- DL manuals

- IBM

- Storage

- TotalStorage Ultrium T800

- Operator's Manual

IBM TotalStorage Ultrium T800 Operator's Manual

Summary of TotalStorage Ultrium T800

Page 1

Ibm totalstorage ultrium tape drive models t800 and t800f setup, operator, and service guide gc26-7697-01.

Page 3

Ibm totalstorage ultrium tape drive models t800 and t800f setup, operator, and service guide gc26-7697-01.

Page 4

Note before using this guide and the product it supports, read the information in “safety and environmental notices” on page ix and “notices” on page 115. Second edition (march 2005) this edition applies to the ibm totalstorage ultrium tape drive models t800 and t800f setup, operator, and service gu...

Page 5: Contents

Contents figures . . . . . . . . . . . . . . . V tables . . . . . . . . . . . . . . . Vii safety and environmental notices . . . Ix danger notices . . . . . . . . . . . . . Ix caution notices . . . . . . . . . . . . . Ix tape drive ac grounding inspection . . . . . . X end of life (eol) plan . . . ....

Page 6

Updating firmware through the library/drive interface . . . . . . . . . . . . . . 46 itdt scsi firmware update, dump retrieval and library/drive test tool . . . . . . . . 47 lto-tdx: lto scsi and fibre drive firmware download & lto drive dump upload tool . . 47 updating the firmware with an fmr tape...

Page 7: Figures

Figures 1. Ac grounding diagram (50 hz and 60 hz) x 2. View of the drive with and without the bezel 1 3. Front panel of the drive . . . . . . . . . 2 4. Rear panel of the scsi drive . . . . . . . 3 5. Rear view of the fibre channel drive . . . . 4 6. Temperature of the drive is taken near the air in...

Page 8

Vi ibm totalstorage ultrium tape drive.

Page 9: Tables

Tables 1. Supported servers and operating systems for scsi and fibre channel attachment . . . . . 6 2. Choosing the port for your topology and fibre channel connection . . . . . . . . . . 8 3. Id settings that provide status about the loop 18 4. Id settings that provide additional loop ids 20 5. Top...

Page 10

Viii ibm totalstorage ultrium tape drive.

Page 11: Safety

Safety and environmental notices when using this product, observe the danger and caution notices contained in this guide. The notices are accompanied by symbols that represent the severity of the safety condition. Danger notices contain a dxxxx reference number. Caution notices contain a cxxxx refer...

Page 12

If the symbol is... It means.... A hazardous condition due to the weight of the unit. Weight symbols are accompanied by an approximation of the product’s weight. Tape drive ac grounding inspection 1. Power off the drive. 2. Disconnect all cables. 3. See figure 1 which is provided for reference only....

Page 13: Summary

Summary of changes the following changes have been applied to the information in this publication. Second edition v information about the fibre channel drive was added. V diagnostic functions f, j and l were modified/added. V the procedure for aborting a diagnostic function was modified. V the infor...

Page 14

Xii ibm totalstorage ultrium tape drive.

Page 15: About

About this guide this guide includes information on setting up, operating and servicing the tape drive in the following chapters: v “product description” on page 1 describes the drive, discusses supported servers, operating systems, and device drivers, and lists hardware specifications. V “installin...

Page 16

Xiv ibm totalstorage ultrium tape drive.

Page 17: Product

Product description the ibm totalstorage ultrium tape drive is a high-performance, high-capacity data-storage device that is designed to backup and restore open systems applications. The drive can be integrated into an enclosure, such as a desktop unit, tape autoloader, or tape library. The drive is...

Page 18

Front panel of the drive 1 status light 3 single-character display (scd) 2 unload button 4 scd dot a82ru001 1 2 3 4 figure 3. Front panel of the drive 2 ibm totalstorage ultrium tape drive.

Page 19

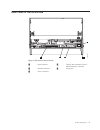

Rear panel of the scsi drive 1 scsi connector 4 library/drive interface (ldi or rs-422 interface) connector 2 scsi id connector 5 serial port 3 power connector 5 1 2 3 4 a82ru01 1 figure 4. Rear panel of the scsi drive product description 3.

Page 20

Rear view of the fibre channel drive 1 power connector 4 fibre channel configuration/status connector 2 feature switches 5&6 fibre channel connectors: 5) port 0 6) port 1, for future use 3 loop identifier (lid) / status connector 7 library/drive interface (ldi or rs-422 interface) connector 1 2 3 4 ...

Page 21

Cartridge compatibility the drive (generation 3) uses the ibm totalstorage lto ultrium 400 gb data cartridge and is compatible with the cartridges of its predecessor, the ibm ultrium internal tape drive (generation 2). The drive performs the following functions: v reads and writes generation 3 cartr...

