- DL manuals

- IBM

- Switch

- TotalStorage 2109 M12

- Installation And Service Manual

IBM TotalStorage 2109 M12 Installation And Service Manual

Summary of TotalStorage 2109 M12

Page 1

Ibm totalstorage san switch 2109 model m12 installation and service guide gc26-7633-00 read before using this product contains software that is licensed under written license agreements. Your use of such software is subject to the license agreements under which they are provided..

Page 3

Ibm totalstorage san switch 2109 model m12 installation and service guide gc26-7633-00

Page 4

Note: before using this information and the product it supports, read the information in “notices” on page 101. First edition (may 2004) the following paragraph does not apply to any country (or region) where such provisions are inconsistent with local law. International business machines corporatio...

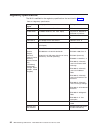

Page 5: Contents

Contents figures . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ix safety and environmental notices . . . . . . . . . . . . . . . . . Xi safety notices and labels . . . . . . . . . . . . . . . . . . . . . Xi danger notices . ....

Page 6

16–port cards . . . . . . . . . . . . . . . . . . . . . . . . 15 control processor cards . . . . . . . . . . . . . . . . . . . . 16 power supplies . . . . . . . . . . . . . . . . . . . . . . . . 17 ac power input connectors and ac power switches (circuit breaker) . . . . 18 blower assemblies . . . ....

Page 7

Removing a power supply or filler panel . . . . . . . . . . . . . . . 75 replacing a power supply or filler panel . . . . . . . . . . . . . . . 77 removing and replacing a blower assembly . . . . . . . . . . . . . . 77 time required . . . . . . . . . . . . . . . . . . . . . . . . 78 items required ....

Page 8

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . 105 index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 vi ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 9: Figures

Figures 1. Safety label on the model m12 . . . . . . . . . . . . . . . . . . . . . . . . . . Xv 2. Linecord caution label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Xv 3. Power supply cover caution label . . . . . . . . . . . . . . . . . . . . . . . . . Xvi 4. Fusing caution label . ....

Page 10

Viii ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 11: Tables

Tables 1. Brocade and ibm product and model number matrix . . . . . . . . . . . . . . . . . Xxvi 2. Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3. 16–port card led patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4. Cp card led patterns . . . ....

Page 12

X ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 13: Safety

Safety and environmental notices this section contains information about: v “safety notices and labels” v “safety inspections” on page xiv v “laser safety” on page xxi v “rack safety” on page xxii v “environmental notices and statements” on page xxiv safety notices and labels when using this product...

Page 14

Danger electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid a shock hazard: v do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm. V connect all power cords to a ...

Page 15

Labels as an added precaution, safety labels are often installed directly on products or product components to warn of potential hazards. The actual product safety labels may differ from these sample safety labels: sj000323 >240 v~ danger hazardous voltage, current, or energy levels are present insi...

Page 16

Caution: this product contains a class 1m laser. Do not view directly with optical instruments. (c028) attention notices an attention notice indicates the possibility of damage to a program, device, or system, or to data. An exclamation point symbol may accompany an attention notice, but is not requ...

Page 17

1. Check for any non-ibm changes that might have been made to the machine. If any are present, obtain the “non-ibm alteration attachment survey” form, number r009, from the ibm branch office. Complete the form and return it to the branch office. 2. Check the condition of the inside of the machine fo...

Page 18

4. Verify that the fusing caution label shown in figure 4 is installed on the model m12 power supply. 5. Verify that the heavy load label shown in figure 5 is installed on the back of the switch. 6. Verify that the sfp labels shown in figure 6 on page xvii and figure 7 on page xvii are installed on ...

Page 19

Sj000317 figure 6. Sfp label (front view) sj000314 figure 7. Sfp label (back view) safety and environmental notices xvii.

Page 20

Ac grounding danger an electrical outlet that is not correctly wired could place hazardous voltage on metal parts of the system or the devices that attach to the system. It is the responsibility of the customer to ensure that the outlet is correctly wired and grounded to prevent an electrical shock....

Page 21

2. Verify that the tilt warning label shown in figure 9 on page xx is installed on the load plate. Sj000749 alinhar a placa de carregamento (p/n 11p4369) com a linha antes de mover a chave ou o chassi da chave para dentro ou fora do gabinete allineare la piastra di carico (p/n 11p4369) e la riga pri...

Page 22

3. Verify that the genie tool and load plate label shown in figure 10 is installed on the load plate. 4. Verify that the pinch point label shown in figure 11 on page xxi is installed on the load plate. Pn 18p5850-c sj000750 figure 9. Tilt warning label this bridge should be used with genie tool (p/n...

Page 23

Laser safety this equipment contains class 1 laser products, and complies with fda radiation performance standards, 21 cfr subchapter j and the international laser safety standard iec 825-2. Caution: this product contains a class 1m laser. Do not view directly with optical instruments. (c028) attent...

