- DL manuals

- IBM

- Switch

- RS/6000 SP

- Service Manual

IBM RS/6000 SP Service Manual

Summary of RS/6000 SP

Page 1

Rs/6000 sp sp switch service guide ga22-7443-04 ibm.

Page 3

Rs/6000 sp sp switch service guide ga22-7443-04 ibm.

Page 4

Note! Before using this information and the product it supports, read the information in “safety and environmental notices” on page ix and “notices” on page a-1. Fifth edition (april 2002) this book replaces ga22-7443-03. Ibm welcomes your comments. A form for readers’ comments may be provided at th...

Page 5: Contents

Contents figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii safety and environmental notices . . . . . . . . . . . . . . . . . . . . . . . . . . Ix safety notices . . . . . . . . . . . ....

Page 6

Selecting the switch clock source . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 determining the correct switch clock source . . . . . . . . . . . . . . . . . . . . . 3-6 removing and restoring switch resources . . . . . . . . . . . . . . . . . . . . . . . 3-7 removing a switch assembly from ...

Page 7: Figures

Figures 1-1. Sp switch high-level diagram . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 1-2. Sp switch wrap plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 1-3. Sp switch inner chassis and front chassis cables . . . . . . . . . . . . . . . . . 1-8 2-1. Front view of frame loc...

Page 8

Vi rs/6000 sp: sp switch service guide.

Page 9: Tables

Tables 1-1. Switch problem diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 1-2. Environmental messages for switches . . . . . . . . . . . . . . . . . . . . . 1-5 1-3. Switch connector resistance values . . . . . . . . . . . . . . . . . . . . . . 1-6 1-4. Fan failure diagnostics . ....

Page 10

Viii rs/6000 sp: sp switch service guide.

Page 11

Safety and environmental notices for general information concerning safety, refer to electrical safety for ibm customer engineers, s229-8124. For a copy of the publication, contact your ibm account representative or the ibm branch office serving your locality. Safety notices the following is a list ...

Page 12

Danger before you connect the power cable of this product to ac power, verify that the power receptacle is correctly grounded and has the correct voltage. ( spsfd004) danger during an electrical storm, do not connect or disconnect any cable that has a conductive outer surface or a conductive connect...

Page 13

Danger the remaining steps of the procedure contain measurements that are taken with power on. Remember that hazardous voltages are present. ( spsfd013) danger the frame main circuit breaker and the controller must not be switched on again now. Before disconnecting the power cables from the power re...

Page 14

Caution: the covers are to be closed at all times except for service by trained service personnel. ( spsfc003) caution: when the unit is being serviced, the covers should not be left off or opened while the machine is running unattended. ( spsfc004) caution: due to weight of each thin node (under 18...

Page 15

Caution: v when moving frames into position, team members should work together. Using one person on each corner of the frame can prevent strain. V in raised floor installations, mechanically safe moldings should be installed around floor cutouts. Extreme caution should be used when moving frames dur...

Page 16

This product might contain nickel-cadmium or lithium batteries in communication adapters. The batteries must be recycled or disposed of properly. Recycling facilities might not be available in your area. In the united states, ibm has established a collection process for reuse, recycling, or proper d...

Page 17: About This Book

About this book this book is part of the rs/6000 ® sp ™ hardware service library and applies to the rs/6000 sp switch. Use this book to assist you in performing the following tasks: v identify field replaceable unit (fru) locations v isolate rs/6000 sp failures using maintenance analysis procedures ...

Page 18

How to send your comments your feedback is important in helping to provide the most accurate and highest quality information. If you have any comments about this book or any other rs/6000 sp documentation: v send your comments by e-mail to mhvrcfs@us.Ibm.Com. Be sure to include the name of the book,...

Page 19: Summary Of Changes

Summary of changes ga22-7443-04 this edition contains replaces ga22-7443-03 and any update versions made to that level and makes them obsolete. This edition contains minor changes and fixes to softcopy cross-book links. Ga22-7443-03 this edition contains replaces ga22-7443-02 and any update versions...

Page 20

Xviii rs/6000 sp: sp switch service guide.

Page 21

Chapter 1. Maintenance analysis procedures (maps) this chapter provides information for identifying problems and guides you to the most likely failed field replaceable unit (fru). The maps then refer you to the fru removal/replacement procedures for the corrective action. V “sp switch description an...

