- DL manuals

- ICC

- Adapter

- OPC-E1-WiE

- Instruction Manual

ICC OPC-E1-WiE Instruction Manual

September 2011

ICC #10719-1.100-000

© 2011 Industrial Control Communications, Inc.

ICC

INDUSTRIAL CONTROL COMMUNICATIONS, INC.

OPC-E1-WiE

Multiprotocol Wireless

Ethernet Interface

Thank you for purchasing the OPC-E1-WiE Multiprotocol Wireless Ethernet Interface.

•

This product is designed to connect the FRENIC-Multi series of inverters to wireless Ethernet

communication networks. Please read this instruction manual thoroughly in order to become

familiar with the proper interface handling, installation and usage procedures.

•

Improper handling may inhibit correct operation or cause premature interface failure.

•

Please deliver this instruction manual to the end user of the interface, and retain it in an

accessible location.

•

For inverter usage instructions, please refer to the applicable FRENIC-Multi inverter instruction

manual.

Instruction Manual

Summary of OPC-E1-WiE

Page 1

September 2011 icc #10719-1.100-000 © 2011 industrial control communications, inc. Icc industrial control communications, inc. Opc-e1-wie multiprotocol wireless ethernet interface thank you for purchasing the opc-e1-wie multiprotocol wireless ethernet interface. • this product is designed to connect...

Page 2

Icc 1 opc-e1-wie multiprotocol wireless ethernet interface instruction manual part number 10719-1.100-000 printed in u.S.A. ©2011 industrial control communications, inc. All rights reserved industrial control communications, inc. Reserves the right to make changes and improvements to its products wi...

Page 3

Icc 2 preface thank you for purchasing the opc-e1-wie multiprotocol wireless ethernet interface. This instruction manual has been prepared to help you connect your frenic-multi inverter to a variety of wireless ethernet control networks. This instruction manual does not contain inverter usage instru...

Page 4

Icc 3 installation and wiring • to avoid electrical shock, remove all power from the inverter and wait at least five minutes prior to starting installation. Additionally, confirm that the dc link bus voltage as measured between the p (+) and n (-) terminals is less than 25 vdc. • installation should...

Page 5

Icc 4 maintenance, inspection, and parts replacement • to avoid electrical shock, remove all power from the inverter and wait at least five minutes prior to starting inspection. Additionally, confirm that the dc link bus voltage as measured between the p (+) and n (-) terminals is less than 25 vdc. ...

Page 6

Icc 5 − table of contents − 1 pre-operation instructions ............................................................. 8 1.1 product overview .................................................................................................... 8 1.2 unpacking and product confirmation ...................

Page 7

Icc 6 5.6.3 submitting changes ......................................................................................................... 33 5.7 config tab.............................................................................................................. 34 5.7.1 information window ..........

Page 8

Icc 7 8.2.3 controllogix examples: setup ......................................................................................... 68 8.2.4 controllogix example: i/o messaging ............................................................................. 69 8.2.5 controllogix example: generic default...

Page 9

Icc 8 1 pre-operation instructions 1.1 product overview the opc-e1-wie wireless ethernet multiprotocol communication interface allows information to be transferred seamlessly between a frenic-multi inverter and several different wireless ethernet-based fieldbus networks with minimal configuration re...

Page 10

Icc 9 network timeout action a configurable network timeout action can be programmed that allows registers to have their own unique "fail-safe" conditions in the event of a network interruption. Refer to section 5.7.6. Field-upgradeable as new firmware becomes available, the interface can be upgrade...

Page 11

Icc 10 1.2 unpacking and product confirmation 1.2.1 shipment confirmation check the enclosed items. Confirm that the correct quantity of each item was received, and that no damage occurred during shipment. • opc-e1-wie interface board (with antenna) in enclosure (see figure 1). • one option retainin...

Page 12

Icc 11 1.2.2 component overview figure 4 shows an overview of the important interface card components. For clarity, the enclosure cover has been removed. Power supply terminal block the power supply terminal block can be used to provide power (7-24vdc) to the interface card. Refer to section 2.3. Ne...