Page 24

Rack safety rack installation danger v always lower the leveling pads on the rack cabinet. V always install stabilizer brackets on the rack cabinet. V to avoid hazardous conditions due to uneven mechanical loading, always install the heaviest devices in the bottom of the rack cabinet. Always install...

Page 25

Rack relocation (19 ″ rack) caution: removing components from the upper positions in the rack cabinet improves rack stability during relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a room or building: v reduce the weight of the rack cabinet by removi...

Page 26

Environmental notices and statements this section describes the environmental notices and statements. Battery notice caution: only trained service personnel may replace this battery. The battery contains lithium. To avoid possible explosion, do not burn or charge the battery. Do not: v throw or imme...

Page 27: About

About this document this document describes how to install and service the ibm totalstorage ®™ san switch 2109 model m12. Throughout this document, the product is referred to as the model m12. The term switch also applies to the model m12. The sections that follow provide information about: v “who s...

Page 28

V brocade secure fabric os user’s guide when you use any of the brocade documents, you will notice that the model numbers reflect the original brocade switches. Table 1 provides a product matrix for you to use to correlate the brocade model numbers to the ibm product and model numbers. Table 1. Broc...

Page 29

Getting help contact your switch supplier for technical support. This includes hardware support, all product repairs, and ordering of spare components. Be prepared to provide the following information to support personnel: v the switch serial number v the switch worldwide name (licenseidshow command...

Page 30

Xxviii ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 31: Chapter

Chapter 1. Introduction this chapter introduces the ibm totalstorage san switch 2109 model m12 switch (hereafter referred to as the model m12 or the m12) and contains the following information: v “overview” v “monitoring and managing the m12” on page 4 overview the model m12 is a high-performance co...

Page 32

Optionally licensed and separately priced features include: v extended fabrics (feature code 7603) provides up to 80 km (49.7 mi) of switched fabric connectivity at full bandwidth over long distances v remote switch (feature code 7602) enables switches to interconnect over wide area network (wan) us...

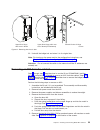

Page 33

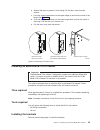

V four power supplies that are hot swappable and have built-in fans v two ac power connectors. Each ac power connector has an on or off ac power switch for information about how to operate the components of the m12, see chapter 3, “operating the m12,” on page 15. Blower assembly side of chassis figu...

Page 34

Monitoring and managing the m12 you can manage the m12 in-band by using fibre channel protocol or out-of-band by connecting to the ethernet port. The management functions allow the administrator to monitor fabric topology, port status, physical status, and other information to aid in performance ana...

Page 35

V web tools v snmp applications v management server for more information about these management interfaces, see the brocade fabric manager user’s guide and the brocade advanced web tools user’s guide. Chapter 1. Introduction 5.

Page 36

6 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 37: Chapter

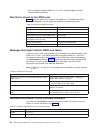

Chapter 2. Starting and configuring the m12 you must configure the m12 appropriately in order for it to operate correctly within the network and fabric. Note: the switch only detects modems during power on or restart. If you connect a modem to an operating switch, you must restart the switch for it ...

Page 38

You can modify the configuration only through a login session to the active cp card. The switch supports up to two telnet sessions with administrative privileges at the same time. The same administrative login account applies to both logical switches. If the password is changed on switch 0, it autom...

Page 39

V two switch names, if the default switch names are not going to be used. Switch names can be up to 15 characters long. Switch names can include alphabetical, numerical, and underscore characters, and must begin with an alphabetical character. The default switch name for the logical switches is: – s...

Page 40

G. At the prompt, type 0 to log in to switch 0. Enter switch number to login or 1>:0 note: at the initial login, the user is prompted to type a new admin password and a new user password. The same administrative account applies to both logical switches. If the password is changed on switch 0, it aut...

Page 41

Ipaddrset 0 b. Type the requested information for this ip address at the prompt: ethernet ip address [10.77.77.77]: ethernet subnetmask [0.0.0.0]: fibre channel ip address [none]: fibre channel subnet mask [none]: the logical ip address is updated immediately. C. To configure the second logical ip a...

Page 42

3) log in as admin. 4) repeat step 8a on page 11 and step 8b on page 11 for the other logical switch. 9. Optional: modify the domain ids, if desired. Type fabricshow to see a list of the current domain ids. Note: the default domain id for both switches is 1 . To prevent a domain id conflict, make th...

Page 43

Note: cables are keyed so that you can only insert them with the correct orientation. If a cable does not slide in easily, ensure that it is correctly oriented. C. Repeat step 11a on page 12 and step 11b on page 12 for the remaining ports. D. Organize the cables as required. 12. Check the m12 switch...

