Summary of LB20

Page 1

Basic purpose printer lb20 user’s guide part number: ek-lb20a-ug.001.

Page 2

Acknowledgment ibm, pc, xt, at, ps/2, proprinter and 4722 are registered trademarks of international business machines corporation ms-dos, windows 3.1x, windows 95 and windowsnt are trademarks of microsoft corporation. A publication of: digital equipment bcfi ab p.O. Box 904 s-175 29 järfälla, swede...

Page 3

Contents 1 introduction 1-1 1.1 scope 1-1 1.2 related documentation 1-1 1.3 order process 1-2 1.4 warnings, cautions and notes 1-2 1.5 manufacturers declaration 1-3 2 installation 2-1 2.1 preparation 2-1 2.2 operating space 2-2 2.3 removal of transport locks 2-3 2.4 trapdoor, lid and document guide ...

Page 4

3.3 setup check 3-9 3.4 performing a setup 3-10 3.4.1 com menu 3-10 3.4.2 ibm menu 3-10 3.4.3 doc menu 3-12 3.4.4 dft menu 3-18 3.4.5 hqd menu 3-18 4 operation 4-1 4.1 controls and indications 4-1 4.1.1 confidence test routine 4-2 4.2 documents 4-2 4.2.1 new pages 4-2 4.2.2 loading a document 4-3 4....

Page 5

5.3 printhead 5-12 5.3.1 preparation 5-12 5.3.2 removing the trapdoor 5-13 5.3.3 releasing the printhead 5-13 5.3.4 lowering the carrier 5-14 5.3.5 removing the printhead 5-14 5.3.6reinstalling the printhead 5-15 5.4 cleaning of edge detection sensor and mylar slide hole 5-16 5.5 cleaning the feed r...

Page 6

Introduction 1-1 1 introduction the lb20 printer is delivered as one of the following: • 9 pin dot matrix serial printer (model: lb20a-aa) or • 9 pin dot matrix parallel printer (model: lb20b-aa) when installed the printer forms an integrated part of a user’s information system and provides a printi...

Page 7

Introduction 1-2 1.3 order process documentation, accessories and spare parts shall be ordered from: digital equipment bcfi ab, attn. Orderdesk p.O.Box 904 175 29 järfälla, sweden telephone: +46 8 759 4600 facsimile: +46 8 621 1718 1.4 warnings, cautions and notes warning! This type of safety instru...

Page 8

Introduction 1-3 1.5 manufacturers declaration document number: s960242-1 this is to certify that the digital equipment bcfi ab, product indicated below complies with the requirements on the eec-directives and/or other standards as indicated below and has been officially released for normal delivery...

Page 9

Installation 2-1 2 installation perform the actions described and illustrated under the headings: 2.1 preparation open the packing carton at one end, pull out the two foam sections and unpack the following: 1. Mains power cable 2. Printer 3. User’s guide 4. Ribbon cartridge box 5. Document guide 6. ...

Page 10

Installation 2-2 2.2 operating space place the printer on a flat, horizontal surface in a clear area as follows: 1. Back - 8in (203 mm) for document removal. 2. Sides - 4in (101mm) for air cooling. 3. Front - 10in (254 mm)for document loading. Note: if necessary, allow further space for power and co...

Page 11

Installation 2-3 2.3 removal of transport locks 1. Lid - lift and remove. 2. Packing - remove and discard. 1 2.

Page 12

Installation 2-4 2.4 trapdoor, lid and document guide 1. Trapdoor - 1) position the two rear lugs, 2) lower, the trapdoor to engage the front lock and press until a ‘click’ is heard. 2. Lid - accurately align at a, b and c. 3. Document guide - 1) position in the front cover, 2) push until a ‘click’ ...

Page 13

Installation 2-5 2.5 connections and settings 1. Power switch - set to the off position. 2. Power setting - check the setting: use a screw- driver to turn the selector to the mains supply voltage you are using. 3. Mains power cable - connect to the printer and the mains supply. 4. Communication cabl...

Page 14

Installation 2-6 2.6 ink ribbon cassette 2.6.1 power on 1. Power switch - set to the on position, • station led - shows red for six seconds and then changes to green. 1 station led lid caution! The printer must be switched on during this task. Note ! If the station led ‘blinks’ red check that the li...

