- DL manuals

- Ice-O-Matic

- Ice Maker

- 16

- Service And Installation Manual

Ice-O-Matic 16 Service And Installation Manual

Summary of 16

Page 1

Service and installation manual the ice series cubers ice0250 through ice2100 series* *includes undercounter and 22 inch series ice-o-matic 11100 east 45th ave denver, colorado 80239 part number 9081270-01 date 1/08.

Page 2

Ice series notes table of contents table of contents page a1 general information how to use this manual page a2 model and serial number format page a3 electrical and mechanical specifications page a5-a8 installation guidelines page a9 electrical and plumbing requirements page a10-a17 remote condense...

Page 3

Ice series table of contents page a1 table of contents table of contents page a1 general information how to use this manual page a2 model and serial number format page a3 electrical and mechanical specifications page a5-a8 installation guidelines page a9 electrical and plumbing requirements page a10...

Page 4

Ice series general information page a2 how to use this manual ice-o-matic provides this manual as an aid to the service technician in installation, operation, and maintenance of the ice series (electro-mechanical) cube ice machines. If used properly this manual can also assist the service technician...

Page 5

Ice series general information page a3 model and serial number format model numbers ice 040 0 h a condenser type: a=air w=water r=remote t=top discharge air cooled cube size: h=half (3/8 x 7/8 x7/8) f=full (7/8 x 7/8 x7/8) voltage: 0=115v 5=240/50/1 6=208-230/60/1 7=208-230/60/3 approximate 24 hour ...

Page 6

Ice series general information page a4 model and serial number format since all enodis companies will eventually be utilizing same operating system, a company wide format for serial numbers has been designed. This format is 14 characters long and begins with a date code followed by the ice-o-matic i...

Page 7

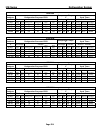

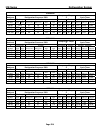

Ice series general information page a5 24 hour capacity wires max min. Voltage @ 90/70 including fuse circuit comp. **refrigerant model hz/phase lbs. Kg. Btuh ground size amps rla type oz. Grams iceu150*a1 115/60/1 117 53 3148 3 15 9.6 6.8 r404a 13 369 iceu150*w1 115/60/1 166 75 3392 3 15 7.9 5.9 r4...

Page 8

Ice series general information page a6 24 hour capacity wires max min. Voltage @ 90/70 including fuse circuit comp. **refrigerant model hz/phase lbs. Kg. Btuh ground size amps rla type oz. Grams ice0500*a1 115/60/1 461 210 10843 3 20 24.8* 18.5 r404a 37 1049 ice0500*a-t1 115/60/1 455 207 10736 3 20 ...

Page 9

Ice series general information page a7 24 hour capacity wires max min. Voltage @ 90/70 including fuse circuit comp. **refrigerant model hz/phase lbs. Kg. Btuh ground size amps rla type oz. Grams ice1406*a1 208-230/60/1 1122 510 22590 3 30 20.2 13.8 r404a 108 3062 ice1406*w1 208-230/60/1 1187 540 225...

Page 10

Ice series general information page a8 50 hz. 24 hour capacity wires max min. Voltage @ 90°/70° including fuse circuit comp. **refrigerant model hz/phase lbs. Kg. Btuh ground size amps rla type oz. Grams ice0305*a2 230/50/1 266 121 7079 3 15 12.4 8.2 r404a 26 737 ice0305*w2 230/50/1 291 132 6590 3 1...

Page 11

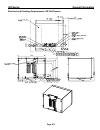

Ice series general information page a9 installation guidelines note: installation should be performed by an ice-o-matic trained service technician. For proper operation of the ice-o-matic ice machine, the following installation guidelines must be followed. Failure to do so may result in loss of prod...

Page 12

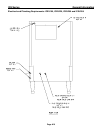

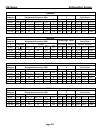

Ice series general information page a10 electrical and plumbing requirements: iceu150, iceu220, iceu205 and iceu206.