Page 22

Frus include: fans, circuit breaker/led card, switch supervisor card, switch power card(s), inner chassis cable, front chassis cable, complete assembly. Sps-8 there are only 8 ports. All clocks are distributed through data cables. Frus include: fans, circuit breaker/led card, switch supervisor card,...

Page 23

There are two leds on the front of each sp switch. For quick reference, their definitions are as follows: environment (yellow) off no environmental problems detected by switch supervisor card. On warning of environmental condition out of nominal range. Preventative maintenance should be scheduled fo...

Page 24

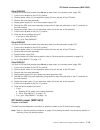

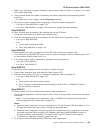

Table 1-1. Switch problem diagnostics priority message or condition action 1 (1 of 3) environmental problems v errpt: “failure...” v log: “shutdown: voltage...” v log: “shutdown: fan...” v log: “shutdown: temperature...” v errpt: “warning...” v log: “warning:...” v environment (yellow) led- on or fl...

Page 25

Sp switch environment (map 0600) purpose of this map this map provides diagnostic information for switch problems that are related to the operating environment. Note: refer to “service position procedures” on page 3-9 for placing a switch into the service position or for removing the switch from the...

Page 26

Step 0600-004 perspectives indicated a shutdown condition and table 1-2 on page 1-5 directed you to this step. 1. One or more of the following conditions exist: v voltage out of range: +5 v “shutdownp5” v voltage out of range: +12 v “shutdownp12” v voltage out of range: −5 v “shutdownn5” 2. Have the...

Page 27

3. Is the measured resistance now within the acceptable range? V if yes, go to “step 0600-017” on page 1-10 to verify fix. V if no, go to “step 0600-008”. Step 0600-008 you replaced the inner chassis cable and the front chassis cable but the measured resistance is still outside of the acceptable ran...

Page 28

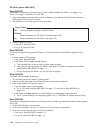

Table 1-4. Fan failure diagnostics priority component action 1 (1 of 5) fan 1, 2, 3, 4 or 5 a. Check specified fans for blockages or loose cable connections. B. Fix any obvious problems and continue at “step 0600-012”. C. If you do not find any problems, continue at priority 2. 2 (2 of 5) fan 1, 2, ...

Page 29

6. Check the environmental (yellow) led for an on or flashing condition. 7. Is the environmental (yellow) led on or flashing? V if the environmental led is on or flashing: a. Put the sp switch’s circuit breaker into the off (‘0’) position. B. Return to “step 0600-011” on page 1-7 and continue servic...

Page 30

2. Remove blockage. 3. If required, put the switch into service position (refer to “service position procedures” on page 3-9). 4. With all cables replugged and environmental (yellow) led off, power on the sp switch. 5. Go to “step 0600-017” to verify fix. Step 0600-017 you have repaired or replaced ...

Page 31

2. Remove the switch supervisor card (refer to “removing the switch supervisor card” on page 4-4). 3. Using a digital multimeter, measure resistance at the planar connection for the supervisor card, between pins 12a and 12b. V the resistance should be in a range of 4 to 20 ohms. 4. Is the measured r...

Page 32

Step 0600-025 you have a ps1fail problem 1. Replace power supply card ps1. 2. Reinstall the sps front panel assembly, being careful to align the guide pins on the p1 to the inner chassis cup guide. 3. Replug the power cable (j1) and supervisor cable (j2) to the rear of the assembly. 4. Put the circu...

Page 33

Step 0600-029 you have a psfusegood problem that did not go away when you removed power supply ps1. 1. Put the circuit breaker in the off (‘0’) position. 2. Remove power cable (j1) and supervisor cable (j2) from the rear of the sp switch. 3. Remove the front panel assembly. 4. Replug power supply ps...

Page 34

Step 0610-001 a message in perspectives indicated that you have a power problem and table 1-1 on page 1-4 or table 1-2 on page 1-5 directed you to this map. 1. From a perspectives window on the control workstation or by looking at the sp switch, check the power (green) led for this sp switch. 2. The...

