- DL manuals

- IBM

- Storage

- TotalStorage 3580 L33

- Setup, Operator, And Service Manual

IBM TotalStorage 3580 L33 Setup, Operator, And Service Manual

Summary of TotalStorage 3580 L33

Page 1

Ibm totalstorage 3580 tape drive model l33/l3h setup, operator, and service guide gc26-7708-03.

Page 3

Ibm totalstorage 3580 tape drive model l33/l3h setup, operator, and service guide gc26-7708-03.

Page 4

Note! Before using this information and the product it supports, read the information in “safety and environmental notices” on page xi and “notices” on page 107. To ensure that you have the latest publications, visit the web at http://www.Ibm.Com/storage/lto . Third edition (march 2006) this edition...

Page 5: Read

Read this first summary of changes third edition v worm media information v new part numbers in the parts list second edition v diagnostic functions f, j, and l were modified / added. V the procedure for aborting a diagnostic function was modified. V the information for error code a was modified. V ...

Page 6

Iv ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 7: Contents

Contents read this first . . . . . . . . . . . . Iii summary of changes . . . . . . . . . . . Iii third edition . . . . . . . . . . . . . Iii second edition . . . . . . . . . . . . Iii accessing online technical support . . . . . . Iii registering for my support . . . . . . . . . Iii sending us your...

Page 8

Resolving problems reported by the server . . . 48 fixing scsi bus errors . . . . . . . . . 48 resolving media-related problems . . . . . . 51 pre-call checklist . . . . . . . . . . . . 52 replacing the tape drive . . . . . . . . . . 53 features, replacement parts, and power cords . . . . . . . . . ...

Page 9: Figures

Figures 1. Ac grounding diagram (50 hz and 60 hz) xii 2. The ibm totalstorage 3580 tape drive . . . . 1 3. Front panel components . . . . . . . . . 2 4. Rear panel components . . . . . . . . . 3 5. Example of connecting one scsi device to the server . . . . . . . . . . . . . . 12 6. Example of conne...

Page 10

Viii ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 11: Tables

Tables 1. 3580 models . . . . . . . . . . . . . 3 2. Performance characteristics . . . . . . . . 4 3. Specifications . . . . . . . . . . . . 6 4. Meaning of status light and single-character display (scd) . . . . . . . . . . . . 17 5. Ultrium data and cleaning cartridge compatibility with ultrium ta...

Page 12

X ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 13: Safety

Safety and environmental notices when using this product, observe the danger and caution notices contained in this guide. The notices are accompanied by symbols that represent the severity of the safety condition. Danger notices contain a dxxxx reference number. Caution notices contain a cxxxx refer...

Page 14

Performing the safety inspection procedure before you service the unit, perform the following safety inspection procedure: 1. Stop all activity on the scsi bus. 2. Turn off the power to the tape drive. 3. Disconnect the scsi cable and check the scsi bus terminator for damage. 4. Unplug the tape driv...

Page 15

Product recycling and disposal this unit must be recycled or discarded according to applicable local and national regulations. Ibm encourages owners of information technology (it) equipment to responsibly recycle their equipment when it is no longer needed. Ibm offers a variety of product return pro...

Page 16

Please recycle batteries flat panel display the fluorescent lamp or lamps in the liquid crystal display contain mercury. Dispose of it as required by local ordinances and regulations. End of life (eol) plan this box is a purchased unit. Therefore, it is the sole responsibility of the purchaser to di...

Page 17: Preface

Preface this guide describes how to install and use the ibm totalstorage ® 3580 tape drive in the following chapters:. “product description” on page 1 describes the product, discusses supported servers, operating systems, and device drivers, and lists hardware specifications. “installation” on page ...

Page 18

Related publications refer to the following publications for additional information. To ensure that you have the latest publications, visit the web at http://www.Ibm.Com/storage/lto . V ibm totalstorage 3580 tape drive quick reference, gc26-7709, illustrates how to configure and operate the ibm tota...

Page 19: Product

Product description the ibm totalstorage 3580 tape drive model l33/l3h offers high-capacity, performance, and technology designed for the midrange open systems environment. This new model incorporates the new linear tape-open (lto) ibm totalstorage ultrium tape drive (generation 3), which more than ...

Page 20

Reliable drive. The generation 3 drive electronics also incorporate on-the-fly error correction of soft errors in the memory arrays in data and control paths. The tape drive is an external stand-alone or rack-mountable unit and is the entry point for the family of ibm ultrium tape products. It provi...