Page 22

Data cartridge capacity scaling the set capacity scsi command enables a customer to capacity scale a data cartridge to enable faster random access. As an example, a customer could capacity scale a data cartridge to 20% of its normal length which improves the average access time by almost a factor of...

Page 23

Because the cables, connectors, and terminators are the same for the ultra160 and ultra2 scsi interfaces, devices with those interfaces can be mixed on the same bus and each device can operate at its fully rated speed. Address assignments each device on a scsi bus must have a scsi identifier (id) th...

Page 24

N_port when it boots. The type of port to which it configures depends on whether the drive recognizes the connection as a loop or a point-to-point connection: v an l_port supports a fibre channel arbitrated loop connection to an nl_port or fl_port. V an n_port supports direct connection to another n...

Page 25

Soft addressing allows the drive to dynamically arbitrate the al_pa with other fibre channel devices on the loop. Hard addressing allows you to choose the lid, which determines the corresponding al_pa. The higher the al_pa, the lower the priority of the device. Generally, servers (initiators) requir...

Page 26

V using an ibm ftp site, enter the following specifications: – ftp site: ftp.Software.Ibm.Com – ip addr: 207.25.253.26 – userid: anonymous – password: (use your current e-mail address) – directory: /storage/devdrvr ibm provides postscript- and pdf-formatted versions of its documentation in the /stor...

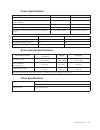

Page 27

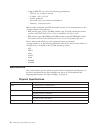

Power specifications power supply 5 v dc 12 v dc tolerance 10% 10% voltage ripple/noise (50 hz - 20 mhz) 60 mv pp 125 mv pp minimum supply current (steady state) 1.3 a 0.2 a maximum supply current (steady state) 3.0 a 1.1 a peak supply current (instantaneous power by power supply) 3.3 a for 100 ms (...

Page 28

12 ibm totalstorage ultrium tape drive.

Page 29: Installing

Installing the drive depending on the type of enclosure, installation procedures may vary. Before starting this installation, read these instructions and compare them to the drive installation instructions for your enclosure. Avoiding drive damage to avoid static electricity damage when handling the...

Page 30

Unpack the drive unpack the drive and store the packaging for future moves or shipping. Acclimate the drive acclimation time is required if the temperature of the drive when unpacked is different than the temperature of its operating environment (measured at the front of the bezel near the air intak...

Page 31

Set the scsi id or arbitrated loop physical address see instructions in the sections that follow to set a scsi id for a scsi drive or an arbitrated loop physical address for a fibre channel drive. Setting the scsi id (scsi drive only) you can set the scsi id in one of three ways: v by placing jumper...

Page 32

Switch must be compatible with the drive’s scsi id connector and must make an electrical connection between the same pins as the jumpers to achieve the same corresponding scsi id. Setting the scsi id through the ldi interface if the drive is being installed into a tape library, a command can be issu...

Page 33

– pin 5 has three states: off (ground), on (3.3 v), and alternating (between off and on). Pin 5 will be off if the drive does not detect light on the fibre channel connector, if (while communicating as an l_port) the drive does not complete the loop initialization protocol (lip), or if (while commun...

Page 34

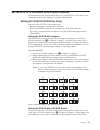

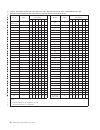

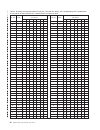

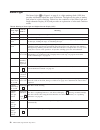

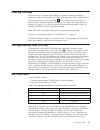

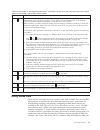

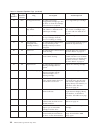

Table 3. Id settings that provide status about the loop. The table lists the al_pas, corresponding lids, and definitions of the jumpers on the connector pins. Feature switch 3 must be set to off . Al_pa lid pin (see notes) al_pa lid pin (see notes) 1 2 3 4 7 8 1 2 3 4 7 8 use soft addressing 0 - - -...

Page 35

Setting the loop id to provide additional loop ids if feature switch 3 on the drive is set to on (see 1 in figure 8 on page 17), the lid/status connector 2 has the following definition: v pins 1 through 7 are used to set the lid. V pin 8 overrides pins 1 through 7. If you place a jumper on pin 8, th...

Page 36

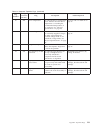

Table 4. Id settings that provide additional loop ids. The table lists the al_pas, corresponding lids, and definitions of the jumpers on the connector pins. Feature switch 3 must be set to on . Al_pa lid pin (see notes) al_pa lid pin (see notes) 1 2 3 4 5 6 7 1 2 3 4 5 6 7 ef 0 - - - - - - - b1 21 -...

