- DL manuals

- IBM

- CD/CDR Drive

- LTO Ultrium 4

- Installation And User Manual

IBM LTO Ultrium 4 Installation And User Manual

IBM LTO Ultrium 4 Half High Tape Drive

Installation and User's Guide

Important:

Review the maintenance information in Chapter 3, "Operating the drive" and in the

Warranty information

document that came with the drive, because periodic maintenance is

not covered by the IBM warranty. Repairs or exchanges that result from improper

maintenance might result in billable service charges.

Summary of LTO Ultrium 4

Page 1

Ibm lto ultrium 4 half high tape drive installation and user's guide important: review the maintenance information in chapter 3, "operating the drive" and in the warranty information document that came with the drive, because periodic maintenance is not covered by the ibm warranty. Repairs or exchan...

Page 3

Ibm lto ultrium 4 half high tape drive installation and user's guide.

Page 4

Note: before using this information and the product it supports, read the general information in appendix b, “notices,” on page 57, the safety information and environmental notices and user guide documents on the ibm documentation cd, and the important notices and warranty information documents that...

Page 5

Safety before installing this product, read the safety information. Antes de instalar este produto, leia as informações de segurança. Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí. Læs sikkerhedsforskrifterne, før du installerer dette produkt. Lees voordat u dit produc...

Page 6

Antes de instalar este produto, leia as informações sobre segurança. Antes de instalar este producto, lea la información de seguridad. Läs säkerhetsinformationen innan du installerar den här produkten. Iv lto ultrium 4 half high tape drive.

Page 7

Statement 1 danger electrical current from power, telephone, and communication cables is hazardous. To avoid a shock hazard: v do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm. V connect all power cords to a p...

Page 8

Statement 3 caution: when laser products (such as cd-roms, dvd drives, fiber optic devices, or transmitters) are installed, note the following: v do not remove the covers. Removing the covers of the laser product could result in exposure to hazardous laser radiation. There are no serviceable parts i...

Page 9

Statement 8 caution: never remove the cover on a power supply or any part that has the following label attached. Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these components. If you suspect a probl...

Page 10

Viii lto ultrium 4 half high tape drive.

Page 11

Contents safety . . . . . . . . . . . . . . . Iii statement 1. . . . . . . . . . . . . . . V statement 3 . . . . . . . . . . . . . . Vi statement 5 . . . . . . . . . . . . . . Vi statement 8 . . . . . . . . . . . . . . Vii figures . . . . . . . . . . . . . . . Xi tables . . . . . . . . . . . . . . ....

Page 12

Federal communications commission (fcc) statement . . . . . . . . . . . . . . 60 industry canada class a emission compliance statement . . . . . . . . . . . . . . 60 avis de conformité à la réglementation d'industrie canada . . . . . . . . . . . 60 australia and new zealand class a statement . 60 eu...

Page 13

Figures 1. The ibm lto ultrium 4 half high tape drive 1 2. Front panel of the drive . . . . . . . . . 2 3. Rear view of the drive . . . . . . . . . 2 4. Temperature of the drive is taken near the air intake area [1] . . . . . . . . . . . . 6 5. Mounting holes on the drive . . . . . . . 8 6. Insertin...

Page 14

Xii lto ultrium 4 half high tape drive.

Page 15

Tables 1. Cru and option part numbers . . . . . . 1 2. Feature switch definitions . . . . . . . . 7 3. Meaning of status led and single-character display (scd) . . . . . . . . . . . . 12 4. Functions that the unload button performs 13 5. Diagnostic and maintenance functions . . . 16 6. Ultrium cartr...

Page 16

Xiv lto ultrium 4 half high tape drive.

Page 17

Chapter 1. Product description this tape drive is a high-performance, high-capacity data-storage device that is designed to back up and restore open systems applications. The drive can be integrated into any supported external tape enclosure or directly into a supported system x server. It is the fo...

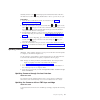

Page 18

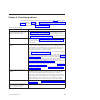

V support for encryption of data on ultrium 4 cartridges (sas drive only) front panel of the drive 1 unload button 4 single-character display (scd) 2 ready status led 5 scd dot 3 fault status led rear view of the drive 1 feature switches 3 rs-422 connector for library interfaces (ldi or adi) selecta...