Page 13

Icc 12 1.3 led indicators 1.3.1 module status and network status leds two stacked leds near the antenna module housing provide a visual indication of the unit’s overall status and communications activity. Refer to figure 5. 1.3.2 wireless ethernet link and activity leds the antenna module housing al...

Page 14

Icc 13 1.4 environmental specifications the interface’s environmental specifications are detailed in table 1. Table 1: environmental specifications item specification operating environment indoors, less than 1000m above sea level, do not expose to direct sunlight or corrosive / explosive gasses oper...

Page 15

Icc 14 2 installation 2.1 pre-installation instructions • to avoid electrical shock, remove all power from the inverter and wait at least five minutes prior to starting installation. Additionally, confirm that the dc link bus voltage as measured between the p (+) and n (-) terminals is less than 25 ...

Page 16

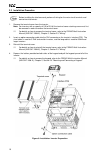

Icc 15 2.2 installation procedure before installing the interface card, perform all wiring for the main circuit terminals and control circuit terminals. 1. Remove the terminal cover from the inverter. Note: for inverters with a capacity of 5.5 to 15 kw, the terminal cover retaining screw must first ...

Page 17

Icc 16 5. Mount the interface card on the inverter, aligning the male rj45 connector on the back side of the interface card with the now-vacant keypad rj45 connector on the inverter. Ensure that the interface card is fully seated on the inverter, and that its plastic enclosure is sitting squarely on...

Page 18

Icc 17 7. Grasping the bottom of the interface card enclosure cover, gently pull it away from the inverter to remove it and expose the interface card pcb. 8. Attach the free end of the option connection cable to the connector labeled cn1 on the interface card pcb. Press firmly to ensure that the cab...

Page 19

Icc 18 2.3 power supply power for the interface card must be externally supplied: it is not automatically drawn from the inverter. A 3-position pluggable terminal block is provided in the lower-left portion of the interface board for connecting an external 7-24vdc power supply. • do not attempt to u...

Page 20

Icc 19 table 4 lists the recommended wire size, terminal screw size and tightening torque when connecting wires to tb1. Additionally, figure 10 indicates the recommended amount of insulation that should be stripped from the wire prior to inserting it into tb1. Table 4: tb1 wiring specifications figu...

Page 21

Icc 20 2.4.2 optional #10694 antenna extension cable icc part #10694 is a 30cm-long antenna extension cable (refer to figure 12). The #10694 antenna extension cable can be used with the optional #10693 desktop antenna (refer to section 2.4.3), but it is most commonly applied in conjunction with the ...

Page 22

Icc 21 2.5 initial wireless settings in order to initially connect to a wireless device, the network’s wireless access point or router must be configured such that it is compatible with the interface card’s initial wireless settings. While these settings can be changed after initial connection, the ...

Page 23

Icc 22 3 inverter function code settings the inverter function codes listed in table 5 are critical for overall operation of the end-to-end communication system. Some of these function codes must be set to specific values, and some may have multiple allowable settings depending on the desired operat...

Page 24

Icc 23 inverter (the transmission of request packets) is performed asynchronously to other threads in the interface card’s internal operating system. Some of these other threads are able to reboot the interface card under certain circumstances (when commanded by the user via the finder program, or a...

Page 25

Icc 24 rs-485 protocol selection (y20) determines the rs-485 port protocol, and must be set to a value of “0” (modbus rtu). 3.2 inverter control-related settings the following function codes relate to whether or not the inverter is to be controlled (command word and/or frequency command) from the ne...

Page 26

Icc 25 4 finder application 4.1 overview the “icc finder” application is a simple windows pc program (just a single .Exe file, no installations, dll’s etc.), which when executed discovers all icc communication interfaces on the current ethernet subnet, regardless of whether or not their network para...

Page 27

Icc 26 4.2 configuring the ip address before you can access the interface from your web browser or begin using it as a part of your automation network, you must know its ip address. The interface comes from the factory configured to obtain an ip address dynamically (dhcp/bootp). You can determine th...