Page 37

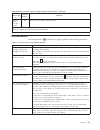

Table 4. Id settings that provide additional loop ids (continued). The table lists the al_pas, corresponding lids, and definitions of the jumpers on the connector pins. Feature switch 3 must be set to on . Al_pa lid pin (see notes) al_pa lid pin (see notes) 1 2 3 4 5 6 7 1 2 3 4 5 6 7 63 4b g - - g ...

Page 38

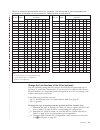

__ 4. Place jumpers on the pins that you identified in steps 1 on page 21 and 2 on page 21. Table 5. Topology and speed settings for the drive fibre channel characteristic pin 1 2 3 4 5 through 8 speed selection drive uses vpd values that can be updated by the ldi or rs-422 (the default value is neg...

Page 39

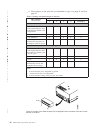

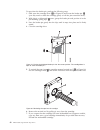

Mount the drive into an enclosure the drive may be shipped with or without a front bezel (see 1 in figure 10). When mounting the drive: v use an appropriate screw length. V ensure that no objects such as screw heads, cables, or adjacent devices, are pressing against the frame. V do not obstruct the ...

Page 40

Connect and test power to the drive the drive does not contain its own power source; it must be powered externally. To connect and test power to the drive: __ 1. Ensure that the enclosure (or unit that supplies power to the drive) is powered off. __ 2. Ensure that the power cord is disconnected from...

Page 41

Run drive diagnostics __ 1. Replace the cover on the enclosure. __ 2. Connect the power cord to both the enclosure and the electrical outlet. __ 3. Power-on the enclosure. __ 4. Run one or more of the following drive diagnostics: v “function code 1: run drive diagnostics” on page 33 v “function code...

Page 42

__ 2. Run the appropriate fibre channel attachment verification procedure from your server (for instructions, refer to the ibm ultrium device drivers installation and user’s guide). If a scsi error occurs, refer to “using sense data” on page 79. Connect the external ldi interface to the server (opti...

Page 43: Operating

Operating the drive operating the drive involves using the following front panel items: v single-character display (scd) v scd dot v status light v unload button single-character display (scd) the scd (3 in “front panel of the drive” on page 2) presents a single-character code for: v error condition...

Page 44

Status light the status light (1 in figure 3 on page 2) is a light-emitting diode (led) that provides information about the state of the drive. The light can be green or amber, and (when lit) solid or flashing. Table 6 lists the conditions of the status light and single-character display (scd) and p...

Page 45

Table 6. Meaning of status light and single-character display (scd) (continued) if the status light is... And the scd is... Meaning flashing amber twice per second off there is a drive dump in flash memory. 1 power should not be removed from the drive until the microcode update is complete. The driv...

Page 46

Inserting a tape cartridge to insert a tape cartridge: 1. Ensure that the drive is powered-on. 2. Ensure that the write-protect switch is properly set (see “write-protect switch” on page 55). 3. Grasp the cartridge so that the write-protect switch faces you (see 1 in figure 11). 4. Slide the cartrid...

Page 47

Removing a tape cartridge to remove a tape cartridge: 1. Ensure that the drive is powered-on. 2. Press the unload button. The drive rewinds the tape and partially ejects the cartridge. The status light flashes green while the tape rewinds, then goes out before the cartridge partially ejects. 3. Afte...

Page 48

Diagnostic and maintenance functions the drive can: v run diagnostics v test write and read functions v test a suspect tape cartridge v update its own firmware v perform other diagnostic and maintenance functions the drive must be in maintenance mode to perform these functions. Attention maintenance...

Page 49

Function code 1: run drive diagnostics approximate run time = 20 minutes per loop total number of loops = 10 function code 1 runs tests that determine whether the drive can properly load and unload cartridges, and read and write data. The diagnostic loops ten times. Press the unload button to stop t...

Page 50

Function code 2: update drive firmware from fmr tape attention when updating drive firmware, do not power-off the drive until the update is complete or the firmware may be lost. Function code 8 loads drive firmware from a field microcode replacement (fmr) tape. 1. Place the drive in maintenance mode...

Page 51

Function code 3: create fmr tape function code 3 copies the drive’s field microcode replacement (fmr) data to a scratch data cartridge. Attention for this function, insert only a scratch (blank) data cartridge or a cartridge that may be overwritten. During the test, the drive overwrites the data on ...

Page 52

Function code 5: copy drive dump function code 5 copies data from a drive dump (captured in function code 4) to the beginning of a scratch (blank) data cartridge. Attention for the 5 - 1 function, insert only a scratch (blank) data cartridge or a cartridge that may be overwritten. During the test, t...

Page 53

Function code 6: run scsi wrap test approximate run time = 10 seconds per loop number of loops = this test runs until stopped by pressing the unload button. Function code 6 performs a check of the scsi circuitry from and to the scsi connector. Note: this test requires that the drive be terminated by...