Page 19

V ultrium 2 (read only): 15, 19, 22, 26, or 30 mbps if the net (compressed) data rate of the server is between two of the active data rates, the drive calculates the appropriate data rate at which to operate. Speed matching dramatically reduces backhitch , the condition that occurs when a tape stops...

Page 20

Standards body. For more information, see http://www.Sffcommittee.Org or ftp://ftp.Seagate.Com/sff/sff-8482.Pdf for connector details. 4 lto ultrium 4 half high tape drive.

Page 21

Chapter 2. Installing the drive depending on the type of enclosure, installation procedures might vary. Refer to the enclosure documentation for drive installation. The following generic procedure can be used if the enclosure documentation is not available. Avoiding drive damage to avoid static elec...

Page 22

Acclimate the drive and media about this task acclimation time is required if the temperature of the drive and media when unpacked is different than the temperature of its operating environment (measured at the front of the bezel near the air intake area as shown in figure 4). The recommended acclim...

Page 23

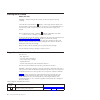

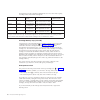

The feature switches are on the rear panel of the tape drive. See 1 in the figure 3 on page 2 for the location of the switches. The switches are labeled 1 through 8 and the on and off positions are marked. The feature switches are defined in the following table. Table 2. Feature switch definitions s...

Page 24

Connect and test power to the drive about this task the drive does not contain its own power source; it must be powered externally. To connect and test power to the drive, complete the following steps: 1. Ensure that the enclosure (or unit that supplies power to the drive) is powered off. 2. Ensure ...

Page 25

Attention: if the scd does not come on, the drive might not be getting power. V the status led will be off during the initial power-on and initialization. The status led briefly becomes green and then becomes amber during the remainder of the power-on and initialization phase. The status led becomes...

Page 26

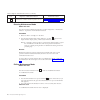

Connect the external interface cable (tape enclosure installations only) about this task for information about connecting the enclosure, refer to the documentation for your enclosure. Connect the external sas interface to the server about this task to connect the enclosure to the sas interface, comp...

Page 27

Chapter 3. Operating the drive operating the drive involves using the following front panel items: v single-character display (scd) v scd dot v status led v unload button single-character display (scd) the scd ( 2 in figure 2 on page 2) presents a single-character code for: v error conditions and in...

Page 28

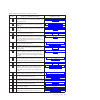

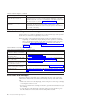

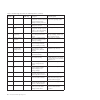

Table 3. Meaning of status led and single-character display (scd) indicator status condition action single- character display (red) "ready" led (green) "fault" led (amber) "1" off on maximum operating temperature exceeded 1 reduce drive temperature. "1" flashing flashing on self test is in progress ...

Page 29

Table 3. Meaning of status led and single-character display (scd) (continued) indicator status condition action single- character display (red) "ready" led (green) "fault" led (amber) notes: 1. The “fault” led must be solid to indicate an overtemp condition (media temperature greater than 52°c or 12...

Page 30

Table 4. Functions that the unload button performs (continued) unload button function how to initiate the function exit maintenance mode press the unload button once per second until 0 displays. Then, press and hold the unload button for three seconds. Maintenance mode is exited when the status led ...

Page 31

Removing a tape cartridge about this task to remove a tape cartridge: procedure 1. Ensure that the drive is powered-on. 2. Press the unload button. The drive rewinds the tape and partially ejects the cartridge. The status light flashes green while the tape rewinds, then goes out before the cartridge...

Page 32

Cleaning the drive head about this task attention: when cleaning the drive head, use the lto ultrium cleaning cartridge. Clean the drive head whenever c displays on the single-character display and the status led is flashing amber once per second. It is not recommended that you clean the drive head ...

Page 33

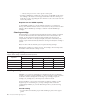

Table 5. Diagnostic and maintenance functions (continued) function code diagnostic or maintenance function instructions location 1 run drive diagnostics: runs tests to determine whether the drive can properly load and unload cartridges, and read and write data. “function code 1: run drive diagnostic...

Page 34

Table 5. Diagnostic and maintenance functions (continued) function code diagnostic or maintenance function instructions location u disable post error reporting: when selected, deferred-check conditions are not reported to the host. “function code u: post error reporting disabled” on page 34 entering...

Page 35

Procedure 1. Press the unload button three times within two seconds to clear the error code and return to function code 0 . 2. Press and hold the unload button for three or more seconds, then release it. Results note: the drive will exit maintenance mode automatically when: v it completes a maintena...