Page 28

Icc 27 5 embedded web server 5.1 overview the interface contains an embedded web server (also known as an http server), which allows users to access the inverter’s internal data in a graphical manner with web browsers such as microsoft internet explorer or mozilla firefox. In this way, the inverter ...

Page 29

Icc 28 5.2 authentication for security, the interface requires valid user authentication whenever the web page is accessed. The authentication request will appear as a browser popup box that will request entry of a user name and password. Refer to figure 19. The factory-default user name is “root”, ...

Page 30

Icc 29 5.4.2 function code group selection list the function code group selection list is located in the upper-left hand corner of the monitor tab. Refer to figure 22. Individual groups can be selected by clicking on the group name. Multiple groups may also be selected by holding down the ctrl key w...

Page 31

Icc 30 figure 23: function code list some items to keep in mind when interacting with the function code list are: • when entering new function code values, be sure that the number being entered is appropriate for the currently-selected radix (refer to section 5.4.6): for example, an entered value of...

Page 32

Icc 31 5.4.5 non-scanned function code refresh the values of all non-scanned function codes are only read from the inverter when the “refresh” button (shown in figure 25) is clicked. Once clicked, the interface card will display the message “refreshing values…” in the information window (refer to se...

Page 33

Icc 32 5.6 bacnet tab the bacnet tab provides for the configuration of the device on a bacnet/ip network. Refer to figure 27. Figure 27: bacnet tab 5.6.1 information window figure 28 shows the information window, which is located in the upper- right hand corner of the bacnet tab. This window display...

Page 34

Icc 33 5.6.3 submitting changes whenever either of the bacnet configuration elements (device name or device id) has been changed, the “submit” button located in the left-hand portion of the web page must be clicked in order to write these settings to the interface card’s filesystem. Note that becaus...

Page 35

Icc 34 5.7 config tab the config tab provides access to various configuration items. Refer to figure 31. Figure 31: config tab 5.7.1 information window figure 32 shows the information window, which is located in the upper-right hand corner of the config tab. This window displays various informationa...

Page 36

Icc 35 5.7.3 ip address configuration figure 34 shows the configuration items used to modify the ip address-related parameters. Modification of these settings is consistent with the technique used with the finder utility (refer to section 4.2.1). 5.7.4 mac address configuration figure 35 shows the e...

Page 37

Icc 36 authentication: the interface supports five different types of authentication: none, wep, wpa, wpa2 and auto. The default setting is auto. None may be chosen if wireless security is not desired. Wep (wired equivalency privacy) and wpa/wpa2 (wi-fi protected access) offer different levels of se...

Page 38

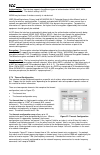

Icc 37 if timeout/failsafe processing is not desired, just set the “register” fields for all indexes to 0 (disabled). This is the default condition. “dec” and “hex” selection buttons are also available, and allow changing the “value” column data display and entry radix between decimal and hexadecima...

Page 39

Icc 38 5.8 ethernet/ip tab the ethernet/ip tab provides access to configuration items related to communication on an ethernet/ip network. Refer to figure 39. Figure 39: ethernet/ip tab 5.8.1 information window figure 40 shows the information window, which is located in the upper-right hand corner of...

Page 40

Icc 39 5.8.3 run/idle flag behavior ethernet/ip clients (such as plcs) have the option of adding a 32-bit “run/idle” header to all class 1 (i/o) data packets sent to devices. Bit 0 of this header is called the “run/idle flag” by the ethernet/ip specification, and is intended to signify when the clie...

Page 41

Icc 40 may request larger consumed and/or produced data sizes, but all unreferenced consumed data will be ignored, and all unreferenced produced data will contain dummy “0” values). The first word (two bytes) of consumed data will be written to register 1799 (operation command register) and the seco...