Page 13

Ice series general information page a11 electrical and plumbing requirements: iceu150, 220, 225 and 226 note: the iceu150, iceu220, iceu225 and iceu226 do not have a splash curtain. These models utilize a thermostatic bin control in place of a mechanical bin switch..

Page 14

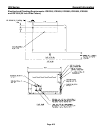

Ice series general information page a12 electrical and plumbing requirements: iceu300 and 305 305 note: the iceu300 does not have a splash curtain. This model utilize a thermostatic bin control in place of a mechanical bin switch..

Page 15

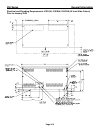

Ice series general information page a13 electrical and plumbing requirements: ice0250, ice0400, ice0500, ice0606, ice0806 and ice1006 (30 inch wide cubers).

Page 16

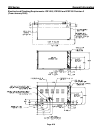

Ice series general information page a14 electrical and plumbing requirements: ice1406, ice1806, ice2106 (48 inch wide cubers) prior to january 2008.

Page 17

Ice series general information page a15 electrical and plumbing requirements: ice0320 and ice0520 (22 inch wide cubers).

Page 18

Ice series general information page a16 electrical and plumbing requirements: ice1400, ice1800 and ice2100 revision 3 (from january 2008).

Page 19

Ice series general information page a17 electrical and plumbing requirements: ice1506 remote.

Page 20

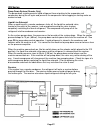

Ice series general information page a18 remote condenser installation for proper operation of the ice-o-matic ice machine, the following installation guidelines must be followed. Failure to do so may result in loss of production capacity, premature part failure, and may void all warranties. Installa...

Page 21

Ice series general information page a19 the following remote ice makers incorporate the mixing valve in the condenser. This configuration allows up to a 100 foot calculated remote line set run. Reference the diagram below to calculate the maximum 100 foot line set run. Ice machine model number remot...

Page 22

Ice series general information page a20 how the ice machine works a general description of how the ice series cubers work is given below. The remainder of the manual provides more detail about the components and systems. With the ice/off/wash switch in the ice position, the compressor, water pump an...

Page 23

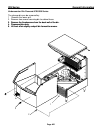

Ice series general information page a21 undercounter bin removal-iceu300 series the storage bin can be removed by: 1 remove the lower grill. 2. Remove two screws securing bin to cabinet base. 3. Remove the thumbscrews from the back wall of the bin. 3. Remove the thumbscrews from the back wall of the...

Page 24

Ice series general information page a22 undercounter bin removal-iceu150/200 series the storage bin can be removed by: 1. Remove the two screws at the rear of the top panel. 2. Remove the two screws from the front panel. 3. Remove two screws securing bin to cabinet base. 4. Disconnect bin drain. 5. ...

Page 25

Ice series general information page a23 warranty information every ice-o-matic machine is backed by a warranty that provides both parts and labor coverage. Parts labor two years on all parts* two years on all components* three years on all ice maker parts* three years on all cube ice maker component...

Page 26

Ice series general information page a24 ice-o-matic parts and labor domestic & international limited warranty mile high equipment llc (the “company”) warrants ice-o-matic brand ice machines, ice dispensers, remote condensers, water filters, and ice storage bins to the end customer against defects in...

Page 27

Ice series scheduled maintenance page b1 maintenance note: maintenance should be performed by an ice-o-matic trained service technician. Electrical shock and/or injury from moving parts inside this machine can cause serious injury. Disconnect electrical supply to machine prior to performing any adju...

Page 28

Ice series scheduled maintenance page b2 cleaning and sanitizing (continued) 5. Add recommended amount of approved nickel safe ice machine cleaner to the water trough according to label instructions on the container. 6. Initiate the wash cycle at the ice/off/wash switch by placing the switch in the ...

Page 29

Ice series winterizing procedures page b3 winterizing procedures important! Whenever the ice machine is taken out of operation during the winter months, the procedure below must be performed. Failure to do so may cause serious damage and will void all warranties. 1. Turn off water to machine. 2. Mak...