Page 21

Rear panel components 1 power receptacle 3 scsi address switch 2 scsi connectors 4 serial number label 3580 models table 1 lists all 3580 models with associated scsi attachment and drive type. Table 1. 3580 models model scsi attachment tape drive l33 lvd ultrium 3 l3h lvd ultrium 3 l23 lvd ultrium 2...

Page 22

Drive performance if you run applications that are highly dependent on tape-processing speed, take advantage of the significant performance improvements provided by this tape drive. Table 2. Performance characteristics performance characteristics ultrium 3 tape drive native data rate 80 mb/s (with u...

Page 23

Supported device drivers ibm offers device drivers which enable the tape drive to interact with a variety of servers. To properly install an ibm device driver (if required), refer to the ibm ultrium device drivers installation and user’s guide. For applications that use other device drivers, see the...

Page 24

Specifications the following are specifications for the tape drive. Specifications for tape cartridges are given in “environmental and shipping specifications for tape cartridges” on page 40. Table 3. Specifications physical specifications specification dimensions width 25.02 cm (9.85 in.) length 29...

Page 25: Installation

Installation attention this is a customer setup unit. It is the customer’s responsibility to install this product. Installation overview installation involves the following steps: __ 1. “unpack the tape drive” on page 8 __ 2. “verify the shipment” on page 8 __ 3. “install the rack mount kit (optiona...

Page 26

Unpack the tape drive attention if you return the unit for service, ship it in its original or equivalent packing material, or the warranty may be invalidated. __ 1. Inspect the unit for shipping damage. If there is damage, do not install the unit. Report the damage immediately by contacting your pl...

Page 27

Inspect the power cord and outlet __ 1. Inspect the power cord plug to ensure that it matches the power receptacle. If it does not match, see “power cords” on page 56 to determine the appropriate power cord. __ 2. Ensure that all associated electrical outlets are properly grounded and that the circu...

Page 28

V where the tape cartridge can be easily inserted. The unit should not be stacked. Do not place anything on top of the unit. Connect power __ 1. Ensure that the unit is powered off. __ 2. Plug the power cord into the rear panel (see 1 in figure 4 on page 3), then plug the other end into a grounded e...

Page 29

Note: if you inserted an invalid or write-protected tape cartridge, 7 appears in the scd. The tape drive unloads the cartridge and exits maintenance mode. V if no error is detected, the test will loop and begin again. To stop the loop, press the unload button for one second and release. When the loo...

Page 30

Attention v do not mix lvd and hvd scsi host adapters, tape drives, or terminators on the same bus, as they could become damaged. V data transfer protocol timeouts for tape and disk drives are very dissimilar. For that reason, it is strongly recommended that you avoid running tape and disk drives on...

Page 31

1 tape drive 5 scsi host adapter card 2 scsi connectors 6 server 3 terminator 7 another tape device 4 scsi bus cable install device drivers a device driver is firmware that enables the tape drive to interact with a variety of servers. Refer to “supported device drivers” on page 5 for instructions on...

Page 32

Register for my support my support registration provides email notification when new firmware levels have been updated and are available for download and installation. For more information, see “registering for my support” on page iii. 14 ibm totalstorage 3580 tape drive setup, operator, and service...

Page 33: Operation

Operation operation of the tape drive involves the following front panel components: v power button v unload button v single-character display (scd) v status light these components allow the user to: v insert and remove a tape cartridge v perform diagnostic and maintenance functions v update drive f...

Page 34

Single-character display (scd) the scd (2 in figure 3 on page 2) presents a single-character code for: v error conditions and informational messages v diagnostic or maintenance functions (while in maintenance mode only) appendix a, “error codes,” on page 61 lists the codes for error conditions and i...

Page 35

Table 4. Meaning of status light and single-character display (scd) if the status light is... And the scd is... Meaning off off the drive has no power or is powered off. Green off the drive is powered on and in an idle state. Flashing green off the drive is reading from the tape, writing to the tape...

Page 36

Inserting a tape cartridge to insert a tape cartridge: 1. Power on the unit. 2. Ensure that the write-protect switch (1 in figure 7) is set to the unlock position (see “write-protect switch” on page 28). 3. Grasp the cartridge so that the write-protect switch faces you. 4. Slide the cartridge into t...

Page 37

Removing a tape cartridge attention failure to remove a cartridge before powering off the unit may result in damage to the cartridge or to the drive. To remove a cartridge: 1. Ensure that the unit is powered on. Note: in the following step, the tape may take as long as 10 minutes to completely rewin...