Page 42

Icc 41 5.9 alarm tab the alarm tab provides a configurable mechanism by which the interface card can autonomously monitor any available inverter register and send emails to up to four recipients when a certain condition is detected. The alarm conditions have both value and time constraints, and can ...

Page 43

Icc 42 5.9.2 email configuration in order for an alarm trigger to successfully send a notification email, some network settings must first be configured properly (refer to figure 47 and figure 48.) dns servers: enter the dotted-decimal ip addresses of the primary and secondary dns servers which will...

Page 44

Icc 43 5.9.3 alarm configuration the interface supports twenty independently-configurable alarms. As shown in figure 51, each alarm has a variety of configuration elements, which will be explained further below. Figure 51: alarm configuration box alarm selection: this drop-down box allows the select...

Page 45

Icc 44 a maximum of the indicated number of times. If at any time during the subsequent transmissions the alarm condition is evaluated as “false”, then the alarm will be reset and email transmissions for this alarm will stop (until the next time the alarm is triggered, of course). Subject: enter a s...

Page 46

Icc 45 5.10 modbus tab the modbus tab provides access to configuration items related to communication on a modbus/tcp network. Refer to figure 53. Figure 53: modbus tab 5.10.1 information window figure 54 shows the information window, which is located in the upper-right hand corner of the modbus tab...

Page 47

Icc 46 5.10.3 register remap configuration at times, it may be convenient to access inverter registers in bulk modbus transactions. This may be especially true in situations where it is desired to access certain registers that are natively non- contiguous. For example, if it were desired to read the...

Page 48

Icc 47 5.10.4 submitting changes whenever the modbus configuration has been changed, the “submit” button located on the right- hand portion of the web page must be clicked in order to write these settings to the interface card’s filesystem. Refer to figure 57. Note that because these configuration e...

Page 49

Icc 48 5.11 dashboard tab the dashboard tab provides access to a virtual keypad, as well as a variety of gauges, meters and graphs that can be configured to provide an at-a-glance graphical overview of critical application variables in real-time. A total of 10 gauge windows are available (two at a t...

Page 50

Icc 49 5.11.2 virtual keypad a “virtual keypad” is displayed on the left-hand side of the dashboard tab, and acts as an interface for several useful pieces of control and monitor information. For an overview of the virtual keypad interface, refer to figure 60. Note that it is recommended to suspend ...

Page 51

Icc 50 • rev: sets bit #1 (“rev”) and clears bit #0 (“fwd”) in the operation command word (register 1799). • stop: clears both bit #0 (“fwd”) and bit #1 (“rev”) in the operation command word (register 1799). • reset: writes a value of “1” to register 1807, which corresponds to inverter function code...

Page 52

Icc 51 max value: the gauge’s maximum indicated value. Similar to the min value attribute, negative values can be used if desired. Indicated value characteristics can even be inverted by setting the max value attribute to a value less than the min value attribute. Update button: clicking the update ...

Page 53

Icc 52 pos/neg meter: refer to figure 66. Similar to the “meter” gauge, this type of meter also implements a common panel meter-type display format, but in this instance the indicated value can be positive or negative (two’s complement interpretation). In other words, raw register values of 0..0x7ff...

Page 54

Icc 53 at times, it may be convenient to zoom in on a particular gauge or meter in order to more clearly see the indicator, or to fill the computer screen with a particular gauge’s image. This can be easily accomplished with the web browser’s flash player plug-in by right- clicking on the gauge and ...

Page 55

Icc 54 6 function code numbering and behavior 6.1 register numbers all accessible inverter function codes are referenced by their modbus register indexes, as defined in the rs-485 user’s manual (meh448), section 3 (table 3.2). These same register numbers are used when accessing and configuring funct...

Page 56

Icc 55 table 6: function code-to-register conversion function code group group number example code name f fundamental functions 0 f07 (acceleration time 1): (0 x 256) + 7 + 1 = 8 e extension terminal functions 1 e98 (terminal [fwd] function): (1 x 256) + 98 + 1 = 355 c control functions 2 c20 (joggi...