Page 36

Attention: for this test, insert only a scratch (blank) data cartridge or a cartridge that can be overwritten. During the test, the drive overwrites the data on the cartridge. Note: if you inserted an invalid tape cartridge (e.G. Gen 1, worm media, or non-fmr cartridge), error code 7 appears in the ...

Page 37

Available, you can use a blank ultrium-3 data cartridge. Make sure that the cartridge is not write-protected or damaged. If a cleaning cartridge is inserted while the drive is in diagnostic mode, it will be ejected. Important: use a blank cartridge that does not contain data. During the self-test, t...

Page 38

Function code 2: update drive firmware from fmr tape about this task attention: when updating drive firmware, do not power-off the drive until the update is complete or the firmware might be lost. The primary firmware update process requires update files. Fmr tape updates should only be attempted if...

Page 39

Function code 3: create fmr tape about this task function code 3 copies the drive field microcode replacement (fmr) data to a scratch data cartridge. The resulting fmr tape can only be used to update the firmware on other lto gen4 tape drives with the same host interface (scsi u160, scsi u320, sas, ...

Page 40

Function code 4: force a drive dump about this task function code 8 performs a dump of data collected by the drive (this process is also known as saving a microcode trace). Procedure 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 18. If a drive dump...

Page 41

Is in rom memory or flashes if the dump is in flash memory. If the drive dump is stored in rom memory (scd dot on solid), the dump will be lost when you turn off the power or reset the drive. The scd dot turns off when you obtain a dump. 2. Press the unload button once per second until 5 appears in ...

Page 42

Function code 6 is selectable on the scsi u320 drive but the test will always exit with 0 on the scd. Procedure 1. Make sure that the host interface wrap plug is connected to the host interface connector at the rear of the drive. A sff-8482 sas cable should be connected to the rear of the drive. Con...

Page 43

2. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 18. 3. Press the unload button once per second until 7 appears in the single-character display (scd). If you cycle past 7 , continue to press the unload button until it displays again. 4. To select the ...

Page 44

V if no error is detected, the diagnostic will exit maintenance mode, 0 temporarily appears in the scd, and the drive returns to operational mode (scd blank, green ready/activity status led on, and the amber fault status led is off). V if an error is detected, the fault status led flashes amber and ...

Page 45

3. Press and hold the unload button for three or more seconds, then release it to select the function. A flashes in the scd, followed by 0 . The tape drive erases all errors from the error code log and exits maintenance mode. Function code c: insert cartridge into tape drive about this task this fun...

Page 46

V if no error is detected, the diagnostic will exit maintenance mode, 0 temporarily appears in the scd, and the drive returns to operational mode (scd blank, green ready/activity status led on, and the amber fault status led is off). V if an error is detected, the fault status led flashes amber and ...

Page 47

Note: if you inserted an invalid tape cartridge (e.G. Gen 1, worm media, or non-fmr cartridge), error code 7 appears in the scd and the amber fault status led flashes. If you inserted a write-protected cartridge, or the media has read-only compatibility (e.G., gen2 media), error code p appears in th...

Page 48

Procedure 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 18. 2. Press the unload button once per second until h appears in the scd. (if you cycle past the desired code, press the unload button once per second until the code reappears.) 3. Press and ...

Page 49

Has read-only compatibility (e.G., gen2 media), error code p appears in the scd. Press the unload button. The tape drive unloads the cartridge and exits maintenance mode after the cartridge is removed. Procedure 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode...

Page 50

3. Press and hold the unload button for three or more seconds, then release it to select the function. The scd changes to a flashing c . 4. Insert a scratch (blank) data cartridge. The scd changes to a flashing l and the tape drive runs the tests. V if no error is detected, the diagnostic will exit ...

Page 51

Disabled, function code u will be displayed in maintenance mode. The drive will default to post error reporting disabled after a reboot or power off/on cycle. Procedure 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 18. 2. Press the unload button on...

Page 52

1. Create an fmr tape (see “function code 3: create fmr tape” on page 23). A single fmr tape can be used to update multiple drives if the drives are the same drive type (e.G. Lto gen4) and host interface (e.G. Scsi, sas, fibre channel). 2. Update the drive firmware (see “function code 2: update driv...

Page 53

Chapter 4. Using ultrium media 1 lto cartridge memory a chip that contains information about the cartridge and the tape, as well as statistical information about the cartridge use. (for more information, see “cartridge memory chip (lto-cm)” on page 38.) 2 cartridge door protects the tape from contam...

