- DL manuals

- ICI Caldaie

- Boiler

- SOLAR C 25

- Instruction Manual

ICI Caldaie SOLAR C 25 Instruction Manual

Summary of SOLAR C 25

Page 1

Wall hung boilers instructions manual to be used for installation, use and maintenance condensing boilers solar c 25 solar c 31 solar system c 25 solar system c 31 important this installation must be carried out by an authorised corgi engineer.

Page 3

1 general rules this instruction book is an integral and essential part of our product and it is delivered together with our boiler. Read carefully the information about safety, installation and maintenance that are shown in it. The boiler installation is to be carried out by qualified corgi registe...

Page 4

2 1 technical data .................................................................... 3 1.1 dimensions ................................................................................................................... 3 1.2 hydraulic scheme ...........................................................

Page 5: 1 Technical Data

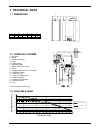

3 1 technical data 1.1 dimensions l h p a b c d (mm) (mm) (mm) (mm) (mm) (mm) (mm) 400 720 300 200 200 182 118 1.2 hydraulic scheme 1 - gas valve 2 - burner 3 - primary exchanger 4 - pump 5 - bypass supply 6 – pressure gauge 7 - safety valve (set to 3 bar) 8 – filter* 9 – supply charge (not for u.K....

Page 6

4 1.4 general layout of the main components 1. Air pressure switch 2. Discharge air valve 3. Primary exchanger limit thermostat (105°c) 4. Flue gas ducts limit thermostat (105°c) 5. Aluminium condensing exchanger copper primary exchanger 6. Copper primary exchanger 7. Ingnition + flame detection 8. ...

Page 7

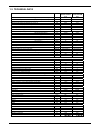

5 1.5 technical data size solar combi solar system c 25 solar combi solar system c 31 nominal heat input to net calorific value (h i ) referred (80 °c /60 °c) kw 25 31 minimum heat input to net calorific value (h i ) referred (80 °c /60 °c) kw 10,5 12,4 nominal heat output (80 °c/60 °c) kw 24,4 30,2...

Page 8

6 1.6 electrical scheme p1 p2 p3 n.A. C 3 1 rosso n l transducer of pressure of heating system dhw micro switch c.H. Sensor modulator of gas valve gas valve fan circulator air pressostat ground phase neutral condensate sensor ambient thermostat (option) primary exchanger limit thermostat (105°c) flu...

Page 9

7 1.7 timer electrical scheme (only for u.K. Market) fuse: 2 x 3,15 af 5x20 - 250 v thermostat 230 v ac 50 hz timer grasslin fm/1 stuzh 1 2 3 4 5 ambient.

Page 10

8 1.8 “s” plant automatic bypass d.H.W. Thermostat room thermostat t°c i-01 t°c i-02 heating circuit d.H.W. Tank m d.H.W. Valve m h.C. Valve boiler.

Page 11

9 1.9 “y” plant automatic bypass 3 way valve d.H.W. Thermostat room thermostat t°c i-01 t°c i-02 heating circuit d.H.W. Tank boiler.

Page 12: 2 Installation Instructions

10 2 installation instructions 2.1 different venting options sealed chamber heaters do not require particular characteristic for set-up and installation; combustion air is drawn from the outside of the property, therefore the boiler does not need air ventilation from the room where the boiler is sit...

Page 13

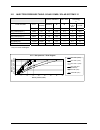

11 2.1.2 length of flue gas duct: solar/solar system c 25 split flue Ø 80 mm n.B.: the flue and aspiration duct length has not to exceed 30 m. For flue lengths of less than 2.0m you must fit a Ø 42 mm restrictor in the vertical adaptor connection for every added 90° elbow the maximum allowable lengt...

Page 14

12 2.1.3 length of flue gas duct: solar/solar system c 31 split flue Ø 80 mm n.B.: the flue and aspiration duct length has not to exceed 30 m. For flue lengths of less than 2.0m you must fit a Ø 42 mm restrictor in the vertical adaptor connection for every added 90° elbow the maximum permitted lengt...

Page 15

13 2.2 boiler positioning follow these instructions: • having considered the boiler dimensions, fix the dimensions template to the wall in the desired position. • drill the holes in the desired position for the boiler hanging bracket, and flue duct as required. • position all terminal pipes such as ...

Page 16

14 2.3 hydraulic connections domestic hot water ( for combination boilers only) the incoming water pressure must not exceed 6 bar with a minimum of 1 bar. In case of higher pressures a pressure reducing valve (prv) must be installed. Supply water flow rate influences the cleaning frequency of the he...

Page 17

15 2.5 commissioning the boiler must be commissioned according uk law regarding all gas appliances. Make sure the gas pipe is not too long in length causing lack of pressure. See minimum & maximum gas pressure requirements. Before commissioning check that the characteristics of the distributed gas a...

Page 18

16 2.6 setting of control panel there are 4 normal modes of operation: a) normal : boiler operation, - flow temperature, gas modulation and flame detection. Alarm function is in section 4.9. B) to view the boiler’s set point parameters: by pushing p1+p2 for 3 seconds. You can view in the following o...

Page 19

17 2.7 adjustment instructions: maximum and minimum heat output the boilers are pre set in the factory for the gas type showing on the data plate. Check the min/max pressure setting. This is important due to the gas supply pressure varying by country. To check and correct the gas pressure proceed in...