Page 30

Ice series cabinet care page b4 cleaning stainless steel commercial grades of stainless steel are susceptible to rusting. It is important that you properly care for the stainless steel surfaces of your ice machine and bin to avoid the possibility of rust or corrosion. Use the following recommended g...

Page 31

Ice series troubleshooting trees page c1 how to use the troubleshooting trees the troubleshooting trees were developed to be used in conjunction with the service information in the sections that follow. If used together as intended, these two parts of the manual will allow the ice machine service te...

Page 32

Ice series troubleshooting trees page c2 troubleshooting trees table of contents machine does not run c3 machine runs, does not make ice c4 – c5 slow production (cube formation good) c6 low suction pressure c7 high suction pressure c8 cubes are hollow c9 uneven bridge thickness c10 ice bridge thickn...

Page 33

Ice series troubleshooting trees page c3 machine does not run check for correct power supply to the machine yes not ok no ok is the selector switch set to ice? Check high pressure safety control check high temperature safety control ok check bin control for proper adjustment, see page f9 is this a r...

Page 34

Ice series troubleshooting trees page c4 machine runs, does not make ice yes go to page c5 no yes is water running over the evaporator? Check for power to the compressor contactor coil check contactor for bad contactor or coil. Replace if defective is the compressor running? No good ok check selecto...

Page 35

Ice series troubleshooting trees page c5 machine runs, does not make ice (continued) high or normal suction check refrigerant pressures, see page e1 if head pressure is also high, make sure condenser is clean and machine has good air flow is water leaking out of the purge drain or water trough? No y...

Page 36

Ice series troubleshooting trees page c6 slow production (cube formation good) no yes does installation meet guidelines? Check refrigeration system, section e check for excessive head pressure ok check water regulating valve, see page e2 check refrigeration system, section e air yes too high clean c...

Page 37

Ice series troubleshooting trees page c7 low suction pressure no yes does installation meet guidelines? Check txv for moisture based restriction check for correct head pressure, see page e10 no check for refrigerant tubing restriction, crimps, etc. Check evaporator coil separation, see page e4 yes y...

Page 38

Ice series troubleshooting trees page c8 high suction pressure no yes have you checked the “slow production” tree? Evacuate and recharge system check hot gas valve, see page e5 no check for leaking purge valve check condenser fan motor and blade for proper operation, and/or water valve or mixing val...

Page 39

Ice series troubleshooting trees page c9 cubes are hollow yes is the water temperature above 100°f (38°c)? Go to the “poor water distribution over evaporator” troubleshooting tree, page c13 no yes yes purge valve has an obstruction or could be defective is water leaking from the purge drain? No not ...

Page 40

Ice series troubleshooting trees page c10 uneven bridge thickness high make sure supply water temperature is below 100°f (38°c) check for water leaking out of purge drain no yes yes problem in water system, see pages d1 and d2. Dirty or defective purge valve is water running into the bin? No ok are ...

Page 41

Ice series troubleshooting trees page c11 ice bridge thickness varies cycle to cycle not ok is air and water temps consistent and within guidelines? Check the purge valve for water leaks no yes ok correct installation deficiency replace timer initiate ok clean purge valve or replace if defective ok ...

Page 42

Ice series troubleshooting trees page c12 machine produces cloudy ice is water running evenly across the evaporator? No yes see “poor water running over evaporator troubleshooting tree page c13 no yes doe machine meet installation guidelines? See section a cloudiness is a result of properties in the...

Page 43

Ice series troubleshooting trees page c13 poor water distribution over the evaporator yes is the machine level? Check water distribution tube for obstructions or improper assembly see section d no yes yes correct deficiency in supply water pressure level the machine is the supply water pressure corr...

Page 44

Ice series troubleshooting trees page c14 machine does not enter harvest yes will suction pressure drop below cut-in of timer initiate? Check purge valve to make sure it is not leaking, if it is replace valve or remove obstruction ok hot gas valve could be leaking does the manual purge switch energi...