Page 15

Installation 2-7 2.6.2 unpacking the ink ribbon cassette 1. Box and plastic bag - open the packing. 2. Ink ribbon cassette - remove from the plastic bag. 3. Skid - unclip from the cassette. 2.6.3 centering the skid 1. Lid - lift and remove, • station led - changes from green to blinking red. 2. Butt...

Page 16

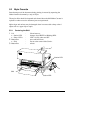

Installation 2-8 2.6.4 raising the carrier 1. Carrier buttons - press in at a and lift to b • the carrier is now locked in a tilted, raised position. 2.6.5 positioning the ink ribbon cassette 1. Ink ribbon cassette - position on the top and sides of the carrier. 1 1 carrier.

Page 17

Installation 2-9 2.6.6 installing the ink ribbon cassette 1. Ink ribbon cassette - push until a ‘click’ is heard at each side of the carrier. 2.6.7 installing the skid 1. Skid - locate in the bottom of the head carrier assembly. 2. Skid - push until a ‘click’ is heard. 1 1 2 head carrier assembly.

Page 18

Installation 2-10 2.6.8 removing slack ribbon 1. Green wheel - turn until the ink ribbon is tight. 2. Carrier - hold at a, lower to b and ensure the printhead locates in the slider. 2.6.9 ready to print 1. Lid - install and align at positions a, b and c, • station led - changes from blinking red to ...

Page 19

Setup 3-1 3 setup setup consists of a number of menu’s that contain software settings. It is important that the correct software settings are made in the doc menu so that everyday customer documents are handled correctly. Document dimensions determine the doc menu software settings. Therefore, when ...

Page 20

Setup 3-2 3.1.2 setup controls these are: button bar providing three functional periods of operation: • press down and release in less than one second (hit) • press down and release after two seconds • press down and hold down until the engine runs and the document moves, then release 3.1.3 menu’s a...

Page 21

Setup 3-3 3.1.4 changing or viewing the setup this involves the following: • entering setup - using a setup control • loading a document - a blank document or an existing document is used • moving to view or a menu - serial printer have 5 menu’s parallel printer have 4 menu’s • printing current sett...

Page 22

Setup 3-4 3.2 setup example the factory default setup is shown below: the above example was produced by performing the procedure printing the printer settings..

Page 23

Setup 3-5 3.2.1 entering setup 1. Lid - lift and remove. 2. Button bar - hold down. 3. Power switch - set to on, • station led - shows red. 4. Button bar - release, • station led - blinks green within 6 seconds. 2 4 1 station led 3 note ! If a document is not loaded or a document is loaded and no fu...

Page 24

Setup 3-6 3.2.2 loading a document prerequisite 1 entering setup has been performed. Prerequisite 2 a blank document at least 8in (203mm) but less than 8.5in (217mm) wide and at least 10in (254mm) long must be used. 1. Document - feed along the left edge of the document guide until the document is g...

Page 25

Setup 3-7 3.2.3 moving to view or a menu prerequisite loading a document has been performed 1. Button bar - press for less than one second (hit), • document - a) advances to the trailing edge, b) print of menu’s are performed, c) returns with the skid pointing at the quit or select point. 2. Menu’s ...

Page 26

Setup 3-8 3.2.4 printing the current settings this is done from the view point. Prerequisite 1: loading a document has been performed. Prerequisite 2: moving to view has been performed. 1. Button bar - press and hold down until the document is advanced and printing begins. Note: when printing has fi...

Page 27

Setup 3-9 3.2.6 validating 10. Load a blank document - perform loading a blank document with the other side of the document you have just used in step 8 above. 11. Print the settings - perform printing the current settings, • the changed parameter will be underlined; font : hqd 3.2.7 quitting 12. Lo...

Page 28

Setup 3-10 3.4 performing a setup an engineer would normally perform this task for you. Prerequisite 1 all types of customer document are available. Prerequisite 2 a measuring ruler. This may be graduated in metric or imperial units. Note: 1 inch = 25.4 mm. Move to each of the menu’s shown below and...