Page 38

Updating drive firmware attention: v to ensure optimum performance, use the latest level of drive firmware. It is the customer’s responsibility to obtain and install drive firmware. V when updating firmware, do not power-off the drive until the update is complete, or the firmware may be lost. Period...

Page 39

For instructions about updating firmware from a server that uses an ibm tape device driver, refer to the ibm ultrium device drivers installation and user’s guide. To update firmware from a server that uses a non-ibm tape device driver, refer to the documentation for that device. Updating the firmwar...

Page 40

To clean the head, insert the cleaning cartridge into the tape load compartment (see figure 7 on page 18). The drive performs the cleaning automatically. The cleaning cycle takes less than two minutes. When the cleaning is finished, the drive ejects the cartridge. Note: anytime a cleaning cartridge ...

Page 41: Ultrium

Ultrium media to ensure that your ibm ultrium tape drive conforms to ibm’s specifications for reliability, use only ibm lto ultrium tape cartridges. You may use other lto-certified data cartridges, but they may not meet the standards of reliability that are established by ibm. The ibm totalstorage l...

Page 42

Data cartridge the different generations of ibm totalstorage ultrium data cartridges can be identified by color: data cartridge case color ultrium 3 slate blue ultrium 3 write once, read many (worm) slate blue top; grey bottom ultrium 2 purple ultrium 1 black all three generations contain 1/2-inch, ...

Page 43

Capacity scaling to control the capacity of the cartridge (for example, to obtain a faster seek time) issue the scsi command set capacity. For information about this command, refer to the ibm totalstorage lto ultrium tape drive scsi reference. Worm (write once, read many) certain records retention a...

Page 44

V information in the servo manufacturer’s word (smw) on the tape must match information from the cartridge memory (cm) module in the cartridge. If it does not match, a media error code 7 will post on the drive’s single-character display (scd). V inserting a worm tape cartridge into a drive that is n...

Page 45

When read by a bar code reader, the bar code identifies the cartridge’s volser to the library. The bar code also identifies the cartridge is a data cartridge or cleaning cartridge. In addition, the bar code includes the two-character media-type identifier lx , where x equals 1, 2, or 3. L identifies...

Page 46

V before applying a new label, remove the old label by slowly pulling it at a right angle to the cartridge case. V use peel-clean labels that do not leave a residue after being removed. If there is glue residue on the cartridge, remove it by gently rubbing it with your finger. Do not use a sharp obj...

Page 47

A67e0026 1 figure 11. Setting the write-protect switch using ultrium media 29.

Page 48

Handling the cartridges attention do not use a damaged tape cartridge. A damaged cartridge can interfere with the reliability of a drive and may void the warranties of the drive and the cartridge. Before inserting a tape cartridge, inspect the cartridge case, cartridge door, and write-protect switch...

Page 49

V never ship a cartridge in a commercial shipping envelope. Always place it in a box or package. V if you ship the cartridge in a cardboard box or a box of a sturdy material, ensure the following: – place the cartridge in polyethylene plastic wrap or bags to protect it from dust, moisture, and other...

Page 50

V do not expose the cartridge to moisture or direct sunlight. V do not expose recorded or blank cartridges to stray magnetic fields of greater than 100 oersteds (for example, terminals, motors, video equipment, x-ray equipment, or fields that exist near high-current cables or power supplies). Such e...

Page 51

Handle the cartridge carefully v do not drop the cartridge. If the cartridge drops, slide the cartridge door back and ensure that the leader pin is properly seated in the pin-retaining spring clips (see 2 in figure 15 on page 34). If the leader pin has become dislodged, go to “repositioning or reatt...

Page 52

Repositioning or reattaching a leader pin attention use a repaired tape cartridge only to recover data and move it to another cartridge. Continued use of a repaired cartridge may void the warranties of the drive and the cartridge. If the leader pin in your cartridge becomes dislodged from its pin-re...

Page 53

To reposition the leader pin, perform the following steps. 1. Slide open the cartridge door (1 in figure 16) and locate the leader pin 2 (you may need to shake the cartridge gently to roll the pin toward the door). 2. With plastic or blunt-end tweezers, grasp the leader pin and position it in the pi...

Page 54

Reattaching a leader pin the first meter of tape in a cartridge is leader tape. Once the leader tape has been removed there is a possibility of tape breakage. After reattaching the leader pin, transfer data from the defective tape cartridge. Do not reuse the defective tape cartridge . The leader pin...