Page 45

Ice series troubleshooting trees page c15 machine enters harvest, then returns to freeze prematurely yes is the harvest assist working properly? See page f6 check the manual purge switch normally closed contacts. See page f1 purge switch is defective open adjust as required or replace defective part...

Page 46

Ice series troubleshooting trees page c16 length of harvest excessive yes does the machine meet installation guidelines? Correct installation deficiency no check harvest assist assembly for proper operation, see page f6 low refrigerant charge, repair leak and weigh in proper charge is the ice format...

Page 47

Ice series troubleshooting trees page c17 ice does not release from evaporator yes clean the evaporator, see page b2 no ok yes level the machine set proper bridge thickness, see page f4 does water run over the evaporator during harvest? Ok too low is the machine level? Replace purge valve or repair ...

Page 48

Ice series troubleshooting trees page c18 hot evaporator, low suction and discharge pressure (remote only) yes correct installation deficiency does the machine have the proper refrigeration charge? No no yes does the machine meet the installation guidelines? Repair leak, evacuate and weigh in refrig...

Page 49

Ice series water system page d1 water distribution and components water enters the machine through the float valve located in the water trough. The water trough holds water used for ice making. The float valve is used to maintain the proper water level in the water trough. During the freeze cycle wa...

Page 50

Ice series water system page d2 water distribution tube water is pumped to a distribution tube located at the top of the evaporator and is used to distribute water evenly over the evaporator. The distribution tube can be removed and dissembled for cleaning if the hole becomes plugged or if there is ...

Page 51

Ice series water system page d3 water splash curtain the water splash curtain covers the evaporator to prevent water from splashing into the bin and is also used to actuate the bin switch. When the bin becomes full of ice, the splash curtain is held open when the ice drops off of the evaporator. The...

Page 52

Ice series water system page d4 water purge valve when the machine enters the harvest cycle, the water pump continues to run and the purge valve opens. This allows mineral laden water to be pumped from the water trough to the drain. This helps keep the water system clean. The water pump and purge va...

Page 53

Ice series water system page d5 water trough the water trough can be easily removed by the following procedures: mounting screws iceu150/200 models 1. Disconnect power to the ice machine. 2. Shut the water supply off to the ice machine. 3. Remove water splash curtains when applicable. 4. Remove wate...

Page 54

Ice series refrigeration system page e1 refrigerant cycle and components before diagnosing the refrigeration system, it is very important that the refrigerant charge be correct. Whenever the refrigeration system has been opened, the filter-drier must be replaced and the proper refrigerant charge mus...

Page 55

Ice series refrigeration system page e8 refrigerant refrigerant in a high-pressure liquid form is fed to an expansion valve where the refrigerant is reduced to a low-pressure liquid. Under this low pressure, the liquid will absorb heat from the evaporator causing the liquid to change to a vapor. Thi...

Page 56

Ice series refrigeration system page e3 thermostatic expansion valve (txv) the thermostatic expansion valve meters the flow of refrigerant into the evaporator changing its state from a high-pressure liquid to a low-pressure liquid. This drop in pressure causes the refrigerant to cool. The cooled ref...

Page 57

Ice series refrigeration system page e4 thermostatic expansion valve (continued) a dual evaporator machine will have one txv for each evaporator. If one txv sticks open and the other is operating normally, the suction pressure will be higher than normal and both evaporators will build thick ice. It ...

Page 58

Ice series refrigeration system page e5 note: permanent discoloration of the evaporator plating is normal and will cause no problems with harvesting the ice or sanitary conditions. Before condemning the evaporator for plating problems, be certain it is not just discoloration. Good evaporators will n...

Page 59

Ice series refrigeration system page e6 remote condenser (continued) if the airflow is restricted or the condenser is dirty, the head pressure will be excessively high, slow production will result and the compressor may overheat and eventually become damaged. The condenser coil and fan blades must b...