Page 54

Function code 7: run rs-422 wrap test this test causes the drive to perform a check of the circuitry from and to the ldi or rs-422 connector. Before selecting this function, attach an ldi or rs-422 wrap plug to the drive’s ldi or rs-422 connector (in place of the ldi or rs-422 cable). 1. Make sure t...

Page 55

Function code 9: display error code log function code 9 displays the last ten error codes, one at a time (the codes are ordered; the most recent is presented first and the oldest is presented last). If there are no errors in the log, function code 0 displays in the single-character display (scd). 1....

Page 56

Function code e: test cartridge & media approximate run time = 15 minutes per loop total number of loops = 10 function code e performs tests that determine whether a suspect cartridge and its magnetic tape are acceptable. The diagnostic loops ten times. Press the unload button to stop the diagnostic...

Page 57

Function code f: write performance test approximate run time = 5 minutes total number of loops = 10 function code f performs tests to ensure that the drive can read from and write to tape. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance mode. Press...

Page 58

Function code h: test head approximate run time = 10 minutes total number of loops = 10 function code h performs tests to ensure that the tape drive’s head and tape-carriage mechanics work correctly. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance ...

Page 59

Function code j: fast read/write test approximate run time = 5 minutes total number of loops = 10 function code j performs tests to ensure that the drive can read from and write to tape. The diagnostic loops ten times. Press the unload button to stop the diagnostic and exit maintenance mode. Pressin...

Page 60

Function code l: load/unload test approximate run time = 15 seconds per loop total number of loops = 10 function code l tests the drive’s ability to load and unload a tape cartridge. The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode, press the unload button once to abo...

Page 61

Function code p: enable post error reporting when selected, deferred-check conditions are reported to the host. Therefore, temporary errors are reported in the sense data. This selection is normally used as a request from support personnel. Default is u (disabled). 1. Place the drive in maintenance ...

Page 62

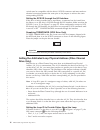

Updating firmware attention: when updating firmware, do not power-off the drive until the update is complete, or the firmware may be lost. Periodically check for updated levels of drive firmware by visiting the web at http://www.Ibm.Com/storage/lto . Update drive firmware using: v the scsi interface...

Page 63

Itdt scsi firmware update, dump retrieval and library/drive test tool attention at the time of publication, the itdt tool was not available. Register with mysupport (http://www.Ibm.Com/support/mysupport) to be notified by email when the tool becomes available, or periodically check the ibm support s...

Page 64

– lto-tdx_wintool (for windows operating systems) – lto-tdx_nwtool (for netware operating systems) – lto-tdx_lxtool (for linux operating systems) v the tool can perform two functions: 1. Download firmware to the drive 2. Upload a dump of the drive firmware logs from the drive to a computer system v ...

Page 65

V the tool is capable of loading back level (older) code. V the program presents the user with a numbered list of firmware files available for selection from the lto firmware folder. The user can then select the number of the firmware file for the program to load. V after the firmware has been loade...

Page 66

Updating the firmware with an fmr tape cartridge attention: scsi drives and fibre channel drives require different firmware images. Tip after creating an fmr tape (see “function code 3: create fmr tape” on page 35), the firmware of multiple drives can be updated with the same fmr tape. After updatin...

Page 67: Using

Using ultrium media to ensure that your ibm ultrium tape drive conforms to ibm’s specifications for reliability, use only ibm lto ultrium tape cartridges. You may use other lto-certified data cartridges, but they may not meet the standards of reliability that are established by ibm. The ibm totalsto...

Page 68

Data cartridge the different generations of ibm totalstorageultrium data cartridges can be identified by color: v the ultrium 3 data cartridge is slate blue v the ultrium 2 data cartridge is purple v the ultrium 1 data cartridge is black all three generations contain 1/2-inch, dual-coat, metal-parti...

Page 69

Cleaning cartridge with each drive, a specially labeled ibm lto ultrium cleaning cartridge is supplied to clean the drive head. The drive itself determines when a head needs to be cleaned. It alerts you by displaying c on the single-character display. To clean the head, insert the cleaning cartridge...

Page 70

Indicates that the cartridge is the third generation of its type. Figure 13 shows a sample bar code label for the lto ultrium tape cartridge. Tape cartridges can be ordered with the labels included or with custom labels. To order tape cartridges and bar code labels, see “ordering media supplies” on ...

Page 71

V position the label within the recessed label area (see 5 in figure 12 on page 51). V with light finger pressure, smooth the label so that no wrinkles or bubbles exist on its surface. V verify that the label is smooth and parallel, and has no roll-up or roll-over. The label must be flat to within 0...

