the following paragraph does not apply to any other country where such provisions are inconsistent with local law. International business ma...

Contents notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V communications statements . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii federal communications commission statement . . . . . . . . . . . . . . . . . . . . Vii canadian department of communications ...

Positioning the rip controller and monitor . . . . . . . . . . . . . . . . . . . . . . 17 positioning the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 positioning the paper supply and fixed tower ventilation . . . . . . . . . . . . . . . . 19 flooring requirements . . . . . ...

Notices references in this document to ibm products, programs or services do not imply that ibm intends to make these available in all countries in which ibm operates. Any reference to an ibm licensed product, program, or service is not intended to state or imply that only ibm’s product, program, or...

Vi ibm infoprint color 100 introduction and planning guide.

Communications statements federal communications commission statement note: this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference w...

German conformity statement dieses gerät erfüllt die bedingungen der en 55022klasse a. Für diese klasse von geräten gilt folgende bestimmung nach dem emvg: geräte dürfen an orten, für die sie nicht ausreichend entstört sind, nur mit besonderer genehmigung des bundesminesters für post und telekommuni...

Trademarks the following are trademarks of ibm or other companies: trademark company adobe type manager adobe systems, inc. Aix international business machines corporation appletalk apple computer colorsync ii apple computer hubbell hubbell, inc. Ibm international business machines corporation infop...

X ibm infoprint color 100 introduction and planning guide.

Preface this publication introduces the ibm infoprint color 100 and provides a summary of its functions. This publication also contains information to help you prepare for installing and using the infoprint color 100. This publication is for executives who are considering purchasing the infoprint co...

Xii ibm infoprint color 100 introduction and planning guide.

Chapter 1. Printer description the ibm infoprint color 100 printer is designed for short-run, high-quality, full-color applications. The innovative, entirely digital, printing technology of the infoprint color 100 brings the advantages of electronic publishing to color printing. Key advantages of th...

The infoprint color 100 is not capable of printing on preprinted forms or pre-die-cut labels. Printer components following is a description of the major components of the printer. Print tower the print tower is the largest component of the infoprint color 100. It houses a web-fed continuous-form pri...

The rip controller contains the operating system and controlling software for the primary graphical user interface. Printer operation, monitor, and control tools are presented the operator through the rip controller operating environment. The rip controller contains prepress disk drive space to stor...

Array can be archived to an external storage device. A functional description of the collator system is shown in figure 1. Table 1. Features of the infoprint color 100 feature image memory (ismt) 8mb/printhead image dasd 64gb collator dasd variable data standard color depth 2 bits/dot software the f...

V rip postscript files v rip variable data files using mergedoc (described below) v print postscript files from the collator or book ticket file (btf) for variable data jobs v manage collator space v rename postscript files on the hard disk or riped sections on the collator v delete postscript files...

Note: the infoprint color 100 printer is shipped with ethernet or token ring. To help prevent installation delays, have someone familiar with your lan configuration available to assist the systems engineer and service representative during the infoprint color 100 installation. See “network protocols...

Necessary to limit the run-length of high-coverage jobs, and to run multiple batches separated by low coverage jobs. For example, to optimize print quality on a high-coverage job requiring 500 copies, it might be best to run 10 jobs at 50 copies per job. The toner saver function allows for a toner s...

8 ibm infoprint color 100 introduction and planning guide.

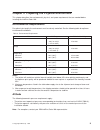

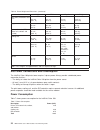

Chapter 2. Preparing the physical environment this chapter describes the environmental, physical, and space requirements that are needed before installing the infoprint color 100. Environmental requirements for optimal print quality the environment must be closely controlled. See the following table...

Ventilation provide appropriate ventilation to conform to health, safety, and environment standards. The american society of heating, refrigeration, and air conditioning engineers (ashrea) recommends a minimum of 34.2 cubic meters per hour (20 cubic feet per minute) per person of outdoor air make-up...

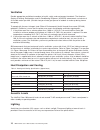

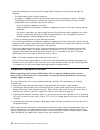

Planning your physical layout this section presents physical planning information to ensure a smooth installation. Information includes: v space requirements v physical dimensions and weights of the shipping crates v weights and dimensions of the printer components v electrical requirements v the be...