Page 29

Setup 3-11 the set values are: • set 1 - [0–31] and [128–159] specify control codes (factory default setting). • set 2 - [03–06], 21 and [128–159] specify printable characters. Note: the pc table may be set such that a range of ascii characters in the code page are interpreted. The font (quality) va...

Page 30

Setup 3-12 the top margin values are: • 1 = 0.1in (2.54mm)(factory default setting) • 2 = 0.2in (5mm) • 3 = 0.3in (7.6mm) • 4 = 0.4in (10mm) • 5 = 0.5in (13mm) • 6 = 0.6in (15.Mm) 3.4.3 doc menu this menu is concerned with documents and the parameter values that must be set so that documents are han...

Page 31

Setup 3-13 the values are shown along the parameter line in the doc menu printout, which follows:.

Page 32

Setup 3-14 the print contrast values are: • 1, 2, 3 (factory default setting), 4 and 5. The form smudging values are: • 1, 2, 3 (factory default setting), 4, 5 and 6 1 = least smudging (anvil in the lowest position).And 6 = most smudging (anvil in the highest position). The psbk smudging values are:...

Page 33

Setup 3-15 the psbk seam type values are: • horz (factory default setting) for horizontal seam passbooks • vert for vertical seam passbooks. The psbk width min. Values are: • 3in (76.2mm), 4in (101.6mm), 5in (127mm) factory default value, 6in (152.4mm), 7in (177.8mm). The printer will handle a docum...

Page 34

Setup 3-16 the psbk range values are: • 0.5in (12.7mm), 1in (25.4mm), 1.5in (38.1mm), 2in (50.8mm), 2.5in (63.5mm) and 3in (76.2mm). Psbk width + psbk range must be greater then the highest psbk width min. Value of any passbook that is used. 1. Measure all passbook widths. Make a note of the maximum...

Page 35

Setup 3-17 the cover offset values are: 0 = 0.1in (2.54mm) factory default setting mechanical top margin = cover offset 1 = up to 0.6in (13.3mm) 2 = up to 1.1in (27.94mm) 3 = up to 1.6in (40.64mm) 4 = up to 2.1in (53.34mm) this setting defines the location of the top edge of an inside sheets with re...

Page 36

Setup 3-18 3.4.4 dft menu the horizontal alignment of a printed line in bi-directional draft (dft) can be adjusted. This is done in two steps, draft coarse and draft fine. 1. Print the dft menu settings. 2. Look at the printout and chose the draft coarse and draft fine settings, indicated on the sam...

Page 37

Operation 4-1 4 operation normal everyday operation is a simple matter of loading a document. Printing is controlled from the customer host system. 4.1 controls and indications 1 power switch - on or off. 2 button bar - having two functional periods: • press down and release in less than one second ...

Page 38

Operation 4-2 4.1.1 confidence test routine when printer power is switched on a confidence test routine (ctr) verifies that all functions are error free. Ctr success or failure is indicated by the station led as follows: • solid or blinking green - success • solid red - fatal failure, preventing nor...

Page 39

Operation 4-3 4.2.2 loading a document it is only possible to load a document when the printer have received data from the host computer, or entering into setup mode or the internal maintenance tests routine. 1 document - check the width • if the document width is less than or equal to 8.7in (221mm)...

Page 40

Operation 4-4 4.2.3 stop while printing to stop the printing, press and hold the button bar for more than 10 seconds. 4.2.4 clearing document jams 1 power - set to off 2 lid - lift and remove 3 carrier - raise and secure in open position 4 document - remove by pulling from the front or rear of the p...

Page 41

Maintenance 5-1 5 maintenance this chapter describes how to do if the performance of the printer is not satisfied. Some actions should be performed to prevent unnecessary wear of the printer, or to keep up the lifetime. The following parts can be replaced. New parts can be ordered from your supplier...

Page 42

Maintenance 5-2 5.1 ink ribbon cassette these have a maximum storage life of 2 years and should be replaced after printing approximately 2.5 million characters. 5.1.1 centering the skid 1 lid - lift and remove, • status led’s - led-1 is on, others are off • station led - changes from green to blinki...