Page 72

Handling the cartridges attention do not insert a damaged tape cartridge into the drive. A damaged cartridge can interfere with the reliability of a drive and may void the warranties of the drive and the cartridge. Before inserting a tape cartridge, inspect the cartridge case, cartridge door, and wr...

Page 73

V never ship a cartridge in a commercial shipping envelope. Always place it in a box or package. V if you ship the cartridge in a cardboard box or a box of a sturdy material, ensure the following: – place the cartridge in polyethylene plastic wrap or bags to protect it from dust, moisture, and other...

Page 74

V do not expose the cartridge to moisture or direct sunlight. V do not expose recorded or blank cartridges to stray magnetic fields of greater than 100 oersteds (for example, terminals, motors, video equipment, x-ray equipment, or fields that exist near high-current cables or power supplies). Such e...

Page 75

Handle the cartridge carefully v do not drop the cartridge. If the cartridge drops, slide the cartridge door back and ensure that the leader pin is properly seated in the pin-retaining spring clips (see 2 in figure 18 on page 61). If the leader pin has become dislodged, go to “repositioning or reatt...

Page 76

Examples of cartridge problems example: split cartridge case (see figure 17 on page 58) the cartridge’s case is damaged. There is a high possibility of media damage and potential loss. Perform the following steps: 1. Look for cartridge mishandling. 2. Use the ibm leader pin reattachment kit (part nu...

Page 77

Repositioning or reattaching a leader pin attention use a repaired tape cartridge only to recover data and move it to another cartridge. Continued use of a repaired cartridge may void the warranties of the drive and the cartridge. If the leader pin in your cartridge becomes dislodged from its pin-re...

Page 78

To reposition the leader pin, perform the following steps. 1. Slide open the cartridge door (1 in figure 19) and locate the leader pin 2 (you may need to shake the cartridge gently to roll the pin toward the door). 2. With plastic or blunt-end tweezers, grasp the leader pin and position it in the pi...

Page 79

Reattaching a leader pin the first meter of tape in a cartridge is leader tape. Once the leader tape has been removed there is a possibility of tape breakage. After reattaching the leader pin, transfer data from the defective tape cartridge. Do not reuse the defective tape cartridge . The leader pin...

Page 80

The following procedure describes how to reattach a leader pin. To reattach a leader pin by using the ibm leader pin reattachment kit: 1. Attach the leader pin attach tool (1 in figure 22) to the cartridge 2 so that the tool’s hook 3 latches into the cartridge’s door 4. Pull the tool back to hold th...

Page 81

2. To find the end of the tape inside the cartridge, attach the cartridge manual rewind tool (1 in figure 23) to the cartridge’s hub 2 by fitting the tool’s teeth between the teeth of the hub. Turn the tool clockwise until you see the end of the tape inside the cartridge. Then, slowly turn the rewin...

Page 82

7. Position the tape in the alignment groove of the leader pin attach tool (see 1 in figure 25). 8. Place a new c-clip into the retention groove 2 (figure 25) on the leader pin attachment tool and make sure that the clip’s open side faces up. 9. Place the leader pin (from step 6 on page 65) into the...

Page 83

13. Use your fingers to remove the leader pin from the cavity 3 in the leader pin attach tool. 14. Use the cartridge manual rewind tool to wind the tape back into the cartridge (wind the tape clockwise). Ensure that the leader pin is latched by the pin-retaining spring clips on each end of the leade...

Page 84

Environmental and shipping specifications for tape cartridges before you use a tape cartridge, acclimate it to the operating environment for 24 hours or the time necessary to prevent condensation in the drive (the time will vary, depending on the environmental extremes to which the cartridge was exp...

Page 85

Disposing of tape cartridges under the current rules of the u.S. Environmental protection agency (epa), regulation 40cfr261, the lto ultrium tape cartridge is classified as non-hazardous waste. As such, it may be disposed of in the same way as normal office trash. These regulations are amended from ...

Page 86

Table 11. Media supplies (continued) supply item methods of ordering ibm lto ultrium 100 gb data cartridge order volser labels separately (see “ordering bar code labels” on page 71). V order as part number 08l9120 through an ibm-authorized distributor (for the closest distributor, visit the web at h...

Page 87

Ordering bar code labels the ibm totalstorage 3580 tape drive does not require cartridge bar code labels. However, if you use your data cartridges or cleaning cartridges in an ibm tape library product, you may need cartridge bar code labels if your tape library product requires them. You can order t...

Page 88

72 ibm totalstorage ultrium tape drive.

Page 89: Resolving

Resolving problems if you encounter problems when running the drive, refer to table 13. If the problem is not identified in table 13, refer to “methods of receiving errors and messages” on page 74. The color and condition of the status light may also indicate a problem. For more information, see “st...