Page 44

14 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 45: Chapter

Chapter 3. Operating the m12 this chapter describes how to operate the m12 and includes the following information: v “turning the switch on and off” v “interpreting led activity” on page 20 v “interpreting post” on page 30 v “maintaining the switch” on page 31 note: throughout this chapter, the term...

Page 46

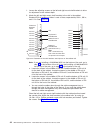

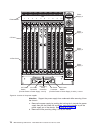

Caution: no user-serviceable parts are inside the 16–port card. Each 16–port card provides 16 auto-sensing fibre channel ports that are capable of auto-sensing data transmission speeds of 1 gbps and 2 gbps. You can install 16–port cards in any combination of slots 1–4 (switch 0) and 7–10 (switch 1),...

Page 47

The modem serial port has an rs–232 connector that is wired as a data terminal equipment (dte) device. It is designed to connect to a distributed computing environment (dce) device, such as a modem. V terminal serial port (also known as a console port) the terminal serial port has an rs–232 signal s...

Page 48

Attention: to protect against ac failure, you must have a minimum of one power supply in slot 1 or slot 3 and one in slot 2 or slot 4. If you install only two power supplies and you install both of them in slots that correspond to the same power cable, unplugging a single power cable will power down...

Page 49

Attention: disassembling any part of the blower assembly voids the part warranty and regulatory certifications. Caution: no user-serviceable parts are inside the blower assembly. Perform the following steps to determine the status of a blower assembly: 1. Check the leds on the blower assembly. 2. Ch...

Page 50

Attention: do not route the cables in front of the air exhaust vent, which is located at the top of the port side of the chassis. The minimum bend radius for a 50–micron cable is 3.05 cm (2 in.) under full tensile load, and 3.048 cm (1.2 in.) with no tensile load. Do not use tie wraps for optical ca...

Page 51

! Port status led (16x) port speed led (16x) power led direction to push yellow ejector button direction to push yellow ejector button status led ejector (2x) port (16x) sj000637 figure 14. 16–port card leds chapter 3. Operating the m12 21.

Page 52

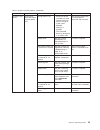

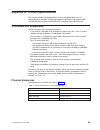

Table 3 describes the 16–port card led patterns. It lists the name, location, and possible colors of each led. It also lists the status of the switch that is associated with each led color and the action that you can take in response to that status. Table 3. 16–port card led patterns name of led loc...

Page 53

Table 3. 16–port card led patterns (continued) name of led location of led color of led status of hardware action port status and activity to the left of each port, below the port speed led no light (led is off) v either the 16–port card does not have incoming power or there is no light or signal ca...

Page 54

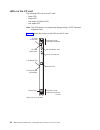

Leds on the cp card the following leds are on the cp card: v power led v status led v link status and activity led v link speed led note: the led patterns can temporarily change during a post and other diagnostic tests. Figure 15 shows the location of the leds on the cp card. ! Link speed led 10/100...

Page 55

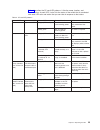

Table 4 describes the cp card led patterns. It lists the name, location, and possible colors of each led. It also lists the status of the switch that is associated with each led color and action that you can take in response to that status. Table 4. Cp card led patterns name of led location of led c...

Page 56

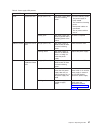

Leds on the power supply the following leds are on each power supply: v power led v predictive failure led v fail led if only one ac power switch is turned on, the fail led on each of the two power supplies without power lights up. Note: the led patterns can temporarily change during a post and othe...

Page 57

Table 5. Power supply led patterns name of led location of led color of led status of hardware action power uppermost led no light (led is off) the power supply does not have incoming power. Ensure the following states: v the power supply is firmly seated. V the switch has incoming power. V both pow...

Page 58

Leds on the blower assembly the following leds are on each blower assembly: v power led v fault led figure 17 shows the location of the leds on the blower assembly. Table 6 describes the blower assembly led patterns. It lists the name, location, and possible colors of each led. It also lists the sta...

Page 59

Table 6. Blower assembly led patterns (continued) name of led location of led color of led status of hardware action fault above and to the right of the blower assembly handle no light (led is off) the blower assembly is either healthy or does not have incoming power. Ensure that the blower assembly...

Page 60

Interpreting post the switch performs a post by default each time that you power on (cold start) the chassis. You can restart the switch with the switchreboot, reboot, or fastboot commands. The fastboot command restarts the switches without running a post. A cp card failover event results in a resta...

Page 61

Perform the following steps to verify that a post completes without errors: 1. Verify that all leds return to a normal state after a post completes. If one or more leds do not return to a normal state, and this is not due to the switch being set to beacon, see “interpreting led activity” on page 20....

Page 62

32 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 63: Chapter

Chapter 4. Installing modems note: throughout this chapter, the term switch refers to the m12. Each cp card in the switch contains a modem serial port that allows you to connect to a hayes-compatible modem. The modem serial port is wired as a standard dte port. You do not need any additional softwar...

