- DL manuals

- Ice And Oven

- Cooktop

- BASE-LINE

- Service Manual

Ice And Oven BASE-LINE Service Manual

Ice And Oven | 1312 | Inducs Service Manual | Version 13-Aug-14

SERVICE-MANUAL

INDUCTION COOKERS

BASE-LINE/INSTALL-LINE/WOK-LINE

BH/BA 1500

BH/BA 1800

BH/BA 2300

BH/BA 2500

BH/BA 3000

BH/BA 3500

BH/IN 2500

SH/BA 3500

SH/BA 5000

SH/IN 3500

SH/IN 5000

SH/WO 3500

SH/WO 5000

SH/WO 8000

SH/WO/IN 3500

SH/WO/IN 5000

SH/WO/IN 8000

Freecall 1800 998 125

www.iceandoven.com

Summary of BASE-LINE

Page 2: Content

-1- 080417_service manual base, wok- and install-line e content 1 safety .............................................................................................................................. 2 1.1 description of danger signs .....................................................................

Page 3: Safety

-2- 080417_service manual base, wok- and install-line e 1 safety 1.1 description of danger signs this symbol identifies the safety information which may cause danger (personal injury) for people at non-observance of proper operation. This dangerous voltage warning symbol indicates a risk of electric...

Page 4

-3- 080417_service manual base, wok- and install-line e connection. The installation of safety and protection must be re-installed after finishing the work. 1.4 unauthorized reconstruction and use of spare parts reconstruction of the cooker or changes to the cooker are not allowed. Contact the manuf...

Page 5: Technical Information

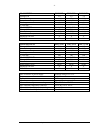

-4- 080417_service manual base, wok- and install-line e 2 technical information modell bh/ba 120 v/1 ph 208 v/1 ph 230 v/1 ph 240 v/1 ph wattage kw 1.5/1.8 2.5/3/3.5 2.3/2.5/3/3.5 2.5/3 /3.5 current a 12.5/15 12/14.5/17 10/11/13/15 10/12.5/14.5 power factor cos φ >0.95 >0.95 >0.95 >0.95 discharge ra...

Page 6

-5- 080417_service manual base, wok- and install-line e modell sh/wo 208 v/1 ph 230 v/1 ph 240 v/1 ph wattage kw 3.5 3.5 3.5 current a max. 16 15 14.5 power factor cos φ >0.95 >0.95 >0.95 discharge rate ma 4 4 4 ∅ coil mm 190 190 190 modell sh/wo 208 v/3 ph 400 v/3 ph 440 v/3 ph wattage kw 5 5/8 5 c...

Page 7: Functioning

-6- 080417_service manual base, wok- and install-line e 3 functioning 3.1 adjusting the performance rate the performance rate is adjusted by the potentiometer (control knob). The inductive performance depends on the position of the potentiometer: • position 1 = minimum power • position 9 (resp. Posi...

Page 8: Tests

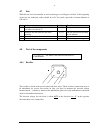

-7- 080417_service manual base, wok- and install-line e 4 tests 4.1 pan material for induction cookers when cooking with induction it is most important to use appropriate pan material. The bottom of the pan is the element that closes the magnetic field generated by the induction coil. We recommend t...

Page 9

-8- 080417_service manual base, wok- and install-line e 4.3 test with pans step action level result 1 put the pan in the middle of the heating area 1.......9 (12) heat, the indicator lights 2 push the pan until the edge of the pan is in the middle of the heating area 1.......9 (12) no heating, the i...

Page 10

-9- 080417_service manual base, wok- and install-line e 4.7 fan with this test, fan, fan controller as well as the degree of soiling are verified. At the beginning of the test, the induction cooker should be cold. You need a pan with a bottom diameter of >28 cm/11“. Step action level result 1 put a ...

Page 11

-10- 080417_service manual base, wok- and install-line e in case one of the four diodes shows a short circuit or an interruption, the rectifier is defective and has to be exchanged. 4.8.2 transistor module (igbt) the igbt (insulated gate bipolar transistor) is fixed on the circuit board with three s...

Page 12: Maintenance/service

-11- 080417_service manual base, wok- and install-line e 5 maintenance/service maintenance work may only be done by authorized personnel. Before starting the maintenance work, the power supply must be turned off and the appliance must have cooled down. The following maintenance works need to be carr...