Page 55

The following procedure describes how to reattach a leader pin. To reattach a leader pin by using the ibm leader pin reattachment kit: 1. Attach the leader pin attach tool (1 in figure 19) to the cartridge 2 so that the tool’s hook 3 latches into the cartridge’s door 4. Pull the tool back to hold th...

Page 56

2. To find the end of the tape inside the cartridge, attach the cartridge manual rewind tool (1 in figure 20) to the cartridge’s hub 2 by fitting the tool’s teeth between the teeth of the hub. Turn the tool clockwise until you see the end of the tape inside the cartridge. Then, slowly turn the rewin...

Page 57

7. Position the tape in the alignment groove of the leader pin attach tool (see 1 in figure 22). 8. Place a new c-clip into the retention groove 2 (figure 22) on the leader pin attachment tool and make sure that the clip’s open side faces up. 9. Place the leader pin (from step 6 on page 38) into the...

Page 58

12. Swing the pivot arm open and trim the excess tape 5 so that it is flush with the reattached leader pin 6. 13. Use your fingers to remove the leader pin from the cavity 3 in the leader pin attach tool. 14. Use the cartridge manual rewind tool to wind the tape back into the cartridge (wind the tap...

Page 59

Disposing of tape cartridges under the current rules of the u.S. Environmental protection agency (epa), regulation 40cfr261, the lto ultrium tape cartridge is classified as non-hazardous waste. As such, it may be disposed of in the same way as normal office trash. These regulations are amended from ...

Page 60

Ordering media supplies table 8 lists the cartridges and media supplies that you can order for the tape drive. Table 8. Media supplies supply item methods of ordering ibm totalstorage lto ultrium 400 gb data cartridge bar code labels are pre-applied to cartridges. V order the cartridge from your ibm...

Page 61

Table 8. Media supplies (continued) supply item methods of ordering ibm totalstorage lto ultrium cleaning cartridge (universal cleaning cartridge for use with ultrium 1, ultrium 2, and ultrium 3 drives) volser labels are included. V order as part number 35l2086 through an ibm-authorized distributor ...

Page 62

Table 9. Authorized suppliers of custom bar code labels (continued) in america in europe and asia netc p. O. Box 1067 fairfield, ct 06825 u. S. A. Telephone: 203-372-6382 http://www.Netcllc.Com/ netc europe ltd town farm bungalow the pavement north curry ta3 6lx somerset u. K. Telephone: 44 (0) 1823...

Page 63: Troubleshooting

Troubleshooting if you encounter problems when running the 3580, refer to the flowchart in figure 23. For explanations of codes on the single-character display (scd), see appendix a, “error codes,” on page 61. Should the drive need to be replaced, go to “replacing the tape drive” on page 53. Please ...

Page 64

Procedure 1: determining firmware level and capturing drive dump perform the following steps to determine the current firmware level installed on the drive. The same utility can be used to update the firmware level as well as to capture a drive dump which may be requested by technical support to aid...

Page 65

Procedure 3: verifying scsi address switch position if your server is not communicating with the drive, the drive’s scsi address switch may be set incorrectly: 1. Check the scsi address switch (3 in figure 4 on page 3) to ensure that it is set to the scsi id chosen in “set the scsi id” on page 9. 2....

Page 66

Procedure 5: verifying scsi interface communications the scsi wrap diagnostic tests scsi function at the device interface. However, to thoroughly verify host-to-device communications, it is highly recommended to exercise activity over the scsi bus from the host to the drive and back. A recommended u...

Page 67

Fault is with the server’s hardware or software. To isolate the cause of the failure, refer to the server’s service documentation. V if the test fails again, replace the drive (see “replacing the tape drive” on page 53). V if the test is successful, refer to your enclosure documentation for addition...

Page 68

4. Replace the drive (see “replacing the tape drive” on page 53). If the problem persists, the problem is with your server. Consult your server’s documentation. Fixing an intermittent error with multiple drives on a scsi bus refer to the server’s error logs to determine which drive is the source of ...

Page 69

Resolving media-related problems to resolve problems that are related to media, the drive’s firmware includes diagnostics that verify whether a suspect cartridge and its magnetic tape are acceptable for use. These diagnostics require the use of a customer-supplied scratch (blank) data cartridge. If ...

Page 70

Pre-call checklist if you have questions or problems, go through this checklist before contacting ibm technical support. If your drive is the only device on the scsi bus, ensure that the total bus length does not exceed 25 m (82 ft). If there are other devices on the bus, ensure that the total lengt...