Page 64

Setting up a remote modem system (optional) note: you should set up the modems before you power on the switch and connect it to the fabric. This section provides information about how to set up a remote modem for testing the switch modems. Perform the following steps to set up the optional remote mo...

Page 65

Table 7. Modem parameters for windows 95, 98, 2000, me, or nt, or term in a unix environment parameter value port speed (bits per second) 115200. This value usually defaults to the highest speed that the modem supports and then possibly negotiates for a slower speed. Data protocol standard ec compre...

Page 66

5. Optional: connect a telephone handset to one of the telephone connections on the modem. See figure 19 on page 34. 6. Connect the rjþ11y adapter to an appropriate analog telephone line. Note: write down the dial-in number. You will use this number later. 7. Turn on the power to the modems. Verify ...

Page 67

The switch modems are now ready to use. Notes: 1. Experienced users can use the hafailover command to further evaluate the attached modems. It is important to wait approximately 5 minutes after a failover (or restart) to allow the system to correctly set up the modems. 2. For security reasons, the m...

Page 68

38 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 69: Chapter

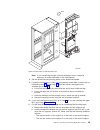

Chapter 5. Installing and removing model m12 switches this chapter describes how to install the 2109 model m12 switch into a 2109 model c36 cabinet, and how to remove an m12 from the cabinet. One m12 is installed in the cabinet at the factory. The cabinet is designed to support one additional 2109 m...

Page 70

V ensure that the two dedicated electrical branch circuits are protected with a circuit breaker that is in accordance with the local electrical codes. V ensure that the supply circuit, line fusing, and wire size are adequate according to the electrical rating on the chassis nameplate. V ensure that ...

Page 71

Note: when you order the lift tool, you will receive an 18–inch load plate. Do not use the 18–inch load plate. You must order and use a 24–inch load plate when you install the m12. You must provide the following information when you order the lift tool. This information is necessary to ensure that t...

Page 72

Unpacking the m12 perform the following steps to unpack the m12. Note: this procedure requires a 1/2 in. Socket wrench to remove the pallet bolts. 1. Remove the upper portion of the packing crate while the switch is still in the shipping area to reduce clutter at the installation site. A. Open the l...

Page 73

B. Support the door to prevent it from falling. Pull the door away from the chassis. C. Push the spring-loaded lever on the upper hinge up and into the notch in the hinge. See figure 21. D. Push the spring-loaded lever on the lower hinge down and into the notch in the hinge. Pull the door out, towar...

Page 74

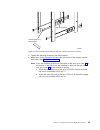

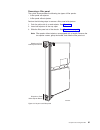

1. Loosen the adjusting screws on the left and right mount shelf brackets to allow for adjustment to the cabinet depth. 2. Attach the left and right mount shelf brackets to the rails in the cabinet. Standard eia rail spacing of holes is sets of three, separated by 5/8 in., 5/8 in., and 1/2 in. See f...

Page 75

3. Tighten the adjusting screws on the shelf brackets. 4. Attach four 10–32 clip nuts to the two rails at the front of the cabinet (service aisle side). See figure 24 on page 46. Note: if you are installing an m12 into the bottom of the rack, go to step 4a for the location of the clip. If you are in...

Page 76

5. Disassemble the left and right upper mount bracket assemblies. Save the screws for later use. 6. Attention: when you insert screws into the chassis, use the exact screws specified in the procedure. Use of longer screws might damage the chassis. Attach the right and left flat upper mount brackets ...

Page 77

7. Attach the two l-shaped upper mount brackets (items 3b and 4b) to the cabinet rails. See figure 26 for orientation. Use two of the 1/4–20 x 1/2 in. Phillips panhead screws with lock washers per bracket. Tighten the screws. Note: if you are installing an m12 into the bottom of the rack, go to step...

Page 78

A. Attach the lower clip nuts to the top of eia unit 6. Attach the upper clip nuts to the middle of eia unit 17. B. Attach the lower clip nuts to the top of eia unit 23. Attach the upper clip nuts to the middle of eia unit 34. 8. Route the cables or cords through the cabinet or along any other route...

Page 79

Note: if you are passing through a narrow passage or door, it might be necessary to rotate the drawer on the load platform. 8. Set the wheel brake by pressing down on the wheel brake pedal. 9. Locate the anti-tips bars. If they are not attached, attach them to the lift tool by performing step 9a thr...

Page 80

Note: you might want to tilt the bridge tool towards the back of the cabinet approximately 45° to make it easier to align the two-pin and one-pin sections with the vertical support. C. Align the two-pin section of the support on the back of the vertical rail with the bottom and middle holes in eia u...