Page 60

Ice series refrigeration system page e7 pump down system (remote only) the pump down system prevents liquid refrigerant from migrating to the evaporator and compressor during the off cycle and prevents the compressor from slugging or starting under an excessive load. Liquid line solenoid when a mach...

Page 61

Ice series refrigeration system page e8 refrigerant refrigerant in a high-pressure liquid form is fed to an expansion valve where the refrigerant is reduced to a low-pressure liquid. Under this low pressure, the liquid will absorb heat from the evaporator causing the liquid to change to a vapor. Thi...

Page 62

Ice series refrigeration system page e9 if the refrigeration system is extremely wet, use radiant heat to raise the temperature of the system. This action will cause the moisture to vaporize at less of a vacuum. The use of two (2) valves, one between the vacuum pump and gauge manifold and the other ...

Page 63

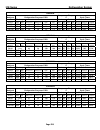

Ice series refrigeration system page e10 electrical and mechanical specifications, “ice” series 60 cycle machine model ref. Type charge ounces back press. Approx. Head press. Approx. Timer initiate setting cycle time approx. Minutes 70/50-90/70 batch weight pounds volt. Cycle phase iceu150*a1 r-404a...

Page 64

Ice series refrigeration system page e11 electrical and mechanical specifications, “ice” series 60 cycle machine model ref. Type charge ounces back press. Approx. Head press. Approx. Timer initiate setting cycle time approx. Minutes 70/50-90/70 batch weight pounds volt. Cycle phase ice0500*a1 r-404a...

Page 65

Ice series refrigeration system page e12 model ref. Type charge ounces back press. Approx. Head press. Approx. Timer initiate setting cycle time approx. Minutes 70/50-90/70 batch weight pounds volt. Cycle phase ice1406*a1 r-404a 108 60 - 35 175 - 400 35 11 - 17 11 208/230-60-1 ice1406*w1 r-404a 28 6...

Page 66

Ice series refrigeration system page e13 model ref. Type charge ounces back press. Approx. Head press. Approx. Timer initiate setting cycle time approx. Minutes 70/50-90/80 batch weight pounds volt. Phase cycle iceu305a r-404a 14 51 - 30 218-400 33 15 - 20 3 220-240/50/1 iceu305w r-404a 13 60 - 27 2...

Page 67

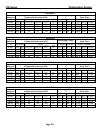

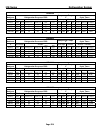

Ice series refrigeration system page e14 iceu150a ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 50/40 167 150 5...

Page 68

Ice series refrigeration system page e15 iceu226a ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 50/40 183 164 5...

Page 69

Ice series refrigeration system page e16 ice0320w ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 70/50 252 244 6...

Page 70

Ice series refrigeration system page e17 ice0500w3 ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 50/40 250 250 ...

Page 71

Ice series refrigeration system page e18 ice0606a3 ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 50/40 198-270 ...

Page 72

Ice series refrigeration system page e19 ice0806w ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete 70/50 250 250 5...

Page 73

Ice series refrigeration system page e20 ice1006r ambients refrigeration pressures psig compressor temps °f cycle times °f discharge suction discharge suction minutes' seconds" air/water start end start freeze end freeze start harv end harv start end start end freeze harvest complete -20/40 240 240 ...

Page 74

Ice series electrical system page f1 control circuit all machines in this manual are electro-mechanical controlled; however the control circuitry on the single evaporator units differs from the dual evaporator units and is detailed below. Selector switch the selector switch is used to put the machin...

Page 75

Ice series electrical system page f2 compressor check (continued) if all starting components are good, check the voltage from the common terminal of the compressor, making sure proper voltage is supplied to the compressor and all wiring is properly connected. If the compressor does not start and the...

Page 76

Ice series electrical system page f3 untimed freeze cycle during the freeze cycle the compressor, water pump and condenser fan motor(s) (if used) are running. On remote systems the liquid line solenoid is also energized, see refrigeration system. As ice forms on the evaporator, the suction pressure ...