492cm (16ft 2in) cooling unit paper supply print tower attachment locations for ventilation pes control unit 100cm (39.4in) 53.3cm (21in) 51cm (20in) 20.1cm (7.9i n) 51cm (20in) 180cm (70.9i n) collator rip controller jogger support feet access clearance (18.9in) 48cm 640cm (21ft 0in) 262cm (8ft 7in...

Hc7i0002 0.20m (0.656ft) figure 3. Minimum space above the printer tower hc7i0003 1.00m (3.28ft) 157cm (62in) 2.10m (6.889ft) 1.60m (5.249ft) 1.00m (3.28ft) paper supply paper output figure 4. Minimum area around the printer chapter 2. Preparing the physical environment 13.

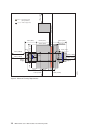

Hc7i0004 95.15cm (37.5") 71.15cm (28.0") 52cm (20.5") 12.4m (4.8") 53.2cm (20. 9") base 98cm (38.6") 162cm (63.8") 100cm (39.4") 225cm (88.6") 12cm (4.7") 30cm (11.8") 1 1 1 30cm (11.8") 25cm (9.8") 97cm (38.1") 4.07m (13.4ft) 2 2 3 3 4 4 1.00m (3.281ft) 2.10m (6.889ft) 2.14m (7.020ft) 1.0 0m (3.2 8...

Hc7i0006 100cm (39.4in) 47.8cm (18.8in) 231.9cm (91.3in) 125.7cm (49.5in) 170.2cm (67.0in) 18.4cm (7.25in) 96cm (37.8in) 73.7cm (29.0in) 50cm (19.6in) printing tower paper supply paper output cooling unit 49 cm (1 9. 3in ) 20.1cm (7.9in) 51cm (20in) 49.5cm (19.5in) 180cm (70.9in) 51cm (20in) 75 cm (...

Printer power and operator console connections the power receptacle on the infoprint color 100 is located at position 1 of figure 10 on page 19. The pes control unit connects to the printer fixed tower at position 2 of figure 10 on page 19. The cable group from the infoprint color 100 to the pes con...

Place the console in a position that will minimize traffic across the cable walkovers. Depending on the placement of the console, you may need to cut a walkover to make it fit between the operator console and the print tower. Positioning the collator and desktop the collator is placed at one end of ...

Figure 9 shows possible positions for the cooling unit. Cooling unit connections two insulated flexible hoses provide coolant to the print tower. The cooling hoses from the cooling unit connect to the print tower at position 1 in figure 9. An externally grounded single phase connection (world trade:...

Positioning the paper supply and fixed tower ventilation the paper supply and printer tower ventilation extracts the vapors that the paper supply and the fuser produce when heating the paper. The ventilation consists of a set of four exhaust tubes and an exhaust air collector. The exhaust air collec...

Flooring requirements the flooring system at the site must be able to support the weight of the printing system, operators, additional support equipment and supplies: the printing system weighs approximately: 1780 kg (3925 lb) the floor should be free of static, and not subject to vibration from oth...

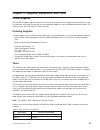

3. In all other countries, contact your ibm representative for container return shipping instructions. Table 5. Shipping crate specifications contents height width depth weight print tower 216 cm (84 in) 171 cm (67 in) 165 cm (64 in) 1380 kg (3036 lb) paper supply 151 cm (59 in) 107 cm (42 in) 110 c...

Table 6. Printer weight and dimensions (continued) content height width depth weight print tower, fixed tower and base 228 cm (89.7 in) 162 cm (63.8 in) 176 cm (69.3 in) 1125 kg (2475 lb) jogger 59 cm (23 in) 98.5 cm (38.6 in) 61 cm (23.8 in) 45 kg (99 lb) operator console (pes control unit, collato...

Electrical requirements for each printer, provide separate electrical outlets with power supplies for the main printer power, the cooling unit power, and the rip controller power. Each power supplies must support and meet all power requirements listed in this section and table 7 on page 22. Supply t...

Print unit cable connector – all other countries (50 hz): the print tower power cable does not have a plug. Provide the appropriate plug and receptacle. Understand the electrical standards for your country, and use only an approved plug. Your marketing representative has information on the voltage r...