Page 81

D. Align the one-pin section of the support on the front of the vertical rail with the middle hole in eia unit 18. 13. Turn the winch crank counterclockwise, 1/4 turn, to set the winch brake. 14. Set the wheel brake and place the wheel chocks around the wheels. 15. Remove the retention straps. 16. S...

Page 82

21. Reinstall the door after you put the chassis in place. See figure 31 on page 53. A. Ensure that the spring-loaded pins that are on both door hinges are retracted. Push the levers into the notches. B. Align the door hinges with the chassis portion of the hinges. C. Release the pins by pushing the...

Page 83

22. Uninstall the bridge tool and return it to its original box. Note: for turning on the power and for the configuration instructions, see chapter 2, “starting and configuring the m12,” on page 7. Attention: do not connect the switch to the network until the ip addresses are correctly set. Removing...

Page 84

6. If you are replacing the lower m12, go to step 7. If you are replacing the upper m12, go to step 8. 7. Install the bridge tool by completing the following steps: a. Remove the bridge tool from its box and adjust the two supports 45°. B. Hold the bridge tool between the two vertical supports near ...

Page 85

13. Set the wheel brake. Place the wheel chocks around the wheels. Caution: a fully populated 2109 model m12 weighs approximately 115 kg (250 lbs) and requires a minimum of two people and a lift tool to install it. (c011) before you install it, verify that the additional weight of the chassis does n...

Page 86

56 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 87: Chapter

Chapter 6. Servicing the m12 note: throughout this chapter, the term switch refers to the m12. This chapter contains information about how to power off the switch and how to remove and replace field replaceable units (frus) and other system components. Safety notices the following safety notices app...

Page 88

Danger electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid a shock hazard: v do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm. V connect all power cords to a ...

Page 89

Power-off procedure perform the following steps to power off the switch: 1. Open the rear door of the cabinet. Check the power cabling from the m12 that is attached to the pdu that you are servicing. These switches have dual power cords and are plugged into pdus with independent ac sources. 2. Remov...

Page 90

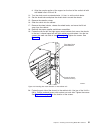

1. Ensure that traffic is not flowing through the port card (port leds should be off) before you disconnect the cables. 2. Disconnect any cables and sfp transceivers from the port card. 3. Notify the switch of a hot-swap request by pushing in the yellow tab on each ejector and clicking the black han...

Page 91

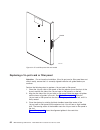

Removing a filler panel the switch accommodates the following two types of filler panels: v a filler panel with ejectors v a filler panel without ejectors perform the following steps to remove a filler panel with ejectors: 1. Push the yellow tab in on each ejector. See figure 33. 2. Lever both eject...

Page 92

Replacing a 16–port card or filler panel attention: do not force the installation. If the 16–port card or filler panel does not slide in easily, ensure that it is correctly aligned inside the rail guides before you continue. Perform the following steps to replace a 16–port card or filler panel: 1. O...

Page 93

Perform these additional steps if you are installing a new 16–port card: 1. Verify that the power led on the 16–port card is displaying a steady green light (it might require a few seconds to turn on). If it does not turn on, ensure that the 16–port card has power and is firmly seated. The front of ...

Page 94

Removing and replacing a cp card or filler panel use this procedure to remove and replace a cp card or filler panel. The switch can continue to operate during this procedure if at least one cp card remains installed and functioning throughout the procedure. However, if the cp card that is being repl...

Page 95

Confirming a failed cp card before you replace the cp card, verify the necessity of the replacement. Any of the following events might indicate that a cp card is faulty: v the status led on the cp card is orange, or the power led is not lit. V the slotshow command does not show that the cp card is e...

Page 96

2. Log into the healthy cp card as admin , then type 0 to log into switch 0. The default password is password . See the following example for possible output. Fabric os (cp0) cp0 console login: admin password: enter switch number to login or 1>: 0 swo:admin> 3. Run the hashow command to determine wh...

Page 97

7. From the serial console for the healthy (and active) cp card, back up the current configuration for logical switch 0. See the possible output from the configupload command in step 8. A. Run the configupload command. B. Enter the requested information at the prompts. 8. Log into logical switch 1 a...

Page 98

V modem cable from the modem serial port v serial cable from the terminal serial port v ethernet cable from the ethernet port b. Notify the switch of a hot-swap request by pushing the yellow tab on each ejector and clicking the black handles until they are slightly open. See figure 36. Wait for the ...

Page 99

Replacing a cp card or filler panel attention: do not force the installation. If the cp card or filler panel does not slide in easily, ensure that it is correctly oriented and aligned in the rail guides before you continue. Figure 38 on page 70 shows the alignment guides in the card slots. Sj000643 ...

Page 100

Perform the following steps to replace a cp card or filler panel: 1. Orient the cp card or filler panel so that the ejectors are at the front of the chassis and the metal pan is on the left. 2. Align the flat-metal side of the cp card or filler panel inside the upper and lower rail guides in the slo...