Page 43

Maintenance 5-3 5.1.2 raising the carrier 1 carrier buttons - press in at (a) and lift to (b), • carrier - is now locked in a tilted, raised position. 5.1.3 removing the skid 1 skid - lift until a ‘click’ is heard. 2 skid - pull forward and remove. 1 1 2.

Page 44

Maintenance 5-4 5.1.4 removing the old ink ribbon cassette 1 skid - position 2 sides - move forward 3 ink ribbon cassette - remove and discard 5.1.5 cleaning perform the following: • mylar cassette slider refer to the procedure on page 4-5-7 • edge detection sensor and mylar slide hole refer to the ...

Page 45

Maintenance 5-5 5.1.7 positioning the new ink ribbon cassette 1 ink ribbon cassette - position on the top and sides of the carrier. 5.1.8 installing the new ink ribbon cassette 1. Ink ribbon cassette - push until a ‘click’ is heard at each side of the carrier. 1 1 carrier.

Page 46

Maintenance 5-6 5.1.9 reinstalling the skid 1 skid - locate in the bottom of the head carrier assembly. 2 skid - push until a ‘click’ is heard. 5.1.10 removing slack ribbon 1 green wheel - turn until the ink ribbon is tight . 2 carrier - hold at a, lower to b and ensure the printhead locates in the ...

Page 47

Maintenance 5-7 5.2 mylar cassette smooth transport of the document during printing is ensured by separating the ribbon from the document by a strip of mylar. The mylar slider should be inspected and cleaned when the ink ribbon cassette is replaced or when excessive document jams are experienced. My...

Page 48

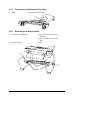

Maintenance 5-8 5.2.2 raising the carrier 1 carrier buttons - press in at (a) and lift to (b), • the carrier is now locked in a tilted, raised position. 5.2.3 removing the mylar cassette 1 left and right hand - a) push on each handle using a finger b) press on the wire with each thumb. 2 mylar casse...

Page 49

Maintenance 5-9 5.2.4 inspecting the mylar edges (bottom view) turn the mylar cassette over and inspect the edges for damage as follows: 1 from cylinder to cylinder - move the slider and check for damage. 2 from slider to left cylinder - move the slider and check that the complete edge stays out. 3 ...

Page 50

Maintenance 5-10 5.2.5 checking for free movement (top view) 1 slider - move full left to full right 5.2.6 reinstalling the mylar cassette 1 left hand and right hand - a)use a finger to push on the handles, b)use a thumb to press on the wire. 2 mylar cassette - install. 1 2 1a wire 1aa 1b handles.

Page 51

Maintenance 5-11 5.2.7 positioning the slider 1 slider - position under the printhead. 2 carrier - hold with each finger and lower the carrier from a to b andensure the printhead locates in the center of the slider. 2 printhead 1 2.

Page 52

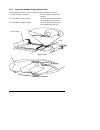

Maintenance 5-12 5.3 printhead the result of printing with a damaged printhead is shown below. The white space in the characters a,b,c,d and e above indicate a pin in the printhead is not operating or is broken. A pin will be damaged when is strikes a sharp or hard object such as a paper clips or st...

Page 53

Maintenance 5-13 5.3.2 removing the trapdoor 1 carrier - support to keep the carrier raised. 2 trapdoor lock - push in to release the lock and lift to remove the trapdoor. 3 printhead tool - position in the printhead assembly. 5.3.3 releasing the printhead 1 carrier - support to keep the carrier rai...

Page 54

Maintenance 5-14 5.3.4 lowering the carrier 1 carrier - hold at a, lower to b and ensure the printhead locates in the slider. 5.3.5 removing the printhead 1 printhead - grip between thumb and finger and remove 1 printhead slider 1 1.

Page 55

Maintenance 5-15 5.3.6 reinstalling the printhead 1 printhead - locate the clip and lock clip in the printhead assembly 2 printhead - push down until a ‘click’ is heard 1 2 printhead assembly lock clip clip.

Page 56

Maintenance 5-16 5.4 cleaning of edge detection sensor and mylar slide hole these should be cleaned when the ink ribbon cassette is changed. Note: if pressurized air is not available a lint free cloth may be used. If necessary, refer to the ink ribbon cassette and mylar cassette procedure 1 pressuri...