Phone line, preferably direct to the public telephone network (some pbxs do not pass a ring signal which the modem recognizes for phone pickup) and a standard power outlet should be available for use during service. The modem will be plugged in only when service is being performed. An additional pho...

V inspect the receiving area and the areas through which the printer must be moved. Consider the following: – the forklift needs space in which to operate. – the printer is shipped in eleven separate crates, which have the dimensions shown in “shipping crate weights and dimensions” on page 20. Check...

Chapter 3. Operator tasks and training requirements operators of the infoprint color 100 printer should have some digital prepress and/or press experience. One or a combination of both of these experience levels is an excellent background for operating the infoprint color 100. Ibm provides complete ...

28 ibm infoprint color 100 introduction and planning guide.

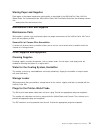

Chapter 4. Supplies, equipment, and tools printer supplies the two rolls of paper and two containers of each color of toner that are shipped with the printer are used in installation and setup. Ensure that you have ordered supplies for your immediate production needs. The infoprint color 100 uses ve...

Table 8. Toner version 2 part numbers (continued) toner color version 2 part number yellow 1402816 black 1402813 toner waste bottles toner waste bottles collect toner not consumed in the electrophotographic process. Replace the toner waste bottles as they become full; order them to fit your needs. A...

Storing paper and supplies store paper at the proper temperature and humidity as described in the ibm infoprint color 100 print media guide. You can download the ibm infoprint color 100 print media guide from the following internet site: www.Printers.Ibm.Com/manuals.Html maintenance parts and suppli...

Tools ibm-supplied densitometer a densitometer is required to optimize control of colors printed by the infoprint color 100. The infoprint color 100 uses a gretag 19c densitometer, provided with the printer, to recommend and execute printer color station setpoint changes to optimize color density. T...

Chapter 5. Communicating with the printer infoprint color 100 network connectivity network connection to the printer is provided through the rip controller. A 10/100baset ethernet adapter is built into the rip controller and can be connected to the network using the catagory 5 twisted pair cables. T...

Permissions are assigned to the folder. Infoprint color 100 appears in the macintosh chooser, under appleshare, as a file server. After connecting to it, the macintosh volume name, set up at the controller, appears as the available resource. More than one macintosh volume can be set up at infoprint ...

Fonts thirty-five adobe type manager (atm) type-1 fonts are resident on the rip controller. The postscript page description language (pdl) allows you to download fonts, such as adobe type-3 fonts. You can also purchase additional true type and adobe type-1 fonts to install on your printer to rip job...

36 ibm infoprint color 100 introduction and planning guide.

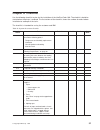

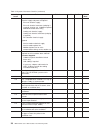

Chapter 6. Checklist use the following checklist to plan for the installation of the infoprint color 100. The checklist should be started when the printer is ordered. The first column of the checklist shows the number of weeks before installation to accomplish the tasks. The checklist is intended fo...

Table 10. Systems assurance checklist (continued) weeks before install task task owner yes/no due date date done 4-6 does the customer have an appropriate electrical supply and power receptacle? V print unit electrical supply v print unit electrical connector (and plug if required), for print unit. ...

Table 10. Systems assurance checklist (continued) weeks before install task task owner yes/no due date date done 2-4 is the system ready for the printer? Lan, cabling, configuration? 2-4 is the prepress hardware and software, with appropriate levels of application software, available? See “prepress ...

40 ibm infoprint color 100 introduction and planning guide.

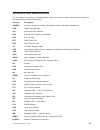

Acronyms and abbreviations this list explains the acronyms and abbreviations used in this manual, and in the other manuals that are part of the printer documentation library. Acronym description ashrea american society of heating, refrigeration and air conditioning engineers. Atm adobe type manager....

Nt new technology. Oehha office of environmental health hazard assessment. Osi open systems interconnections. Pbx private branch exchange. Pc open system interconnection. Pes print engine supervisor. Pdl page description language. Pod print on demand. Prs paper supply. Rip raster image processing. S...