Page 101

The message ha-state in sync also displays. If not, post is not complete or the cp cards have not yet achieved redundancy. Wait a minute and re-run the command until you can verify that redundancy has been achieved. See the sample output from the hashow command before redundancy is achieved. Sw1:adm...

Page 102

B. When the firmware is unzipped, it creates a folder and a set of firmware files. Use the following directory and file name when you download this firmware to the switch: /v4.X.X/release.Plist c. Download the firmware by using either of the following command options: v run the firmwaredownload comm...

Page 103

10. Verify that the configuration has successfully propagated to the new cp card by checking any configuration parameters for which you specified non-default values. To do this, run the configshow command, followed by a text string (in quotation marks) that relates to the parameter, for example, con...

Page 104

Sw0:admin> switchdisable sw0:admin> configdownload server name or ip address [host]: 123.456.78.90 user name [none]: user file name [config.Txt]: config.Txt password: xxxxxx committing configuration...Done. Download complete sw0:admin> sw0:admin> switchenable 10 9 8 7 6 5 4 3 2 1 fabric: principal s...

Page 105

Removing and replacing a power supply or filler panel use this procedure to remove and replace a power supply. The switch can continue to operate during the replacement if at least one power supply continues operating for every four 16–port cards that are installed. You need a minimum of two power s...

Page 106

Attention: support the power supply from underneath while removing it from the chassis. A. Remove the power supply by pushing the locking tab in towards the power supply then pull the handle out and down, and use the handle to pull the power supply out of the chassis. See figure 40 on page 77. B. Re...

Page 107

Replacing a power supply or filler panel attention: do not force the installation of the power supply or filler panel. If the part does not install easily, ensure that it is properly oriented. Perform the following steps to replace a power supply: 1. Orient the power supply so that the handle is tow...

Page 108

Note: you do not need to notify the switch of a hot-swap request before you remove a blower assembly. Attention: the switch requires a minimum of two operating blower assemblies at all times. To ensure continuous adequate cooling, maintain three operating blower assemblies at all times except for th...

Page 109

Removing and replacing the cable management tray use this procedure to remove and replace the cable management tray. The switch can continue to operate during the replacement. Attention: do not use a power screwdriver on the cable management tray. Time required less than 5 minutes items required #2 ...

Page 110

3. Rotate the front of the tray down, then lift the back to disengage the tabs on the back of the tray from the chassis. Replacing a cable management tray perform the following steps to replace the cable management tray: 1. Orient the tray. See figure 43 on page 81. 2. Insert the two tabs on the und...

Page 111

Removing and replacing the wwn card the wwn card is highly reliable. Before you replace the wwn card, verify that a replacement is necessary. If you are installing a new wwn card, the installation instructions are included with the product. If you are going to replace a wwn card for fabric os earlie...

Page 112

V error messages regarding wwn unit 1 or unit 2 (see messages that might indicate wwn card failure) data that is stored on the wwn card table 9 shows the data that is stored on the wwn card. The wwn card might need to be replaced if you have difficulty retrieving or modifying this data. Table 9. Dat...

Page 113

Table 11. Reference information for the fruinfoset command (continued) description this command provides for the setting of the four externally modifiable fields in the header that is associated with each fru. After the new data is written, the final contents of the fields are printed. No other fiel...

Page 114

84 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 115: Appendix

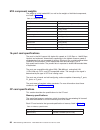

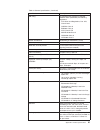

Appendix a. Product specifications this chapter contains the specifications for the 2109 model m12 only. For specifications for the ibm totalstorage cabinet 2109 model c36, see the ibm totalstorage san cabinet 2109 model c36 installation and service guide. 2109 model m12 components the m12 contains ...

Page 116

M12 component weights the weight of a fully loaded m12, as well as the weights of individual components, are listed in table 13. Table 13. Component weights component weight fully loaded chassis approximately 114 kg (250.0 lb) empty chassis 47.1 kg (104.0 lb) door 3.4 kg (7.6 lb) blower assembly 4 k...

Page 117

Table 14. Memory specifications (continued) memory type amount flash memory v user flash: 16 mb of 16–bit wide memory, stored in two 8 mb banks v compact flash: 256 mb, partitioned in two 128 mb sections boot flash memory 512 kb of 8–bit wide memory for system startup battery specifications the cp c...

Page 118

Table 16. Pinouts with signal and description pin signal description 1 2 txdata transmit data 3 rxdata receive data 4 5 gnd logic ground 6 7 8 9 modem serial port specifications each cp card has a modem serial port (labeled rs–232) with a fully rs–232 compliant db–9 connector. Note: for dust and esd...