Page 90

Methods of receiving errors and messages use table 14 as a guide for identifying error codes and message codes reported by the drive, its enclosure (if applicable), or the server. Note: the codes on the single-character display (scd) have different meanings, depending on whether they display during ...

Page 91

Error codes and messages table 15 gives descriptions of the errors and messages that pertain to the drive, and tells what to do when you receive them. Attention: if the drive detects a permanent error and displays an error code other than 0 , it automatically performs a drive dump. If you force a dr...

Page 92

Table 15. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 8 firmware or tape drive problem. The tape drive determined that a firmware or tape drive hardware fai...

Page 93

Table 15. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 6 tape drive or media error. The tape drive determined that an error occurred, but it cannot isolate t...

Page 94

Table 15. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action 7 a high probability of media error. The tape drive determined that an error occurred because of a fau...

Page 95

Table 15. Error codes on the single-character display (continued). To clear error and cycle power, press the unload button for ten seconds. A drive dump will be created. Error code cause and action a tape drive hardware problem. The tape drive determined that a problem occurred which degraded the op...

Page 96

Ibm ultrium device drivers installation and user’s guide contains information about how to obtain sense data after an error has occurred. If your application uses other device drivers, see the appropriate documentation for those drivers to obtain the sense data. Raw sense data (as returned from the ...

Page 97

Obtaining error information from the rs/6000 or pseries the aix ® tape and media changer device driver for the ibm rs/6000 or ibm eserver pseries provides logging to the system error log for a variety of errors. You can view the error log by issuing the aix errpt command. Figure 28 on page 82 displa...

Page 98

Label: tape_err1 identifier: 4865fa9b date/time: wed oct 11 11:39:43 sequence number: 25264 machine id: 000d090d4c00 node id: tsm class: h type: perm resource name: rmt2 resource class: tape resource type: lto location: 40-60-00-2,0 vpd: manufacturer................Ibm machine type and model......Ul...

Page 99

Example of a scsi bus error: label: scsi_err10 identifier: 0ba49c99 date/time: wed oct 18 09:55:32 sequence number: 16140 machine id: 00003abf4c00 node id: ofgtsm class: h type: temp resource name: scsi3 resource class: adapter resource type: sym896 location: 40-59 vpd: product specific.( ).......Du...

Page 100

Obtaining a drive dump you can obtain a drive dump by selecting a function code on the drive or by using a device driver utility (or a system tool) on the server. The sections that follow describe each method. Using itdt attention at the time of publication, the itdt tool was not available. Register...

Page 101

To determine where to send a file that contains a drive dump to be analyzed, contact your oem product application engineer (pae). Viewing the drive error log the drive keeps an error log that you can use to identify and correct errors. The log contains the 10 most recent error codes, which appear (o...

Page 102

Resolving problems reported by the server the procedure for fixing scsi bus errors varies, depending on whether the error is consistent or intermittent, and whether your configuration contains single or multiple drives. The sections that follow describe how to fix each type of error. Fixing scsi bus...

Page 103

– if the test fails, replace the drive (see “removing a scsi drive from an enclosure” on page 93). V if the error does not occur, connect one drive at a time back to the bus and repeat step 3 for each drive until you can identify which drive is defective. Note: ensure that the scsi terminator is alw...

Page 104

Fixing fibre channel errors if you are connected to a fibre channel storage area network (san) by using a san data gateway, use the ibm storage area network gateway module setup, operator, and service guide to determine whether the problem is occurring between the drive and the san data gateway. If ...

Page 105

Fixing a consistent error with multiple drives on a fibre channel loop use the following procedure to determine if all of the drives on the fibre channel have the problem: 1. Use a device driver utility (such as ntutil or tapeutil) to verify that the drive is available and properly configured at the...

Page 106

Fixing intermittent fibre channel errors 1. Determine the type of fibre channel topology that you are using (see page 7). 2. Ensure that the configuration and software levels are supported (see “fibre channel interface” on page 7). 3. Check that each fibre channel cable does not exceed 500 m (1640 f...

Page 107

If it is not possible to run the tape cartridge in a different drive, perform the following procedures: 1. Clean the failing drive and run the drive diagnostics (see “cleaning the drive head” on page 31 and “function code 1: run drive diagnostics” on page 33). If the drive diagnostics run successful...

Page 108

92 ibm totalstorage ultrium tape drive.

Page 109: Servicing

Servicing the drive removing a scsi drive from an enclosure to remove a scsi drive from an enclosure, perform the following steps: 1. Ensure that the drive does not contain a tape cartridge. 2. Deconfigure the drive from the server (for instructions, see your server’s documentation). 3. Turn off the...

Page 110

Removing a fibre channel tape drive from an enclosure to remove a fibre channel drive from an enclosure, perform the following steps: 1. Ensure that the tape drive does not contain a tape cartridge. 2. Deconfigure the drive from the server, switch, or hub (for instructions, see the documentation for...