Page 71

Replacing the tape drive to replace your tape drive, perform the following steps: 1. Remove the replacement unit from its packaging. 2. Locate the repair identification (rid) tag (included with the replacement unit). See 1 in figure 24) 3. Write down the serial number of the failed unit on the rid t...

Page 72

54 ibm totalstorage 3580 tape drive setup, operator, and service guide.

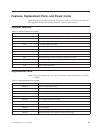

Page 73: Features,

Features, replacement parts, and power cords optional features, replacement parts, and power cords for your drive are listed in this appendix along with associated feature code and part number. Optional features table 10. Optional features for the 3580 feature code (fc) product description 1748 cust...

Page 74

Power cords to avoid electrical shock, a power cord with a grounded attachment plug has been provided. Use only properly grounded outlets. Table 12 lists the power cord part number, feature code, the country or region where the power cord can be used, and the plug’s standard reference. The last colu...

Page 75

Table 12. Power cords (continued) description, feature code (fc), and part number (pn) plug standard reference country or region index number in figure 25 on page 60 us/canada v 2.8 m, 250 v v fc 9833 v pn 39m5095 nema 6-15p aruba, bahamas, barbados, bermuda, bolivia, brazil, canada, cayman islands,...

Page 76

Table 12. Power cords (continued) description, feature code (fc), and part number (pn) plug standard reference country or region index number in figure 25 on page 60 south africa v 2.8 m, 250v v fc 9829 v pn 39m5144 sabs 164 bangladesh, burma, pakistan, south africa, sri lanka 6 united kingdom v 2.8...

Page 77

Table 12. Power cords (continued) description, feature code (fc), and part number (pn) plug standard reference country or region index number in figure 25 on page 60 japan lv* v 2.8 m, 125v v fc 9842 v pn 39m5199 jis c8303, c8306 japan 15 japan hv** v 2.8 m, 250v v fc 9843 v pn 39m5186 jis c8303, c8...

Page 78

1 2 3 4 5 6 7 8 9 13 17 10 14 18 11 15 19 12 16 20 a77ug005 figure 25. Types of receptacles 60 ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 79: Appendix

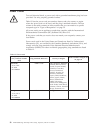

Appendix a. Error codes error codes are presented on the single-character display (scd), and the status light will be flashing amber once per second. If an error code displays, refer to “troubleshooting” on page 45 to determine the problem. Table 13 describes the messages and codes. Note: the codes ...

Page 80

Table 13. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 3 firmware problem. The tape drive determined that a firmware error occurred. Perform the following ac...

Page 81

Table 13. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 6 tape drive or media error. The tape drive determined that an error occurred, but it cannot isolate t...

Page 82

Table 13. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 7 a high probability of media error. The tape drive determined that an error occurred because of a fau...

Page 83

Table 13. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action a tape drive hardware problem. The tape drive determined that a problem occurred which degraded the op...

Page 84

66 ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 85: Appendix

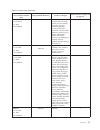

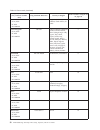

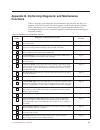

Appendix b. Performing diagnostic and maintenance functions table 14 describes each diagnostic and maintenance function that the drive can perform, gives the function code which appears on the single-character display (scd), and directs you to the instructions for performing the function. It is reco...

Page 86

Table 14. Diagnostic and maintenance functions (continued) function code diagnostic or maintenance function instructions location j fast read/write test: performs tests to ensure that the drive can read from and write to tape. Page 80 l load/unload test: tests the drive’s ability to load and unload ...

Page 87

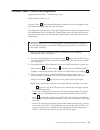

Function code 1: run drive diagnostics approximate run time = 20 minutes per loop total number of loops = 10 function code 1 runs tests that determine whether the drive can properly load and unload cartridges, and read and write data. The diagnostic loops ten times. Press the unload button to stop t...

Page 88

Function code 2: update drive firmware from fmr tape attention when updating drive firmware, do not power-off the drive until the update is complete or the firmware may be lost. Function code 8 loads updated drive firmware from a field microcode replacement (fmr) tape. 1. Place the drive in maintena...

Page 89

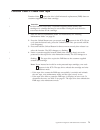

Function code 3: create fmr tape function code 3 copies the drive’s field microcode replacement (fmr) data to a customer-supplied scratch data cartridge. Attention for this function, insert only a customer-supplied scratch (blank) data cartridge or a cartridge that may be overwritten. During the tes...