Page 77

Ice series electrical system page f4 timed freeze when the freeze timer is energized, the machine is in the timed portion of the freeze cycle. The freeze timer will time out the remainder of the freeze cycle. Once the time has passed, the machine will enter the harvest cycle. Freeze timer the freeze...

Page 78

Ice series electrical system page f5 harvest cycle single evaporator machines once the freeze timer has timed out, power is sent to relay 1 and the machine enters the harvest cycle. Once in harvest motor, the purge valve, hot gas valve and harvest motor are energized. The water pump continues to run...

Page 79

Ice series electrical system page f6 harvest assist assembly the harvest assist assembly has several purposes: to assist in moving the ice off of the evaporator, to control the length of harvest and to terminate harvest. When the machine enters harvest, power is sent to the harvest motor which turns...

Page 80

Ice series electrical system page f7 probe tip and swivel the probe tip is attached to the clutch and makes contact with the back of the ice slab during harvest. The swivel allows the probe tip to pivot as the clutch turns so that the probe is pushed straight through the evaporator probe guide. The ...

Page 81

Ice series electrical system page f8 cam switch adjustment check the cam switch for proper adjustment by slowing turning the clutch by hand in a counterclockwise direction while listening for the switch contacts to change. The switch should have an audible “click” as the roller reaches the high part...

Page 82

Ice series electrical system page f9 undercounter machines: a thermostatic bin control is used on the undercounter models. The bin thermostat is located in the control box with a capillary tube, which is in a brass thermo-well mounted to the water trough. When ice comes in contact with the capillary...

Page 83

Ice series electrical system page f10 electrical sequence for the ice1400 series version 3, ice1800 series version 3 and the ice2100 series version 3 cubers. (manufactured from january, 2008) ice1400a/w3, 1800w3 and 2100w3 electrical sequence (includes 50 hz. And 3 phase) 1. Suction pressure starts ...

Page 84

Ice series electrical system page f11 electrical sequence for the ice1400 series version 3, ice1800 series version 3 and the ice2100 series version 3 cubers. (manufactured from january, 2008) ice1400r3, 1800r3 and 2100r3 electrical sequence (includes 50 hz. And 3 phase) this unit incorporates a time...

Page 85

Ice series electrical system page f12 electrical sequence for theice1506 series version 3 (manufactured from january, 2008) this unit incorporates a timer upstream of the low pressure control for low ambients. 1. When the selector switch is set to ice, relay number 2 coil is energized through cam sw...

Page 86

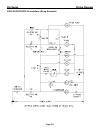

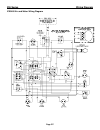

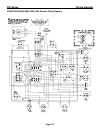

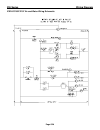

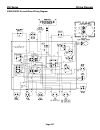

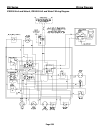

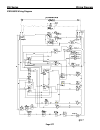

Ice series wiring diagram page g1 iceu150/200/205/206 air and water wiring diagram.

Page 87

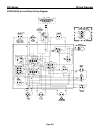

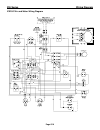

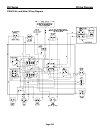

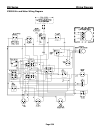

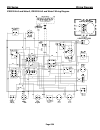

Ice series wiring diagram page g2 iceu150/200/205/206 air and water wiring schematic.

Page 88

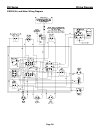

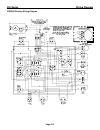

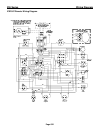

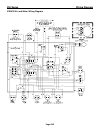

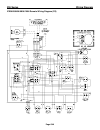

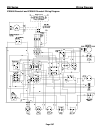

Ice series wiring diagram page g3 iceu150/220/225/226 air and water wiring diagram.