Page 57

Icc 56 inverter. If the value was not accepted by the inverter, then the unsuccessful write can be observed by reading the current (unchanged) value of the register during a subsequent network transaction. If the unsuccessful write was initiated via the web browser’s monitor tab, then the displayed ...

Page 58

Icc 57 7 filesystem & firmware 7.1 overview the interface card’s on-board filesystem is used to store files for use by the application firmware. Currently, the application firmware’s main use of the filesystem is to store xml-encoded configuration files that dictate the characteristics of the variou...

Page 59

Icc 58 7.2 initiating ftp via the finder utility after discovering all interface cards on the current subnet as described in section 4, select the target interface card and then click on the “open ftp interface” button. This will open the computer’s default ftp application, which could be windows ex...

Page 60

Icc 59 you will then be presented with an authentication dialog (refer to figure 75.) the user name will already be filled-in. Enter the case-sensitive password (default is “icc”) and click “log on.” figure 75: ftp authentication windows explorer will then display the filesystem’s contents (refer to...

Page 61

Icc 60 7.4 using ftp with a windows command prompt to use ftp with a windows command (dos) prompt, first open a command prompt by either selecting start …all programs …accessories …command prompt, or by selecting start …run and typing “cmd” in the “run” dialog. Once the command prompt opens, type “f...

Page 62

Icc 61 7.5 using ftp with core ftp le core ftp le (lite) is a third- party ftp application that can be downloaded for free from http://www.Coreftp.Com. Core ftp is just one example of the various commercial and freeware ftp client applications available on the internet. After installing core ftp le,...

Page 63

Icc 62 unit by choosing the file to upload and then clicking the “upload” button in the left-hand (source) side of the main page. Like most third-party ftp client applications, core ftp le has a wide array of configuration and file management capabilities, which are beyond the scope of this manual. ...

Page 64

Icc 63 8 protocol-specific information this section will discuss topics that are specific to each of the supported protocols. 8.1 modbus/tcp 8.1.1 overview the interface card supports schneider electric’s modbus/tcp protocol, release 1.0. The interface is conformance class 0 and partial class 1 and ...

Page 65

Icc 64 8.1.2 coil & discrete input mappings the modbus/tcp driver provides read/write support for coils (0x references) and read-only support for discrete inputs (1x references). These will collectively be referred to from here on out as simply “discretes”. Accessing discretes does not reference any...

Page 66

Icc 65 8.2 ethernet/ip 8.2.1 overview the ethernet/ip protocol is an application-level protocol implemented on top of the ethernet tcp/ip and udp/ip layers. It shares its object model with controlnet and devicenet through the common industrial protocol (cip). This protocol allows the transfer of dat...

Page 67

Icc 66 8.2.2 odva ac/dc drive profile the interface card supports the odva ac/dc drive profile. No special ethernet/ip configuration of the interface card is required when using the ac/dc drive profile: all that is needed is that the controller must target either assembly instances 20 & 70 or 21 & 7...

Page 68

Icc 67 netref: not used (value is ignored). Speed reference: inverter speed reference in rpm. Maps to inverter register 1798 (function code s05 / frequency command). The speed reference component of the ac/dc drive profile output instances is always in units of rpm. Therefore, the interface card app...

Page 69

Icc 68 drive state: indicates the current state of the control supervisor object state machine. Refer to the odva ethernet/ip specification (object library) for detailed information on the control supervisor object state machine. Speed actual: inverter operating speed in rpm. Maps to inverter regist...

Page 70

Icc 69 9) switch to online mode. Right click on the 1756-enbt/a module in the i/o configuration and choose “properties”. 10) select the port configuration tab from the module properties dialog box. 11) confirm that the ip address, subnet mask and gateway address fields are configured correctly. The ...

Page 71

Icc 70 2) right click on the 1756-enbt/a node under the i/o configuration in the controller organizer view and choose “new module…” 3) choose “generic ethernet module” in the select module dialog box and click “ok”. Refer to figure 86. Figure 86: adding a new generic ethernet module 4) the module pr...