Page 119

A serdes that accepts 10–bit wide parallel data and serializes it into a high-speed serial stream. The parallel data is expected to be 8b/10b encoded data or equivalent. The ports are compatible with the following sfps and sfp-compatible cables: v optical swl: 780–850 nm v optical lwl: 1270–1350 nm ...

Page 120

Table 18 lists the power specifications for the m12. Table 18. Power specifications specification value total power available from each power supply 1 kw input voltage 200–240 v ac input line frequency 50–60 hz harmonic distortion active power factor correction per iec1000–3–2 heat output (btu ratin...

Page 121

Table 20. General specifications (continued) specification description emi rating an operating m12 conforms to the emi radiation levels specified by the following regulations: v fcc rules and regulations, part 15b, class a level v cispr22 class a v en55022 class a v vcci class a ite v as/nzs 3548 cl...

Page 122

Regulatory specifications the m12 is certified for the regulatory specifications that are listed in table 21. Table 21. Regulatory specifications country or region safety specification emc specification canada csa 22.2 no. 60950 third ed. Ices–003 class a united states ul 60950 third ed., info. Tech...

Page 123

Post and boot specifications the m12 performs a post by default each time that you power on (cold boot) or restart or reset the chassis. You can restart the m12 with the switchreboot command, the reboot command, or the fastboot command. The fastboot command restarts the switches without running post...

Page 124

94 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 125: Appendix

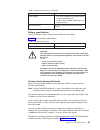

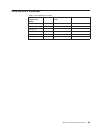

Appendix b. Model m12 parts information this section contains fru part numbers and part descriptions for a 2109 model m12 only. For information regarding parts for the 2109 model c36 cabinet, see the see the ibm totalstorage san cabinet 2109 model c36 installation and service guide. 2109 model m12 p...

Page 126

96 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 127: Appendix

Appendix c. Blank planning worksheets this chapter contains the following blank worksheets that you can use when you plan the installation of a 2109 model m12: v planning worksheet v port configuration worksheet v zone definition worksheet v zone configuration worksheet make as many copies of the bl...

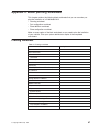

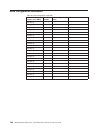

Page 128

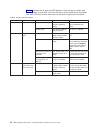

Port configuration worksheet table 23. Port configuration worksheet port number device name device port cable length port type notes cable number 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 98 ibm totalstorage san switch: 2109 model m12 installation and service guide.

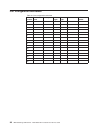

Page 129

Zone definition worksheet table 24. Zone definition worksheet zone member type (switch, port, wwn) zone member zone configuration name comments port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) appendix c. Blank planning worksheets 99.

Page 130

Zone configuration worksheet table 25. Zone configuration worksheet zone member type (switch, port, wwn) zone member zone configuration name connects to port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port (id, p) port...

Page 131: Notices

Notices this information was developed for products and services offered in the u. S. A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently available in your...

Page 132

Trademarks the following terms are trademarks of the international business machines corporation in the united states, other countries, or both: ibm netfinity totalstorage microsoft, windows, and windows nt are trademarks of microsoft corporation in the united states, other countries, or both. Unix ...

Page 133

Failure to satisfy the protection requirements resulting from a non-recommended modification of the product, including the fitting of non-ibm option cards. This product has been tested and found to comply with the limits for class a information technology equipment according to european standard en ...

Page 134

Taiwan class a electronic emission statement japan vcci class a ite electronic emission statement 104 ibm totalstorage san switch: 2109 model m12 installation and service guide.

Page 135: Glossary

Glossary this glossary provides definitions for fibre channel and switch terminology used for ibm totalstorage san switches and related products. It also provides additional definitions of technical terms and abbreviations. If you do not find the term you are looking for, see the ibm glossary of com...

Page 136

Arbitrate primitive signal (arb). A primitive signal that is transmitted as the fill word by a loop port (l_port) to indicate that the l_port is arbitrating to access to the loop. Applies only to the arbitrated loop topology. Arbitrated loop. A shared 100 mbps fibre channel transport structured as a...

Page 137

Buffer-to-buffer flow control. Management of the frame transmission rate in either a point-to-point topology or in an arbitrated loop. See also buffer-to-buffer credit. C cam. Content addressable memory. Cascade. Two or more interconnected fibre channel switches that can build large fabrics. Switche...

Page 138

Data rate. The rate at which data is transmitted or received from a device. Interactive applications tend to require a high data rate, while batch applications can usually tolerate lower data rates. Data terminal equipment (dte) port. A port that is capable of interfacing to a transmission circuit t...

Page 139

Elp. Extended link parameters. Elwl. See extra long wavelength. Emc. See electromagnetic compatibility. Emi. See electromagnetic interference. Enabled zone configuration. The currently enabled configuration of zones. Only one configuration can be enabled at a time. See also defined zone configuratio...