Page 89

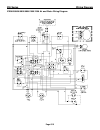

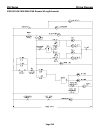

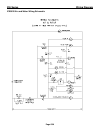

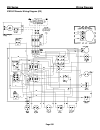

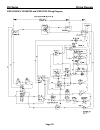

Ice series wiring diagram page g4 iceu150/220/225/226 air and water wiring schematic.

Page 90

Ice series wiring diagram page g5 ice0250 air and water wiring diagram.

Page 91

Ice series wiring diagram page g6 ice0250 air and water wiring schematic.

Page 92

Ice series wiring diagram page g7 ice0400 air and water wiring diagram.

Page 93

Ice series wiring diagram page g8 ice0400 air and water wiring schematic.

Page 94

Ice series wiring diagram page g9 ice0405/0406 air and water wiring diagram.

Page 95

Ice series wiring diagram page g10 ice0405/0406 air and water wiring schematic.

Page 96

Ice series wiring diagram page g11 ice0500 air and water wiring diagram.

Page 97

Ice series wiring diagram page g12 ice0500 air and water wiring schematic.

Page 98

Ice series wiring diagram page g13 ice0500 remote wiring diagram.

Page 99

Ice series wiring diagram page g14 ice0500 remote wiring schematic.

Page 100

Ice series wiring diagram page g15 ice0605/0606/0805/0806/1005/1006 air and water wiring diagram.

Page 101

Ice series wiring diagram page g16 ice0605/0606/0805/0806/1005/1006 air and water wiring schematic.

Page 102

Ice series wiring diagram page g17 ice0605/0606/0805/0806/1005/1006 remote wiring diagram.

Page 103

Ice series wiring diagram page g18 ice0605/0606/0805/0806/1005/1006 remote wiring schematic.

Page 104

Ice series wiring diagram page g19 ice1007 air and water wiring diagram.

Page 105

Ice series wiring diagram page g20 ice1007 air and water wiring schematic.

Page 106

Ice series wiring diagram page g21 ice1007 remote wiring diagram.

Page 107

Ice series wiring diagram page g22 ice1007 remote wiring schematic.

Page 108

Ice series wiring diagram page g23 ice1405/1406/1806/2005/2106 air and water wiring diagram.

Page 109

Ice series wiring diagram page g24 ice1405/1406/1806/2005/2106 air and water wiring schematic.

Page 110

Ice series wiring diagram page g25 ice1405/1406/1806/2005/2106 remote wiring diagram.

Page 111

Ice series wiring diagram page g26 ice1405/1406/1806/2005/2106 remote wiring schematic.

Page 112

Ice series wiring diagram page g27 ice1407/1807/2107 air and water wiring diagram.

Page 113

Ice series wiring diagram page g28 ice1407/1807/2107 air and water wiring schematic.

Page 114

Ice series wiring diagram page g29 ice1407/1807/2107 remote wiring diagram.

Page 115

Ice series wiring diagram page g30 ice1407/1807/2107 remote wiring schematic.

Page 116

Ice series wiring diagram page g31 ice1606 remote wiring diagram.

Page 117

Ice series wiring diagram page g32 ice1606 remote wiring schematic.

Page 118

Ice series wiring diagram page g33 ice0320 air and water wiring diagram.

Page 119

Ice series wiring diagram page g34 ice0320 air and water wiring schematic.

Page 120

Ice series wiring diagram page g35 ice0520 air and water wiring diagram.

Page 121

Ice series wiring diagram page g36 ice0520 air and water wiring schematic.

Page 122

Ice series wiring diagram page g37 ice0325/0525 air and water wiring diagram.

Page 123

Ice series wiring diagram page g38 ice0325/0525 air and water wiring schematic.

Page 124

Ice series wiring diagram page g39 ice0305 air and water wiring diagram.

Page 125

Ice series wiring diagram page g40 ice0305 air and water wiring schematic.

Page 126

Ice series wiring diagram page g41 ice1506 remote.

Page 127

Ice series wiring diagram page g42 ice1506 remote.

Page 128

Ice series wiring diagram page g43 iceu300 air and water.

Page 129

Ice series wiring diagram iceu300 air and water page g44.