Page 35

Step 0610-005 when you put the circuit breaker into the on (‘1’) position, the circuit breaker tripped into the off (‘0’) position. 1. Have the customer remove the sp switch from the active configuration and power off the sp switch. 2. Put the switch into service position (refer to “service position...

Page 36

V if yes: a. Have the customer remove the sp switch from the active configuration and power off the sp switch. B. Go to “step 0610-010”. V if no: a. Fix any cable connection problems. B. Return to “step 0610-006” on page 1-15. Step 0610-010 you have an sp type switch that is either tripping the circ...

Page 37

A. Replace the front chassis cable. B. Return to “step 0610-004” on page 1-14 to verify the replacement cable. V if no: a. Replace the circuit breaker. B. Return to “step 0610-004” on page 1-14 to verify the replacement breaker. Step 0610-013 you have continuity on all cables. 1. If this is the firs...

Page 39

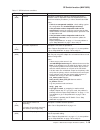

Table 1-7. Sp switch error conditions error # message/condition description and action 2 (sps) initialized description: initialization detected a wrapped port where a processor node or dependent node was expected (this may result from isolation procedures), or else a disconnected cable. Action: 1. I...

Page 40

Table 1-7. Sp switch error conditions (continued) error # message/condition description and action −3 (sps) device status: device has been removed from network because of a bad signature link status: not operational description: possible hardware problem. Action: go to “step 0620-004” on page 1-21. ...

Page 41

Table 1-7. Sp switch error conditions (continued) error # message/condition description and action −8 (sps) device status: device has been removed from network because of a miswire link status: link has been removed from network, probable miswire description: initialization of this link detected a d...

Page 42

Refer to notes at beginning of “sp switch function (map 0620)” on page 1-17 for more information on cable connections and logical-to-physical frame translations. C. Be aware that for logical frames consisting of two physical frames, all out.Top even-numbered nodes represent nodes physically located ...

Page 43

1. Make sure a wrap plug is properly installed on the connector. Refer to figure 1-2 on page 1-4 for views of the switch wrap plugs. 2. Have customer check (and update if necessary) the switch configuration file appropriately before continuing: v for code level 1.02 and higher, use the etopology com...

Page 44

V if yes: a. An srn was obtained from diagnostics. B. Use the following srn table (table 1-9) to continue service. C. After using table 1-9, go to “step 0620-012” on page 1-26. V if no: a. The diagnostics did not detect a problem, therefore the problem is in sp switch. B. Go to “step 0620-041” on pa...

Page 45

Table 1-9. Service request number (srn) table for sp switch adapters (continued) service request number srn source failing component(s) description 763-200 through 763-299 (except 763-282) d ext clock sps mx adapter wrap plug problem detected with the external clock (sp switch). 763-282 d switch cab...

Page 46

Table 1-9. Service request number (srn) table for sp switch adapters (continued) service request number srn source failing component(s) description 764-2a0 through 764-2a9 d sp system attachment adapter problem detected with the internal clock. 764-3xx (see note) d sp system attachment adapter syste...

Page 47

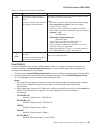

Table 1-10. Switch problem priority listing priority failing component action 1 (1 of 7) software a. Have customer verify that the software is configured and operating correctly for this processor node/system. B. If no problem is found, continue with next highest priority item in the list for this s...

Page 48

Step 0620-013 an srn listed in table 1-9 on page 1-24 indicated that you have a switch clock problem and priority 2 in table 1-10 on page 1-27 directed you to this step. 1. Check the switch clock selections on the “problem” switches . 2. Do the clock settings on the “problem” sp switches appear to b...

Page 49

Step 0620-019 since the diagnostics did not return an srn, no problem was detected. 1. Have you just reseated, repaired, or replaced a component? V if yes, go to “step 0620-043” on page 1-36 to verify fix. V if no: a. Problem is in the sp switch. B. Go to “step 0620-041” on page 1-35 to service or r...

Page 50

Note: when unplugging the two ends of the suspect cable, check /var/adm/splogs/css/out.Top to verify only two (2) ports were lost. If four (4) ports were lost, then two cables were swapped across that switch to switch connection. Connect the cables correctly and check /var/adm/splogs/css/out.Top for...