Page 111

Manually removing a tape cartridge the purpose of this section is to assist you in determining the condition of the cartridge or the magnetic tape and to direct you to the procedure you must follow to remove the cartridge. Attention v before using this procedure, you must have exhausted all other me...

Page 112

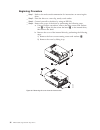

Beginning procedure __ step 1. Refer to the enclosure documentation for instructions on removing the drive. __ step 2. Place the drive on a non-slip, sturdy work surface. __ step 3. Ground yourself to the drive by using an esd kit. __ step 4. Remove the cover of the drive by performing the following...

Page 113

__ step 5. Inspect the drive to decide which of the following conditions most closely matches the symptom on the drive: v tape spooled off the supply reel - all the tape appears to be on the take up reel and no tape is on the supply reel (inside the cartridge). Test the drive after the procedure is ...

Page 114

Tape spooled off supply reel __ step 1. With the front of the drive facing you, pull an arm’s length of tape out of the take up reel from the left side of the drive. __ step 2. From the take up reel, thread tape around the rear of the tape path and over the head rollers on the left side of the drive...

Page 115

Tape pulled from or broken near leader pin 1 loader motor worm gear 6 threader mechanism gear 2 cartridge loader tray guide bearing 7 lever 3 rotator stub 8 loader mechanism gear 4 threader motor worm gear 9 threader worm gear 5 threader intermediate gear __ step 1. From the left side of the drive, ...

Page 116

__ step 4. As the lba is secured in the cartridge, you should hear the lba retention spring clips click into place. If you do not hear the click, continue rolling until the threader motor worm gear (4 in figure 32 on page 99) stops. The lba is in the correct position. Note: be sure to keep tension o...

Page 117

Tape broken in mid-tape __ step 1. With the front of the drive facing you, pull an arm’s length of tape out of the take up reel from the left side of the drive. Note: if there is less than approximately 5 cm (2 in.) of tape on the take up reel, go to “tape pulled from or broken near leader pin” on p...

Page 118

__ step 8. Reassemble the drive by reversing the procedure in step 4 on page 96 in beginning procedure. __ step 9. Allow the drive to perform mid-tape recovery. This takes several minutes. When this activity completes, the cartridge ejects automatically. __ step 10. Test the drive (see “function cod...

Page 119

__ step 5. Continue spooling into the cartridge until the tape is taut and remains within the flanges of the tape guiding rollers. Ensure that you do not stretch the tape. __ step 6. Locate the threader motor worm gear (4 in figure 36) on the rear of the drive. You can either: a. Use your finger to ...

Page 120

Note: be sure to keep tension on the tape as the lba is drawn into the cartridge by using a hex wrench as shown in figure 35 on page 102. __ step 8. Notice the: a. Loader mechanism gear (6 in figure 36 on page 103) nearest the front of the drive that actuates the cartridge loader mechanism. B. Posit...

Page 121

__ step 2. From the bottom of the drive, locate the access hole (1 in figure 38). __ step 3. Insert a 2.5 mm offset hex wrench through the bottom cover access hole and into the reel motor axle. Begin spooling the tape back into the cartridge by turning the hex wrench clockwise. __ step 4. Continue s...

Page 122

1 loader motor worm gear 6 threader mechanism gear 2 cartridge loader tray guide bearing 7 lever 3 rotator stub 8 loader mechanism gear 4 threader motor worm gear 9 threader worm gear 5 threader intermediate gear __ step 6. As the tape leader block assembly (lba) is secured in the cartridge, you sho...

Page 123

__ step 9. Rotate the threader motor worm gear (4 in figure 39 on page 106) to turn the threader mechanism gear (6 in figure 39 on page 106) counterclockwise. This moves the lba out of the cartridge and past the read/write head. Stop this rotation when the lba is near the tape guide roller nearest t...

Page 124

108 ibm totalstorage ultrium tape drive.

Page 125: Parts

Parts list table 16 lists the tools and supplies that you can use with the ibm totalstorage ultrium tape drive. To order tools and supplies, contact your oem product application engineer (pae) or visit the web at http://www.Ibm.Com/storage/lto . Table 16. Tools and supplies for the ibm totalstorage ...

Page 126

110 ibm totalstorage ultrium tape drive.

Page 127: Appendix.

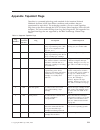

Appendix. Tapealert flags tapealert is a patented technology and standard of the american national standards institute (ansi) that defines conditions and problems that are experienced by tape drives. The technology enables a server to read tapealert flags from a tape drive through the scsi or librar...

Page 128

Table 17. Supported tapealert flags (continued) flag number flag parameter (in hex) flag description action required 12 0ch unsupported format set when you load an unsupported cartridge type into the drive or when the cartridge format has been corrupted. Use a supported tape cartridge. 15 0fh cartri...