Page 130

Ice series wiring diagram page g45 iceu305 air and water.

Page 131

Ice series wiring diagram page g46 iceu305 air and water.

Page 132

Ice series wiring diagram page g47 ice0500 remote wiring diagram (r3).

Page 133

Ice series wiring diagram page g48 ice0500 remote wiring schematic (r3).

Page 134

Ice series wiring diagram ice0605/0606/0806/1006 remote wiring diagram (r3) page g49.

Page 135

Ice series wiring diagram page g50 ice0605/0606/0806/1006 remote wiring schematic (r3).

Page 136

Ice series wiring diagram page g51 ice1007 remote wiring diagram (r3).

Page 137

Ice series wiring diagram page g52 ice1007 remote wiring schematic (r3).

Page 138

Ice series wiring diagram page g53 ice0250 air4 and water4, ice0400 air3 and water3 wiring diagram.

Page 139

Ice series wiring diagram page g54 ice0250 air4 and water4, ice0400 air3 and water3 wiring schematic.

Page 140

Ice series wiring diagram page g55 ice0320 air3 and water3, ice0520 air3 and water3 wiring diagram.

Page 141

Ice series wiring diagram ice0320 air4 and water4, ice0520 air3 and water3 wiring schematic page g56.

Page 142

Ice series wiring diagram page g57 ice0406/405 air3 and water3, ice0305 air3 and water3 wiring diagram.

Page 143

Ice series wiring diagram page g58 ice0406/405 air3 and water3, ice0305 air3 and water3 wiring schematic.

Page 144

Ice series wiring diagram page g59 ice0325 air3 and water3, ice0525 air3 and water3 wiring diagram.

Page 145

Ice series wiring diagram ice0325 air3 and water3, ice0525 air3 and water3 wiring schematic page g60

Page 146

Ice series wiring diagram ice0500 air3 and water3 wiring diagram page g61.

Page 147

Ice series wiring diagram page g62 ice0500 air3 and water3 wiring schematic.

Page 148

Ice series wiring diagram page g63 ice0500 remote4 wiring diagram.

Page 149

Ice series wiring diagram page g64 ice0500 remote4 wiring schematic.

Page 150

Ice series wiring diagram ice0606 air3 and water3, ice0605 air3 and water3 wiring diagram page g65.

Page 151

Ice series wiring diagram page g66 ice0606 air3 and water3, ice0605 air3 and water3.

Page 152

Ice series wiring diagram ice0606 remote4 and ice0605 remote4 wiring diagram page g67.

Page 153

Ice series wiring diagram page g68 ice0606 remote4 and ice0605 remote4 wiring schematic.

Page 154

Ice series wiring diagram page g68 ice0606 remote4 and ice0605 remote4 wiring schematic.

Page 155

Ice series wiring diagram ice1405/6a3/w3, ice1806w3 and ice2106w3 wiring diagram page g69.

Page 156

Ice series wiring diagram page g70 ice1405/6a3/w3, ice1806w3 and ice2106w3 wiring schematic.

Page 157

Ice series wiring diagram ice1407a3/w3, ice1807w3 and ice2107w3 wiring diagram page g71.

Page 158

Ice series wiring diagram page g72 ice1407a3/w3, ice1807w3 and ice2107w3 wiring schematic.

Page 159

Ice series wiring diagram page g73 ice1405/6r3, ice1806r3 and ice2106r3 wiring diagram.

Page 160

Ice series wiring diagram page g74 ice1405/6r3, ice1806r3 and ice2106r3 wiring schematic.

Page 161

Ice series wiring diagram page g75 ice1407r3, ice1807r3 and ice2107r3 wiring diagram.

Page 162

Ice series wiring diagram page g76 ice1407r3, ice1807r3 and ice2107r3 wiring schematic.

Page 163

Ice series wiring diagram page g77 ice1506r3 wiring diagram.

Page 164

Ice series wiring diagram page g78 ice1506r3 wiring schematic.