Page 51

V if yes, go to “step 0620-027”. V if no: a. The problem switch is providing the master clock for the system. B. Have customer use the eclock command to select a different master clock for the system. C. Go to “step 0620-043” on page 1-36 to verify fix. Step 0620-027 the clock selection is set to on...

Page 52

V s00-bh-j9 5. Disconnect the switch data cable at the tailgate of the frame containing the processor node. 6. Connect the end of the processor node data cable to the jack. 7. Run advanced diagnostics on “css0” on the “test” processor node and its associated switch port. V do not perform the cable w...

Page 53

Step 0620-033 all ground straps connecting the frames make adequate contact at both ends. 1. Disconnect clock source data cable at s00-bh-j3, j5, j7, or j9, then reconnect to sp switch. (this is done to eliminate clocking noise from cable.) 2. Find a processor node in the “problem” frame which is us...

Page 54

5. Set the switch clock selections on the “problem” switches (refer to “selecting appropriate switch clocks” on page 3-6). 6. Run advanced diagnostics on “css0” on the “test” processor node and its associated switch port. V do not perform cable wrap test. V refer to ″ running diagnostics in a proces...

Page 55

5. Look for an srn indicating a clock problem, such as “external clock” being listed as one of the failing components. 6. Do the “css0” diagnostics fail with indication of a clock problem? V if yes: a. Problem is the clock selection in this sp switch. B. Return to “step 0620-035” on page 1-33. V if ...

Page 56

2. Put the sp switch’s circuit breaker into the on (‘1’) position. 3. Go to “step 0620-043” to verify fix. Step 0620-043 you have replaced switch components and need to verify that the problem has been fixed. 1. Make sure any processor node(s) that was put in service mode is returned to normal mode....

Page 57: Chapter 2. Locations

Chapter 2. Locations naming standard for rs/6000 sp components . . . . . . . . . . . . . . . . . . . . . 2-1 format structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 example of format structure . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 frame (www) . . . . . . ...

Page 58

– 01 - 99 for frames 1-99 (specific to that frame) notes: 1. E01 designates rs/6000 sp physical frame 1 2. L00 designates any/all rs/6000 sp logical frames 3. S00 designates any/all rs/6000 sp multi-switch frames 4. For locations inside a frame, the frame (www) and/or major assembly (xxx) strings ma...

Page 59

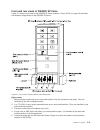

Front and rear views of rs/6000 sp frame figure 2-1 shows a front view of the rs/6000 sp frame locations. “frame (fra)” on page 2-6 describes the assembly designations for the rs/6000 sp frame. Figure notes: 1. Wide processor nodes take up an entire shelf position (two thin processor node slots). Th...

Page 60

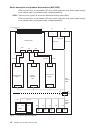

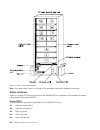

Figure 2-2 shows a front view of the rs/6000 sp multi-switch frame. Figure 2-3 on page 2-5 shows a front view of the model 3ax (49-inch) frame. Main power switch with led left skirt right skirt switch asm s2 switch asm s4 switch asm s6 switch asm s8 switch asm s10 switch asm s12 switch asm s14 switc...

Page 61

Figure notes: 1. Wide processor nodes take up an entire shelf position (two thin processor node slots). They are identified by the odd numbered position. 2. In a f/c 2030/1 frame, switch assemblies take up an entire shelf partition. (they are identified by the even-numbered position.) 3. Processor n...

Page 62

Note: see notes under figure 2-1 on page 2-3 for processor node/switch assembly numbering. Frame locations figure 2-1 on page 2-3 shows a front view of the rs/6000 sp frame locations, with numbered processor nodes, and the three phase sepbu. Frame (fra) this list shows the designations specifically ...

Page 63

G6: front door ground g7: rear door ground g8: ground sw: power-on switch ld: led card fc: front cover rc: rear cover example: e01-fra-g1 chapter 2. Locations 2-7.

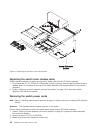

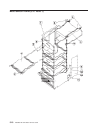

Page 64: A I R B A F F L E

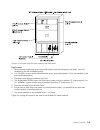

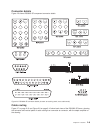

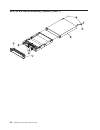

Switch assembly locations fan 5 p6 p4 p5 fan 4 fan 3 fan 2 fan 1 cb & led card j1 j2 switch planar power supply 2 supervisor card power supply 1 supervisor bus card a i r b a f f l e figure 2-5. Sps/sps-8 assembly 2-8 rs/6000 sp: sp switch service guide.