Page 57

Maintenance 5-17 5.5 cleaning the feed rollers these should be cleaned when feeding problems are experienced or when black vertical lines appear on the document. 1 lid - lift and remove • station led - changes from green to blinking red, • status led’s - ooox, where x = on. 2 button bar - press for ...

Page 58

Maintenance 5-18 5.6 ready to print after completion of maintenance, the printer must be set back to operational mode - printer is set to on-line status - ready for receiving data and printing. 1 if necessary, reinstall the parts by performing the tasks as described on previous pages (reverse order)...

Page 59

Specifications 6-1 6 specifications these are as follows: 6.1 printer characteristics width 16.14" (410mm) depth w/o doc. Guide 10.43" (265mm) depth with doc. Guide 13.78" (350mm) height 07.48" (190mm) weight 19.16 lb. (8.7 kg) interface, serial interface, parallel one rs232c port, 9-pin male connec...

Page 60

Specifications 6-2 6.2 serial interface - rs232c this signal port option is one serial line that conforms to rs232c-eia standard. The printer input buffer size is 4k bytes. 6.2.1 configurable parameters these are as follows, where factory defaults are in italic: • baud rate - 1200, 2400, 4800, 9600,...

Page 61

Specifications 6-3 rxd - receives data from the host. The interface ignores rx data when dsr is low. Txd - when using xon/xoff, printer to host, clear to send (cts) must be high to enable transmission. The printer does not transmit any data when rts or cts are high. Dtr - is set and remains ‘high’ w...

Page 62

Specifications 6-4 6.3 parallel interface - centronics this is an unidirectional interface that transfers 1 byte at a time. Signal name description pin in pin out source d strobe ce data 1 ce data 2 ce data 3 ce data 4 ce data 5 ce data 6 ce data 7 ce data 8 ack busy pe select out auto feed not used...

Page 63

Specifications 6-5 6.4 documents the printer handles two basic document types, forms and passbooks. Forms can be single-ply or multi-ply or envelopes. Passbooks can have a vertical or a horizontal seam. Vertical seam passbooks horizontal seam passbooks minimum width 4.0" (101 mm) 4.0" (101 mm) maxim...

Page 64

Specifications 6-6 the paper used for a form should be: single-ply two-ply multi-ply total thickness 0.004" to 0.02" (0.1 to 0.45 mm) 0.004" to 0.02" (0.1 to 0.45 mm) 0.004" to 0.02" (0.1 to 0.45 mm) max. No. Of copies 1 1 + 1 1 + 3 * top sheet weight bottom sheet weight inner sheet weight 16 to 32 ...

Page 65

Specifications 6-7 6.4.1 recommendations and restrictions • transparent documents or documents containing transparent areas cannot be used. Reflective ink surfaces (i.E. Silver, gold) do not cause problems with the edge detection system. • dark areas at the top of a form, close to the left and right...

Page 66

Specifications 6-8 6.4.3 center outfold bulge when the passbook is opened at the middle page, the height of the bulge at the center outfold shall not exceed 0.01" (0.3 mm). 6.4.4 passbook squareness when the passbook is closed, the edge of the shorter side must be at a 90° angle to the longer side..

Page 67

Glossary 7-1 7 glossary ascii american standard code for information interchange. A standardized set of machine-readable 7 or 8-bit codes consisting of control codes and codes representing alphanumeric characters and symbols. Awg american wire gauge bi-directional printing where printing occurs from...

Page 68

Glossary 7-2 electrical and functional characteristics of equipment. Emulation where software allows the printer to imitate another printer. Emphasized where text is printed in two passes with a horizontal offset. Expanded where characters are printed in one pass at twice their normal width. Esc a s...

Page 69

Glossary 7-3 host. Rts/cts request to send / clear to send. One of the standards used by the rs232c protocol for controlling the flow of data between two communicating devices using handshake signals. When the host wants to send data to the printer, it must wait for the printer rts line to go on. If...

Page 70

Printed in sweden on totally chlorine free paper (tcf).