Page 90

Function code 4: force a drive dump function code 8 performs a dump of data collected by the drive (this process is also known as saving a microcode trace). 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 68. 2. Press the unload button once per secon...

Page 91

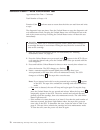

Function code 5: copy drive dump function code 5 copies data from a drive dump (captured in function code 4) to the beginning of a customer-supplied scratch (blank) data cartridge. Attention for the 5 - 1 function, insert only a customer-supplied scratch (blank) data cartridge or a cartridge that ma...

Page 92

Function code 6: run scsi wrap test approximate run time = 10 seconds per loop number of loops - this test runs until stopped by pressing the unload button. Function code 6 performs a check of the scsi circuitry from and to the scsi connector. Note: this test requires that the drive be terminated by...

Page 93

Function code 8: unmake fmr tape function code 8 erases the field microcode replacement (fmr) data and rewrites the cartridge memory on the tape. This converts the cartridge into a valid customer-supplied scratch (blank) data cartridge. 1. Place the drive in maintenance mode. For instructions, see “...

Page 94

Function code a: clear error code log function code a erases the contents of the error code log. 1. Place the drive in maintenance mode. For instructions, see “entering maintenance mode” on page 68. 2. Press the unload button once per second until a appears in the scd. (if you cycle past the desired...

Page 95

Function code e: test cartridge & media approximate run time = 15 minutes per loop total number of loops = 10 function code e performs tests that determine whether a suspect cartridge and its magnetic tape are acceptable. The diagnostic loops ten times. Press the unload button to stop the diagnostic...

Page 96

Function code f: write performance test approximate run time = 5 minutes total number of loops = 10 function code f performs tests to ensure that the drive can read from and write to tape. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance mode. Press...

Page 97

Function code h: test head approximate run time = 10 minutes total number of loops = 10 function code h performs tests to ensure that the tape drive’s head and tape-carriage mechanics work correctly. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance ...

Page 98

Function code j: run fast read/write test approximate run time = 5 minutes total number of loops = 10 function code j performs tests to ensure that the drive can read from and write to tape. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance mode. Pre...

Page 99

Function code l: load/unload test approximate run time = 15 seconds per loop total number of loops = 10 function code l tests the drive’s ability to load and unload a tape cartridge. The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode, press the unload button once to abo...

Page 100

Function code p: enable post error reporting when selected, deferred-check conditions are reported to the host. Therefore, temporary errors are reported in the sense data. This selection is normally used as a request from support personnel. Default is u (disabled). 1. Place the drive in maintenance ...

Page 101: Appendix

Appendix c. Tapealert flags tapealert is a patented technology and standard of the american national standards institute (ansi) that defines conditions and problems that are experienced by tape drives. The technology enables a server to read tapealert flags from a tape drive through the scsi interfa...

Page 102

84 ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 103: Appendix

Appendix d. Installing a 19-inch rack mount kit before you begin, read these instructions to familiarize yourself with the installation procedure. Rack safety the following general safety information should be used for all rack-mounted devices: danger v always lower the leveling pads on the rack cab...

Page 104

Caution: removing components from the upper positions in the rack cabinet improves rack stability during relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a room or building: v reduce the weight of the rack cabinet by removing equipment starting at the...

Page 105

Installing the shelf 1. Decide at what level you want to install the shelf. The 3580 requires 3 units (eias) of rack space (see 2 in figure 26). Note: all vertical rack measurements are given in rack units (u). One u is equal to 4.45 cm (1.75 in.). The u levels are marked on labels on one front moun...

Page 106

8. Route cables down one of the rear rack rails by threading each tie wrap (see 5 in figure 27) through a hole in the rail and around the cables. One tie wrap should be located near the rear of the 3580; the other should be located farther down the rack rail. Tighten cable ties securely around the c...

Page 107: Appendix

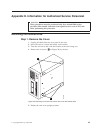

Appendix e. Information for authorized service personnel attention these procedures must be performed only by a trained ibm service provider. Ssrs should claim their time against service code 33 eca 013 when performing this procedure. Removing the internal drive step 1. Remove the cover 1. Unplug al...

Page 108

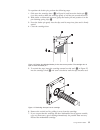

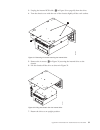

6. Remove the 5 screws (2 in figure 29) along the outside edges of the sides (1 screw on each side) and the top (3 screws) of the rear panel. 7. Gently push on the drive’s front bezel below the cartridge load compartment to remove the chassis from the cover (see figure 30). Step 2. Remove the intern...