Page 54

Each generation of data cartridge is identified by case color, native data capacity, recording format and nominal cartridge life. Data cartridge case color native data capacity recording format* nominal cartridge life (load/unload cycles) ultrium 4 green 800 gb (1600 gb at 2:1 compression) reads and...

Page 55

Worm (write once, read many) cartridge certain records retention and data security applications require a write once, read many (worm) method for storing data on tape. The lto ultrium generation 3 and 4 drives enable worm support when a worm tape cartridge is loaded into the drive. Because standard ...

Page 56

– a library will post an error on the operator control panel v inserting a worm tape cartridge into a drive that is not worm capable causes the cartridge to be treated as an unsupported medium. The drive will report a media error code 7 . Upgrading the drive firmware to the correct code level will r...

Page 57

V ensure that anyone who handles tape has been properly trained in handling and shipping procedures. This includes operators, users, programmers, archival services, and shipping personnel. V ensure that any service or contract personnel who perform archiving are properly trained in media-handling pr...

Page 58

V check that the leader pin is properly seated. V if you suspect that the cartridge has been mishandled but it appears usable, copy any data onto a good cartridge immediately for possible data recovery. Discard the mishandled cartridge. V review handling and shipping procedures. Handle the cartridge...

Page 59

V never ship a cartridge in a commercial shipping envelope. Always place it in a box or package. V if you ship the cartridge in a cardboard box or a box of a sturdy material, ensure the following: – place the cartridge in polyethylene plastic wrap or bags to protect it from dust, moisture, and other...

Page 60

The best storage container for the cartridges (until they are opened) is the original shipping container. The plastic wrapping prevents dirt from accumulating on the cartridges and partially protects them from humidity changes. When you ship a cartridge, place it in its jewel case or in a sealed, mo...

Page 61

Chapter 5. Resolving problems if you encounter problems when running the drive, refer to table 8. If the problem is not identified in table 8, refer to “methods of receiving errors and messages” on page 46. The color and condition of the status led might also indicate a problem. For more information...

Page 62

Table 8. Troubleshooting tips (continued) problem description corrective action codes display on the scd, but the status led does not turn on. The status led does not turn on immediately during a power-on or reboot. During the power-on or reboot, random patterns will display on the scd while the sta...

Page 63

Attention: if the drive detects a permanent error and displays an error code other than 0 , it automatically performs a drive dump. If you force a drive dump, the existing dump will be overwritten and data will be lost. After you force a drive dump, do not turn off the power to the drive or you migh...

Page 64

Table 10. Error codes on the single-character display (continued) error code cause and action 8 firmware or hardware problem. The tape drive determined that a firmware or tape drive hardware failure occurred. Perform the following actions: 1. Collect a drive dump from one of the following: note: do ...

Page 65

Table 10. Error codes on the single-character display (continued) error code cause and action if the problem occurs with multiple tape cartridges, run “function code 1: run drive diagnostics” on page 19: v if the diagnostics fail, replace the tape drive. V if the diagnostics succeed, run“function co...

Page 66

Table 10. Error codes on the single-character display (continued) error code cause and action 7 media error. The tape drive determined an error occurred because of a faulty tape cartridge or an invalid tape cartridge. Ensure the tape cartridge is the correct media type: v ultrium 1 tape cartridges a...

Page 67

Table 10. Error codes on the single-character display (continued) error code cause and action a degraded operation. The tape drive determined that a problem occurred that degraded the operation of the tape drive, but it did not restrict continued use. If the problem persists, determine whether the p...

Page 68

Table 10. Error codes on the single-character display (continued) error code cause and action encryption error. Displayed when the drive detects an error associated with an encryption operation. If the problem occurred while the tape drive was writing data to or reading data from, the tape: 1. Check...

Page 69

5. From the server, issue the scsi read command to read the dump from the tape to a file or electronic image (you may need to issue the command several times to read the complete dump). 6. To determine where to send the file for analysis, contact your oem product application engineer (pae). Using a ...

Page 70

Replacing the tape drive the drive is a tier 1 customer replaceable unit (cru). Replacement of tier 1 crus is your responsibility. If ibm installs a tier 1 cru at your request, you will be charged for the installation. For more information about the terms of the warranty and getting service and assi...