Page 13: Fault Finding

-12- 080417_service manual base, wok- and install-line e 6 fault finding 6.1 generally caution do not open the cooker while the power is connected. Dangerous tension! The induction cooker may only be serviced by authorized personnel. Stop any work if the heating area (ceran glass) is broken. The ind...

Page 14

-13- 080417_service manual base, wok- and install-line e number of flashing signals error code signification measure to take 5 -.....-.....-.....- error on power switch 3) a. Check connection b. Check power switch 6 -......-......-......- temperature inside the unit too high 3) c. Check whether the ...

Page 15

-14- 080417_service manual base, wok- and install-line e 1) the induction unit can only be restarted when the fault has been rectified (turn power rotary knob „off“) 2) the induction unit continues working. 3) the induction unit does not heat.. Order of error message for error code 1-8: the indicato...

Page 16

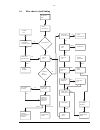

-15- 080417_service manual base, wok- and install-line e 6.3 flow chart to fault finding unit does not work! Check mains supply connection o.K? No yes connect unit is there any led indication? No short circuit connection poti? Check connection poti check led yes no dismount unit replace led defect o...

Page 17: Exchange Of Spare Parts

-16- 080417_service manual base, wok- and install-line e 7 exchange of spare parts caution all spare parts and accessories may only be changed by authorized personnel. Caution in order to guarantee safety use only genuine spare parts and accessories from inducs ltd.. If other components are used no ...

Page 18

-17- 080417_service manual base, wok- and install-line e 7.3 repair of spare parts repair of spare parts and of whole units may only be effected by inducs ltd. Therefore check and replace only parts described in this service manual. In case you should repair parts, please describe exactly the faults...

Page 19

-18- 080417_service manual base, wok- and install-line e 8 adjustment of process parameters the induction unit (excluding wok-units) with new cu sensors can be adjusted. This can be done either by means of the short circuit plug poti-led art. Nr. 94900096 or by pc/laptop. In addition, the pan detect...

Page 20

-19- 080417_service manual base, wok- and install-line e 8.2 initialisation of the induction unit by pc/laptop the initialization of the cu sensors as well as the adjustments of pan detection and performance can be done by means of the hyperterminal program. You will find exact information for the h...

Page 21

-20- 080417_service manual base, wok- and install-line e 5. Set the limit of the mains current (see mains current parameters in chapter 8.2): n increase the limit of the mains current (+) n decrease the limit of the mains current (-) the following message appears on the hyperterminal program: linecu...

Page 22

-21- 080417_service manual base, wok- and install-line e different information about the unit is shown in the adjusting mode. The following parameters can be read: output on the hyperterminal program: 1: kk:58 cu1:22 cu2:22 b:33 --- --- f:20080 1: kk:58 cu1:22 cu2:24 b:33 --- --- f:20080 1: kk:57 cu...

Page 23

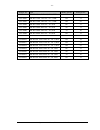

-22- 080417_service manual base, wok- and install-line e 8.4 parameters for mains current and pan detector article nr. Unit mains current pan detector bh/ba 1500, 120vac, 1n, 1,5kw 160 29 99560102 bh/ba 1800, 120vac, 1n, 1,8kw 187 21 99560103 bh/ba 2500, 208vac, 1n, 2,5kw 153 23 99560104 bh/ba 2500,...

Page 24

-23- 080417_service manual base, wok- and install-line e article nr. Unit mains current pan detector 99570001 sh/wo 3500, 208vac, 1n, 3,5kw 192 29 99570002 sh/wo 3500, 230vac, 1n, 3,5kw 192 31 99570003 sh/wo 3500, 240vac, 1n, 3,5kw 185 41 99570004 sh/wo 5000, 208vac, 3n, 5kw 167 23 99570005 sh/wo 50...

Page 25: Ir Interface

-24- 080417_service manual base, wok- and install-line e 9 ir interface 9.1 build-up of ir communication to build-up the ir communication, you need the software hyper terminal which is usually already available in windows under start =>program=>accessories => hyperterminal. Prior to the first use, h...

Page 26

-25- 080417_service manual base, wok- and install-line e select the following settings: 2400 bits/sec., 8 databits, no parity, 1 stop bit, hardware protocol these adjustments will be saved under the access name ir2400.Ht..