Page 109

3. Unplug the internal scsi cable (1 in figure 30 on page 90) from the drive. 4. Turn the chassis over with the rear of the chassis slightly off the work surface. 5. Remove the 4 screws (4 in figure 31) securing the internal drive to the chassis. 6. Lift the chassis off the drive as shown in figure ...

Page 110

Manually removing a tape cartridge the purpose of this section is to assist you in determining the condition of the cartridge or the magnetic tape and to direct you to the procedure you must follow to remove the cartridge. Attention v before using this procedure, you must have exhausted all other me...

Page 111

Beginning procedure __ step 1. Perform the procedure, “removing the internal drive” on page 89, or refer to the enclosure documentation for instructions on removing the drive. __ step 2. Place the drive on a non-slip, sturdy work surface. __ step 3. Ground yourself to the drive by using the esd kit....

Page 112

__ step 5. Inspect the drive to decide which of the following conditions most closely matches the symptom on the drive: v tape spooled off the supply reel - all the tape appears to be on the take up reel and no tape is on the supply reel (inside the cartridge). Test the drive after the procedure is ...

Page 113

Tape spooled off supply reel __ step 1. With the front of the drive facing you, pull an arm’s length of tape out of the takeup reel from the left side of the drive. __ step 2. From the takeup reel, thread tape around the rear of the tape path and over the head rollers on the left side of the drive. ...

Page 114

__ step 11. Allow the drive to perform mid-tape recovery. This takes several minutes. When this activity completes, the cartridge ejects automatically. __ step 12. Test the drive (see “function code 1: run drive diagnostics” on page 69) to determine if it should be replaced. Tape pulled from or brok...

Page 115

B. Use a #1 flathead screwdriver to turn the threader worm gear (9 in figure 35 on page 96) clockwise. This rotates the threader motor worm gear (4 in figure 35 on page 96) clockwise, drawing the tape leader block assembly (lba) into the cartridge. __ step 4. As the lba is secured in the cartridge, ...

Page 116

__ step 10. Reassemble the drive by reversing the procedure in step 4 on page 93 in beginning procedure. __ step 11. Reassemble the drive chassis by following the steps in “replacing the internal drive” on page 106. __ step 12. Refer to the appropriate procedure to install the new drive and return t...

Page 117

__ step 7. Turn the supply reel clockwise, carefully guiding the mended portion of the tape to wind around the hub of the supply reel located inside the cartridge. Continue spooling into the cartridge until the tape is taut. The tape must remain within the flanges of the tape guiding rollers. Ensure...

Page 118

__ step 2. Set the drive on its left side with the head and tape path facing up. __ step 3. From the bottom of the drive, locate the access hole (1 in figure 38). __ step 4. Insert a 2.5 mm offset hex wrench through the bottom cover access hole and into the reel motor axle. Begin spooling the tape b...

Page 119

1 loader motor worm gear 6 threader mechanism gear 2 cartridge loader tray guide bearing 7 lever 3 rotator stub 8 loader mechanism gear 4 threader motor worm gear 9 threader worm gear 5 threader intermediate gear __ step 7. As the tape leader block assembly (lba) is secured in the cartridge, you sho...

Page 120

__ step 10. Rotate the threader motor worm gear (4 in figure 39 on page 101) to turn the threader mechanism gear (6 in figure 39 on page 101) counterclockwise. This moves the lba out of the cartridge and past the read/write head. Stop this rotation when the lba is near the tape guide roller nearest ...

Page 121

__ step 2. From the bottom of the drive, locate the access hole (1 in figure 41). __ step 3. Insert a 2.5 mm offset hex wrench through the bottom cover access hole and into the reel motor axle. Begin spooling the tape back into the cartridge by turning the hex wrench clockwise. __ step 4. Continue s...

Page 122

1 loader motor worm gear 6 threader mechanism gear 2 cartridge loader tray guide bearing 7 lever 3 rotator stub 8 loader mechanism gear 4 threader motor worm gear 9 threader worm gear 5 threader intermediate gear __ step 6. As the tape leader block assembly (lba) is secured in the cartridge, you sho...

Page 123

__ step 9. Rotate the threader motor worm gear (4 in figure 42 on page 104) to turn the threader mechanism gear (6 in figure 42 on page 104) counterclockwise. This moves the lba out of the cartridge and past the read/write head. Stop this rotation when the lba is near the tape guide roller nearest t...