Page 20

18 2.9 different gases the boiler can operate on natural gas or lpg. To switch from one gas type to the other follow the following instructions: transformation from natural gas to lpg gas • replace burner injectors • change the jp1 jumper position and set it to “lpg” position (see the electrical sch...

Page 21

19 2.11 injectors pressure table: solar combi / solar system c 31 injectors diameters diafr. Gas* gas diapg h. P.C.I inlet pressure quantity Ø Ø min. Heat = 12,4 kw qnom. = 31 kw type of gas mj/m3 mbar n° mm mm mbar mbar nat.Gas g20 (2h+) 34,02 20 13 1,30 6,5 2 13,2 nat.Gas g25 (2h+) 29,25 25 13 1,3...

Page 22

20 2.12 technical fault finding for corgi registered engineers only 1 the burner flame does not ignite possible causes check - remedy a - the water temperature is higher than that of the hot water adjustment thermostat; b - the gas cock is closed; c - boiler lockout; d - lack of the ignition electro...

Page 23

21 3 smell gas possible causes check - remedy a - gas system leakage (of both the internal and external pipe system). A - close the main gas cock and check the pipe system 4 boiler condensation possible causes check - remedy a - the boiler temperature is too low. A - adjust the boiler thermostat to ...

Page 24

22 the above check/ fault finding should only be performed by a corgi registered engineer. In the event of a request for an in warranty service call to rectify a manufacturering fault, this will require in the first instance, relevent information which is contained in your benchmark logbook, which w...

Page 25

23 the above check/ fault finding should only be performed by a corgi registered engineer. In the event of a request for an in warranty service call to rectify a manufacturering fault, this will require in the first instance, relevent information which is contained in your benchmark logbook, which w...

Page 26

24 the above check/ fault finding should only be performed by a corgi registered engineer. In the event of a request for an in warranty service call to rectify a manufacturering fault, this will require in the first instance, relevent information which is contained in your benchmark logbook, which w...

Page 27: 3 Maintenance Instructions

25 3 maintenance instructions 3.1 introduction all maintenance operations have to be carried out by corgi registered engineer. Maintenance operations must be carried out at least once a year and according to uk building regulations. Prior to winter it is advisable to make sure the boiler is working ...

Page 28: 4 User Instructions

26 4 user instructions 4.1 control panel thermometer: temperature of the central heating circuit can be seen via the thermometer. Manometer: the system water pressure can be seen. It must not be less than 1 bar and must not exceed 3 bar. Always see the pressure when the system is cold. Central heati...

Page 29

27 4.2 ignition open the manual gas supply valve, located outside of the boiler. Set to the summer or winter position: the boiler should ignite automatically. If the boiler does not ignite you will see a failure in the display. 4.3 summer mode for domestic hot water only. Set menu to summer position...

Page 30

28 4.9 fault finding 1 the burner flame does not ignite possible causes check - remedy a - the water temperature is higher than that of the hot water adjustment thermostat; b - the gas cock is closed; c - boiler lockout ; d - lack of flame e - lack of the ignition electrode sparkle; f - air in the p...

Page 31

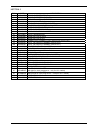

29 5 exploded views and parts lists tav 1.

Page 32

30 list tav. 1 pos. Code description 1 acpia00p casing support side l/r 2 acpsc00p casing support back panel 3 aclsg0p2 support lower outlet pipes 4 10020090 aluminium rivet ø3x6 5 acccop1s combustion chamber complete 6 acccc1p2 cover front combustion chamber 7 aclsc00p plate support control panel 8...

Page 33

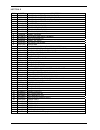

31 tav 2.

Page 34

32 list tav. 2 pos. Code description 1 acbruw6p burner ng 13 jet size 1,20 (solar c25) 1a acbruw10 burner lpg 13 jet size 0,72 (solar c25) 1b acbruw8p burner ng 13 jet size 1,30 (solar c31) 1c acbruw9p burner lpg 13 jet size 0,80 (solar c31) 2 acgug00p gasket jet 3 acuge20p jet ng 1.20 (solar c25) 3...

Page 35

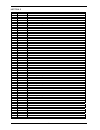

33 tav. 3.

Page 36

34 list tav. 3 pos. Code description 1 acsca10p heat exchanger 5 tubes water/gas 2 50000820 gasket 3/4" x 2 mm 3 actub11p pipe connection 18 mm he-condenser 4 acscac0p condenser 4a acneo00p neoprene stick inside condenser 4b aclic31p inner condenser aluminium plate 5 acori13p o ring r13 (16,9 x 2,7)...

Page 39

Declaration of conformity the undersigned emanuela lucchini managing director of the ici caldaie spa. With registered office - italy declares that the boilers solar c 25, solar system c 25 solar c 31, solar system c 31 manufactured by: ici caldaie spa via giovanni pascoli, 38, 37059 campagnola di ze...

Page 40

18000074 ed. 2-11/05 2-st. 100 - 11/05 ici caldaie ltd unit 6 west link business park guide street salford m50 1ew tel + 44(0) 161 743 9595 fax + 44(0) 161 736 8675 salesuk@icicaldaie.Com www.Icicaldaie.Com www.Icicaldaie.Co.Uk pictures, descriptions and data are not binding on ici caldaie ltd..