Page 129

Table 17. Supported tapealert flags (continued) flag number flag parameter (in hex) flag description action required 36 24h drive temperature set when the drive’s temperature sensor indicates that the drive’s temperature is exceeding the recommended temperature of the enclosure (see “physical specif...

Page 130

114 ibm totalstorage ultrium tape drive.

Page 131: Notices

Notices trademarks the following terms are trademarks of international business machines corporation in the united states, other countries (or regions), or both: v aix v as/400 v ibm v ibmlink ™ v linux v os/400 v totalstorage ® the following are u. S. Trademarks of hewlett-packard company, internat...

Page 132

Electronic emission notices the following statement applies to this product. The statement for other products that are intended for use with this product will appear in their accompanying manuals. Federal communications commission (fcc) class a statement note: this equipment has been tested and foun...

Page 133

Germany electromagnetic compatibility directive zulassungsbescheinigung laut dem deutschen gesetz über die elektromagnetische verträglichkeit von geräten (emvg) vom 18. September 1998 (bzw. Der emc eg richtlinie 89/336) dieses gerät ist berechtigt, in Übereinstimmung mit dem deutschen emvg das eg-ko...

Page 134

Korean class a electronic emission statement getting help if you need assistance while installing or operating your ibm totalstorage ultrium tape drive, contact your oem product application engineer (pae). Warranty the warranty for this product is negotiated on a per-customer basis. 118 ibm totalsto...

Page 135: Glossary

Glossary this glossary defines the special terms, abbreviations, and acronyms that are used in this publication. Numbers and symbols 2:1 compression. The relationship between the quantity of data that can be stored with compression as compared to the quantity of data that can be stored without compr...

Page 136

Capacity. The amount of data that can be contained on storage media and expressed in bytes. Cartridge. See tape cartridge. Cartridge door. On a tape cartridge, the hinged barrier that can be opened to access, or closed to protect, the magnetic tape within the cartridge. Cartridge manual rewind tool....

Page 137

Duplex adapter. A mechanism that allows a device to send and receive communication at the same time. Duplex transmission. Transmission in both directions, either one direction at a time (half-duplex) or both directions simultaneously (full-duplex). E eject. To remove or force out from within. Electr...

Page 138

Hub. A communications device to which nodes on a multi-point bus or loop are physically connected. Hubs are commonly used in fibre channel networks to improve the manageability of physical cables. They maintain the logical loop topology of the network of which they are a part, while creating a “hub ...

Page 139

Hewlett-packard, and seagate. Lto technology is an “open format” technology, which means that its users have multiple sources of product and media. The “open” nature of lto technology enables compatibility between different vendors’ offerings by ensuring that vendors comply with verification standar...

Page 140

Native storage capacity. The amount of data that can be stored without compression on a tape cartridge. Native sustained data transfer rate. See data transfer rate. Negotiated speed. Defined by fibre channel standards, the algorithm that ensures the highest speed that is supported by both the drive ...

Page 141

Public device. A device that is attached to a fabric or switch, and can communicate to that fabric or switch. A public device can be part of an arbitrated loop topology or point-to-point topology. Q quiesce. To put a device into a temporarily inactive or inhibited state, but not remove it from the s...

Page 142

Sense data. Data that describes an i/o error. Sense data is presented to a server in response to a sense i/o command. Serial interface. An interface that sequentially or consecutively executes two or more operations in a single device, such as an arithmetic and logic operation. Server. A functional ...

Page 143

Tapeutil. Created by ibm, a utility program for lto devices that connect to all supported servers except windows nt and windows 2000. Tapeutil provides service aids for tape subsystems, offers a menu-driven tool for exercising or testing ibm tape and medium changer devices, and includes a command-li...

Page 144

World wide web. A network of servers that contain programs and files. Many of the files contain hypertext links to other documents that are available through the network. Write. To make a permanent or transient recording of data in a storage device or on a data medium. Write protected. Applicable to...

Page 145: Index

Index a ac grounding diagram x adjust data rate 5 as/400 requirements for attaching tape drive to 6 attaching tape drive to server 6 b bar code labels ordering 71 bar code labels 53 guidelines for using 54 c capacity scaling 6 cartridge 51 capacity scaling 6, 51, 52 cleaning 53 compatibility 5, 51 d...

Page 146

Ldi external server connection 26 internal cable connection 24 ldi interface 16 linux requirements for attaching tape drive to 6 load/unload test 44 lto-tdx drive dump 49 firmware download 48 lto-tdx tool 47 m maintenance create fmr tape 35 update firmware with fmr tape 34 maintenance function selec...

Page 148

Printed in usa gc26-7697-01.