Page 65

Connector details figure 2-6 shows rs/6000 sp component connector details. Cable routing figure 2-7 on page 2-10 and figure 2-8 on page 2-10 show back views of the rs/6000 sp frame, showing the horizontal and vertical paths of cable routing from connector-to-connector, with the depth amplified on th...

Page 66

Note: when attaching exterior and interior cables to a power3 smp high node allow for enough cable for a 2-foot service loop for node movement into service position. Note: for a multi-switch frame (f/c 2030/1), refer to figure 2-7. Figure 2-7. Frame cabling routing path in rear of rs/6000 sp frame —...

Page 67

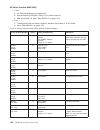

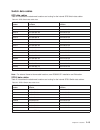

Table 2-1 shows external cable routing in a rs/6000 sp frame populated with 16 processor nodes. (refer to “cable routing” on page 2-9 to see the routing paths.) table 2-1. External cable routing slot number (node) cable budget millimeters (inches) frame entrance (new style) frame entrance (old style...

Page 68

Figure 2-9. Frame cable routing paths in rear of rs/6000 sp multi-switch frame (f/c 2030/1) — 1.93 m frame figure 2-10. Frame cable routing paths in rear of rs/6000 sp multi-switch frame (f/c 2030/1) — 2.01 m frame 2-12 rs/6000 sp: sp switch service guide.

Page 69

Switch data cables sps data cables table 2-2 describes the attachment locations and routing for the internal sps switch data cables: table 2-2. Sps switch data cable chart cable part number plug from location plug to location 46h9710 e00-s00-bh-j7 e00-n01-bh-pa 46h9711 e00-s00-bh-j8 e00-n02-bh-pa 46...

Page 70

2-14 rs/6000 sp: sp switch service guide.

Page 71

Chapter 3. Service procedures personal esd requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 tools and files overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 using the css.Snap script . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 switch ...

Page 72

Table 3-1. Service procedure tools utility (see note) runs on description fault_service_worm_rtg all nodes monitors the switch for faults. It restarts the switch if a fault is detected. Fs_monitor all nodes monitors the adapter for interrupts that have not been serviced. This is required because of ...

Page 73

Table 3-3. Tuning output files (continued) file (see note) location description daemon.Stderr primary a record of which nodes were not initialized. Out.Top primary reports errors from the last tuning procedure. It begins as a copy of the topology file and errors are indicated to the right of each en...

Page 74

The files ending in .Out are produced by running the appropriate command to dump internal (in memory) trace information or dump data to a file. The completed output file will be found in /var/adm/splogs/css/css.Snap.[date-time]tar.Z. Css.Snap avoids flooding /var by following these rules: v if less ...

Page 75

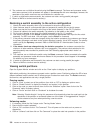

2. In the node pane, click the icon of the node you want to verify 3. Click the ″ notebook ″ icon on the tool bar v when the notebook window opens, make certain that the ″ node status ″ tab is selected 4. The ″ node failure: ″ attribute displays the status of the node supervisor v ″ no ″ displayed i...

Page 76

V ″ yes ″ displayed in a red box indicates that the switch supervisor has failed and it is not responding to the frame supervisor. Note: clicking ″ help ″ in the notebook window’s lower right corner displays attribute descriptions. Selecting appropriate switch clocks the following procedure describe...

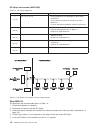

Page 77

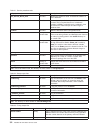

1 input 1 (bh-j3 for sps) 2 input 2 (bh-j4 for sps) 3 input 3 (bh-j5 for sps) table 3-4. Setting switch clock sources model number of logical frames master clock choice 1 2 3 30x 1-4 l01-s00 = i l02-s00 = 1 l03-s00 = 1 l04-s00 = 1 l01-s00 = 1 l02-s00 = i l03-s00 = 2 l04-s00 = 2 l01-s00 = 2 l02-s00 =...