Page 124

Replacing the internal drive step 1. Replace the internal drive 1. Place the drive on the chassis. 2. Reconnect the internal scsi cable to the drive. 3. Reconnect the internal scsi address cable to the drive. 4. Reconnect the internal power cable to the drive. 5. Turn chassis and drive over with the...

Page 125: Notices

Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries or regions. Consult your local ibm representative for information on the products and services currently availabl...

Page 126

Vary significantly. Some measurements may have been made on development-level systems and there is no guarantee that these measurements will be the same on generally available systems. Furthermore, some measurements may have been estimated through extrapolation. Actual results may vary. Users of thi...

Page 127

Other company, product, and service names may be trademarks or service marks of others. Notices 109.

Page 128

Electronic emission notices the following statement applies to this product. The statement for other products intended for use with this product will appear in their accompanying manuals. Ibm totalstorage 3580 tape drive , models l33/l3h federal communications commission (fcc) class a statement note...

Page 129

Properly shielded and grounded cables and connectors must be used in order to reduce the potential for causing interference to radio and tv communications and to other electrical or electronic equipment. Such cables and connectors are available from ibm authorized dealers. Ibm cannot accept responsi...

Page 130

Taiwan class a electronic emission statement korea class a electronic emission statement 112 ibm totalstorage 3580 tape drive setup, operator, and service guide.

Page 131: Glossary

Glossary this glossary defines the special terms, abbreviations, and acronyms that are used in this publication. Numbers 2:1 compression. The relationship between the quantity of data that can be stored with compression as compared to the quantity of data that can be stored without compression. In 2...

Page 132

Customer replaceable unit (cru). A part that a customer (rather than a service representative) replaces. Current. The quantity of charge per unit of time, measured in amperes (amps, a). D data. Any representations such as characters or analog quantities to which meaning is, or might be, assigned. Da...

Page 133

I id. Identifier. Insert. Pertaining to the drive, to place a tape cartridge into the tape drive. Install. To set up for use or service. The act of adding a product, feature, or function to a system or device either by a singular change or by the addition of multiple components or devices. Internet....

Page 134

Message display. Located on the front of the drive, an lcd display that provides information about the status of the tape drive and any error conditions. Metal particle tape. In the lto ultrium tape cartridge, tape that uses very small, pure metal particles (rather than oxide coatings) in the magnet...

Page 135

Scsi bus cable. See scsi bus. Scsi cable. See scsi bus. Scsi command. An operation performed by a target (tape drive) for an initiator (server). The command is initiated by the operator from the host console. Scsi connector. One of the set of all female and male connectors on the scsi bus. Scsi devi...

Page 136

U u. Pertaining to the rack that houses a drive, the amount of space between two holes in a mounting rail. One u is equal to 4.45 cm (1.75 in.). Ultra scsi. See small computer systems interface (scsi). Ultra-2 scsi. See small computer systems interface (scsi). Unattended backup. The act of copying f...

Page 137: Index

Index a ac grounding diagram xii b bar code labels ordering 43 bar code labels 26 c cables connecting scsi 11 cartridge removing 19 cartridges 23 capacity scaling 25 cleaning 26 compatibility 23 data 24 disposal of 41 inserting 18 inspecting for damage 46 leader pin 34 ordering 42 proper handling 30...

Page 138

Server connection configuring 13 servers supported 4 single-character display 16 specifications cartridges 40 environmental 6 physical 6 power 6 status light 16 t tapealert flags 83 technical support accessing online iii my support iii u unload button 15 updating firmware using fmr tape 21 using scs...

Page 139: Readers’

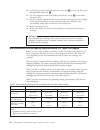

Readers’ comments — we’d like to hear from you ibm totalstorage 3580 tape drive model l33/l3h setup, operator, and service guide publication no. Gc26-7708-03 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall sati...

Page 140: Business

Readers’ comments — we’d like to hear from you gc26-7708-03 gc26-7708-03 cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape no postage necessary if mailed in the united states business reply mail first-class...

Page 142

Part number: 23r6251 printed in usa gc26-7708-03 (1p) p/n: 23r6251.

Page 143

Spine information: ib m to ta ls to ra ge 35 8 0 t ape d rive mo de l l3 3/l3h ib m to ta ls to ra ge 35 8 0 tape dri ve se tu p , o pe rato r, an d se rvi ce gu id e.