Page 71

Appendix a. Getting help and technical assistance if you need help, service, or technical assistance or just want more information about ibm ® products, you will find a wide variety of sources available from ibm to assist you. This section contains information about where to go for additional inform...

Page 72

Getting help and information from the world wide web on the world wide web, the ibm website has up-to-date information about ibm systems, optional devices, services, and support. The address for ibm system x ® and xseries ® information is http://www.Ibm.Com/systems/x/. The address for ibm bladecente...

Page 73

Appendix b. Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently availab...

Page 74

Microsoft, windows, and windows nt are trademarks of microsoft corporation in the united states, other countries, or both. Adobe and postscript are either registered trademarks or trademarks of adobe systems incorporated in the united states, other countries, or both. Linux is a registered trademark...

Page 75

Particulate contamination attention: airborne particulates (including metal flakes or particles) and reactive gases acting alone or in combination with other environmental factors such as humidity or temperature might pose a risk to the tape drive that is described in this document. Risks that are p...

Page 76

U.S.A. In the request, be sure to include the publication part number and title. When you send information to ibm, you grant ibm a nonexclusive right to use or distribute the information in any way it believes appropriate without incurring any obligation to you. Electronic emission notices federal c...

Page 77

Attention: this is an en 55022 class a product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. Responsible manufacturer: international business machines corp. New orchard road armonk, new york 10504 914-499-1900 e...

Page 78

914-499-1900 der verantwortliche ansprechpartner des herstellers in der eu ist: ibm deutschland technical regulations, department m456 ibm-allee 1, 71137 ehningen, germany telephone: +49 7032 15-2937 e-mail: tjahn@de.Ibm.Com generelle informationen: das gerät erfüllt die schutzanforderungen nach en ...

Page 79

People's republic of china class a electronic emission statement taiwan class a compliance statement appendix b. Notices 63.

Page 80

64 lto ultrium 4 half high tape drive.

Page 81

Appendix c. Specifications physical specifications width 146.0 mm (5.75 in.) without bezel 148.3 mm (5.84 in.) with bezel length 205.5 mm (8.09 in.) without bezel 210.5 mm (8.29 in.) with bezel height 82.5 mm (3.25 in.) without bezel 84.8 mm (3.34 in.) with bezel weight (without a cartridge) 3 kg (6...

Page 82

66 lto ultrium 4 half high tape drive.

Page 83

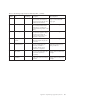

Appendix d. Tapealert flags supported by the drive tapealert is a standard that defines status conditions and problems experienced by devices such as tape drives, autoloaders, and libraries. The standard enables a server to read tapealert messages (called flags ) from a tape drive via the scsi bus. ...

Page 84

Table 13. Tapealert flags supported by the ultrium tape drive (continued) flag number flag snmp trap description action required 10 no removal no set when the tape drive receives an unload command after the server prevented the tape cartridge from being removed. Refer to the documentation for your s...

Page 85

Table 13. Tapealert flags supported by the ultrium tape drive (continued) flag number flag snmp trap description action required 34 download fail no set when an fmr image is unsuccessfully downloaded to the tape drive through the scsi or fibre channel interface. Ensure that it is the correct fmr ima...

Page 86

Table 13. Tapealert flags supported by the ultrium tape drive (continued) flag number flag snmp trap description action required 55 loading failure yes when loading a tape into a drive, a hardware malfunction can prevent the tape from being loaded into the drive, or the tape may actually get stuck i...

Page 87

Table 13. Tapealert flags supported by the ultrium tape drive (continued) flag number flag snmp trap description action required 56 unload failure yes when attempting to unload a tape cartridge, a drive hardware malfunction can prevent the tape from being ejected. The tape may actually be stuck in t...

Page 88

72 lto ultrium 4 half high tape drive.

Page 89

Index a accessible documentation 59 acclimate drive 6 adjust data rate 2 altitude specification 65 assistance, getting 55 c cartridge 37 capacity scaling 37 cleaning 40 compatibility 40 data 37 inserting 14 mid-tape recovery 15 proper handling 40 removing 15 specifications 40 write-protect switch 37...

Page 90

Power specifications 65 problems reported by server resolving 53 r read/write capability 40 replaceable components 54 replacement procedure 54 rs-422 wrap test 26 s sas interface 3 external 10 internal cable connection 9 scsi host interface wrap test 25 scsi interface external server connection 10 i...

Page 92

Part number: 60y1485 printed in usa (1p) p/n: 60y1485.