Page 78

6. The customer can re-initialize the switch using the estart command. The frame and processor nodes which were removed in this procedure will appear in the out.Top file with error messages; however, the remainder of the switch resources are now available for customer use. 7. If switch re-initializa...

Page 79

Efence of primary and primary backup nodes by design, efence of primary and primary backup nodes is not allowed. If you attempt to fence either of these nodes, you will get the following responses: efence: 0028-147 node number designates the primary node. Efence: 0028-166 node number designates the ...

Page 80

D. Choose “normal mode” e. Choose “display current bootlist” this will display the current bootlist. 2. Power down the node, service it, and hook it back into the frame. 3. On the control workstation, run spbootins to set the node to boot in maintenance mode. For example, if it is node 12 of frame 2...

Page 81

The following 3 adapters require functional microcode to be installed: adapter package escon ® control unit adapters feature 2756 escon blkmux s/370 ™ control unit feature 2755 blkmux fddi adapters features 2723, 2724, 2725, 2726 fddi these adapters might need updating to the latest level in their f...

Page 82

To complete the microcode update, it is usually necessary to remove and then replace the device from the configuration. The most reliable method to do this is to reboot the node. Some adapters can actually require a power off cycle to complete the microcode update. Others can be updated simply by ru...

Page 83

Chapter 4. Fru removals and replacements handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 procedures for switch assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 removing the switch assembly . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 84

Procedures for switch assemblies caution: the unit weight exceeds 18 kg (40 lbs) and requires two service personnel to lift. (spsfc002) attention: components in the frame are susceptible to damage from static discharge. Always use an esd wristband when working inside frame covers. (see “personal esd...

Page 85

Removing the switch fans note: refer to “handling static-sensitive devices” on page 4-1 before removing or installing esd sensitive devices. Perform these procedures to remove a fan from an sp switch assembly: 1. Perform “placing a switch assembly into service position” on page 3-9 to place the swit...

Page 86

Perform these procedures to remove the fan control cable from an sp switch assembly: 1. Perform “placing a switch assembly into service position” on page 3-9 to place the switch assembly into the service position. 2. Unplug connectors p7, p8 and p9. Remove cable by unhooking retaining material along...

Page 87

Replacing the switch supervisor card perform these procedures to replace the supervisor card in an sp switch assembly: 1. Insert supervisor card. 2. Rotate card thumb locks inward to seat card. 3. Plug connector p5. 4. Perform “replacing a switch assembly from service position” on page 3-9 to remove...

Page 88

Replacing the switch inner chassis cable perform these procedures to replace the supervisor power cable from an sp switch assembly: 1. Plug connectors p3, p4, p5 and p6. Route cable along the raceway, hooking retaining material where needed. Attach p1 connector to the rear of the switch assembly wit...

Page 89

4. Remove power supply card. Replacing the switch power cards perform these procedures to replace the switch power cards) in an sp switch assembly: 1. Insert power supply card. 2. Rotate card thumb locks inward to seat card. 3. Plug connector p4 (ps1) or p6 (ps2). 4. Perform “replacing a switch asse...

Page 90

4-8 rs/6000 sp: sp switch service guide.

Page 91: Chapter 5. Parts Catalog

Chapter 5. Parts catalog sps, sps-8 switch assembly (feature) (view 1) . . . . . . . . . . . . . . . . . . . . . 5-2 sps, sps-8 switch assembly (feature) (view 2) . . . . . . . . . . . . . . . . . . . . . 5-4 sps, sps-8 switch assembly (feature) (view 3) . . . . . . . . . . . . . . . . . . . . . 5-6...

Page 92

Sps, sps-8 switch assembly (feature) (view 1) 5-2 rs/6000 sp: sp switch service guide.

Page 93

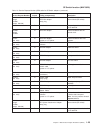

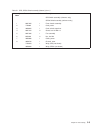

Table 5-1. Sps, sps-8 switch assembly (feature) (view 1) assembly index part number units description sps switch assembly (reference only) sps-8 switch assembly (reference only) 1 26h7255 1 front chassis assembly 2 77g0961 1 card, power 3 46h9305 1 card, switch supervisor 4 26h7212 2 screw, hex hd m...

Page 94

Sps, sps-8 switch assembly (feature) (view 2) 5-4 rs/6000 sp: sp switch service guide.