Page 72

Icc 71 output: the output assembly is the collection of command & configuration data that is sent as an output from the plc and consumed by the interface card. Its structure is defined by the consumed register configuration as described in section 5.8.4. The output assembly instance must be set to 1...

Page 73

Icc 72 we can directly interact with these tags in order to control and monitor the inverter. In figure 91, for example, we can see that the first 16-bit word of output data (fuji_inverter:o.Data[0]) has been set to a hexadecimal value of 0x0001. Referring back to figure 43, we can see that the firs...

Page 74

Icc 73 figure 93: create generic default aoi tags 5) double click “mainroutine” under tasks …maintask …mainprogram in the controller organizer view. 6) right click on the first ladder logic rung in the mainroutine window and select “add ladder element...” 7) the “add ladder element” window appears. ...

Page 75

Icc 74 figure 95: configure generic default aoi 11) the program is now complete. 12) save, download and run the program. 8.2.6 controllogix example: ac/dc drive profile add-on instruction the ac/dc drive profile add-on instruction is a simple interface to command and monitor the inverter. It is base...

Page 76

Icc 75 figure 97: ac/dc drive profile aoi 3) double click “controller tags” in the controller organizer view and select the “edit tags” tab at the bottom. 4) create the tags in figure 98. Figure 98: create ac/dc drive profile aoi tags 5) double click “mainroutine” under tasks …maintask …mainprogram ...

Page 77

Icc 76 10) edit the add-on instruction according to figure 100. Figure 100: configure ac/dc drive profile aoi 11) the program is now complete. 12) save, download and run the program. 8.2.7 explicit messaging tag reference when class 3 (explicit messaging) connections are used, register contents are ...

Page 78

Icc 77 (such as “rd_reg_2050[8]”, which starts at register 2050+8 = register 2058, the inverter’s output frequency register). In a similar manner, to write data to the interface card, the application plc program must reference a “destination element” to which to start writing and the “number of elem...

Page 79

Icc 78 2) add a msg instruction to the main program. A) double click “mainroutine” under tasks …maintask …mainprogram in the controller organizer view. B) right click on the first ladder logic rung in the mainroutine window and select “add ladder element...” c) the “add ladder element” window appear...

Page 80

Icc 79 figure 106: msg instruction configuration c) “configuration” tab settings: i) change the “message type” to “cip data table read”. Ii) in the "source element” field, enter the read tag you wish to access (refer to section 8.2.5.) in this example, we will be reading a total of 21 registers begi...

Page 81

Icc 80 after every transmission. For efficiency, it is recommended to enable “cache connections”. Figure 108: setting the communication path e) click “ok” to close the msg configuration dialog. At this stage, mainroutine should look like figure 109. Figure 109: mainroutine 5) assign a tag to the xio...

Page 82

Icc 81 figure 110: configure xio element figure 111: complete program figure 112: viewing the register values.

Page 83

Icc 82 8.2.9 controllogix explicit messaging example: read a single register the configuration and execution for reading a single register is in general identical to that required for reading a block of registers as detailed in section 8.2.8. The only difference is in the configuration of the msg in...

Page 84

Icc 83 8.2.11 controllogix explicit messaging example: reading and writing often times, applications may need to both read data from and write data to the inverter. At a minimum, this will require two msg instructions and two message controller tags. Figure 115 shows an example of three msg instruct...

Page 85

Icc 84 8.3 allen bradley csp 8.3.1 overview ethernet-enabled allen-bradley legacy plcs (such as the plc5e and slc-5/05 series) use a protocol called csp (client server protocol) to communicate over the ethernet network. The flavor of csp used by these plcs is also known as “pccc” (programmable contr...

Page 86

Icc 85 table 12: examples of ethernet/ip-style bulk access via file n60 offset/element start target register of configuration array max number of accessible elements 0 1 st 32 : : : 15 16 th 16 : : : 31 32 nd 1 the application plc program uses a msg instruction that is configured with a “data table ...

