- DL manuals

- Ice-O-Matic

- Ice Maker

- GEMU090 Series

- Service Manual

Ice-O-Matic GEMU090 Series Service Manual

Summary of GEMU090 Series

Page 1

Service manual gemu090 series ice-o-matic 11100 east 45th ave denver, colorado 80239 p t n b 9081430 02 d t 9/11 part number 9081430-02 date 9/11.

Page 2

Ice-o-matic parts and labor domestic & international limited warranty mile high equipment llc (the “company”) warrants ice-o-matic brand ice machines, ice dispensers, remote condensers, water filters, and ice storage bins to the end customer against defects in material and factory workmanship for th...

Page 3

Gem090 service this section contains information for the service and repair of the gemu090 ice machine. Page 1 gemu090 service service table of contents gem090 service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1 components: . . . . . . . . . . . ....

Page 4

Components: • refrigeration system, including air cooled condenser, compressor, capillary tube and evaporator. • control system, including ice level sensor, water sensor, auger motor sensor, controller, control pad and transformer. • auger drive system, including auger motor, gear reducer and auger....

Page 5

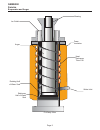

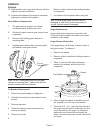

Evaporator and auger page 3 gemu090 service cut away view stationary half of water seal rotating half of water seal heat exchange tube coil auger ice outlet bearing foam insulation water inlet.

Page 6

Control system the control system operates the machine. The controller operates on 12 volts ac, supplied by the transformer. It uses an ultrasonic ice sensor to measure ice level. The ultrasonic system transmits sound waves into the ice storage bin and measures the return time, when the return time ...

Page 7

Water system the auger is driven at about 11 rpm by the gear reducer. The gear reducer is a sealed component and does not require lubrication, as it contains a charge of grease. The auger motor drives a set of gears that all together reduce the motor speed to the 11 rpm output speed and correspondin...

Page 8

Storage the ice storage system is made up of a plastic lined ice storage bin, covered by an insulated top panel and an insulated swing open door with gasket. The ice storage bin is foamed in place, so the side panels are not removable. Page 6 gemu090 service ice making check water time to clean clea...

Page 9

Performance and technical specs overall: • refrigerant: 4.5 oz r-134a • compressor: hermetic, 1390 btuh • condenser: forced draft • fan blade: 3 blade, 6 inch • evaporator: stainless steel tube, copper coil jacketed • metering device: cap tube • auger drive: output speed 11 rpm • water valve: float ...

Page 10

Electrical sequence upon power being supplied, all the lights will blink once and the control system will immediately check for water in the reservoir. If there is water no further action will occur until the on/off button is pushed. Pushing the on/off button starts the machine. The ice making light...

Page 11

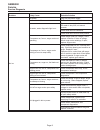

Service diagnosis page 9 gemu090 service problem likely cause probable solution no ice no power plug unit into power supply unit switched off push and release on/off button no water, water diagnostic light is on restore water supply, check sensor. If ro water is too pure, unit cannot operate. Check ...

Page 12

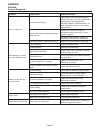

Service diagnosis page 10 gemu090 service problem likely cause probable solution no ice, continued ice level sensor failure with power on and ice making light on, check connector, if secure jump the two middle pins at j2 (bin stat)on the controller together. Unit should start. If it does, replace th...

Page 13

Component diagnostics membrane switch unplug and check connector pins (left side is pin 1), read about 10 ohms when activating the button, and ol when not pressing the button: pin 2-3 on/off switch; 4-3 clean reset switch compressor check temperature of compressor, if very hot, add access valves to ...

Page 14

Ice capacity the rate of ice making is relatively fixed, it depends upon the heat load and the ambient temperature the machine is operating in. As either increase the amount of ice made will decrease. The machine will work to keep the ice bin full. A full bin of ice is when the ice level is even wit...

Page 15

Removal and replacement component access the machine is designed to be cleaned while built in. See the maintenance section for more information. Most components require the machine to be removed from a built-in situation: • fan motor – side service panel • controller – top panel • auger motor – top ...

Page 16

Page 14 gemu090 service gem090 gearbox access & removal 1. Shut off water supply 2. Remove drain plug inside bin compartment 3. Disconnect power supply or unplug unit 4. Uninstall unit and pull out as needed for top and back access. 5. Remove top panel 6. Remove back panel 7. Remove ice chute/bin wa...

Page 17

15. Remove breaker & set aside 16. Pull auger from freezer by lifting straight up (be careful as auger has sharp edges!) note: if auger does not lift freely, see auger removal procedure. 17. Inspect auger flights for signs of wear 18. Inspect evaporator barrel for signs of radial scoring 19. Remove ...

Page 18

Water seal replacement 1 go through the prior steps to remove the gear reducer. 2 remove rotating half of water seal from bottom of auger. 3 clean auger of any sealant at water seal mounting position. 4 add a small bead of food grade silicone sealant to the shoulder of the auger where the water seal...

Page 19

13 slide breaker onto auger shaft. Secure with the original four allen head bolts. 14 reverse the balance of the steps to complete putting the machine back together. Gear reducer replacement 1 the gear reducer contains no internal serviceable parts. Replace as a unit. 2 follow all steps to remove ge...

Page 20

Evaporator replacement 1 go through all steps to remove the gear reducer. 2 add temporary refrigeration system access valves to the discharge and suction sides of the refrigeration system . 3 recover the refrigerant. 4 un-sweat the suction line and cap tube connections from the evaporator. 5 remove ...

Page 21

Drain pump (if equipped) 1 shut off water supply 2 remove all ice and/or any standing water. 3 disconnect power or unplug unit 4 uninstall and pull unit out to get access to left side service panel. 5 remove five screws and the service panel. 6 disconnect electrical plug to pump motor 7 disconnect d...

Page 22

Compressor replacement. Note: if built in the unit will need to be pulled out. 1 shut off water supply 2 disconnect power supply or unplug unit 3 uninstall unit and pull out as needed for side and back access. 4 remove all panels and door: • back panel including drain and power supply panels. • side...

Page 23

Bin and cabinet the bin and cabinet can be separated from the base. Either the ice making evaporator system must be lifted out and securely suspended or the refrigeration system opened and the connections to the evaporator unbrazed. 1 remove the unit from its installed position. 2 disconnect water s...

Page 24

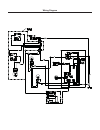

Wiring diagram gemu090 service parts auger auger.

Page 25

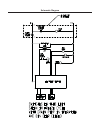

Schematic diagram gemu090 auger.