Page 95

Table 5-2. Sps, sps-8 switch assembly (feature) (view 2) assembly index part number units description sps switch assembly (reference only) sps-8 switch assembly (reference only) 1 11p0655 1 inner chassis assembly sps (includes all assembly in shaded area) 1 11p0656 1 inner chassis assembly sps-8 (in...

Page 96

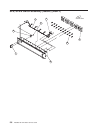

Sps, sps-8 switch assembly (feature) (view 3) 8 7 6 5 4 3 2 1 air flow 5-6 rs/6000 sp: sp switch service guide.

Page 97

Table 5-3. Sps, sps-8 switch assembly (feature) (view 3) assembly index part number units description sps switch assembly (reference only) sps-8 switch assembly (reference only) 1 26h7391 1 cable, front chassis 2 32g1547 1 screw, hex m4 x 5 3 46h9778 2 cup guide (2.01 m, order kit) 3 77g1079 2 pin g...

Page 98

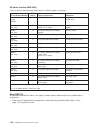

Switch cables (feature) table 5-4. Switch cables (feature) assembly index part number units description sp switch data cables (sps) 11j6091 ar cable, switch data node 01 - (1345 mm) 11j6092 ar cable, switch data node 02 - ( 1040 mm) 11j6093 ar cable, switch data node 03 - ( 1320 mm) 11j6094 ar cable...

Page 99

Chapter 5. Parts catalog 5-9.

Page 100

Multi-switch frame (f/c 2030/1) 5-10 rs/6000 sp: sp switch service guide.

Page 101

Table 5-5. Multi-switch frame (f/c 2030/1) assembly index part number units description 1 sps switch assembly 2 54g3281 16 screw, phil pan hd m5 x 12 3 93g1065 ar shelf assembly 4 0375867 8 nut, clip 5 84x4761 8 screw, hex fl hd supradrive 6 17h5026 8 screw, sl hex fl hd m5 x 6 7 54g2877 4 panel, sw...

Page 102

5-12 rs/6000 sp: sp switch service guide.

Page 103: Notices

Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently available in your a...

Page 104

Electronic emissions notices federal communications commission (fcc) statement this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interferenc...

Page 105

For installations in japan: the following is a summary of the vcci japanese statement in the box above. This is a class a product based on the standard of the voluntary control council for interference by information technology equipment (vcci). If this equipment is used in a domestic environment, r...

Page 106

A-4 rs/6000 sp: sp switch service guide.

Page 107: Index

Index numerics 0375867 5-11 04h9469 5-11 08j5557 5-11 11j3975 5-8 11j3976 5-8 11j3977 5-8 11j3978 5-8 11j3979 5-8 11j3980 5-8 11j3981 5-8 11j3982 5-8 11j5189 5-11 11j5191 5-11 11j5193 5-11 11j5195 5-11 11j6091 5-8 11j6092 5-8 11j6093 5-8 11j6094 5-8 11j6095 5-8 11j6096 5-8 11j6097 5-8 11j6098 5-8 11...

Page 108

Frame locations 2-3, 2-5, 2-6 frame naming standard 2-1 frame supervisor verification 3-5 front chassis cable, sps 1-8 front view of 49-inch frame locations 2-4 front view of frame locations 2-3 front view of multi-switch frame locations 2-4 h handling static-sensitive devices 4-1 i installing adapt...

Page 109

Sps assembly, placing into service position 3-9 sps assembly, removing 4-2 sps assembly, replacing 4-2 sps assembly, replacing from service position 3-9 sps fan control cable, removing 4-3 sps fan control cable, replacing 4-4 sps fans, removing 4-3 sps fans, replacing 4-3 sps front chassis cable 1-8...

Page 110

X-4 rs/6000 sp: sp switch service guide.

Page 111

Reader’s comments – we’d like to hear from you rs/6000 sp sp switch service guide publication no. Ga22-7443-04 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall satisfaction h h h h h how satisfied are you that t...

Page 112

Readers’ comments — we’d like to hear from you ga22-7443-04 ga22-7443-04 ibm cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape place postage stamp here ibm corporation department 55ja, mail station p384 245...

Page 114

Ibm ga22-7443-04.