Page 87

Icc 86 8.3.3 slc-5/05 example: read a register block this example program will show how to continuously read a block of registers from the inverter with a single msg instruction. Only one read request is outstanding at any given time. 1) run rslogix 500, and create a new configuration. 2) create a c...

Page 88

Icc 87 figure 119: msg instruction selection figure 120: xio instruction selection 5) configure the msg instruction. A) set the “read/write” field to “read”, “target device” field to “plc5”, “local/remote” field to “local”, and “control block” to “n20:0”. B) upon hitting the key while in the “contro...

Page 89

Icc 88 figure 121: msg configuration, "general" tab figure 122: msg configuration, "multihop" tab figure 123: plc program after msg instruction configuration.

Page 90

Icc 89 6) assign a tag to the xio element. A) double-click on the xio element located to the left of the msg block. Type in n20:0/15 (msg instruction’s enable bit). This configuration causes the msg instruction to automatically retrigger itself when it completes. While this is acceptable for the pur...

Page 91

Icc 90 figure 126: read the inverter’s output frequency register 8.3.5 slc-5/05 example: multiple msg instructions at times, reading from different groups of registers may be necessary. For example, a specific application may require some registers located in various disjoint locations in the regist...

Page 92

Icc 91 8.3.6 slc-5/05 example: reading and writing often times, applications may need to both read data from and write data to the inverter. At a minimum, this will require two msg instructions and two message control files. Figure 128 shows an example of two msg instructions, one for reading and on...

Page 93

Icc 92 8.4 bacnet/ip • the interface card supports the bacnet/ip (annex j) protocol over ethernet via udp port 47808. • the bacnet driver does not trigger timeout events (section 5.7.6). 8.4.1 protocol implementation conformance statement bacnet protocol date: june 1, 2011 vendor name: icc, inc. Pro...

Page 94

Icc 93 lontalk, (clause 11), medium: ______ other: ______ device address binding: is static device binding supported? (this is currently for two-way communication with ms/tp slaves and certain other devise.) yes no networking options: router, clause 6 - list all routing configurations annex h, bacne...

Page 95

Icc 94 object types/property support table table 13: bacnet object types /properties supported property object type device binary input binary output analog input analog output object identifier r r r r r object name r r r r r object type r r r r r system status r vendor name r vendor identifier r m...

Page 96

Icc 95 8.4.2 supported objects table 14: binary input object instance summary instance id object name description active/ inactive text bi1 fwd_rot_status forward rotation status forward/off bi2 rev_rot_status reverse rotation status reverse/off bi3 ext_status dc injection braking braking/off bi4 in...

Page 97

Icc 96 table 15: binary output object instance summary instance id object name description active/ inactive text bo1 fwd_rot_cmd forward rotation command forward/off bo2 rev_rot_cmd reverse rotation command reverse/off bo3 x1 general purpose input on/off bo4 x2 general purpose input on/off bo5 x3 ge...

Page 98

Icc 97 8.4.3 supported object details binary input objects bi1 ........ Indicates whether the inverter is running forward. Corresponds to function code m14, bit 0. Bi2 ........ Indicates whether the inverter is running reverse. Corresponds to function code m14, bit 1. Bi3 ........ Indicates dc injec...

Page 99

Icc 98 9 troubleshooting although by no means exhaustive, table 18 provides possible causes behind some of the most common errors experienced when using the interface card. Table 18: troubleshooting problem symptom solution no communications between the interface card and the inverter the interface ...

Page 100

Icc 99 revisions date manual number details april 2009 10719-1.000-000 preliminary release may 2009 10719-1.000-000 official v1.000 firmware release march 2010 10719-1.000-001 minor corrections september 2011 10719-1.100-000 minor driver updates.

Page 101

Icc industrial control communications, inc. 1600 aspen commons, suite 210 middleton, wi usa 53562-4720 tel: [608] 831-1255 fax: [608] 831-2045 http://www.Iccdesigns.Com printed in u.S.A.