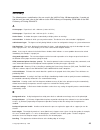

Glossary the following terms are defined as they are used in the infoprint color 100 documentation. If you do not find the term you need, refer to the index or to the ibm dictionary of computing, sc20-1699 or the ibm dictionary of printing, g544-3973. A a3-size paper. Paper that is 297 x 420 mm (11....

Bias test patches. Cmyk patches on control strips that are used to measure and control lower densities. Bitmap. An image formed by a rectangular grid of pixels. Each pixel is assigned a value to denote its color and the density of color. Black overprinting. A page-setup parameter that causes 100% bl...

Conditioned engine state. During this engine state, the print tower conditioning is turned on and the paper conditioning and fusing systems are turned off the engine is idle and no printing is taking place. Conditioning circuit. A circuit that controls the temperature and humidity of the air in the ...

Density control. The window used to monitor and sometimes adjust the parameters that affect the density of the printed image. Density test patches. Cmyk patches on control strips that are used to measure and control the higher densities. Developer. A mixture of toner and carrier particles. Developer...

Finishing. A properties window option used to look at and change finishing settings, such as the output bin. Fixed tower. The area of the tower where the toner is fused to the paper to produce the final image. The fixed tower is located at the end near the paper output. Fix t element measured. A fus...

I ics (imaging control system). A system that controls the eight led writing heads. Imaging. A properties window option used to change image settings, such as copy count and data depth. Imposition. The process of arranging pages on a press sheet to ensure proper order during final cutting/folding/bi...

Msds (material safety data sheet). International standards describing how to handle and dispose of chemical substances. Mb. Megabyte or 1 048 576 bytes (1 000 kb) of data. Menu bar. Contains several menu items used to access the functions needed to operate the printer. Mount paper roll window. The w...

Pes (print engine supervisor) platform. One of two platforms in the printer controller module. This platform controls the operation of the print engine. Pixel. (1) picture element. (2) in architecture, the smallest printable or displayable unit on a physical medium. In computer graphics, the smalles...

Q queue manager. A window that lets you view and manage all jobs currently in the print queue. As soon as a job prints, it disappears from the list of jobs in the queue. Quit pes at exit. A preferences window checkbox used to have the pes quit automatically when you quit the operator interface. R ra...

Service key. The key that must be inserted and turned clockwise before service intervention is used. Setpoint-adjustment processes. Processes that include parameters to monitor and setpoints to adjust to control or to optimize print quality. Density control and web tension are examples of setpoint-a...

Tested papers. Papers that have been tested and approved by ibm for use in the printer. Test frequency. A properties window imaging setting used to specify how often a test sheet should be printed during the printing of one or more jobs in the print queue. Test sheet. A single sheet inserted at spec...

U ucr (under color removal). Conversion of neutral color areas into black ink. Reduces the use of cmy inks, improves trapping, and reduces setup time. Generally, ucr is performed during image scanning, but some rips perform ucr during processing. Also known as gcr. W warmup paper-conditioning state....

Index a acoustic levels 10 adobe type manager (atm) 35 altitude specifications 9 attachments 3 aui adapters 3 c cables connectors cooling unit 24 densitometer, world trade 24 main power (50 hz) 24 main power (60 hz) 23 main power 23 operator console 16 pes control unit 16 checklist 37 cleaning suppl...

Fonts adobe 35 resident 35 true type 35 g glossary 43 graphical user interface (gui) 2, 4, 6 h heat dissipation 10 hoses cooling unit 16, 18 print tower cooling 18 i image registration 7 installation planning 25 procedures 26 tools 32 j job setup, density and registration 6 jogger unit, paper output...

Physical (continued) environment (continued) lighting 10 preparing 9 requirements 9, 20 ventilation 10, 19 layout clearances 13, 18 collator placement 17 cooling unit placement 17, 18, 19 guidelines 11 installation area 11 monitor, keyboard, and mouse 17 operator console placement 16 pes control uni...

Software (continued) screening technology 5 thruprint 4 variable data 5 windows nt 4 xpose 4 space above the printer tower 13 for loading paper 18 for service and maintenance 18 minimum requirements 11, 13, 14 typical installation 12 specifications cooling 10 maximum coverage 6 optical density 7 per...

Ibm part number: 24l4197 printed in u.S.A. G544-5612-00 24l4197.