Page 140

Fabric watch. A feature that runs on fabric operating system (os) and allows monitoring and configuration of fabric and switch elements. Failover. The act that causes control to pass from one redundant unit to another. Fan. Fabric address notification. Fc. See fibre channel. Fca. See fibre channel a...

Page 141

Fspf. See fibre channel shortest path first. Ftp. See file transfer protocol. Full duplex. A mode of communication that allows the same port to simultaneously transmit and receive frames. See also half duplex. Fx_port. A fabric port that can operate as either a fabric port (f_port) or fabric loop po...

Page 142

In-order delivery (iod). A parameter that, when set, guarantees that frames are either delivered in order or dropped. Integrated fabric. The fabric created by six switches cabled together and configured to handle traffic as a seamless group. Internet protocol (ip). In the internet suite of protocols...

Page 143

Loop master timeout value (lm_tov). The minimum time that the loop master waits for a loop initialization sequence to return. Loop mode. One of the modes for a loop port (l_port). An l_port is in loop mode when it is in an arbitrated loop and is using loop protocol. An l_port in loop mode can also b...

Page 144

O operating system (os). A collection of system programs that control the overall operation of a computer system. Ordered set. A transmission word that uses 8b/10b mapping and begins with the k28.5 character. Ordered sets occur outside of frames, and include frame delimiters, primitive signals, and ...

Page 145

Public nl_port. A node loop port (nl_port) that logs into the fabric, can function within either a public or private loop, and can communicate with either private or public nl_ports. Q quad. A group of four adjacent ports that share a common pool of frame buffers. Quickloop. (1) a feature that makes...

Page 146

Communication between components, terminals, and modems. See also db–9 connector, dce port, and dte port. Rscn. See registered state change notification. Rsh. Remote shell. Rtc. Real time clock. Rw. Read-write. S san. See storage area network. San island. A group of storage devices and servers conne...

Page 147

Switch port. A port on a switch. Switch ports can be expansion ports (e_ports), fabric ports (f_ports), or fabric loop ports (fl_ports). Swl. See short wavelength. Synchronous dynamic random access memory (sdram). The main memory for the switch. Used for volatile storage during switch operation. T t...

Page 148

Well-known address. As pertaining to fibre channel, a logical address defined by the fibre channel standards as assigned to a specific function, and stored on the switch. Wide area network (wan). A network that provides communication services to a geographic area larger than that served by a local a...

Page 149: Index

Index numerics 16-port card leds 20 specifications` 86 16–port card description 15 removing 59 replacing 62 2109 model m12 16–port card 15 ac power input connectors and ac power switches 18 blower assembly description 18 side 3 cable management items 19 circuit breaker 18 components 15, 85, 86 contr...

Page 150

C cabinet installing the 2109 model m12 43 removing a 2109 model m12 from 53 cable management items 19 tray removing 79 replacing 80 cables alignment 12 guides 19 recommendations for managing 63 card 16–port card 15 control processor 16 wwn 19 caution labels fusing xvi linecord xv power supply xv ca...

Page 151

G general specifications of the 2109 model m12 90 genie tool and load plate label, inspecting xviii getting software updates xxvi getting help xxvii ground checks xviii lug xviii guidelines safety 2109 model m12 39 h heavy load label xvi help, getting xxvii high-availability feature 1 how to send yo...

Page 152

N non-ibm alteration attachment survey form xiv notice, edition ii notices caution, battery xxiv ibm 101 safety 57 safety and environmental xi o operating the 2109 model m12 15 optical port terminators xxi ordering the lift tool and the 24–inch load plate 40 out-of-band management method 4 overview ...

Page 153

Running a post 30 s safety certification label xv electrical 57 environmental notices xi guidelines 2109 model m12 39 inspection, how to conduct xiv label check xv laser xxi notices xi, 57 product disposal xxiv safety information rack safety xxii safety inspection external machine checks xiv interna...

Page 154

W web sites xxvi weight, component 86 who should read this document xxv worksheets blank 97 planning 97 port configuration 98 zone configuration 100 zone definition 99 world trade ordering procedure for the lift tool and the 24-inch load plate 40 wwn card and bezel 19 and bezel leds 29 restarting th...

Page 155: Readers’

Readers’ comments — we’d like to hear from you ibm totalstorage san switch 2109 model m12 installation and service guide publication no. Gc26-7633-00 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall satisfaction...

Page 156: Business

Readers’ comments — we’d like to hear from you gc26-7633-00 gc26-7633-00 cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape no postage necessary if mailed in the united states business reply mail first-class...

Page 158

Part number: 17p7363 printed in usa gc26-7633-00 (1p) p/n: 17p7363.

Page 159

Spine information: ib m t ota ls to ra ge sa n sw it ch 21 0 9 mo de l m1 2 in sta ll at io n an d s ervi ce gu id e.